Patents

Literature

89 results about "Polyethyleneglycol stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental-friendly foam drainage bar, and preparation method thereof

ActiveCN106244128AEasy to carrySimple filling processDrilling compositionSodium bicarbonatePolyethyleneglycol stearate

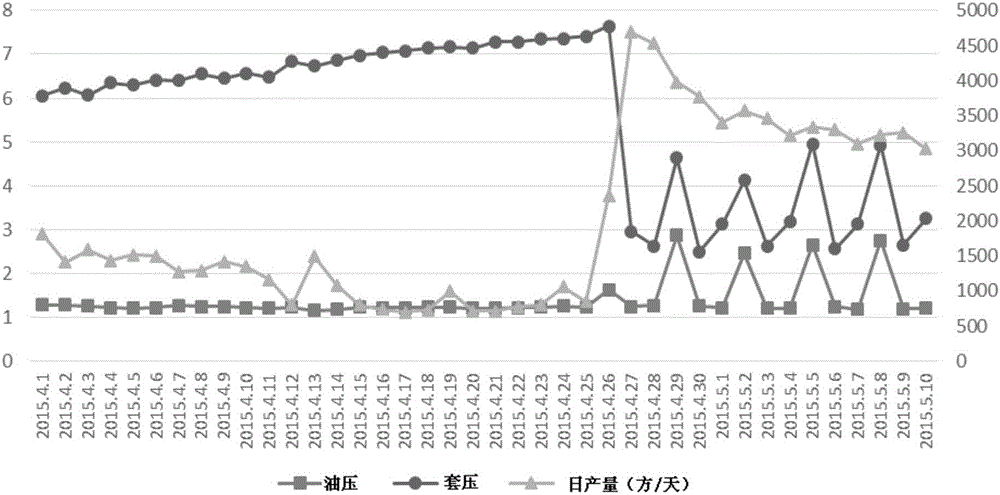

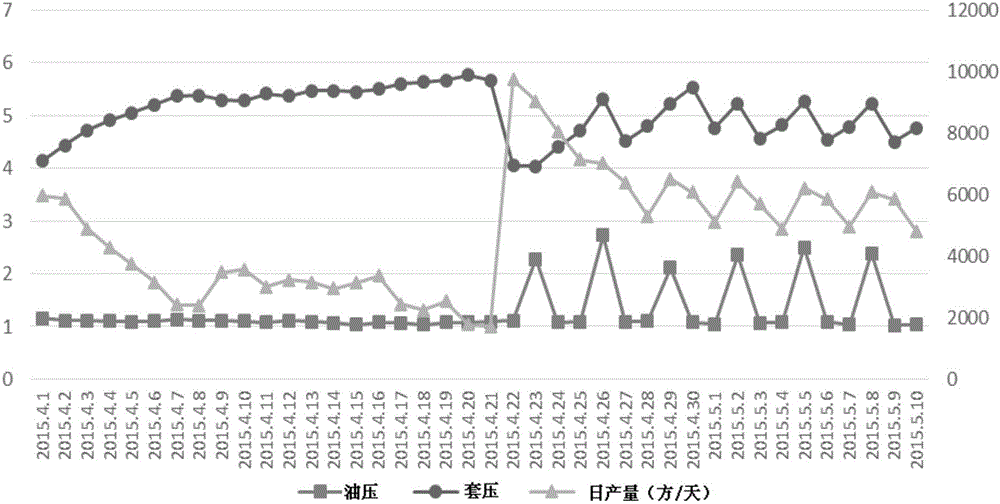

The invention discloses an environmental-friendly foam drainage bar, and a preparation method thereof. The environmental protection performance of the environmental-friendly foam drainage bar is used for referring that the environmental-friendly foam drainage bar is prepared from biodegradable raw materials. Foam drainage is used for referring discharging of well bottom accumulated water or accumulated liquid out of wells via utilization of water-containing or fluid-carrying capability of foam, so that gas recovery factor of gas wells is increased fully. The environmental-friendly foam drainage bar is capable of satisfying requirements of foam draining gas recovery and achieving excellent foam draining effect in field tests because of the excellent foaming ability, foam stabilizing ability, and liquid carrying capacity of the environmental-friendly foam drainage bar. The environmental-friendly foam drainage bar comprises following raw materials: cocamidopropyl betaine, sodium lauryl oxyethyl sulfonate, sodium lauroyl glutamate, fatty alcohol polyoxyethylene ether, polyethylene glycol monostearate, urea, citric acid, sodium bicarbonate, and sodium carbonate.

Owner:北京众博达石油科技有限公司

Antistatic finishing agent for wool and wool blended fabrics and preparation method thereof

The invention discloses an antistatic finishing agent for wool and wool blended fabrics and a preparation method thereof. The antistatic finishing agent comprises the following components in parts by weight: 2-5 parts of polydimethylsiloxane, 1-3 parts of polymethyl hydrogen siloxane, 10-20 parts of butyl acrylate, 1-3 parts of methylparaben, 10-20 parts of glycerol, 0.2-0.6 part of potassium alkyl benzene sulfonate, 3-8 parts of 2-hydroxypropyl acrylate, 2-5 parts of calcium chloride, 5-8 parts of polyethyleneglycol stearate and 80-100 parts of water. The fabric treated by the antistatic finishing agent has greatly lower surface resistance, higher soaping resistance and favorable softness.

Owner:吴江市钱氏纺织有限公司

Silane paste protective agent and preparation method thereof

ActiveCN103601527AFix stability issuesSolve easy delamination and demulsificationSilanesPolyethylene glycol

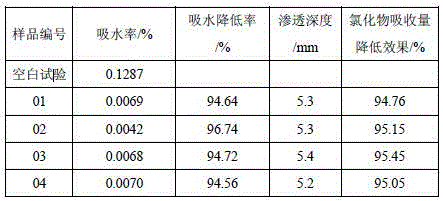

The invention relates to a silane paste protective agent and a preparation method thereof. The silane paste protective agent comprises the following formula by the weight percentage: 65%-85% of a silane monomer, 3.0%-5.0% of an emulsifier, 0.5%-1.0% of a thickening agent, 1.0%-1.5% of an emulsifying stabilizer, 0.1%-1.0% of a buffering agent, and 10%-28% of deionized water; the silane monomer is a mixture obtained by mixing one or more alkyl alkoxy silanes in any proportion; the emulsifier is a combination of one or more of alkylphenol ethoxylates OP series, fatty alcohol-polyoxyethylene ether MOA series, peregal OS series, Tween series, high fatty alcohol sulfate esters, and sulfonate emulsifier series; the emulsion stabilizer is any one of Span series, polyethylene glycol monolaurates, polyethylene glycol stearates, and glyceryl stearates. The silane paste protective agent has the advantages of excellent permeability, waterproof and durability, long-term storage stability, rapid bead coagulation and the like.

Owner:中建材苏州防水研究院有限公司

Hard alloy extrusion forming agent, preparation method thereof and application of hard alloy extrusion forming agent in extrusion production

The invention discloses a hard alloy extrusion forming agent, a preparation method thereof, and application of the hard alloy extrusion forming agent in extrusion production. The hard alloy extrusion forming agent comprises the following components in percentage by weight: 60 to 85 percent of a solvent namely ethylene glycol diacetate, 10 to 30 percent of a bonding agent namely ethyl cellulose and 5 to 10 percent of a surface active agent namely fatty alcohol-polyoxyethylene ether. The preparation method of the hard alloy extrusion forming agent comprises the steps of blending, mixing, heating and stirring materials. The application of the hard alloy extrusion forming agent in extrusion production of a hard alloy comprises the following steps of: blending materials, and performing ball milling on 0.8 to 3.0 weight percent of a plasticizer namely polyethylene glycol stearate and the balance of a hard alloy raw material; drying and granulating to obtain a mixture containing the plasticizer; mixing 5 to 7 weight percent of a forming agent with the mixture to obtain an extrusion feeding material; extruding a blank; drying to remove the solvent in the forming agent; curing the blank, and fixing the length of the blank through semi-finishing to form a semi-finished product; and sintering to obtain a finished product. By adopting the hard alloy extrusion forming agent, the qualified rate and labor efficiency of a product are improved, the cost is reduced, the localization, safety and environmental friendliness of raw materials are achieved, and the operating environment is improved.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Anti-wrinkling finishing agent of garment fabric

The invention relates to an anti-wrinkling finishing agent of a garment fabric. The anti-wrinkling finishing agent of the garment fabric consists of citric acid, polyethylene glycol monostearate, zinc isoocatanoate, magnesium chloride, hydrogen-containing dimethyl polysiloxane, polyethylene glycol ether and water; the mass percentages of substances are as follows: 10-30 percent of dimethylformamide, 2-6 percent of polyethylene glycol monostearate, 5-15 percent of zinc isoocatanoate, 5-15 percent of magnesium chloride, 1-3 percent of hydrogen-containing dimethyl polysiloxane, 2-6 percent of polyethylene glycol ether, 3-7 percent of fluorine-containing quinolone methacrylate, 2-6 percent of fatty alcohol-polyoxyethylene ether, 1-3 percent of sodium polyacrylate and balance of water. The anti-wrinkling finishing agent of the garment fabric can realize very good anti-wrinkling finishing to various chemical fiber, cotton-spun and silk-woven fabrics and can perform anti-wrinkling treatment to solidification of fabrics caused by various reasons in life, the process is safe and nontoxic, and a very good effect of preventing fabrics from balling and surfaces from being wrinkled can be achieved by using the anti-wrinkling finishing agent of the garment fabric.

Owner:石忠

Composition for leveling agent and leveling agent as well as preparation method thereof

The invention discloses a composition for a leveling agent, the leveling agent and a preparation method thereof. The composition for the leveling agent comprises the following raw materials in parts by weight: 15 to 20 parts of polyethylene glycol stearate, 3 to 6 parts of fatty amine polyoxyethylene ether, 6 to 8 parts of polysorbate, 2 to 4 parts of sodium dodecyl benzene sulfonate, and 35 to 40 parts of deionized water. The invention also provides a method for preparing the leveling agent by using the composition. The method for preparing the leveling agent by using the composition comprises the following steps of adding the polyethylene glycol stearate, the fatty amine polyoxyethylene ether, the polysorbate and the dodecyl benzene sulfonate into a reaction kettle with an agitator in sequence, mixing and agitating an obtained mixture, and adding the deionized water into the obtained mixture while agitating the obtained mixture. The invention also provides the leveling agent, which is prepared according to the method. Matching raw materials of the composition for the leveling agent are a few, and are simple and easy to obtain; the preparation cost is low; the prepared leveling agent is good in retarding, migration and dispersion effects; further, the reparation method is simple.

