Patents

Literature

92results about How to "Simple filling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

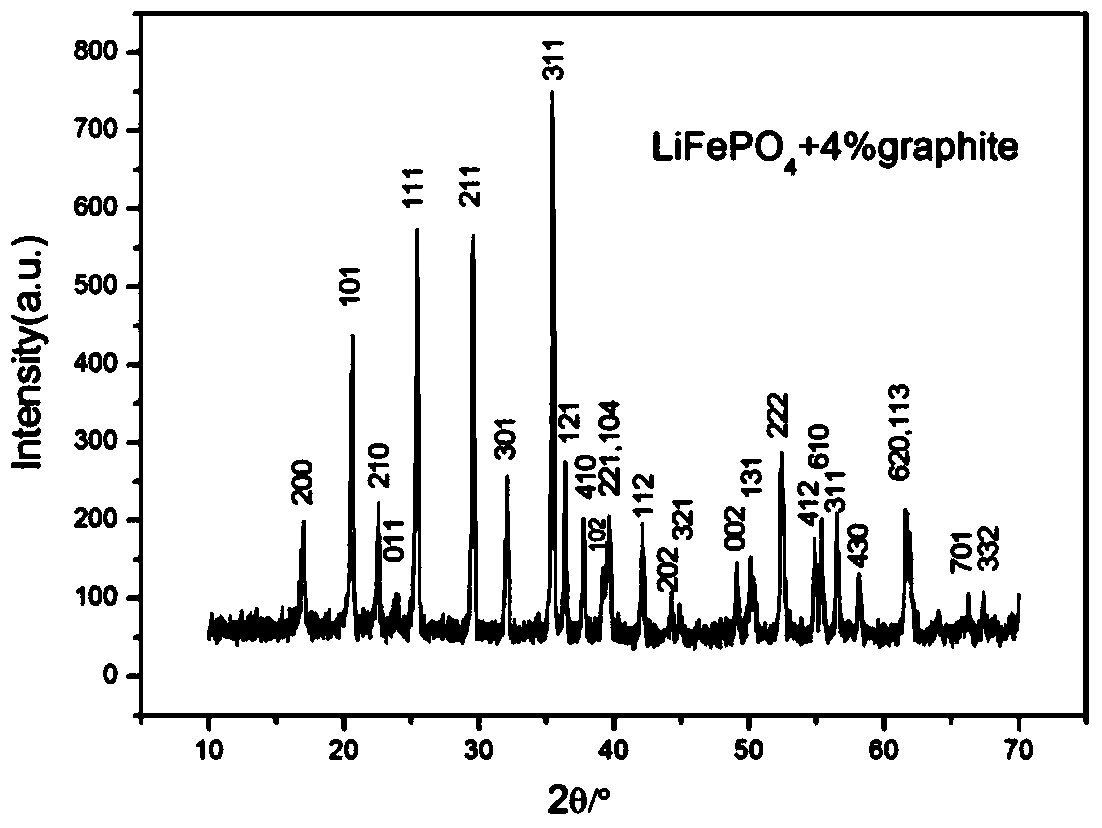

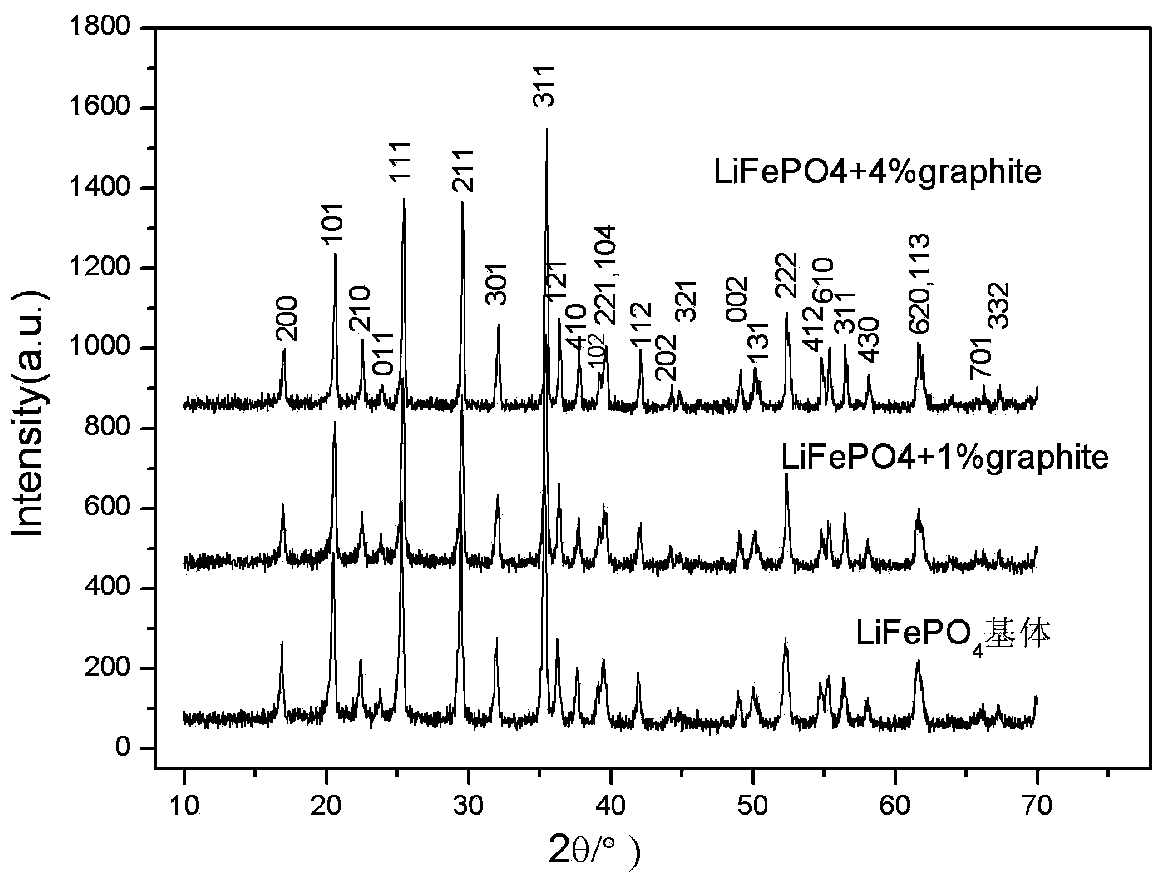

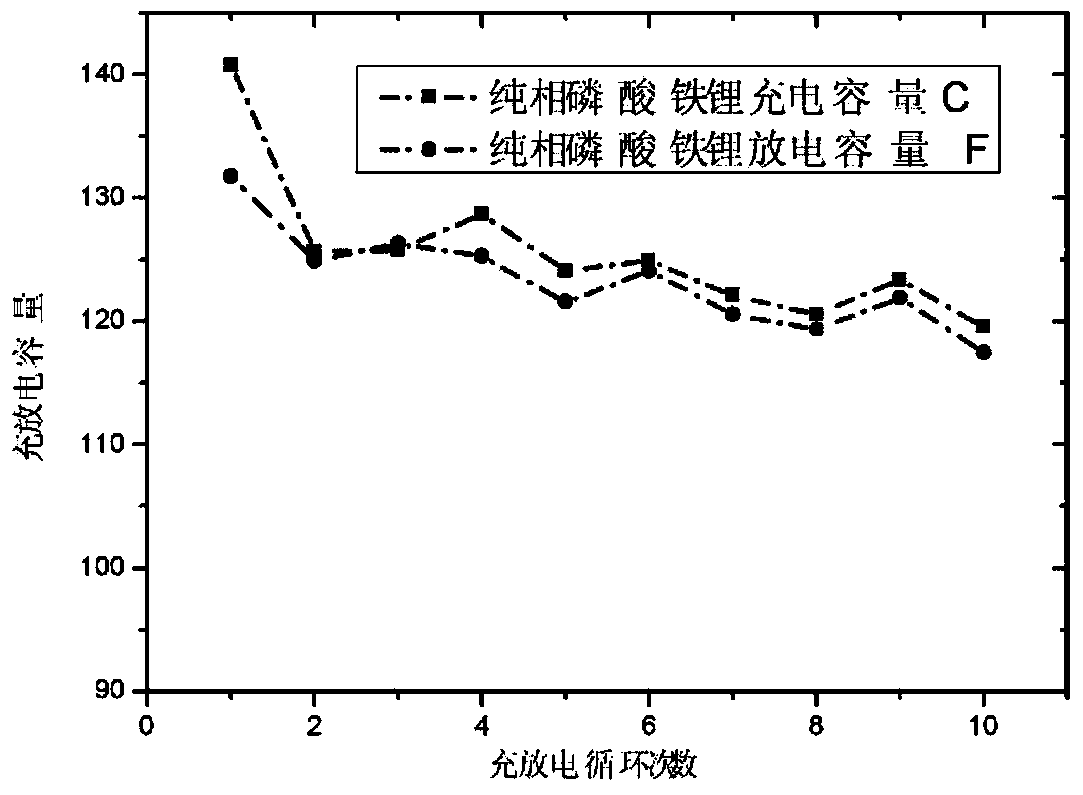

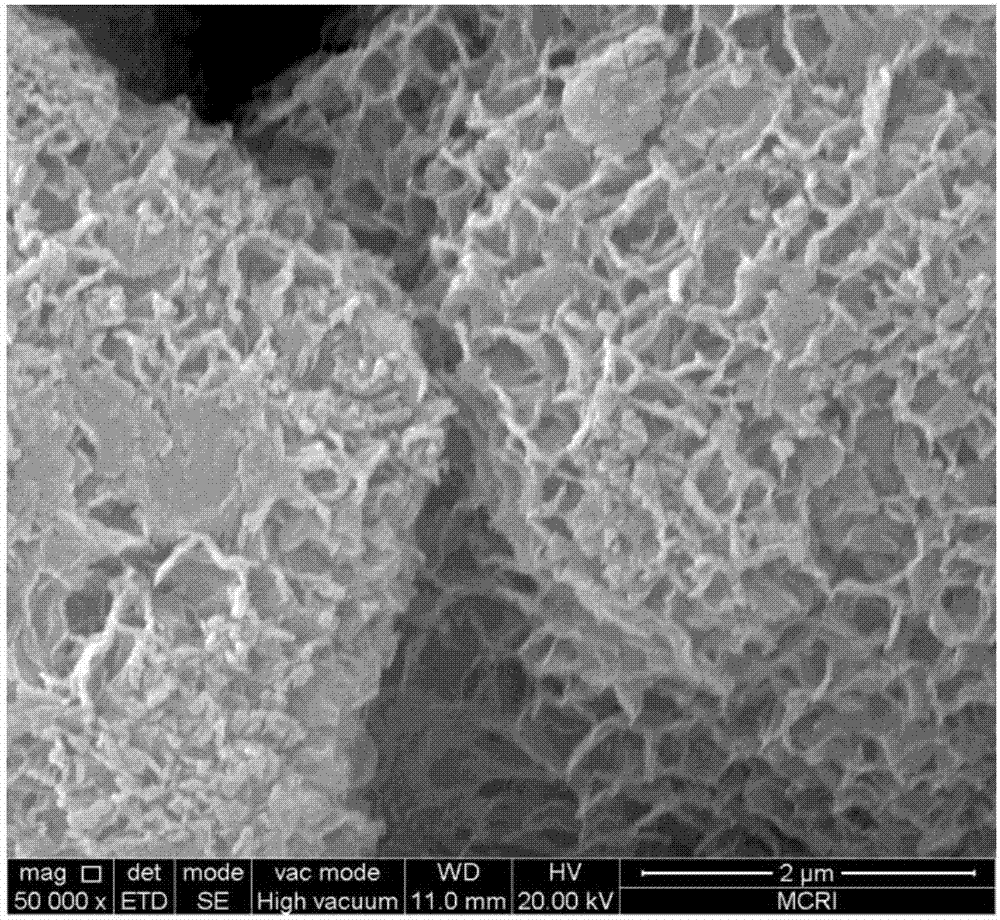

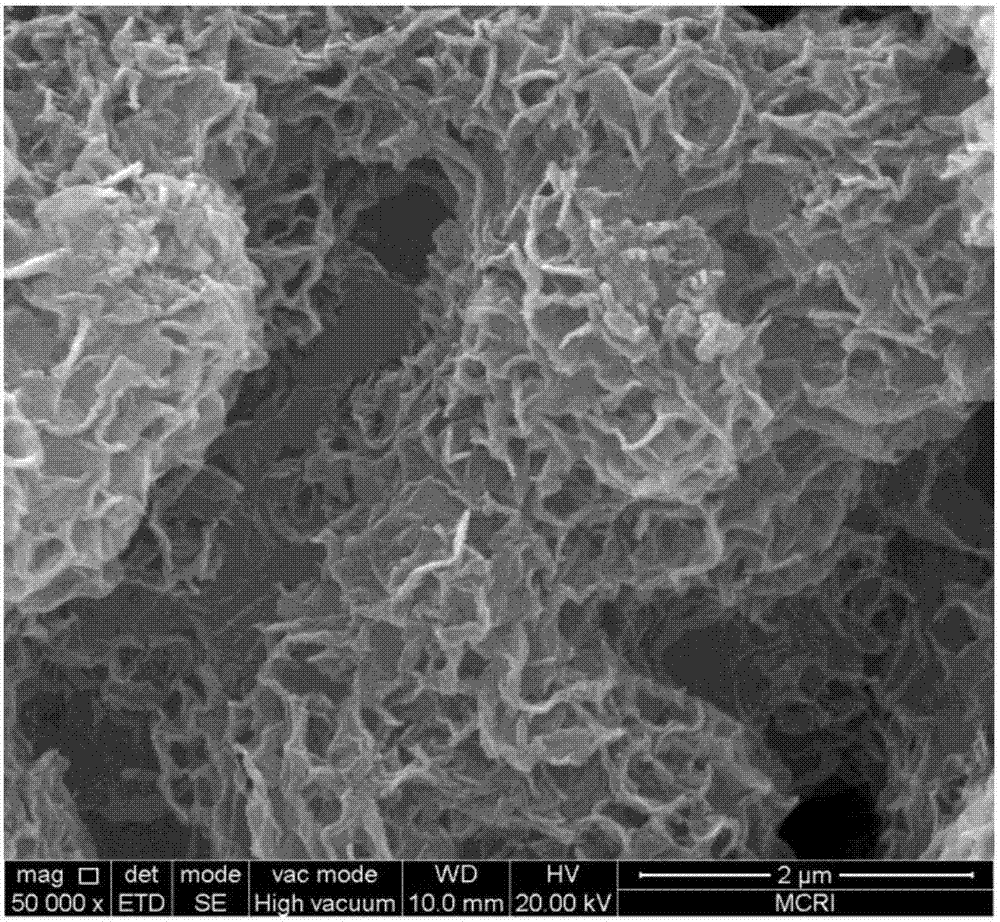

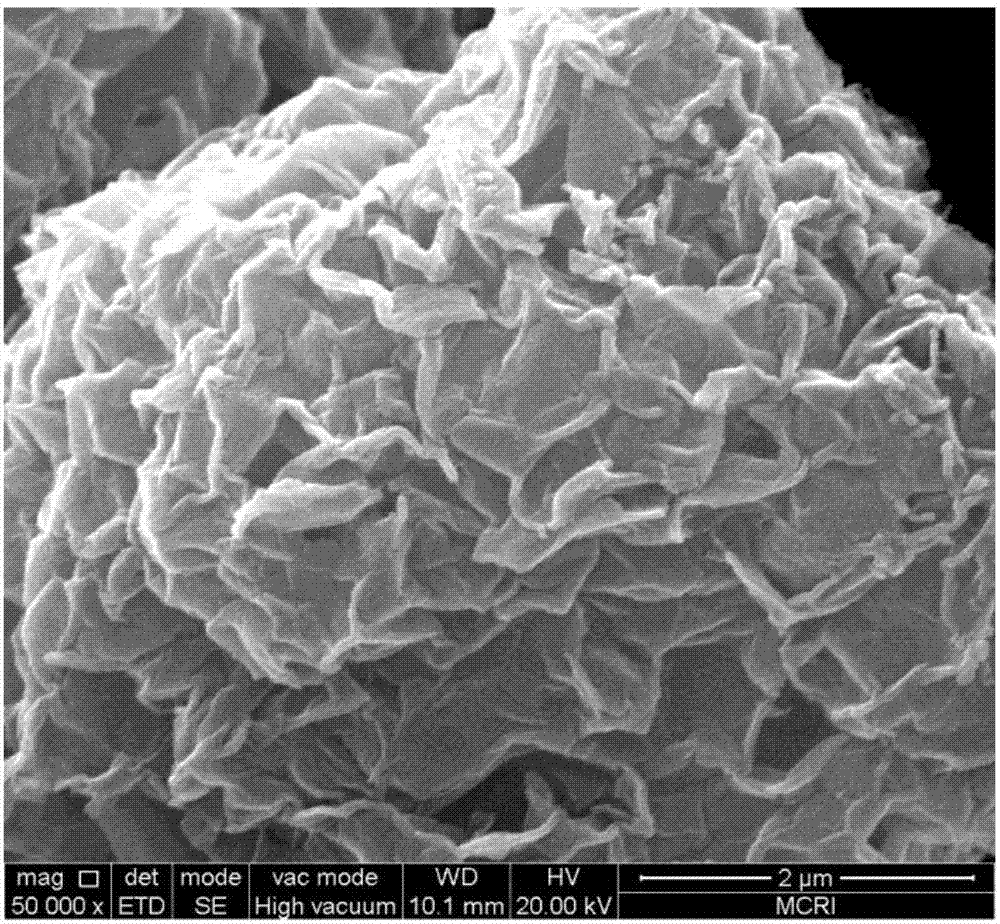

Composite positive electrode material of graphene and lithium iron phosphate battery and preparation method thereof

InactiveCN103872287ASimple filling processLow priceSecondary cellsPositive electrodesLithium vanadium phosphate batteryLithium iron phosphate

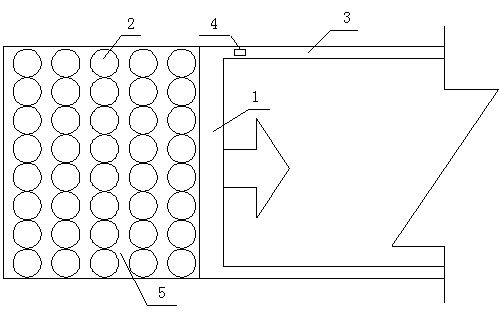

The invention discloses a composite positive electrode material of a graphene and lithium iron phosphate battery and a preparation method thereof. The composite positive electrode material of the graphene and lithium iron phosphate battery is composed of graphene and a LiFePO4 lithium ion battery positive electrode material in the mass percentage range of 0.1%-8%. The composite material sufficiently utilizes the good conductive performance of the graphene so that the electronic conductivity and the discharging rate capability of the positive electrode material of the lithium iron phosphate ion battery are improved; a graphene filling process is simple and the price is low.

