Method for water drainage and gas recovery of ultra-deep gas well by adopting solid foam water drainage agent composition

A foam drainage agent, water drainage and gas recovery technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor high temperature resistance, production reduction or even stop spraying liquid foam drainage agent and difficulty in filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

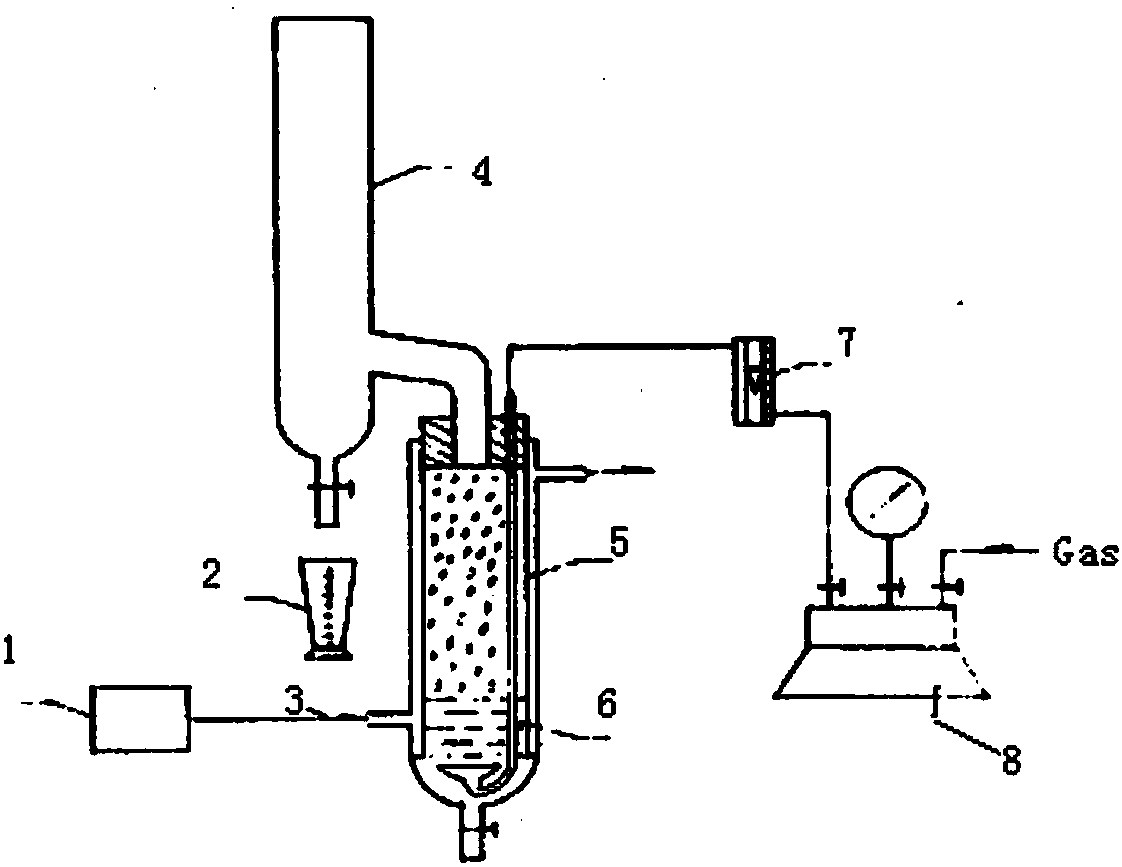

Image

Examples

Embodiment 1

[0080] (1) Preparation of foaming agent FMG01

[0081] a. Add 127.6 grams (0.55 moles) of pentaethylenehexamine and 1.4 grams (0.025 moles) of potassium hydroxide solid in the reaction flask equipped with mechanical stirring, thermometer, dropping funnel and atmospheric distillation device, and slowly drop them under stirring Add 148 grams (0.5 moles) of methyl oleate, react at a reaction temperature of 120 to 160°C for 6 hours, and collect the methanol generated by the reaction at the same time to obtain the desired amide compound C 17 h 33 CO(NHCH 2 CH 2 ) 5 NH 2 , yield 93.8%.