Owner:JIANGSU HAIAN PETROCHEM PLANT

Computer electronic display screen cleaning agent and preparation method thereof

InactiveCN105238579AThe preparation process is simpleEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBenzoic acidPhosphoric Acid Esters

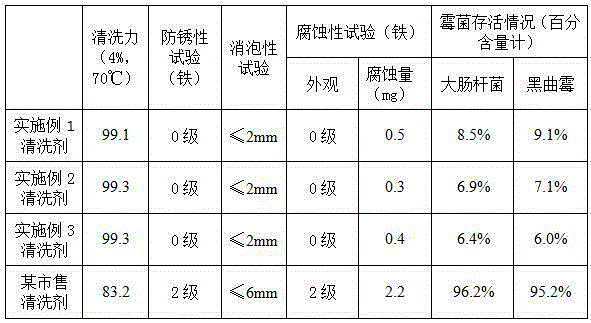

The present invention relates to a computer electronic display screen cleaning agent, which comprises, by mass, 52-56 parts of biochemical fulvic acid, 54-58 parts of benzotriazole, 50-54 parts of 1-hydroxyethylidene-1,1-diphosphonicacid, 54-58 parts of alkanol phosphate ester, 50-54 parts of hydroxyethylenediamine, 54-58 parts of sodium ligninsulfonate, 50-54 parts of caprylic / capric triglyceride, 56-60 parts of benzoic acid, 50-54 parts of potassium dihydrogen phosphate, 54-58 parts of polyacrylamide, 50-54 parts of polyethylene glycol stearate, 54-58 parts of sodium humate, 50-54 parts of polyepoxysuccinic acid, 54-58 parts of mercaptobenzothiazole, 50-54 parts of isothiazolinone, 54-58 parts of cyclic silicone oil, 50-54 parts of lecithin, 54-58 parts of permethrin, 50-54 parts of butyl acetate, 54-58 parts of dodecyl dimethyl benzyl ammonium chloride, 50-54 parts of benzimidazole allyl thioether, 54-58 parts of aliette, 50-54 parts of a silver ion antibacterial agent, and 1000-2000 parts of water. The cleaning agent of the present invention has good cleaning ability.

Owner:龚灿锋

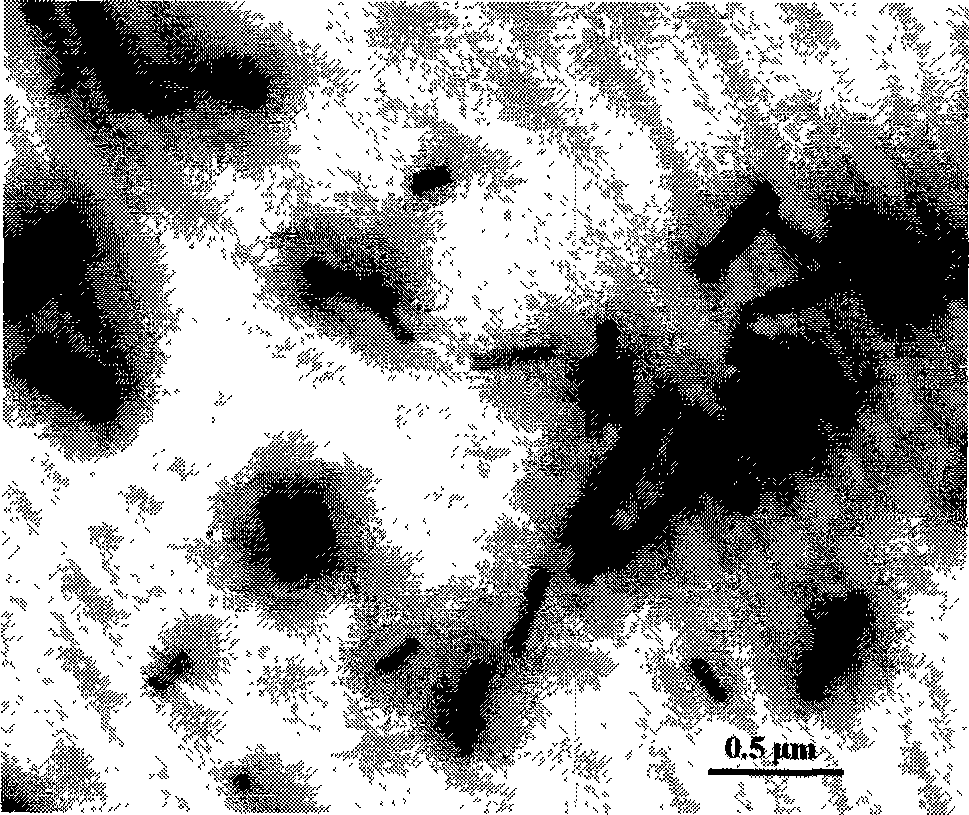

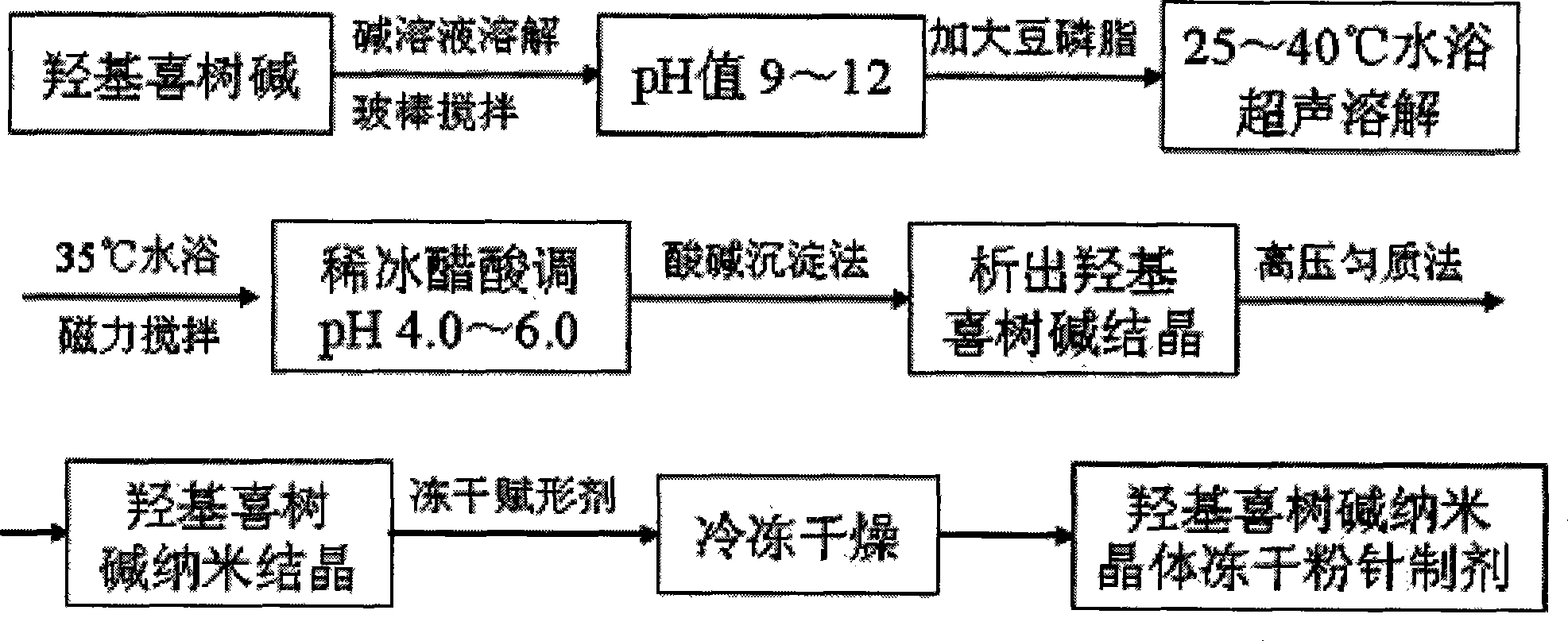

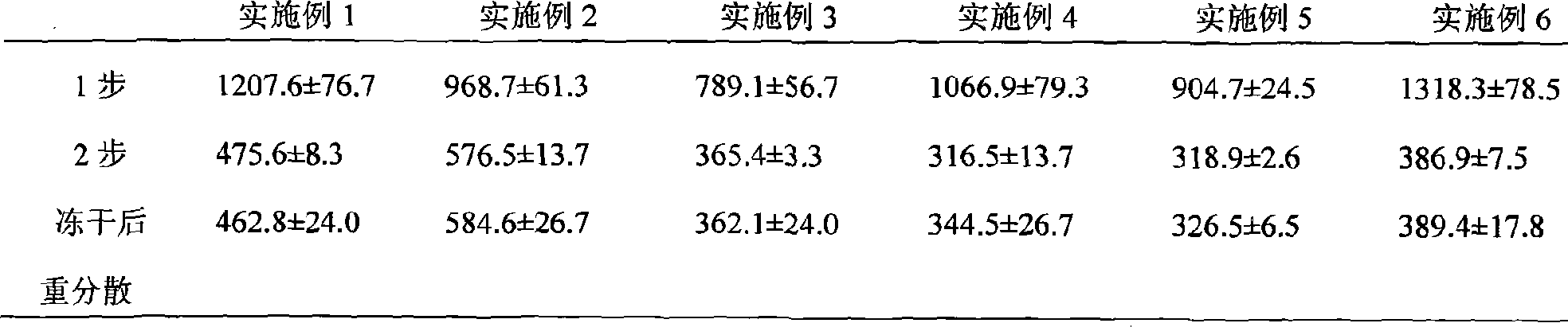

Hydroxycamptothecin nano crystal lyophilized powder for injection preparation and preparation method thereof