Owner:CHONGQING TECH & BUSINESS UNIV

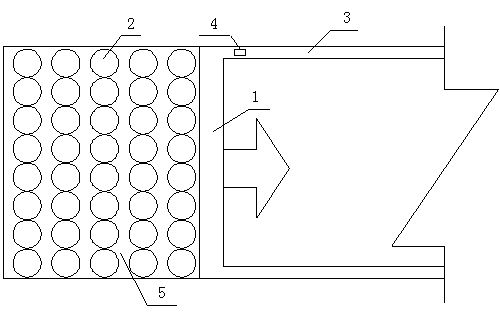

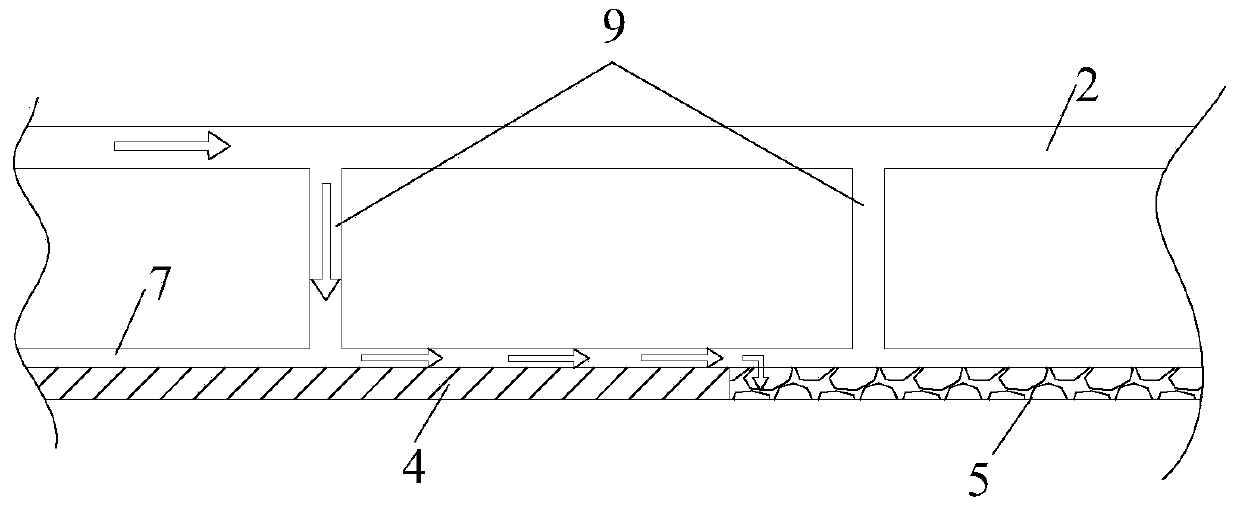

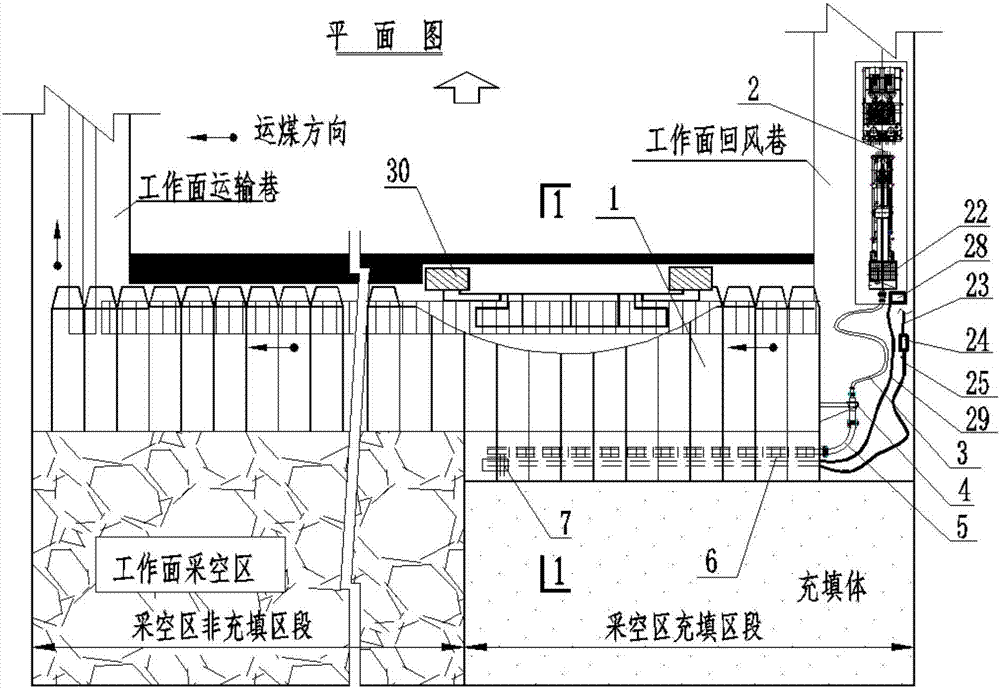

Filling and mining method of coal gases

InactiveCN102155225ALow costWide variety of sourcesUnderground miningSurface miningMining engineeringHigh pressure

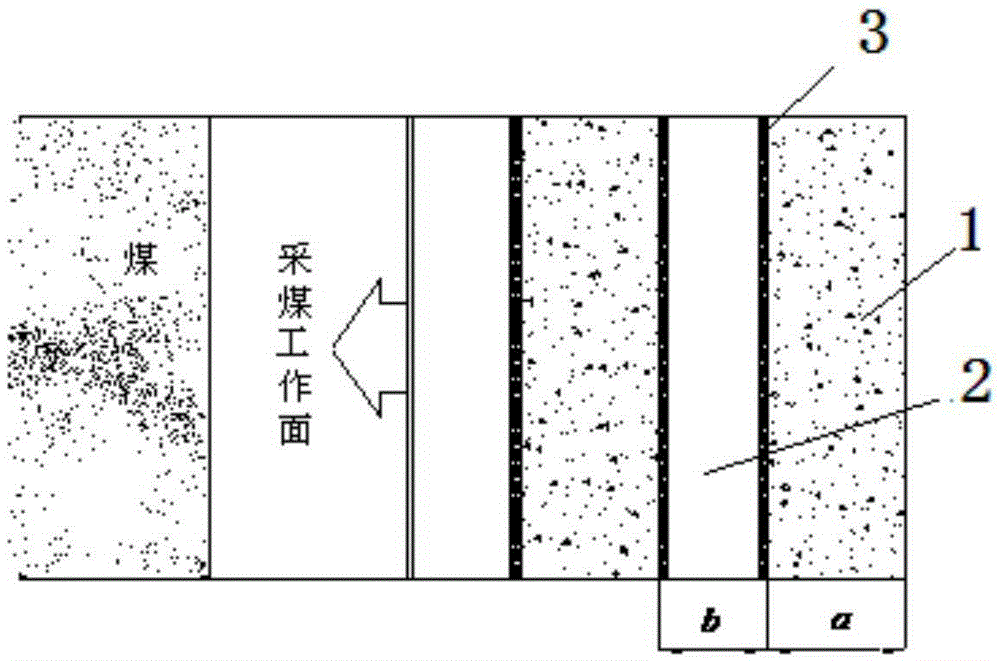

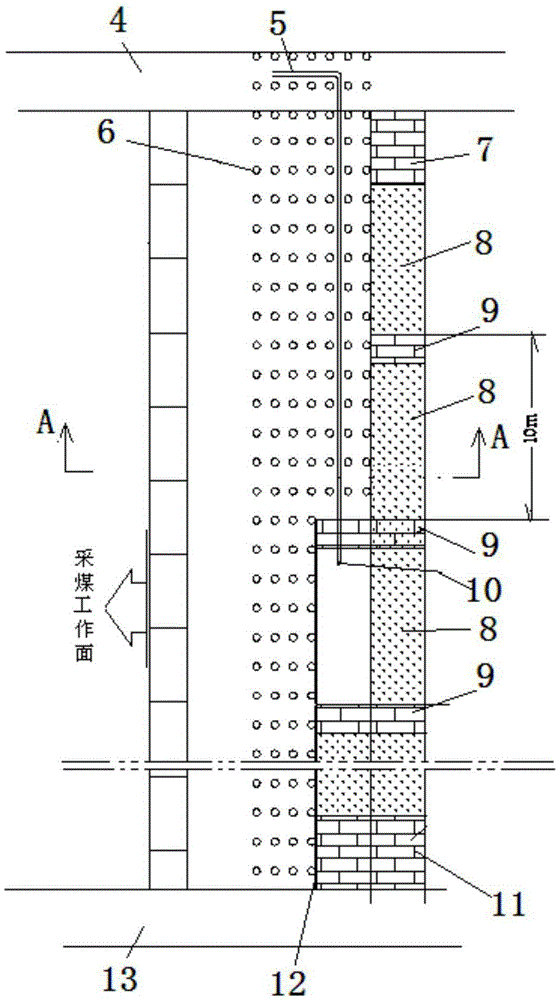

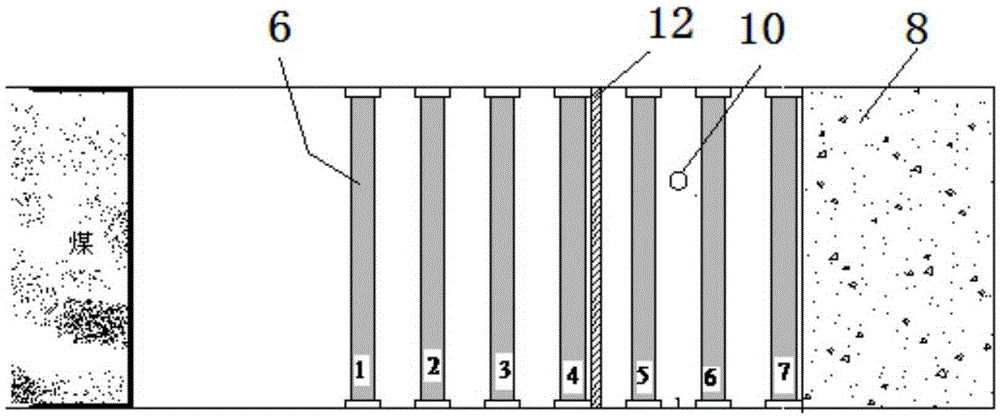

The invention relates to a filling and mining method of coal gases, comprising the following steps: arranging a gas pressurization room on the ground and then arranging an underground gas booster pump connected with a ground high-pressure gas storage tank pipeline in a mining region haulage way in front of an underground coal mining working face; distributing a row of cylindrical rubber airbags in a gob behind the coal mining working face when the coal mining working face is advanced for 5-8 m from the open-off cut; filling gas into the cylindrical rubber airbags till the top is tight; sealing the openings of the cylindrical rubber airbags to finish filling gas into one cylindrical rubber airbag; continuously distributing a row of cylindrical rubber airbags behind the row of gas-filling cylindrical rubber airbags when the coal mining working face is advanced for each step along with the continuous advance of the coal mining working face and charging gas in rows till finishing the gas filling and supporting in the whole gob. In the invention, the filling method is simple, the gas filling speed is high, the cost is low and the filling capacity is great, and the method is convenient for onsite underground operation.

