Preparation method of negative electrode slurry

A negative electrode slurry and glue technology, which is applied in the field of negative electrode slurry preparation, can solve the problems of high pulping efficiency and slurry stability, improve coating appearance and uniformity of coating thickness, reduce agglomeration, and improve dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

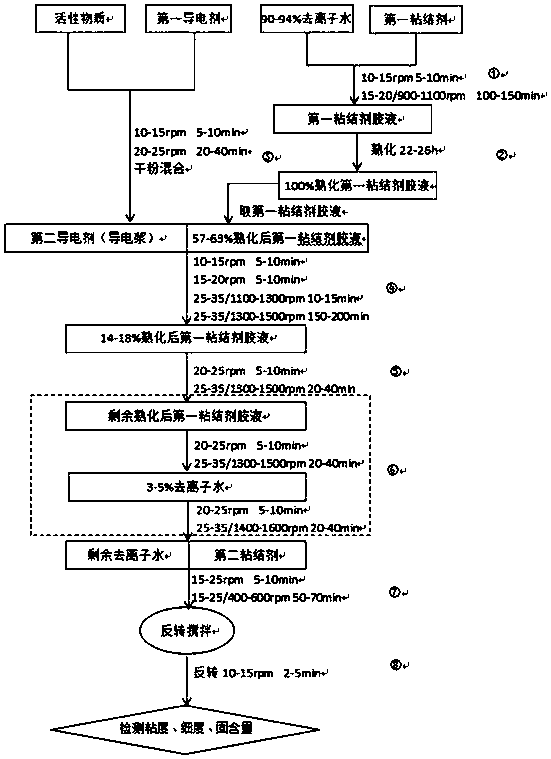

[0042] Such as figure 1 Shown, a kind of preparation method of negative electrode slurry comprises the steps:

[0043] (1) Preparation of glue solution: Divide the deionized water into three parts, namely: a large part of deionized water, a small part of deionized water and the remaining deionized water. Mix 90-94% multi-part deionized water, first stir at a revolution speed of 10-15rpm for 5-10min, then stir for 100-150min at a revolution speed of 15-20rpm and an autorotation speed of 900-1100rpm, and prepare Take the glue, the solid content of the glue is 1.5-2.0%;

[0044] (2) Glue curing: the glue in the step (1) is left to stand for 22-26h to obtain the cured first adhesive glue;

[0045] (3) Dry powder mixing: mix the active material with the first conductive agent, first stir at a revolution speed of 10-15rpm for 5-10min, and then stir at a revolution speed of 20-25rpm for 20-40min to obtain a dry powder mixture, mixing the first conductive agent with the active mate...

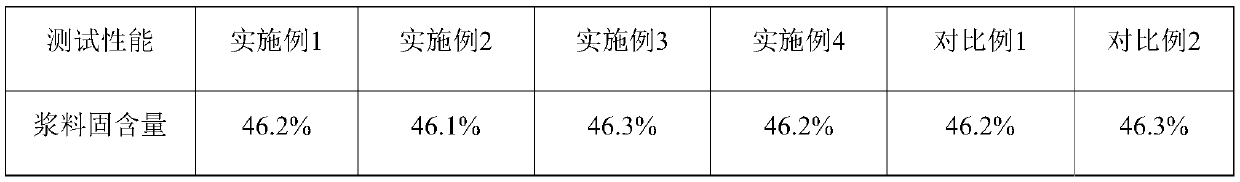

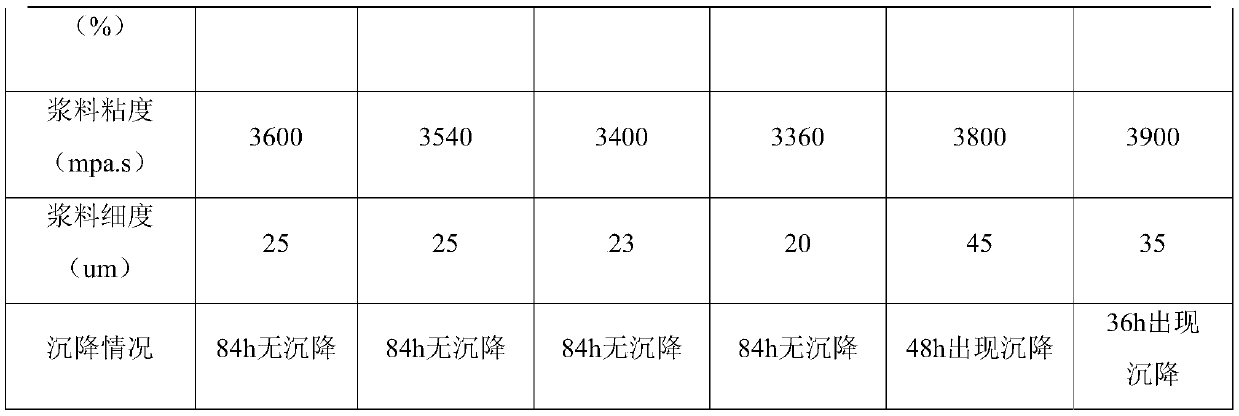

Embodiment 1

[0052] A preparation method of negative electrode slurry, comprising the steps of:

[0053] (1) Preparation of glue: mix CMC with 92% deionized water at a temperature of 30°C, first stir for 5 minutes at a revolution speed of 10 rpm, and then stir for 120 minutes at a revolution speed of 20 rpm and an autorotation speed of 1000 rpm , to prepare glue, the solid content of glue is 1.6%;

[0054] (2) Glue curing: the glue in the step (1) is allowed to stand for 24 hours to obtain the cured CMC glue;

[0055] (3) Dry powder mixing: Mix the mixture of graphite and silicon-based negative electrodes with conductive carbon black, first stir at a revolution speed of 10rpm for 5min, then stir at a revolution speed of 25rpm for 30min to obtain a dry powder mixture, and mix the conductive carbon black Mix it with the dry powder of the mixture of graphite and silicon-based negative electrode, so that the conductive carbon black is evenly dispersed on the surface of the mixture particles o...

Embodiment 2

[0062] A preparation method of negative electrode slurry, comprising the steps of:

[0063] (1) Preparation of glue solution: Mix 1 / 2 of CMC with 92% deionized water heated at 30°C, stir for 5 minutes at a revolution speed of 10 rpm, and then mix the remaining 1 / 2 of CMC Add it and mix, stir for 5min at a revolution speed of 10rpm, and then stir for 120min at a revolution speed of 20rpm and an autorotation speed of 1000rpm to prepare glue with a solid content of 1.6%; in the above stirring process, it is divided into two steps Add CMC powder for mixing and stirring, so that CMC and heated deionized water are fully and uniformly mixed, accelerating the dissolution of CMC, shortening the stirring time, and making CMC better play the role of improving dispersibility and anti-settling; the stirring temperature during the stirring process is controlled at 25-35°C, prevent CMC failure if the temperature of the glue is too high, and CMC is difficult to dissolve when the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com