InactiveCN101461787AGood redispersibilityImprove stabilityPowder deliveryOrganic active ingredientsWater bathsDispersity

The invention discloses a method for preparing a nanometer hydroxycamptothecin crystal freeze-dried powder preparation. Main raw materials of the nanometer hydroxycamptothecin crystal freeze-dried powder preparation consist of an active raw material, namely hydroxycamptothecin, phospholipids, a surfactant, namely poloxamer 188 or polyethylene glycol stearate-15, and a freeze-dried auxiliary material excipient. The method for preparing the nanometer hydroxycamptothecin crystal freeze-dried powder preparation comprises the following steps: after the hydroxycamptothecin is added into an alkaline solution to be dissolved, the phospholipids are added in an ultrasonic water bath, and the poloxamer 188 or the polyethylene glycol stearate-15 is added into the mixture under magnetic stirring to be dissolved; the pH value of glacial acetic acid is adjusted to be between 4.0 and 6.0, and hydroxycamptothecin crystals are precipitated; and then the high-pressure homogenization is performed to obtain a nanometer hydroxycamptothecin crystal suspension, and then the freeze-dried auxiliary material excipient is added to be freezely dried to obtain the nanometer hydroxycamptothecin crystal freeze-dried powder preparation. The method is simple and easy to operate. Nanometer crystal freeze-dried powder has the advantages of high dispersity, good stability and so on. The average size of the crystals is 355.6nm, the average content of the hydroxycamptothecin in a sample is 98.5 percent of labeled amount, and the effect of inhibiting and killing liver cancer and gastric cancer cells of the preparation is remarkably stronger than that of a hydroxycamptothecin injection.

Owner:ZHENGZHOU UNIV

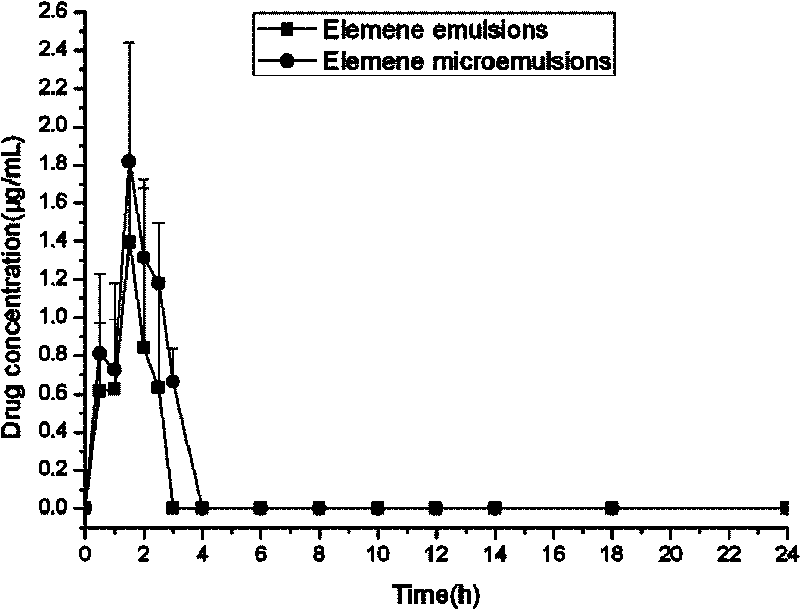

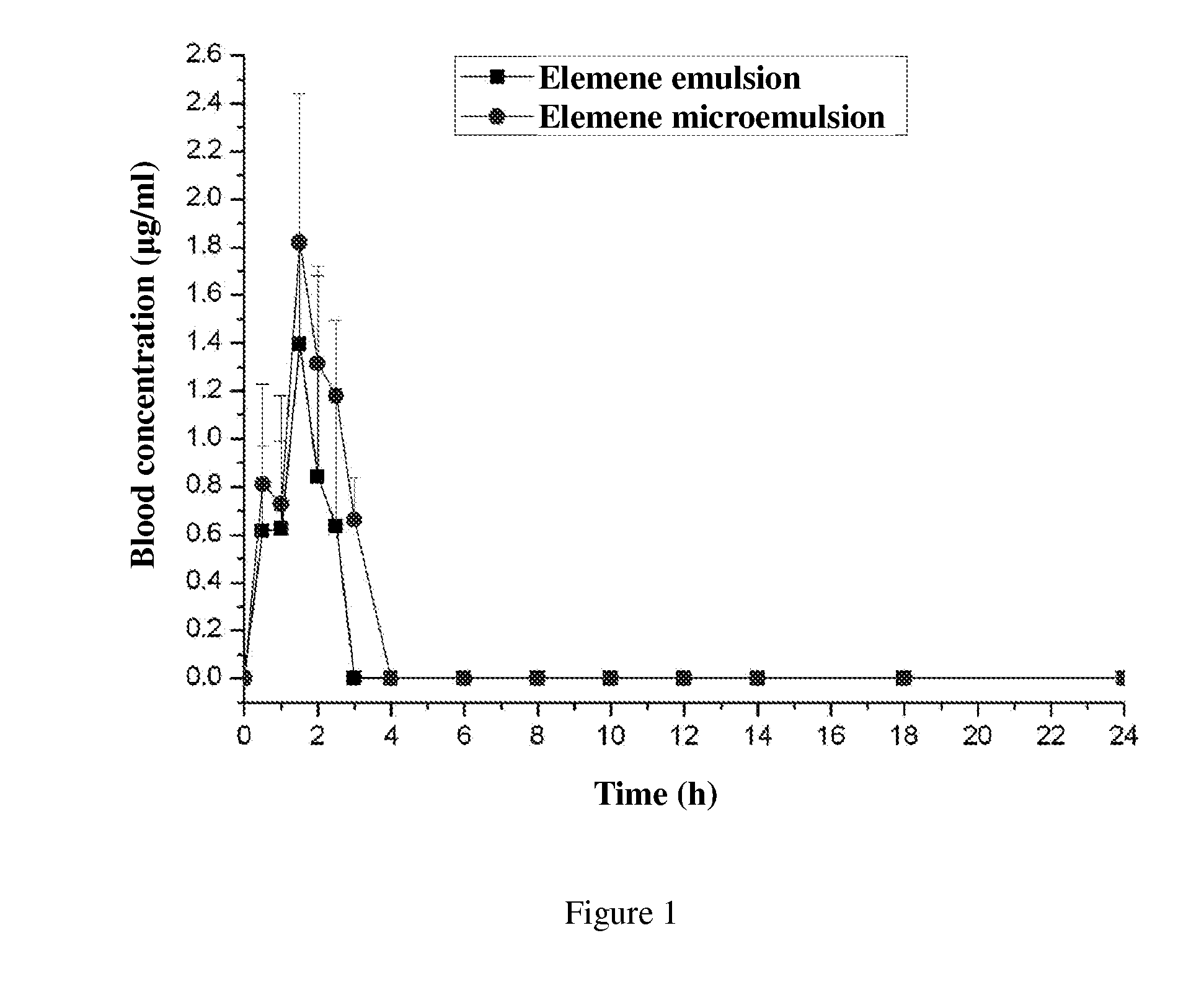

Elemene micro-emulsion

ActiveCN101756900ASolve the disadvantage of water insolubilityAddress insoluble shortcomingsOrganic active ingredientsDispersion deliveryPolyoxyethylene castor oilSide effect

Owner:谢恬

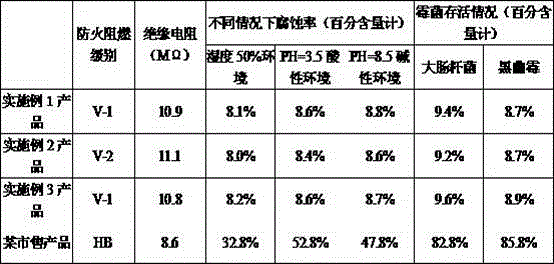

Preparation method of flame-retarding anti-cracking type graphite heat dissipation sheet

InactiveCN108218378AHas a fibrous structureImprove flame retardant performanceModifications by conduction heat transferFiberInsulation layer

The invention relates to a production method of graphite heat dissipation sheets and in particular relates to a preparation method of a flame-retarding anti-cracking type graphite heat dissipation sheet. The flame-retarding anti-cracking type graphite heat dissipation sheet is prepared by taking modified expanded graphite as a matrix and modified talcum powder and modified wollastonite fibers as areinforcing agent, and adding with silica sol, copper powder, iron powder and the like; firstly, graphite powder is modified by utilizing a concentrated sulfuric acid solution; the modified graphitepowder is blended with acetic anhydride and potassium permanganate to obtain expanded graphite; after the graphite is treated through concentrated sulfuric acid, a relatively good heat-insulation layer is formed, so that the flame-retarding property of the graphite heat dissipation sheet is improved; a pyrophosphoric acid acyloxy group is introduced into the surface of the graphite heat dissipation sheet so that the flame-retarding property of the graphite heat dissipation sheet is improved; polyethylene glycol stearate and the silica sol are continually used for modifying the wollastonite fibers; the contact area between the graphite heat dissipation sheet and the matrix is enlarged by adopting a coarse surface structure, and the bonding strength of an interface can be effectively improved, so that the anti-cracking performance of the graphite heat dissipation sheet is improved and the graphite heat dissipation sheet has a wide application prospect.

Owner:常州水精灵环保设备有限公司

High-toughness plastic rubber

The invention discloses a high-toughness plastic rubber, which belongs to the technical field of office supplies. The present invention is made of the following raw materials in parts by weight: 60-75 parts of natural rubber, 0.5-1 part of polyethylene glycol stearate, 1-5 parts of bone glue, 1-5 parts of cetyl alcohol, hydroxyl 5-8 parts of acetic acid, 5-8 parts of carboxyacetic acid, 5-10 parts of limonene, 0.5-1 part of sodium bicarbonate and 2-4 parts of pigment. The present invention is by adding a certain proportion of polyethylene glycol stearate, bone glue, cetyl alcohol, glycolic acid, carboxyacetic acid, limonene and sodium bicarbonate (especially glycolic acid, combination of carboxyacetic acid and limonene), so as to effectively improve the decontamination effect of the product rubber.