Owner:CHINA UNIV OF MINING & TECH

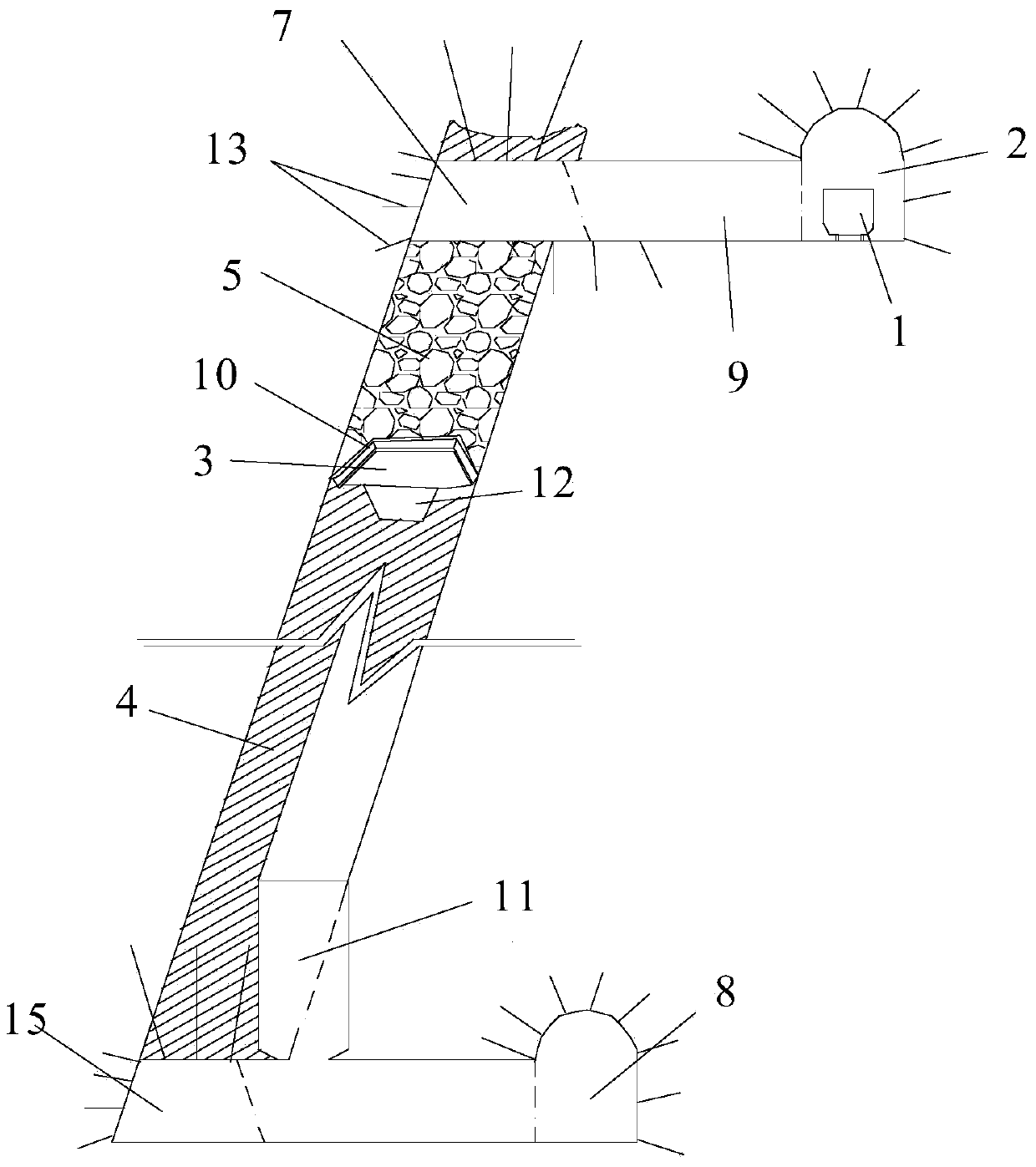

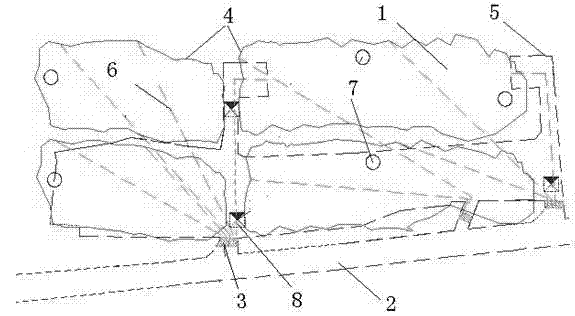

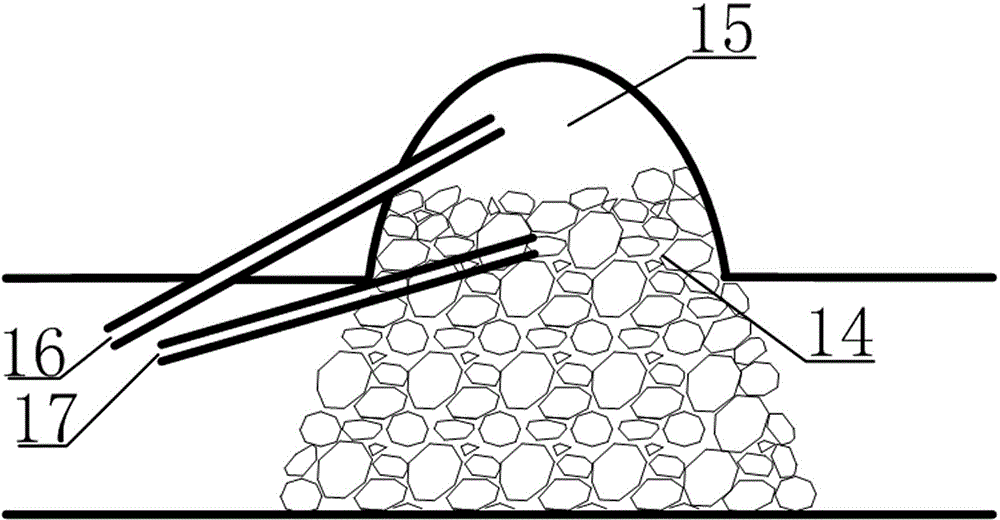

Gangue-filling coal mining method for sharp inclined coal seam under flexible shield support

ActiveCN103742148AReduce labor intensityEasy to operateUnderground miningSurface miningEngineeringWorking space

The invention provides a gangue-filling coal mining method for a sharp inclined coal seam under flexible shield support. The method comprises the steps of distributing working faces corresponding zones in a downhill mining mode, dropping coal by adopting an air pick, supporting the working face by using the corresponding flexible shield support to form a working space, and filling gangues above the flexible shield support through the corresponding floor tunnel along with the gradual mining operation to a coal body which is positioned below the working face, so as to enable the corresponding flexible shield support to be sunk under the dead weight and the weight of the covered gangues and form a mode of mining while filling, wherein trenches are distributed in the working faces corresponding to the zones, workers work in the trenches, produced coal is pushed to inclined coal dropping roadways corresponding to the zones by a scraper bucket and drops into a coal bunker at the underside, and then the coal is transported to a mining area through a haulage roadway after being loaded in a mine car. The flexible shield support does not need to be removed and lengthened for multiple times during mining, the filling procedure is simplified, the filling cost is reduced and the labor intensity of workers is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

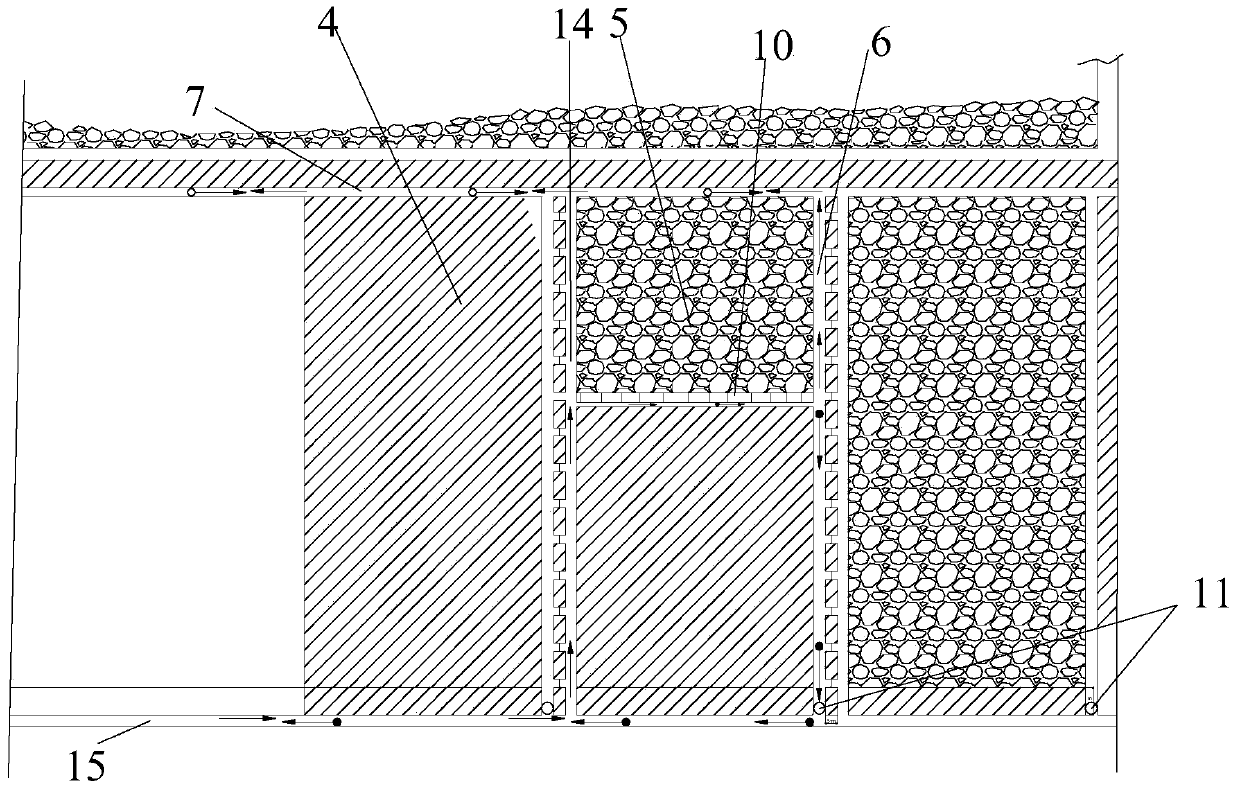

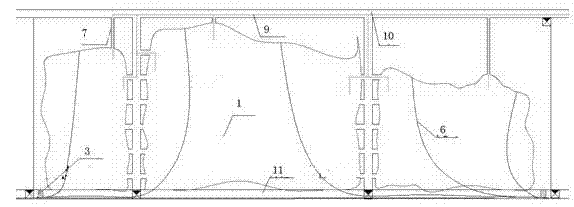

Large-range goaf group filling method

InactiveCN103046955AGuarantee normal productionSimple filling processMaterial fill-upDrainagePipeRetaining wall

The invention relates to a large-range goaf group filling method and belongs to the technical field of mining engineering. According to the technical scheme, the method includes: dividing filling units, selecting filling material, and laying out filling pipes; calculating to determine the thickness of a filling retaining wall, performing site construction, reserving drain holes and filter holes in the filling retaining wall, and stacking a hillock inverted filter layer behind the filling retaining wall; laying filter pipes, allowing the filter pipes to extend out from the drain holes of the filling retaining wall; constructing a filling borehole, 133mm-150mm in diameter, at a highest point, applying the filling borehole as an overhead discharge point, ensuring roof contact, constructing the corresponding number of filling boreholes according to practical situation, and performing alternating filling. The large-range goaf group filling method has the advantages that filling process is simplified, filling efficiency is increased, plugging amount is decreased, filling amount is decreased, filling period is shortened, filling cost is lowered, and normal mine production is guaranteed.