[0082] b. After removing the water in the three-necked flask device equipped with a reflux condenser, a dropping funnel, and a thermometer, add 11.4 grams (0.3 moles) of lithium aluminum hydride and 90 milliliters of dry dioxane, stir, disperse and mix, and then - Add 49.6 grams (0.1 moles) of C 17 h 33 CO(NHCH 2 CH 2 ) 5 NH 2 40wt% dioxane solution, after the dropwise addition, the temp...

Embodiment 2

[0089] Same as [Example 1], the difference is that when measuring the performance of FMG01, the pH is adjusted to 7, 4 and 2 with hydrochloric acid to simulate neutral and acidic gas environments, and the results are shown in Table 2.

Embodiment 3

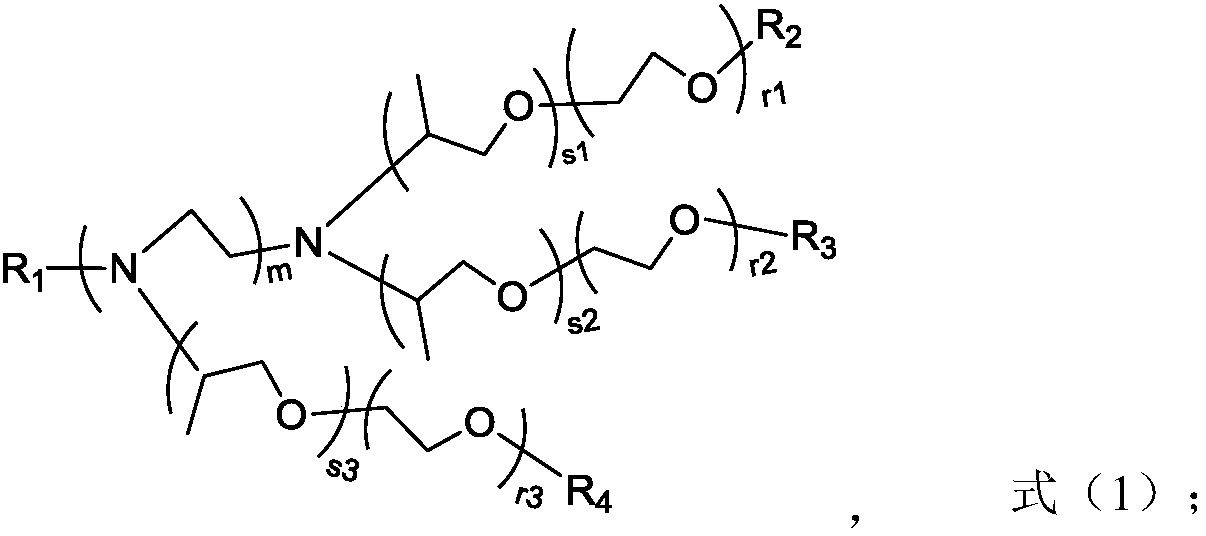

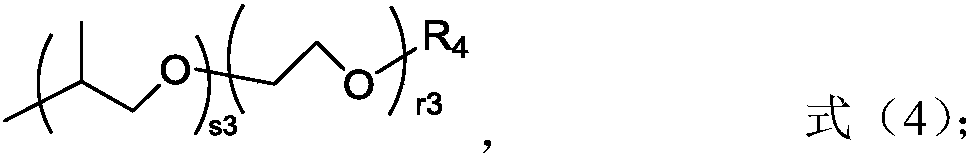

[0091] With [Example 1], the difference is that the long-chain polyamine polyether compound 1 (R 1 =C 18 h 35 , m=5, s1+s2+5s3=20, r1+r2+5r3=3) sodium hydroxypropanesulfonate (R 2 , R 3 , R 4 One of them is CH 2 CH(OH)CH 2 SO 3Na, the rest is H) 50 grams, C 16 h 33 OC 2 h 4 N + (CH 3 ) 3 Br - 50 grams, 100 grams of sodium sulfate, 50 grams of potassium bicarbonate, 30 grams of sodium borate, and 30 grams of biuret were mixed evenly, and 30 grams of 5% dextrin aqueous solution were added and mixed evenly to obtain a foam drainage rod FMG02. The results are shown in Table 3 Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com