Owner:吴东华

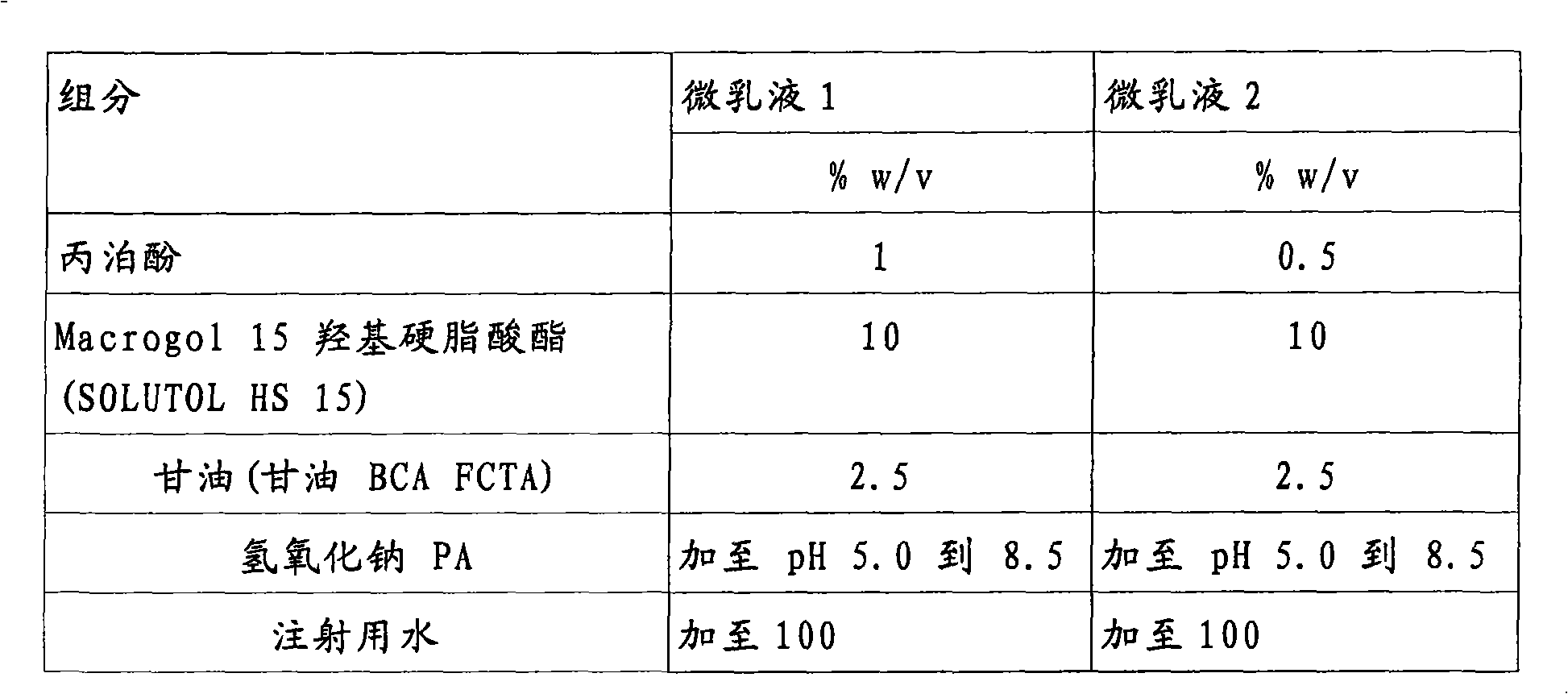

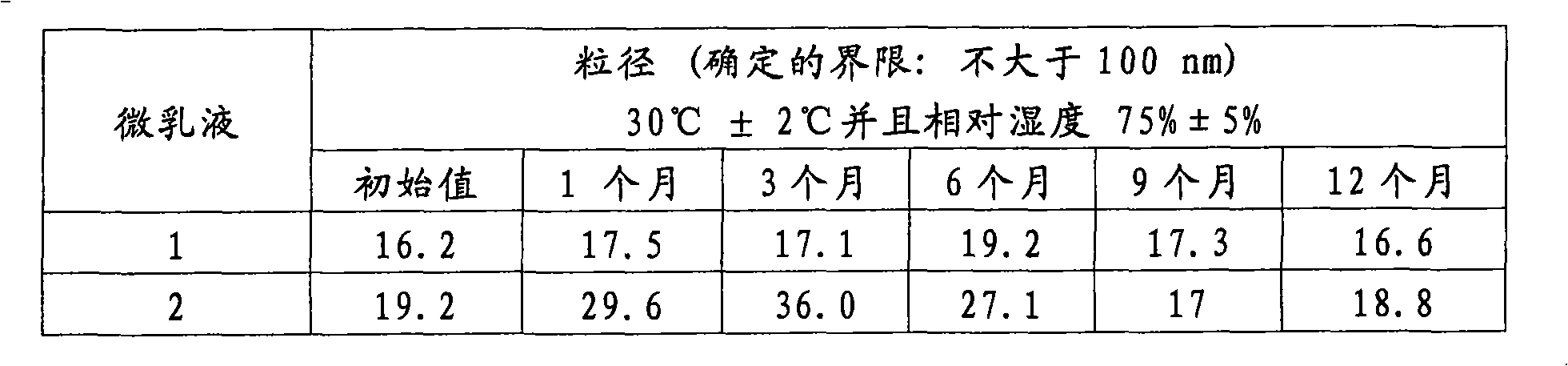

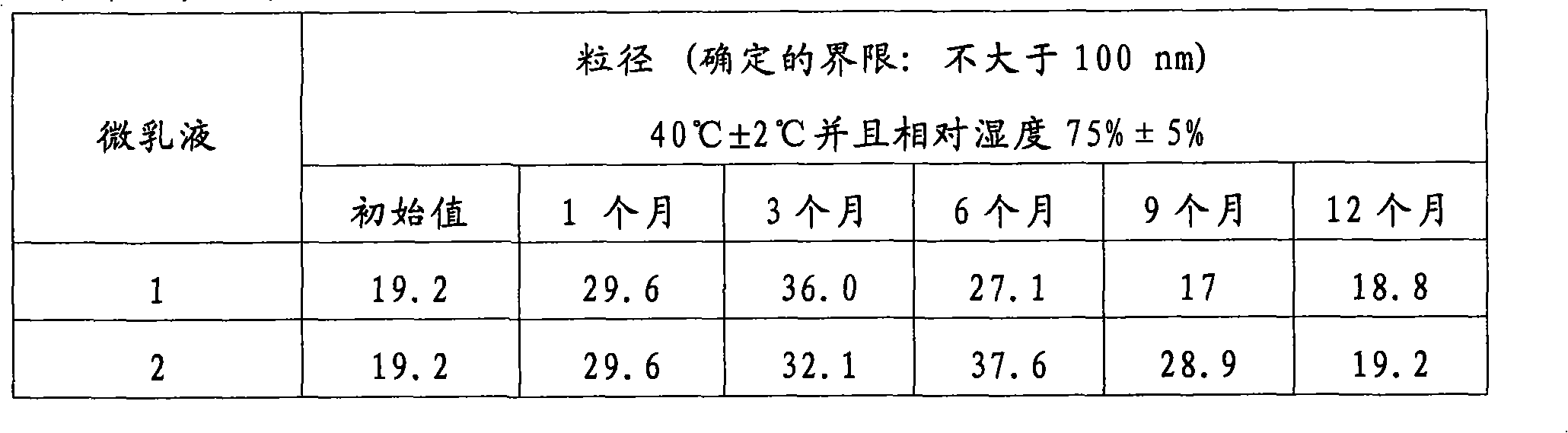

Stable and ready-to-use oil-in-water propofol microemulsion

InactiveCN101553215AEliminate side effectsReduce riskHalogenated hydrocarbon active ingredientsNervous disorderPolyethylene glycolReady to use

The present invention describes a new propofol-containing anesthetic pharmaceutical composition for parenteral administration, in the form of an oil-in-water microemulsion in which the oily phase is constituted by propofol in the form of particles with size comprised between 1 and 100 nm using a single surfactant selected from the group consisting of polyethylene glycol stearates with general formula C17H35COO.(OCH2CH2)nH or C17H35COO.(OCH2CH2)n.COOC17H35. The anesthetic pharmaceutical composition of the present invention is more potent for induction of hypnosis and anesthesia, has a ready-to-use presentation and highly stable particle size, presenting improved physicochemical properties, and preventing the potential risks of undesirable effects encountered in the state-of-the-art propofol formulations.

Owner:CRISTALIA PROD QUI FARM LTDA

Preparation method of fireproof insulation board with high flexural strength

InactiveCN107602055AImprove adhesionImprove mechanical propertiesGlass making apparatusPolymer scienceFlexural strength

The invention discloses a preparation method of a fireproof insulation board with high flexural strength, and belongs to the technical field of board preparation. A mixture of polyphenyl granules andvitrified beads is taken as a substrate; honey is used for modifying the mixture; self-made basalt fiber is modified by polyethylene glycol monostearate; basalt is pulled into fibrous structure basalt; after the basalt fiber is modified, the bonding strength of an interface can be enhanced greatly; the polyphenyl granules are prone to burn at a high temperature; surface modification is performed on magnesium cement by a silane coupling agent; magnesium cement has very high density in a setting and hardening process, and is taken as an interfacial bonding agent after being modified; internal pores of the insulation board are effectively filled with the granules; magnesium hydroxide and aluminum hydroxide are modified together through a titanate coupling agent TMC-201, so that the flame temperature is lowered; a flame-retardant pyrophosphoric acid acyloxy group in the titanate coupling agent TMC-201 is introduced, so that the fire retardancy of the insulation board is enhanced.