Owner:HEBEI IRON & STEEL GRP MINING +2

Rapid-hardening inorganic filling support material for mine and using method of support material

The invention discloses a rapid-hardening inorganic filling support material for mine. The support material consists of a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 93-97 parts of sulphoaluminate cement clinker, 2-5 parts of an XWZ-A type compound admixture, 0.01-0.1 part of an air entraining agent, 0.0-0.05 part of an air entraining admixture, 0.2-1.0 part of a foam stabilizer and 0.25-2 parts of fibers; and the component B comprises the following raw materials in parts by weight: 75-88 parts of gypsum, 10-25 parts of lime, 2-5 parts of an XWZ-A type compound admixture, 0.01-0.1 part of an air entraining agent, 0.0-0.05 part of an air entraining admixture, 0.2-1.0 part of a foam stabilizer and 0.25-2 parts of fibers. The prepared filling support material disclosed by the invention has the characteristics of quick setting property, lightweight, rapid hardening property, early strength, high compressibility, high residual strength, good gas tightness and the like, and is particularly suitable for the mine filling support aspect.

Owner:HENAN POLYTECHNIC UNIV

Environmental-friendly foam drainage bar, and preparation method thereof

ActiveCN106244128AEasy to carrySimple filling processDrilling compositionSodium bicarbonatePolyethyleneglycol stearate

The invention discloses an environmental-friendly foam drainage bar, and a preparation method thereof. The environmental protection performance of the environmental-friendly foam drainage bar is used for referring that the environmental-friendly foam drainage bar is prepared from biodegradable raw materials. Foam drainage is used for referring discharging of well bottom accumulated water or accumulated liquid out of wells via utilization of water-containing or fluid-carrying capability of foam, so that gas recovery factor of gas wells is increased fully. The environmental-friendly foam drainage bar is capable of satisfying requirements of foam draining gas recovery and achieving excellent foam draining effect in field tests because of the excellent foaming ability, foam stabilizing ability, and liquid carrying capacity of the environmental-friendly foam drainage bar. The environmental-friendly foam drainage bar comprises following raw materials: cocamidopropyl betaine, sodium lauryl oxyethyl sulfonate, sodium lauroyl glutamate, fatty alcohol polyoxyethylene ether, polyethylene glycol monostearate, urea, citric acid, sodium bicarbonate, and sodium carbonate.

