Middle-low pressure gas collection technique

A process method and gas gathering technology, which can be used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of inconvenient production and management, and increase production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

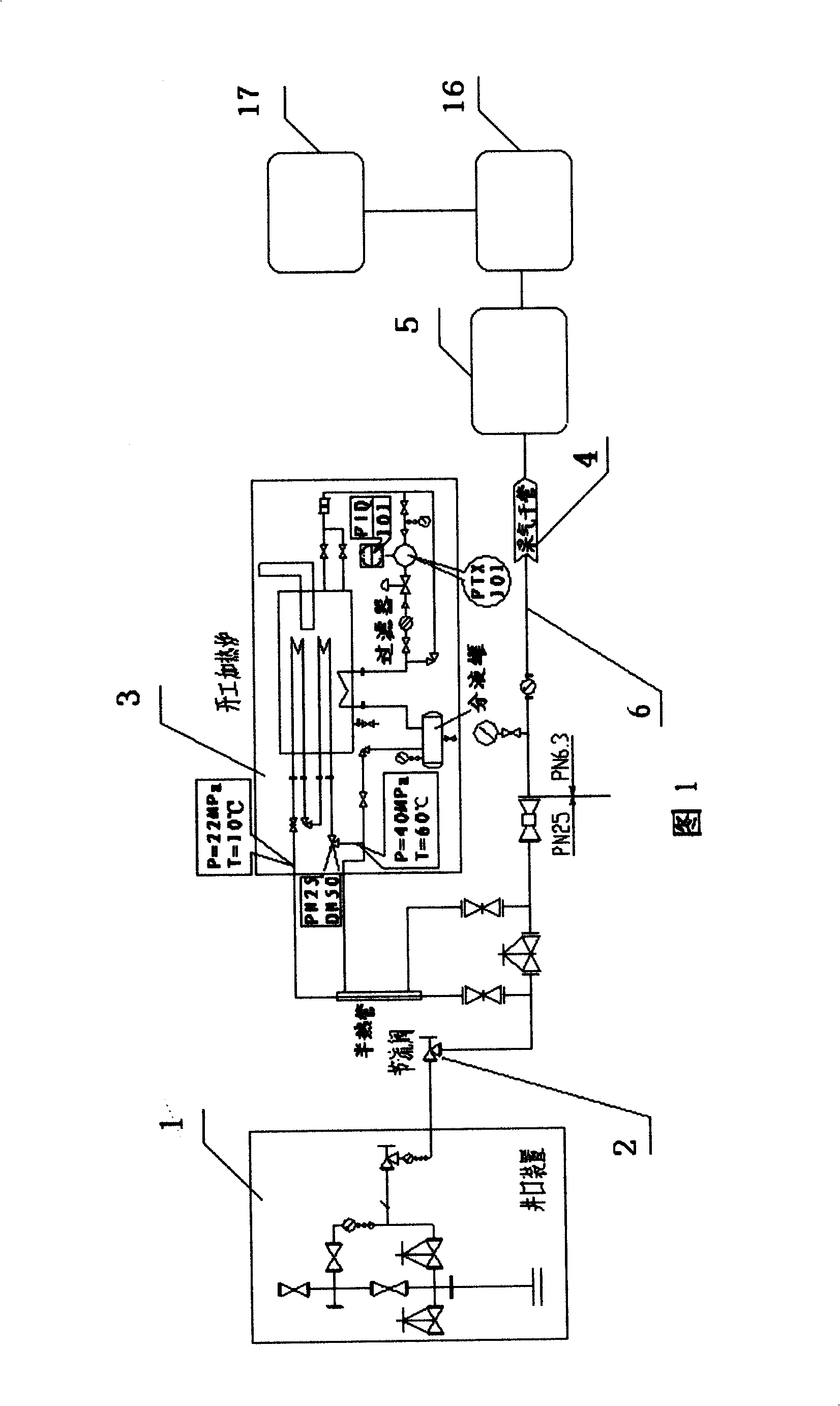

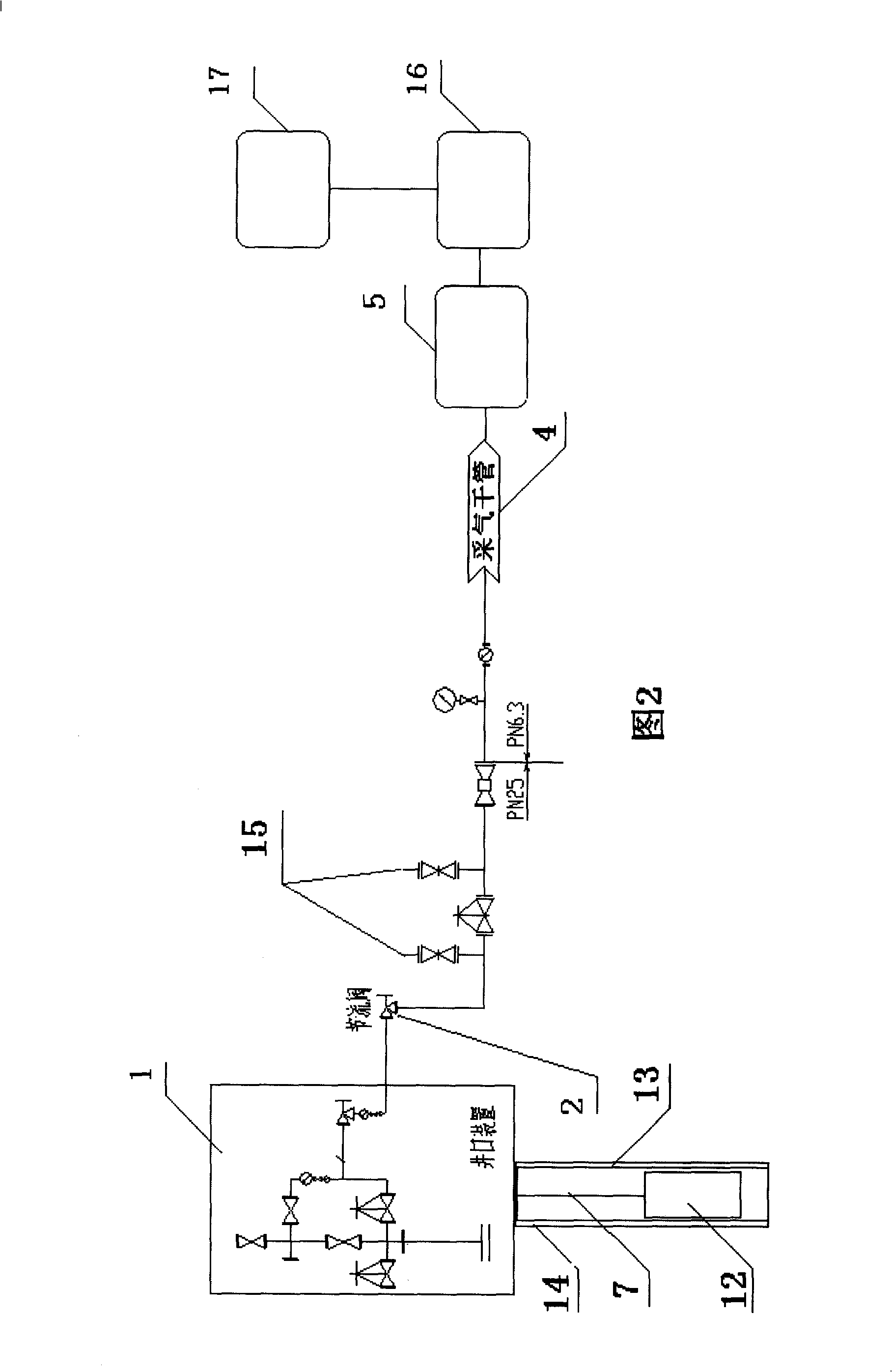

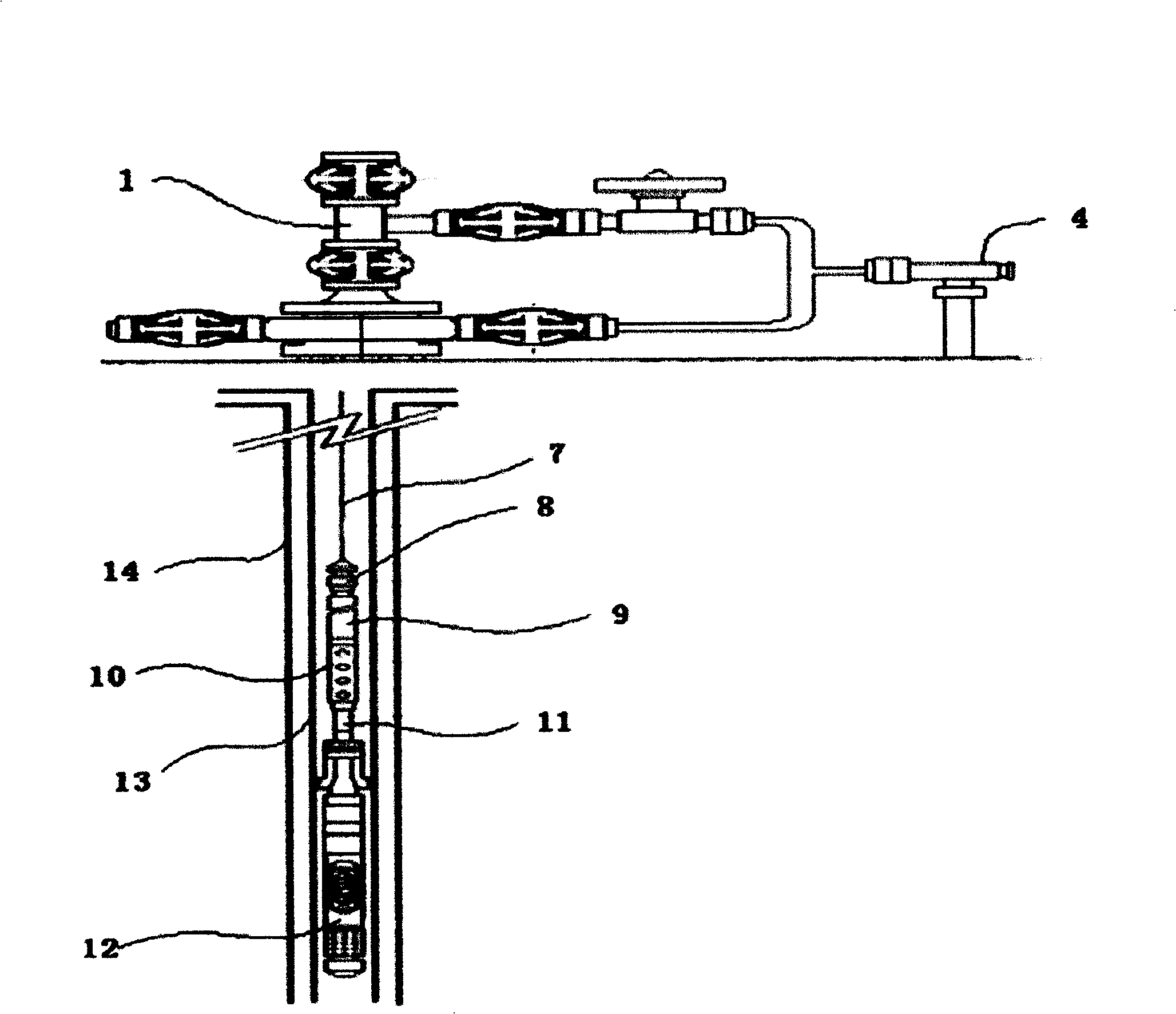

[0016] As shown in Figure 1, it is a conventional gas field treatment process. The natural gas in the gas well is connected to the wellhead device 1 through a pipeline, and the natural gas output directly from the well has a high pressure. It must pass through the throttle valve 2 and then be connected to the heating furnace 3 , so that the natural gas pressure becomes lower. In this process, the control system is required to adjust various valves, and the flow, temperature, and pressure need to be measured. Then it is connected to the gas gathering station 5 through the gas production pipeline 4 for processing, and at the same time, the wellhead needs to inject hydrate inhibitors to prevent the pipeline from freezing or to insulate the pipeline. When the number of wells in the gas field is large, the well spacing is small, and the output of a single well is low, the above-mentioned process obviously brings a lot of inconvenience to production and management, and increases the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com