Owner:陈合华

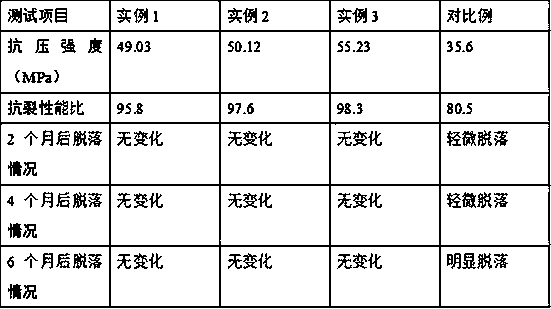

Preparation method of high-cracking resistance rock wool board

InactiveCN108117364AImprove crack resistanceHigh bonding strengthCrack resistancePolyethylene glycol

The invention discloses a preparation method of a high-cracking resistance rock wool board, belonging to the technical field of preparation of rock wool boards. According to the preparation method, the rock wool board with high cracking resistance and bonding strength is prepared by taking basalt fibers as a main material and rubber powder polyphenyl particles, glass melting liquid, quartz sand and the like as reinforcing filling materials, and the main material and the reinforcing filling materials are firmly connected together, so that the bonding strength of the rock wool board is effectively improved; polystyrene is foamed by virtue of a foaming agent to form a hard hole-closed structure, and formed polystyrene particles are dually modified by virtue of a bonding agent and a silane coupling agent, so that the bonding strength of the rock wool board is improved; the glass melting liquid is modified by virtue of polyethylene glycol stearate, so that the expansion of cracks can be inhibited, the mechanical property of the rock wool board can be improved; and after glass fibers are modified, the contact areas with the basalt fibers are increased by virtue of rough surface structures, the bonding strength of an interface can be substantially enhanced, the cracking resistance and bonding strength of the rock wool board are further improved; and the preparation method has wide application prospects.

Owner:常州富思通管道有限公司

Polyurethane protective film and preparation method thereof

PendingCN113388142AImprove antistatic performanceNot easy to precipitatePolyurea/polyurethane coatingsElectrically-conductive paintsPolymer sciencePolythylene glycol

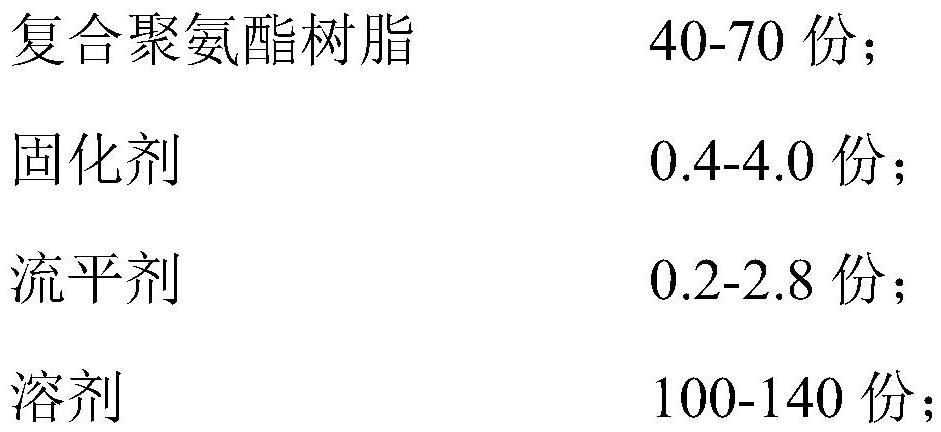

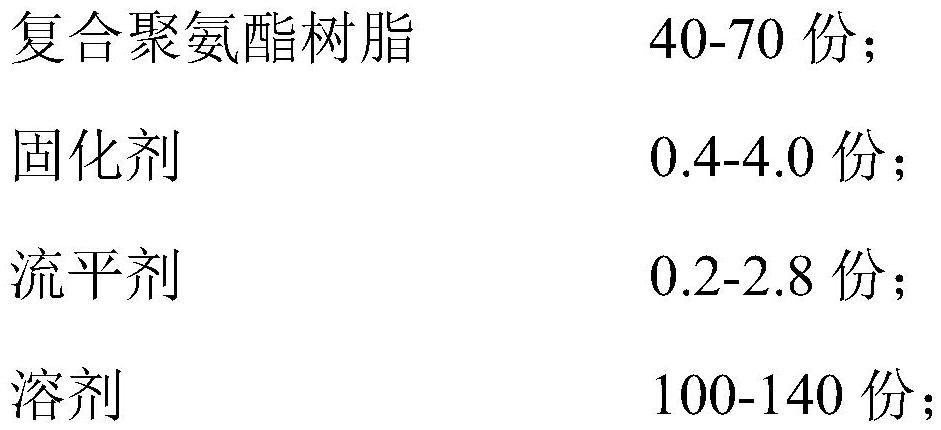

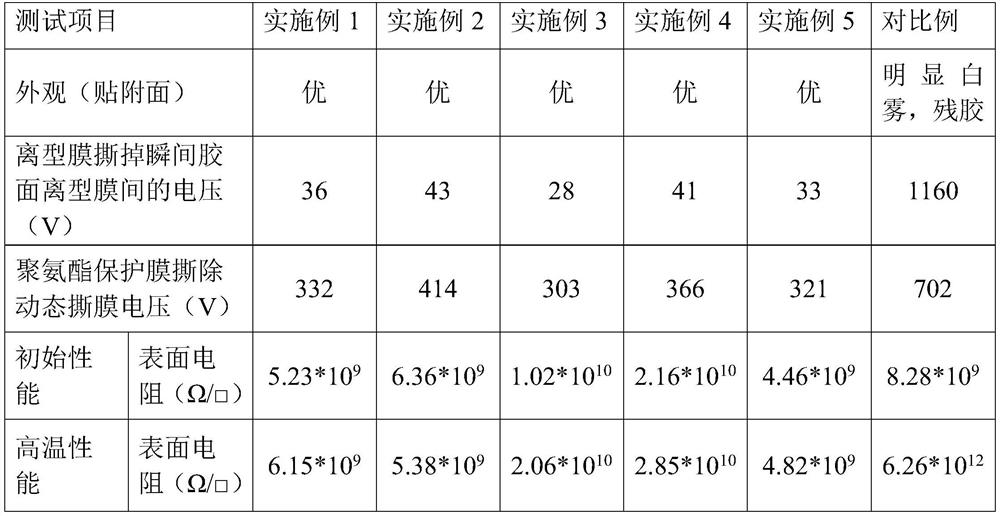

The invention relates to a polyurethane protective film and a preparation method thereof, the polyurethane protective film comprises a single-side antistatic PET base material layer, an antistatic coating and a PET antistatic release film layer, the other side of the single-side antistatic PET base material layer is coated with the antistatic coating, and the antistatic coating comprises the following components in parts by weight: 40-70 parts of composite polyurethane resin; 0.4-4.0 parts of a curing agent; 0.2-2.8 parts of a leveling agent; and 100-140 parts of a solvent, wherein the composite polyurethane resin is prepared from polyurethane resin and a modified antistatic agent; the antistatic agent comprises a trihydroxyethyl methyl quaternary ammonium methyl sulfate salt, or one or any combination of the trihydroxyethyl methyl quaternary ammonium methyl sulfate salt, polyethylene glycol stearate and polyethylene glycol laurate; the ratio of the polyethylene glycol laurate to the trihydroxyethyl methyl quaternary ammonium sulfate methyl ester salt to the polyethylene glycol stearate is (0-0.4): 1: (0-0.6). According to the polyurethane protective film disclosed by the invention, the tearing voltage generated when the protective film of the touch screen is torn is relatively low, and the modified antistatic agent is not easy to separate out under high-temperature and high-humidity conditions.

Owner:HEFEI LUCKY SCI & TECH IND

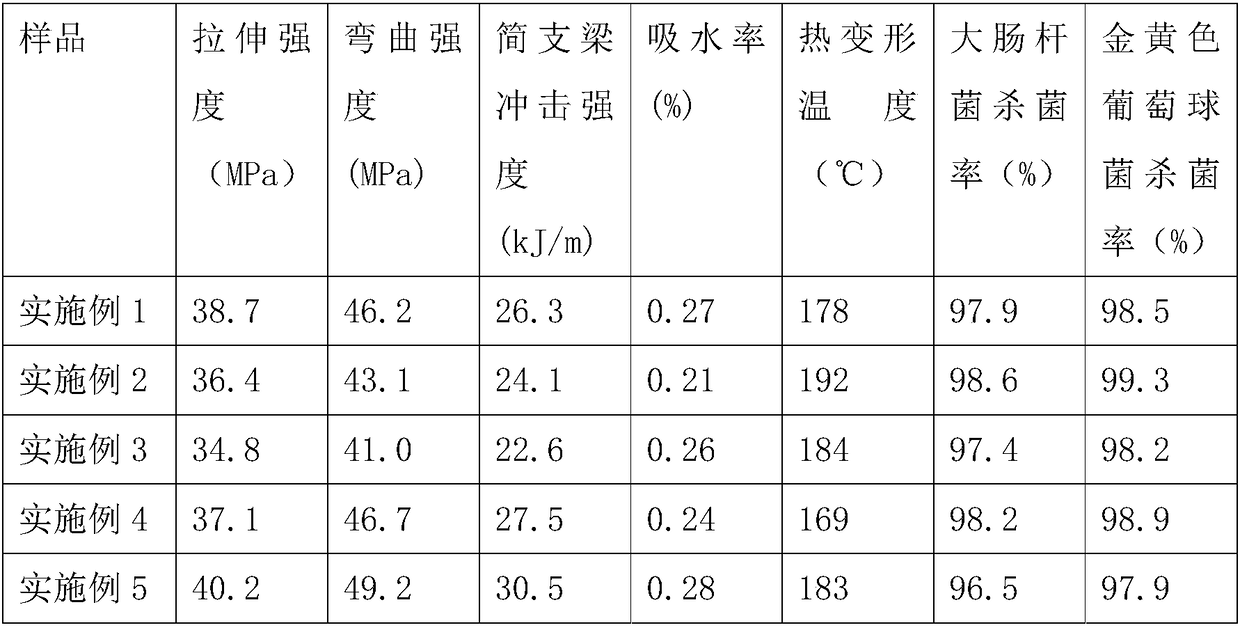

Fall resistant and antibacterial PP plastic meal box and preparation method thereof

The invention discloses a fall resistant and antibacterial PP plastic meal box and a preparation method thereof. The meal box comprises the following raw materials, by weight: 100 parts of PP resin, 50-100 parts of bagasse, 5-10 parts of chitosan, 5-15 parts of shell powder, 10-20 parts of nanometer calcium carbonate, 3-6 parts of a sepiolite fiber, 1-2 parts of phytic acid, 1-3 parts of a modifier, 0.5-2 parts of a coupling agent, 1-2 parts of a plasticizer, 0.5-1.5 parts of an antioxidant, 0.5-2 parts of a composite antibacterial agent, 1-3 parts of cocoamidopropyl betaine, and 3-5 parts ofcarboxymethyl cellulose. The modifier consists of octa(aminophenyl)silsesquioxane and polyethylene glycol stearate in a ratio of 1:1-3. The preparation method adopts the unique raw material formula and coordination effect of the components, the compatibility is good, and the prepared PP plastic meal box has the advantages of high strength, strong impact resistance, fall resistance, wear resistance, weather resistance, high temperature resistance, aging resistance, deformation resistance, good stability, good antibacterial effect and the like, is good in processing performance, simple in process and low in cost, and has good market prospects.