Owner:北京众博达石油科技有限公司

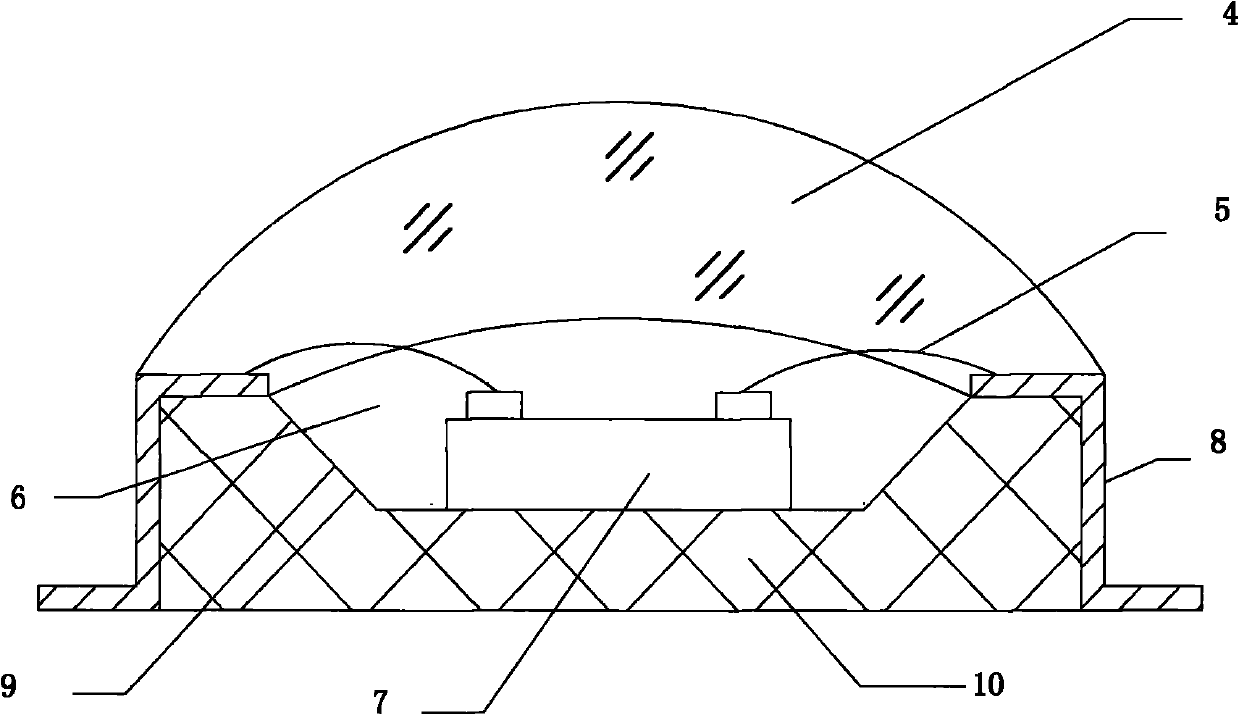

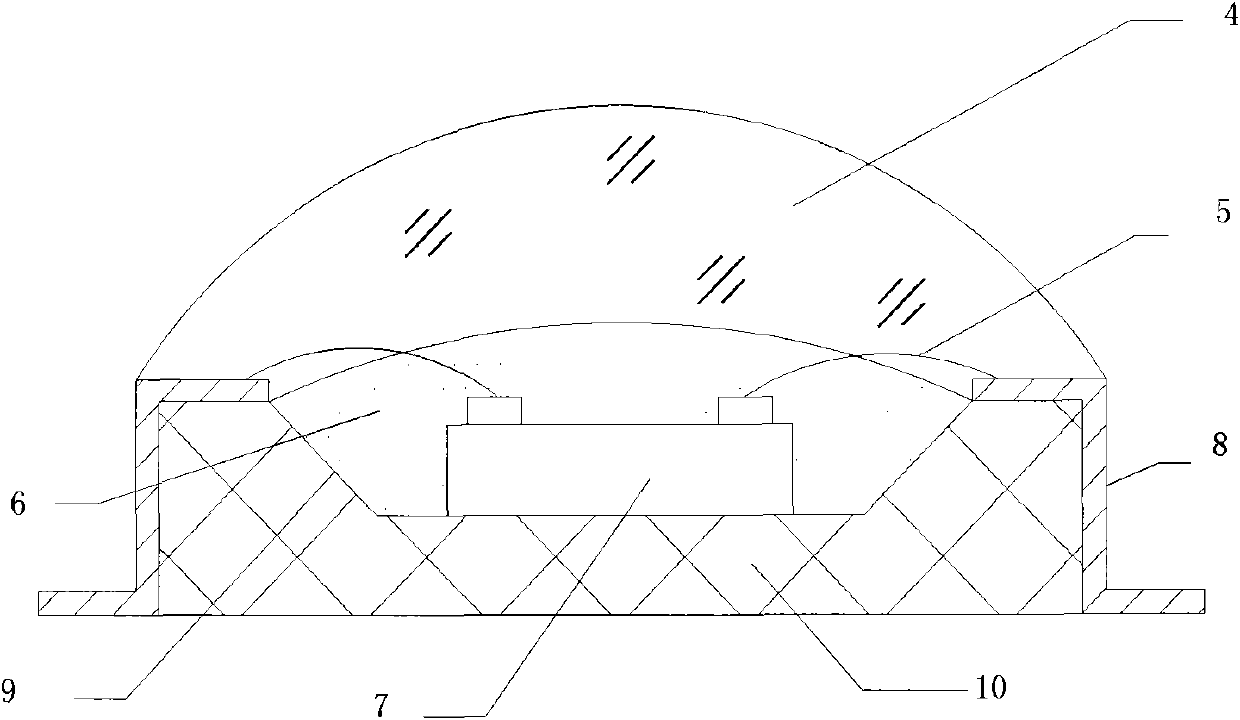

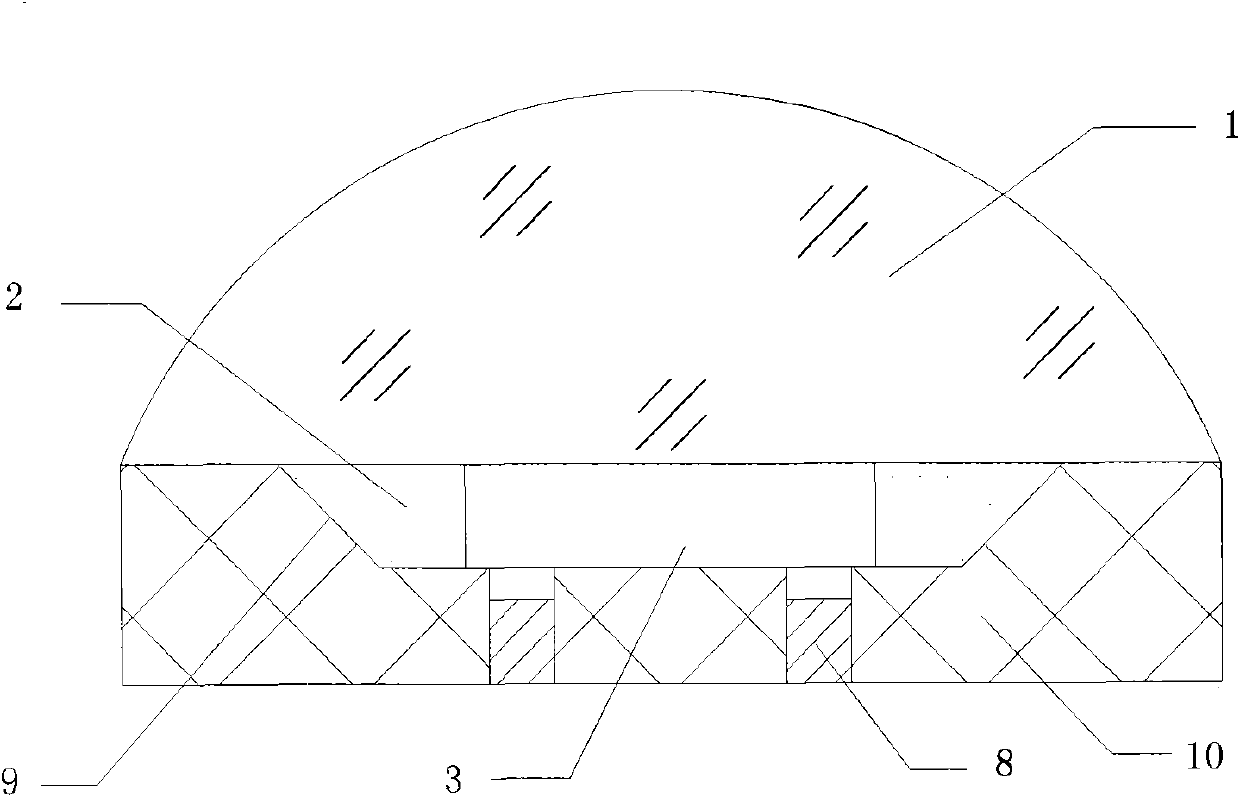

Power type white LED based on fluorescence lens

InactiveCN101950788AImprove thermal stabilityImprove light extraction efficiencySolid-state devicesSemiconductor devicesEpoxyFluorescence

The invention discloses a power type white LED based on a fluorescence lens, comprising an LED chip packaged by flip-chip bonding, an electrode, a reflective cup and a heat sink, wherein the fluorescence lens doped with light-emitting ions serves as a functional device with three functions of fluorescence conversion, optical light distribution and package protection. The invention has the technical effects that a glass-based fluorescence lens with high heat stability is adopted to realize more superior overall heat stability of the power type white LED; the heat dissipation efficiency and the light emitting efficiency of the LED chip are improved, thereby improving the overall light-emitting efficiency and the thermal stability of the power type white LED and overcoming the defect of coordinate drifting of illuminant colors brought by the fact that optical epoxy resin is easy to age and turn to yellow; and the package process has clear steps and is simple, therefore the overall package process of the power type white LED is simple and is easy to operate and realize.

Owner:CHONGQING UNIV

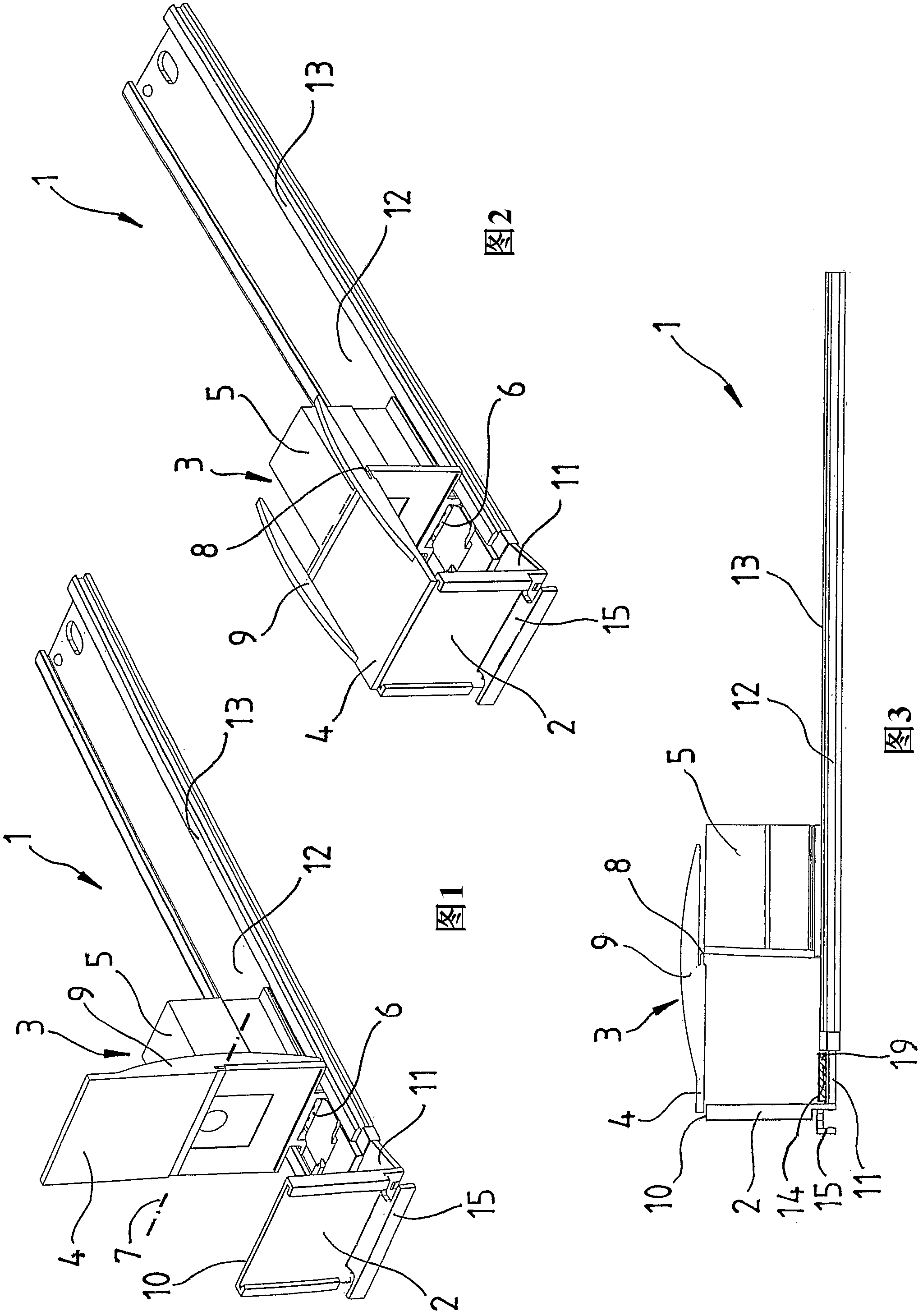

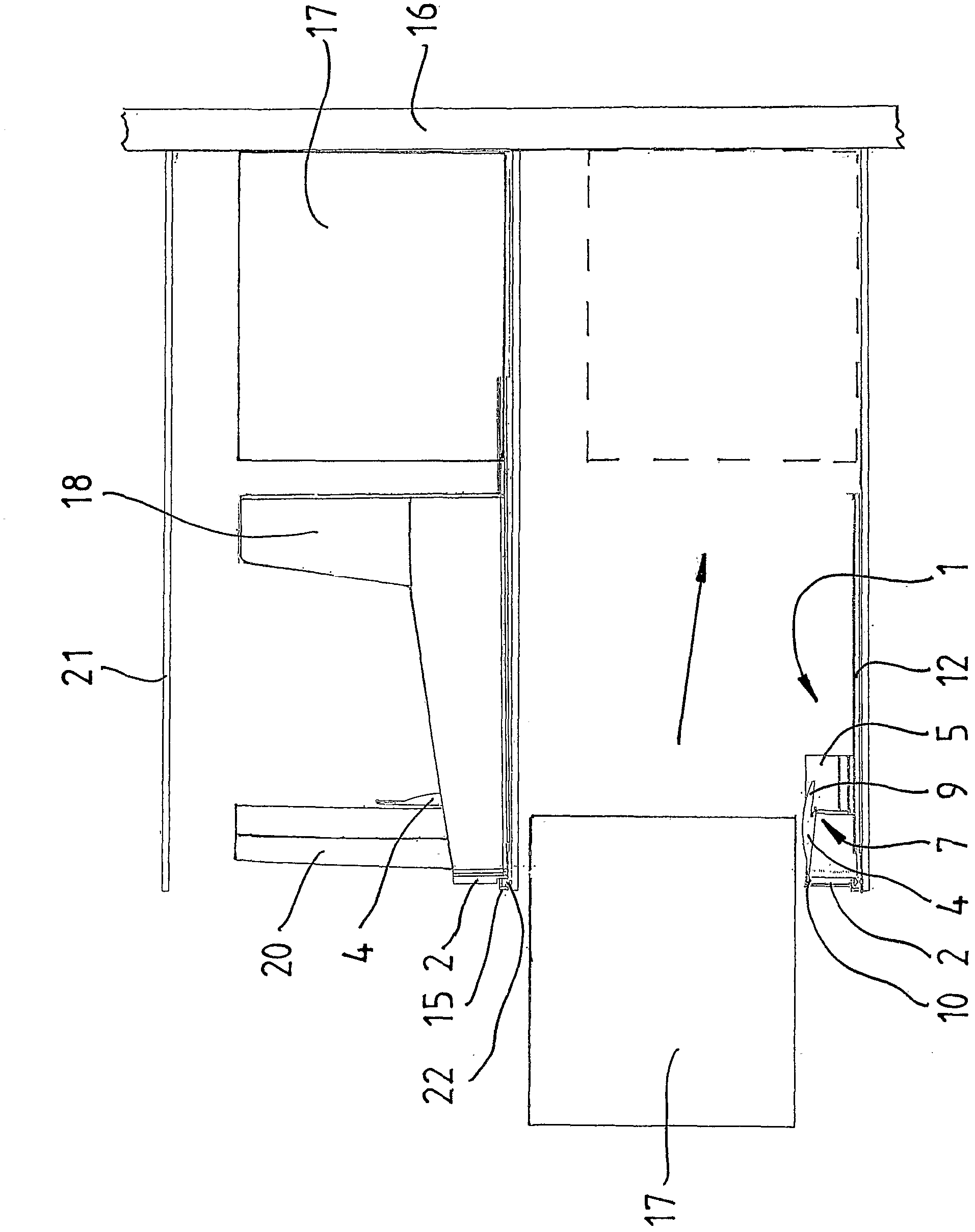

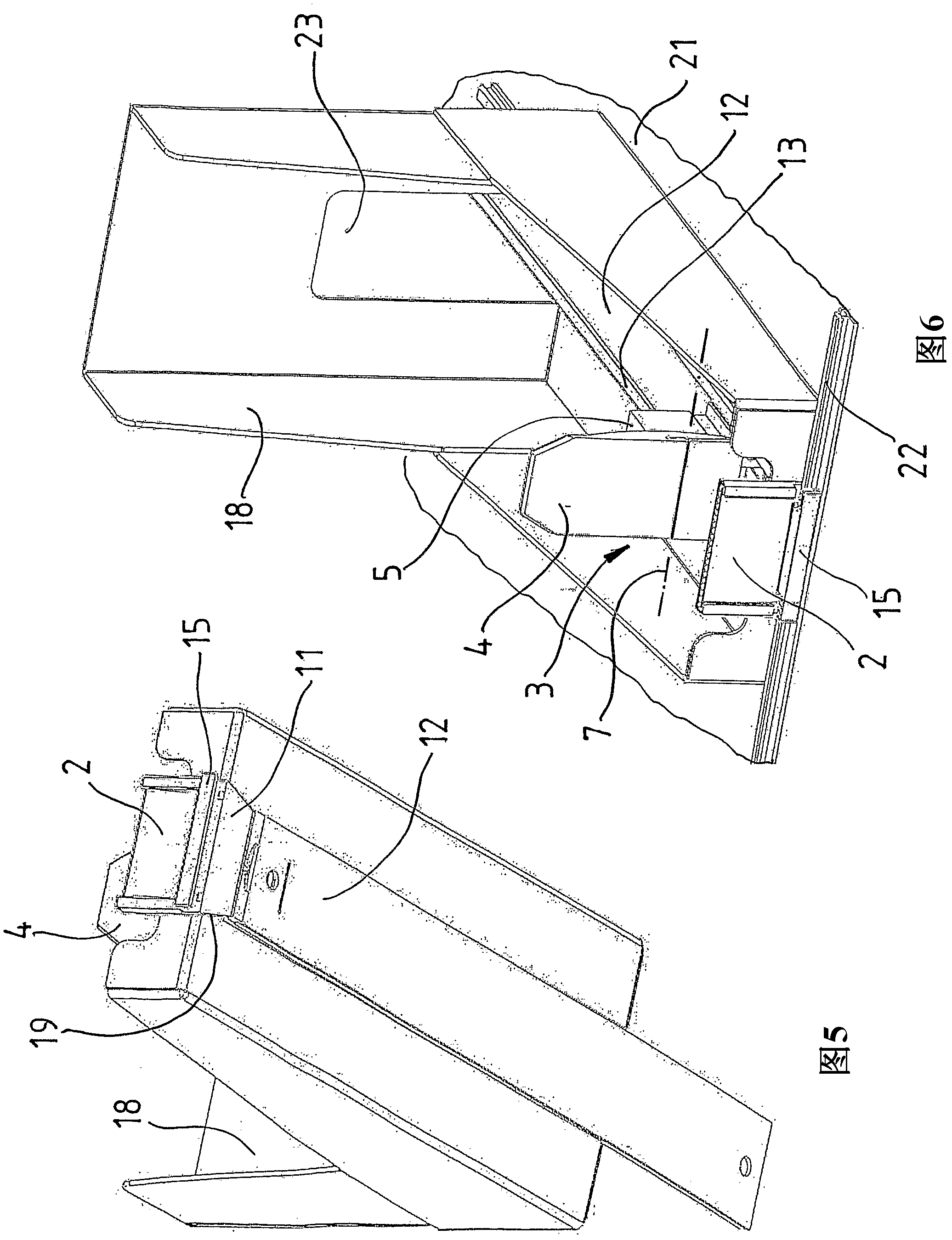

Goods advancing device

The functionality and effectiveness of a goods advancing device for a front cardboard box or goods tray of several cardboard boxes or goods trays of a shelf-ready packaging system arranged one behind the other on a shelf of a display rack or storage rack, said cardboard boxes or goods trays having goods or packagings of goods stored therein, said goods advancing device comprising a pushing plate for the goods on a slide housing, are improved further and manual shelf stocking of deep sales racks having tight shelf spacings and several cardboard boxes or goods trays stored one behind the other is made substantially easier, which is achieved in that the pushing plate (4) is fixed to the slide housing (5) so as to be height adjustable and can be moved from an erect functional position to a flattened position.

Owner:POS TUNING UDO VOSSHENRICH GMBH & CO KG

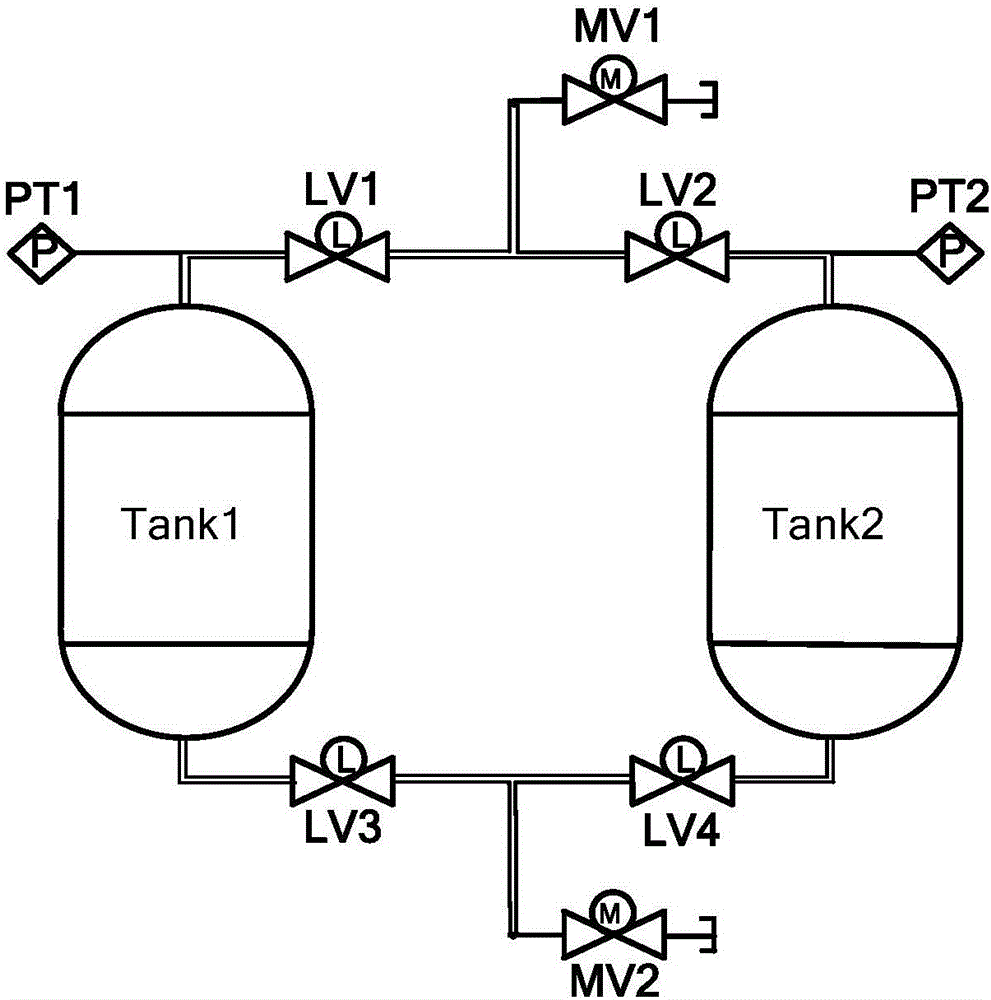

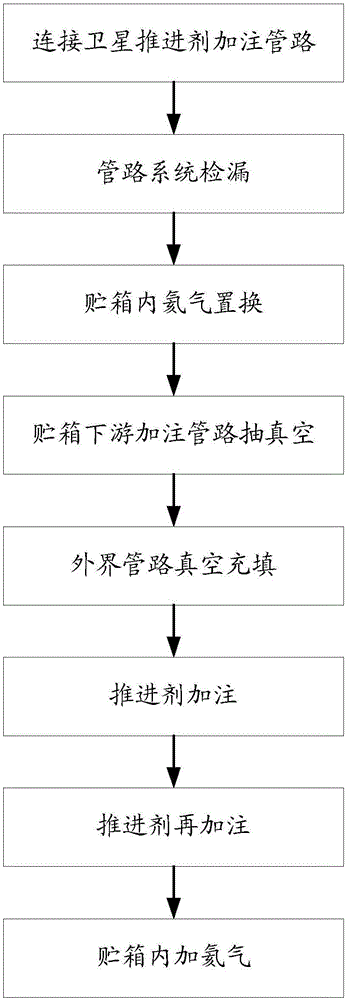

Parallel balanced filling method for high-capacity semi-management surface tension storage tank

ActiveCN106762224AReal-time display of total filling amountReal-time monitoring of parallel balanceLiquid handling installationsCosmonautic propulsion system apparatusEngineeringHelium

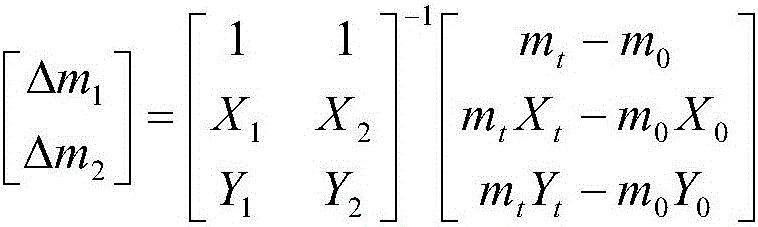

A parallel balanced filling method for a high-capacity semi-management surface tension storage tank comprises steps as follows: (1) a satellite propellant filling pipeline is connected, and the leakage rate of a filling pipeline system is ensured to meet the requirements; (2) two parallel storage tanks are simultaneously filled with helium or release helium for replacement until sampled gas is tested to be qualified; (3) the propellant filling pipeline and pipelines at the downstream of the parallel storage tanks are vacuumized; (4) valve ports of filling and drainage valves of the parallel storage tanks are filled with the propellant; (5) the parallel storage tanks are simultaneously and stably filled until 90% or above of the rated filling quantity is reached; (6) refilling is performed on the parallel storage tanks until the filling quantity of each storage tank meets the task requirement; (7) air cushions are added to the storage tanks until required air cushion pressure is reached. By means of the method, parallel balanced filling of the high-capacity semi-management surface tension storage tank can be realized, time for filling the parallel storage tanks with the propellant is shortened, and the reliability and the safety of the satellite filling process are guaranteed.