Owner:何亚龙

Bamboo charcoal and cashmere blended fabric softener

The invention discloses a bamboo charcoal and cashmere blended fabric softener which comprises a first component, a second component and a third component. The second component comprises a component A and a component B. The first component comprises, by mass, 52 to 68 parts of linoleic acid and 9 to 15 parts of hydroxyethylenediamine. The component A in the second component comprises, by mass, 5 to 9 parts of sodium stearate, 8 to 12 parts of sodium pyrophosphate, 7 to 9 parts of sodium tripolyphosphate and 33 to 38 parts of ethanediol. The component B in the second component comprises, by mass, 22 to 24 parts of amino silicon oil, 6 to 8 parts of glycol stearate, 3 to 7 parts of glycerin monostearate, 1 to 3 parts of diethyl phthalate and 1 to 5 parts of dimethyl sulfate. The third component comprises, by mass, 2 to 4 parts of benzyl chloride and 0.5 to 1 part of polyether. The bamboo charcoal and cashmere blended fabric softener is simple in product process, raw materials are environmentally friendly, the softening effect on fabric is good, the fabric is soft, fluffy, comfortable and not prone to be hardened, and static generation is not likely to happen.

Owner:SUZHOU JIN YUAN OIL MACHINERY

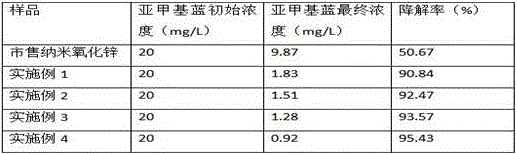

Preparation method for supported zinc oxide photocatalyst

InactiveCN106362749ALarge specific surface areaImprove pore structureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsThioureaRed mud

The invention discloses a preparation method for a supported zinc oxide photocatalyst. The preparation method comprises the following steps: weighing raw materials consisting of, by weight, 30 to 50 parts of cadmium nitrate hexahydrate, 5 to 10 parts of polyethylene glycol stearate, 15 to 20 parts of thiourea, 5 to 10 parts of red mud, 1 to 2 parts of cobaltous carbonate and 10 to 15 parts of kaolin; adding cadmium nitrate hexahydrate into an ultrasonic generator, adding absolute ethyl alcohol for dissolving, then adding a sodium hydroxide solution and carrying out an ultrasonic reaction so as to obtain a suspension A; adding thiourea into a stirrer and then adding a proper amount of water so as to obtain a suspension B; pouring the suspension B into the suspension A, then adding polyethylene glycol stearate and carrying out an ultrasonic reaction so as to obtain a mixed solution; adding the mixed solution, red mud, cobaltous carbonate and kaolin into a ball mill, adding a proper amount of water and carrying out stirring so as to obtain a paste; and carrying out drying, crushing and roasting so as to obtain the photocatalyst. The preparation method has the advantages of wide sources of raw materials, low cost, simple preparation process, high production efficiency and low energy consumption; and the prepared photocatalyst has the advantages of good adsorption performance, high catalytic activity, high catalysis efficiency, etc.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Oral microemulsion of elemene

InactiveUS20120322892A1Eliminate side effectsSave raw materialsBiocideOrganic active ingredientsPolyoxyethylene castor oilPolyethylene glycol

Owner:XIE TIAN

Multifunctional protection coating of teaching aid

InactiveCN106118408AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsSodium BentoniteSodium metasilicate

The invention relates to a multifunctional protective coating for teaching equipment, which is composed of the following components: chlorohydrin rubber, chlorosulfonated polyethylene resin, bisphenol A epoxy resin, hexabromocyclododecane, triethylene glycol di Isooctanoate, zinc borate hydrate, sodium antimonate, methyl p-hydroxybenzoate, oxazolidinone, tetramethylthiuram disulfide, dibromomethane, fluoroquinolone, nano aluminum powder, nano silicon carbide, nano oxide Aluminum powder, albite powder, zirconium boride powder, bentonite, sodium metasilicate, polyglycerol ricinoleate, polyether silicone oil, polyvinyl acetate emulsion, sunflower oil, polyethylene glycol stearate, Furfurylamine, Diphenyl Ether, Diisononyl Phthalate, Tributyl Phosphate, Thiourea, Chlorinated Paraffin. The product of the invention has relatively superior flame retardancy, acid and alkali resistance, anti-mildew and antibacterial properties, and improves product performance.

Owner:XIAOGAN QISIMIAOXIANG CULTURAL MEDIA

Smooth type high-strength packaging film

The invention relates to a smooth type high-strength packaging film, which is characterized by being prepared from the following raw materials in parts by mass: 100 parts of PE (polyethylene) resin, 5 to 8 parts of plasticizer, 2 to 3 parts of heat stabilizer, 0.5 to 4 parts of lubricating agent, 10 to 14 parts of methacrylic acid-butadiene-styrene copolymer resin, and 8 to 18 parts of polyoxyethylene stearate. According to the smooth type high-strength packaging film provided by the invention, through adding the polyoxyethylene stearate, the flexibility of the film is increased, the usage amount of a softening agent can be reduced, and the stability of a preparation system is improved; meanwhile, the transparency of the film is maintained through adding a surface modifier.

Owner:无锡市锡佳印刷包装有限公司

Smell-removing disinfectant for pets and preparation method thereof

InactiveCN106577802ANo health hazardEffectively removes odorsBiocideDead animal preservationWater bathsPolyvinyl alcohol

The invention discloses smell-removing disinfectant for pets and a preparation method thereof. According to the technical scheme, the smell-removing disinfectant for the pets comprises the raw materials of silver nitrate, tea polyphenol, peppermint extract, sodium dodecyl sulfate, polyethylene glycol, polyvinyl alcohol, glycol stearate, deionized water and a small quantity of a sodium hydroxide solution with the mass concentration being 30%, wherein the sodium hydroxide solution is used for adjusting the pH value to a neutral value. The preparation method includes the steps that first, in the certain amount of deionized water, a water bath is heated, the sodium dodecyl sulfate, polyethylene glycol, polyvinyl alcohol, tea polyphenol and the peppermint extract are slowly added under stirring, and a uniform solution A is formed after stirring; second, the silver nitrate is added into the solution A, and a solution B is obtained after stirring; finally, the saturated sodium hydroxide solution is added into the solution B, the pH value of the solution is adjusted to the neutral value, and the smell-removing disinfectant for the pests is prepared.

Owner:龚娟

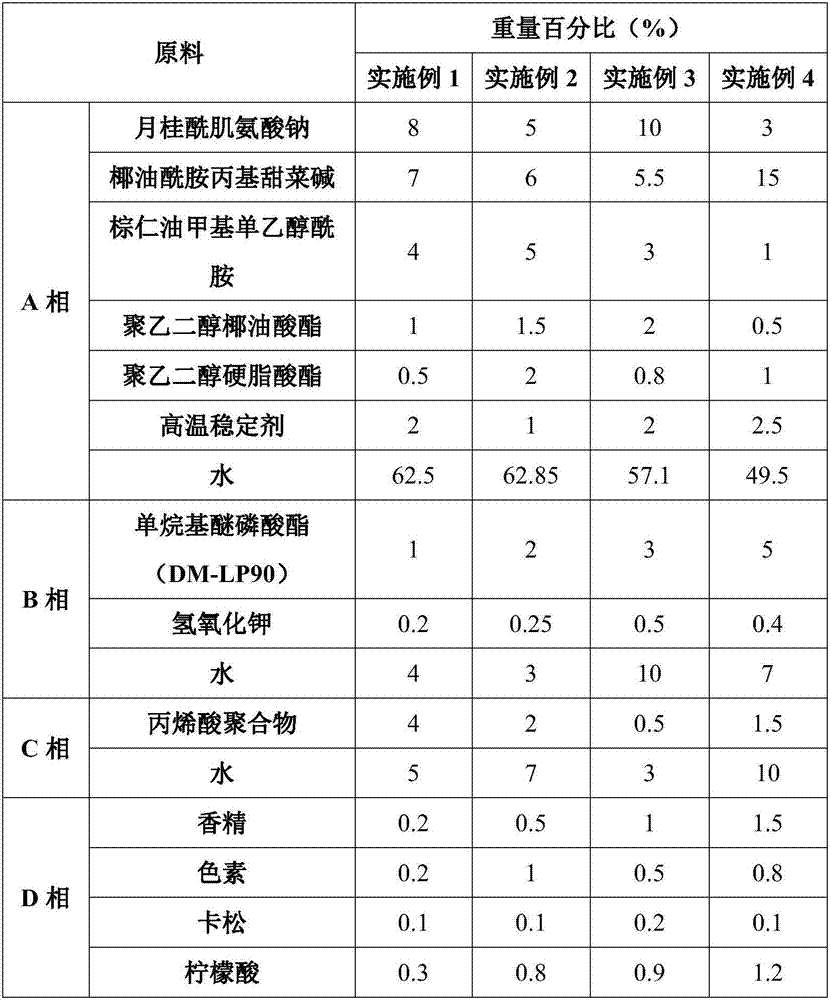

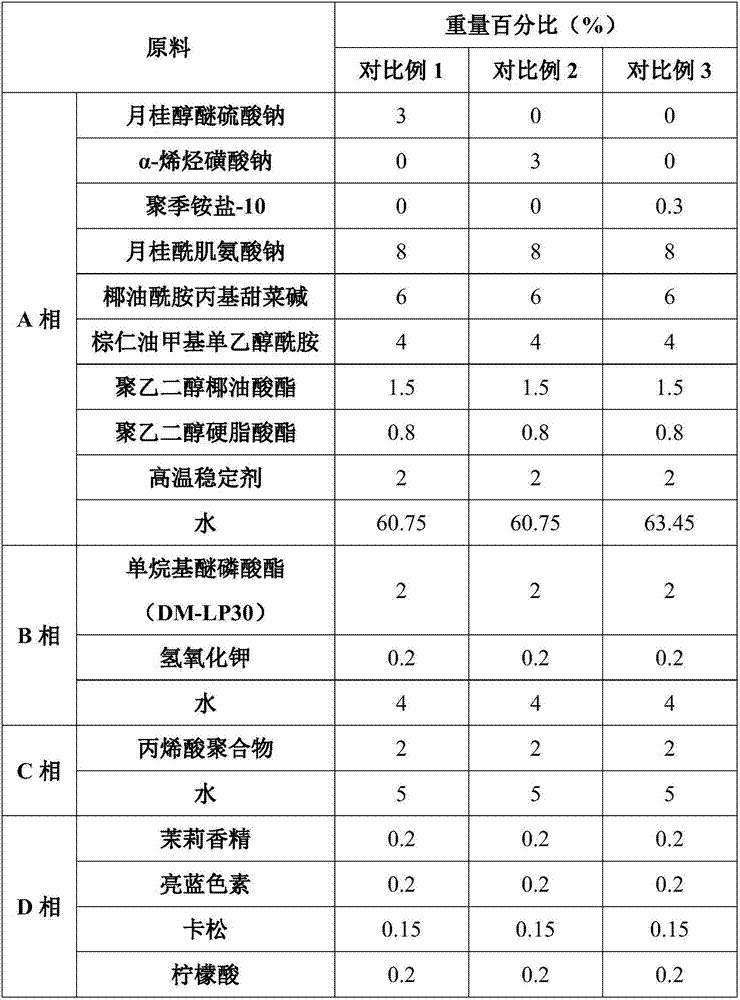

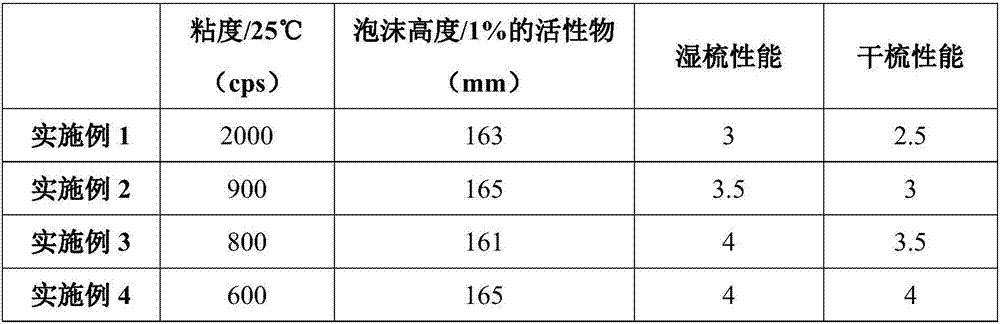

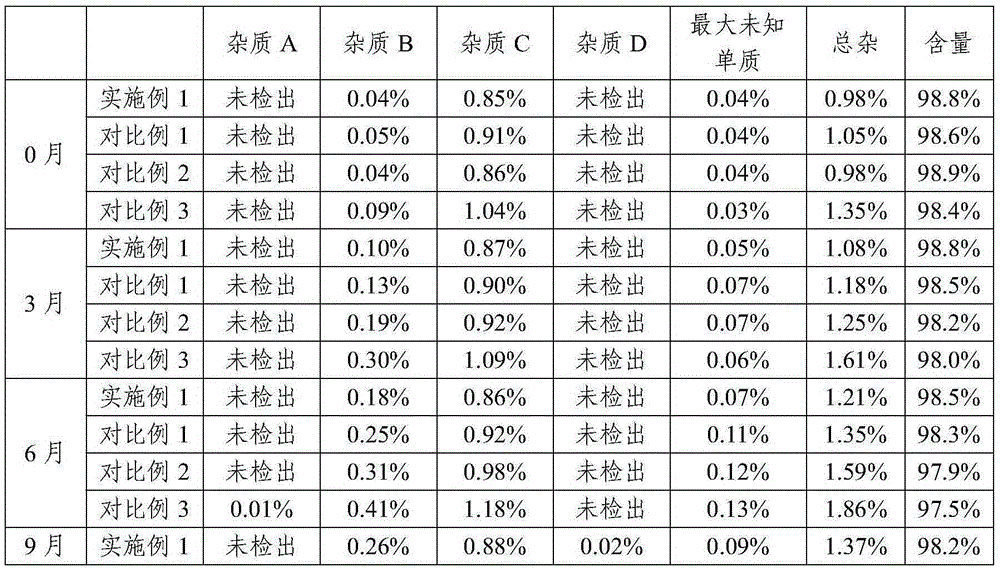

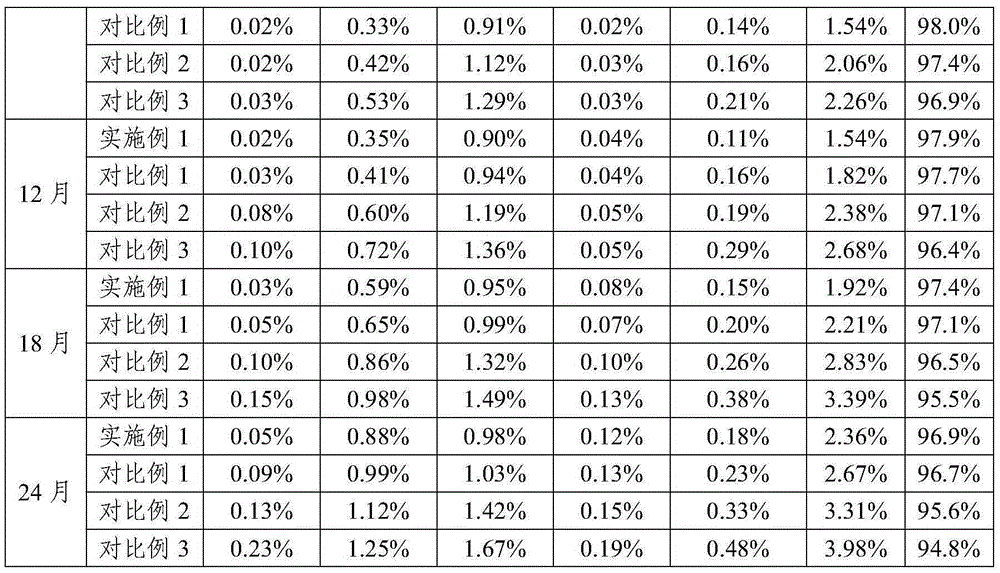

Non-irritable silicon-free shampoo and preparation method thereof

InactiveCN107375028ANon-irritatingEliminate residueCosmetic preparationsHair cosmeticsIrritationPhosphate

The invention discloses non-irritable silicon-free shampoo and a preparation method thereof. The shampoo is prepared from raw materials including a phase A, a phase B, a phase C and a phase D, wherein the phase A is prepared from sodium lauroyl sarcosine, cocamidopropyl betaine, palm kernel oil methyl monoethanolamide, polyethylene glycol cocoate, polyethylene glycol stearate, a high-temperature stabilizer and water; the phase B is prepared from monoalkyl ether phosphate, potassium hydroxide and water; the phase C is prepared from an acrylic polymer and water; the phase D is prepared from essence, pigment, Kathon and citric acid. The preparation method is simple, the raw materials of the phase A, the phase B, the phase C and the phase D are mixed sufficiently and uniformly in batches, and the non-irritable silicon-free shampoo is prepared. The non-irritable silicon-free shampoo contains no silicon oil, cationic surface active agents or sulfate type surfactants, adopts an anionic-non-ionic surfactant compounding system, eradicates the problems that silicon oil, the cationic surface active agents and the sulfate type surfactants have residues, are stacked, block pores and the like, has no irritation to scalp and is green and environment-friendly.

Owner:广州道明研究院有限公司

Antibacterial and deodorant sweat-absorbing fabric and preparation method thereof

InactiveCN110258000AImprove performanceGood hygroscopicityBiochemical fibre treatmentWoven fabricsPolyesterEscherichia coli

The invention provides an antibacterial and deodorant sweat-absorbing fabric and a preparation method thereof. The antibacterial and deodorant sweat-absorbing fabric comprises, by weight, 20-40 parts of bamboo charcoal fiber, 15-30 parts of chitin fiber, 15-25 parts of honeycomb polyester fiber, 18-30 parts of cotton hemp fiber, 10-20 parts of polyurethane fiber, 12-20 parts of negative ion fiber, 8-15 parts of nanometer silver sol, 6-10 parts of mesoporous silicon oxide, 3-8 parts of gold nanostar, 4-9 parts of polyvinyl alcohol, 5-10 parts of diethylaminoethyl methacrylate, 5-12 parts of polyethylene glycol stearate and 3-6 parts of vinyl trialkoxysilane. The fabric prepared with the method has good moisture absorption performance, the inhibition of staphylococcus aureus, Escherichia coli and bacillus subtilis is over 99%, and the fabric has an important application prospect as a kind of the sports fabric.

Owner:SUZHOU INST OF TRADE & COMMERCE

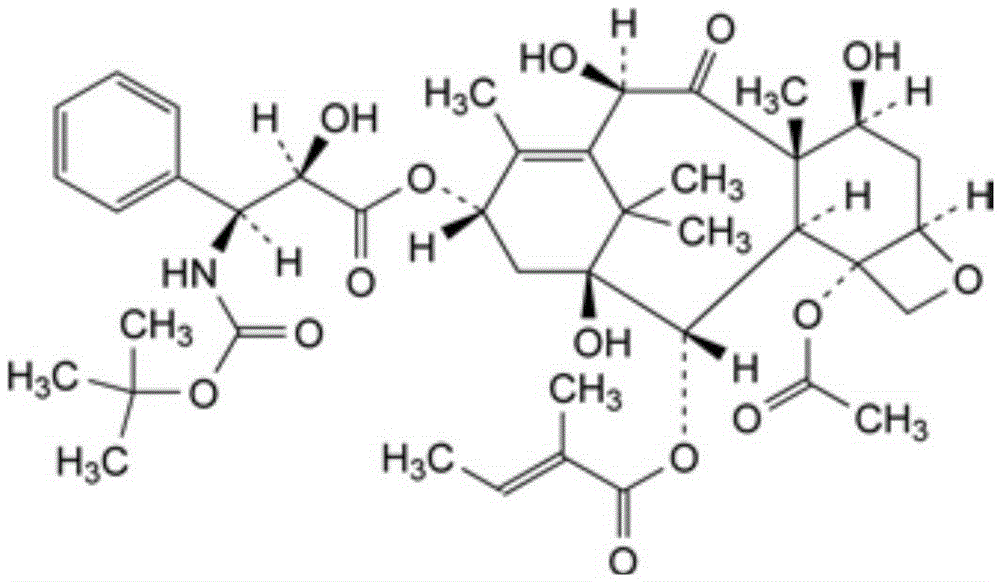

Docetaxel injection and preparation method thereof

InactiveCN105395477AAntioxidantImprove stabilityOrganic active ingredientsPharmaceutical delivery mechanismAlcoholPolyethylene glycol

The invention relates to a docetaxel injection. The docetaxel injection is prepared from docetaxel, lipoic acid, medicinal absolute ethyl alcohol and polyethylene glycol stearate. The lipoic acid is added into the docetaxel injection, and stability of double bonds in the docetaxel is facilitated. In addition, the lipoic acid has the anti-oxidation effect and can slow down product degradation. In the injection preparation process, compared with an existing technology, the medicinal absolute ethyl alcohol is not removed. During clinical use, the step of adding ethyl alcohol for dilution is omitted, and use is safer, more convenient and faster. The four components in the injection are compounded for use, the docetaxel injection meets the USP35 docetaxel injection standard within the two-year life time, and the clinical application is safer.

Owner:李宏 +1

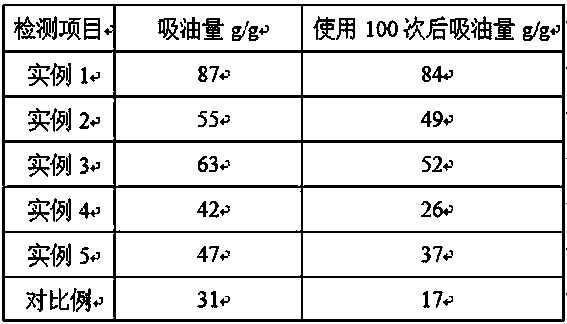

Preparation method of recyclable lightweight graphene sponge oil absorbing material

InactiveCN109453740AIncrease layer spacingStructural refinementOther chemical processesGrapheneIron saltsPolyethyleneglycol stearate

The invention discloses a preparation method of a recyclable lightweight graphene sponge oil absorbing material, and belongs to the technical field of environmentally friendly materials. The preparation method of the recyclable lightweight graphene sponge oil absorbing material comprises the following steps: after carrying out mixing reaction on graphene oxide, sodium polystyrenesulfonate and water, filtering, washing and drying the mixture to obtain pretreated graphene oxide; after mixing and dipping the pretreated graphene oxide in an iron salt solution, carrying out slow heating reaction under the protection state of reducing gas, and then carrying out acid leaching, washing and drying to obtain an impurity removed reducing material; and then dispersing the impurity removed reducing material in anhydrous ethanol, successively adding (N-guanyl) dodecylacrylamide, polyoxyethylene stearate, dicyclopentadienyl iron and p-dichlorobenzene in a constant-temperature stirring state, keepingstirring reaction, and then carrying out suction filtering, washing and drying to obtain the recyclable lightweight graphene sponge oil absorbing material. The recyclable lightweight graphene sponge oil absorbing material prepared by the technical scheme has the characteristics of excellent oil absorbing property and recycling property, and has wide prospect in development of the environmentally friendly material technical industry.

Owner:胡果青

Traditional Chinese medicine bath shampoo and preparation method thereof

InactiveCN105055232AEasy to cleanGood refreshingCosmetic preparationsAntipyreticPhosphoric Acid EstersPolythylene glycol

The invention relates to traditional Chinese medicine bath shampoo and a preparation method thereof. The traditional Chinese medicine bath shampoo comprises the following components in parts by mass: 10-20 parts of palmitic acid, 2-6 parts of lauryl alcohol phosphoric acid ester potassium, 1-2 parts of glycerol monostearate, 1.5-4.5 parts of mineral oil, 2-5 parts of potassium hydroxide, 115-140 parts of water, 75-85 parts of sodium lauryl sulfate, 8-16 parts of polyoxyethylene glyceryl monooleate, 1-5 parts of polyethylene glycol monostearate, 36-45 parts of sorbitol, 4-9 parts of lauryl alcohol ammonium sulfate, 2-4 parts of aloe, 0.1-0.3 part of jasmine essence, 8-15 parts of radix sophorae flavescentis, 5-12 parts of fructus kochiae and 5-12 parts of gardenia jasminoides. The traditional Chinese medicine bath shampoo provided by the invention has good effects of cleaning, refreshing and moistening skin, and further has excellent efficacies of relieving itching, clearing away heat, purging pathogenic fire, cooling blood and deswelling, can further treat symptoms of heat toxin, pyogenic skin infection, swelling and pain due to sprain.

Owner:SUZHOU HEALTH COLLEGE

Polypeptide donkey-hide gelatine dextran freeze-drying preparation and preparing process thereof

InactiveCN102210706AThe prescription of the preparation is scientific and reasonableImprove stabilityPowder deliveryUnknown materialsFreeze-dryingPolyethylene glycol

The invention relates to a polypeptide donkey-hide gelatine dextran freeze-drying preparation and a preparing process thereof, belonging to the technical field of medicines. The polypeptide donkey-hide gelatine dextran freeze-drying preparation is characterized by comprising the components as follows: polypeptide donkey-hide gelatine, Solutol HS-15(polyglycol stearate 15, polyglycol-12-hydroxy stearate) and phospholipid. According to the invention, lots of screening and researches find that: the Solutol HS-15 and the phospholipid which are formed as micelles can solve the problem that the polypeptide donkey-hide gelatine dextran freeze-drying preparation placed for a long time cannot be dissolved completely in the case water is added for dissolution, and both the Solutol HS-15 and the phospholipid are very safe auxiliary materials for intravenous injection.

Owner:JIANGSU JIANZHONG INVESTMENT

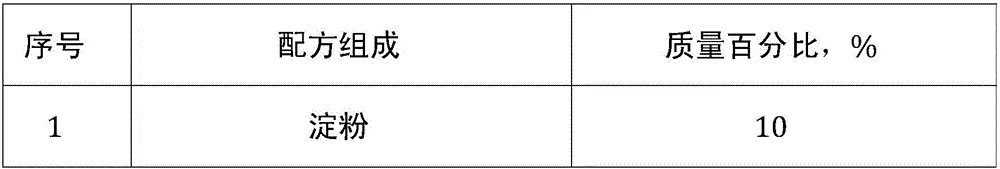

Automatic cleaning and disinfection equipment cleaning effect monitoring card and its preparation method

The invention discloses an automatic cleaning and disinfection equipment cleaning effect monitoring card and its preparation method, comprising simulated contaminants and plastic material carriers wherein the simulated contaminants comprise 1 to 10% starch, 1 to 10% protein, 3 to 15% fat, 2 to 15% binder, 0.2 to 3% pigment, and enough water. The binder includes one of the following components or a plurality of the following components: shellac varnish, alkyd resin, urea-formaldehyde resin, amino resin, acrylic resin and polyethylene glycol stearate. According to the automatic cleaning and disinfection equipment cleaning effect monitoring card and its preparation method provided in the invention, the monitoring method is simple and the monitoring card can be directly placed into automatic cleaning and disinfection equipment. The monitoring result is easy to read; and the method is convenient and fast. The adequate adhesion of the monitoring card is consistent with that of simulated contaminants. With a novel structure, the monitoring card can be simply transported and stored. The monitoring card is also safe to use because it does not contain any blood product or toxic substance.

Owner:NANJING JUSHA DISPLAY TECH

High-tear-resistance PLA-PBAT composite degradable resin as well as preparation method and application thereof

ActiveCN113045879AHas negative ion propertiesHas both negative ion propertiesBio-packagingPolymer sciencePolyethylene glycol

The invention relates to high-tear-resistance PLA-PBAT composite degradable resin as well as a preparation method and application thereof, belonging to the technical field of degradable resin. The PLA-PBAT composite degradable resin provided by the invention is prepared from the following components in parts by weight: 60 to 85 parts of polylactic acid, 10 to 40 parts of poly(butylene adipate / terephthalate), 2 to 3 parts of chlorinated methyl palmitoleate, 5 to 7 parts of tri-n-butyl citrate, 1.5 to 2.5 parts of silicon dioxide-coated negative ion powder, 0.1 to 0.5 part of polyethylene glycol stearate, 1 to 5 parts of a coupling agent and 0.3 to 0.5 part of a chain extender. The PLA-PBAT composite degradable resin with high tear resistance, which is prepared from the above raw material components by adopting the specific preparation method according to the ratio of the raw materials provided by the invention, has negative ion characteristics and good mechanical properties, and particularly has very good tear resistance.

Owner:漯河市瑞博塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com