Owner:BEIJING INST OF CONTROL ENG

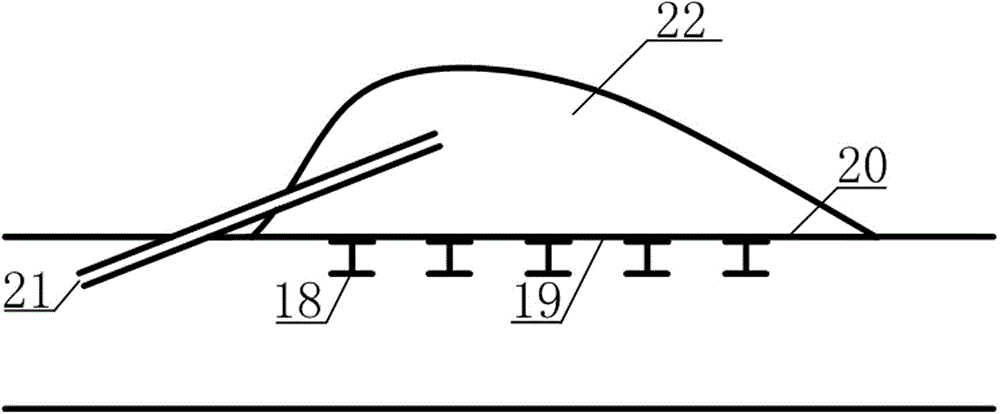

Strip filling method of conventional mining face goaf pumping cementing materials

InactiveCN105332733AThere will be no collapse accidentsSinking is stable and controllableMaterial fill-upBody positionsSlurry

The invention discloses a strip filling method of conventional mining face goaf pumping cementing materials. The method includes: designing strip filling bodies in a goaf along an advancing direction, constructing a first small filling strip at determined strip filling body positions according to a principle that the intervals among rear four rows of support columns are filled when a conventional mining face advances to the seventh row of support columns, sequentially completing small filling sections from bottom to top along the inclination direction of the mining face in the same manner, and building an upper-end gangue wall on the lying side of an upper roadway so as to prevent gangue slurry from overflowing and form the first small filling strip; constructing a second small filling strip and the like according to the construction step of the first small filling strip until the design width of the strip filling bodies is reached. The method has the advantages that during the filling process and after the strip filling is completed, the method is good in roadway safety, good in strip forming quality, high in construction efficiency, low in filling cost, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

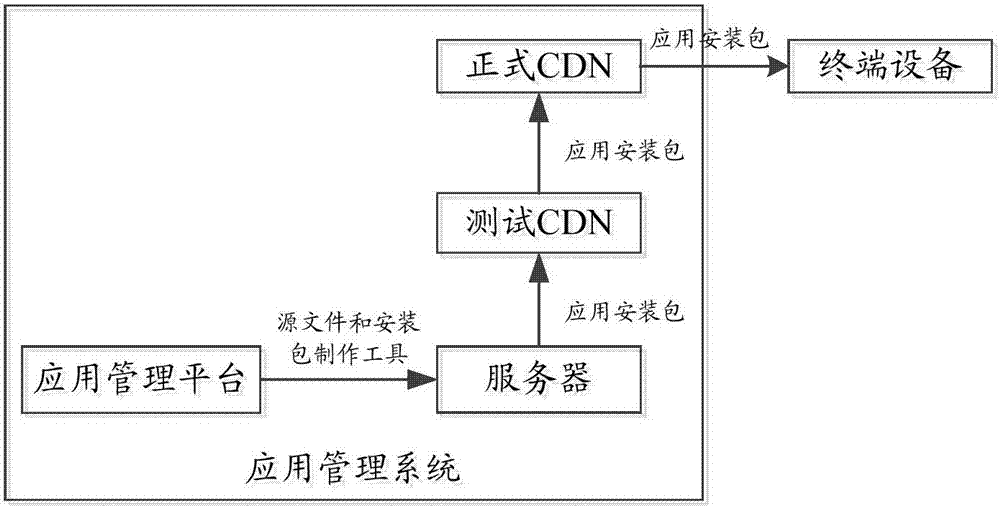

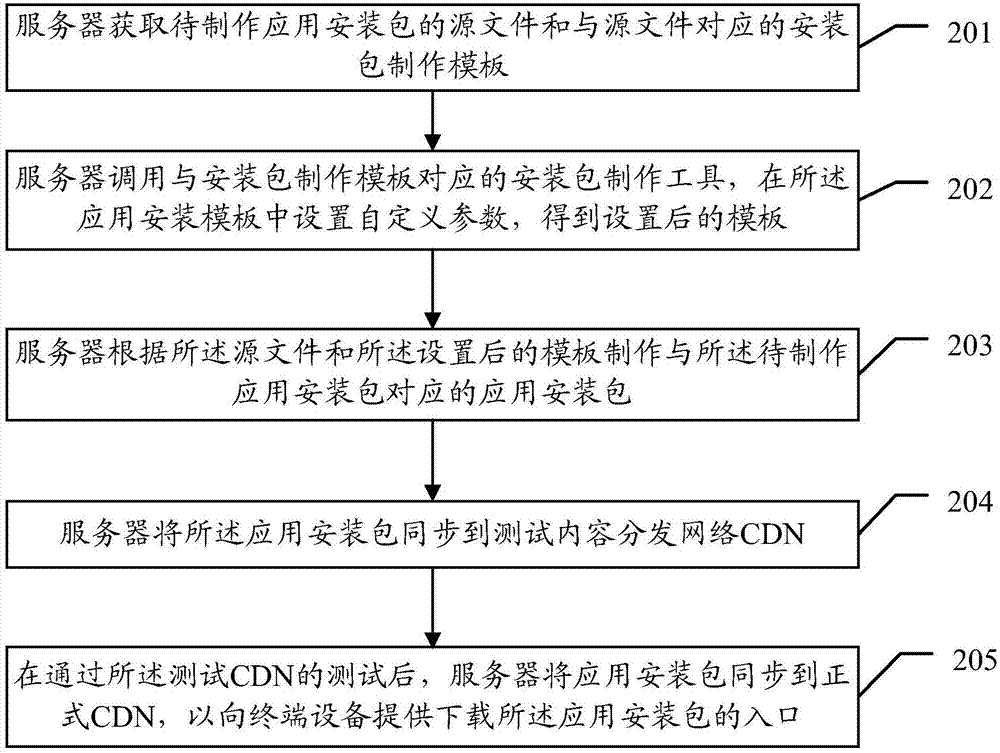

Application installation package making method and server

ActiveCN106936633ASimplify the filling processReduce the phenomenon of filling errorsError preventionUser identity/authority verificationTerminal equipmentSoftware engineering

The invention relates to an application installation package making method and a server. The method is applied to the server in an application management system, and comprises the steps of: obtaining a source file of an application installation package to be made and an installation package making template corresponding to the source file, wherein the installation package making template includes pre-set fixed parameters; calling an installation package making tool corresponding to the installation package making template, setting self-defined parameters in an application installation template to obtain a set template, and making an application installation package corresponding to the application installation package to be made according to the source file and the set template; synchronizing the application installation package to a test content delivery network CDN; and, after the test of the test CDN is passed, synchronizing the application installation package to a formal CDN, and providing an entry for downloading the application installation package for terminal equipment. By means of the scheme, the parameter filling process can be simplified; and furthermore, the wrong parameter filling phenomenon can be reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

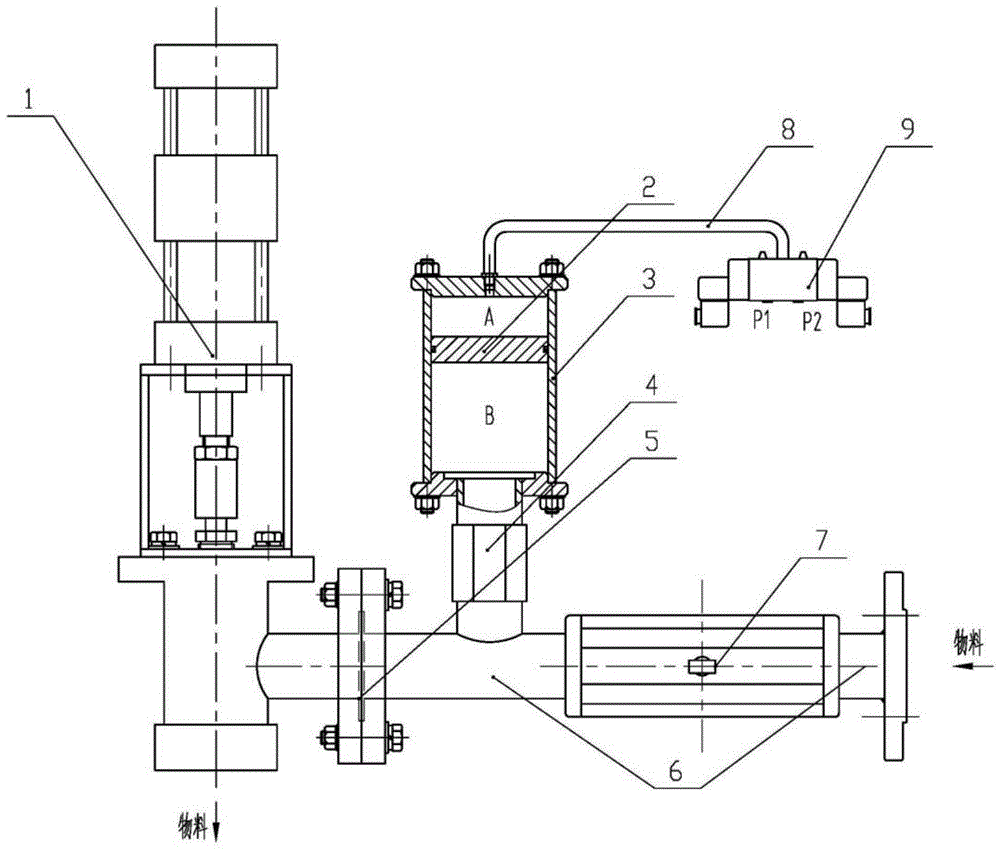

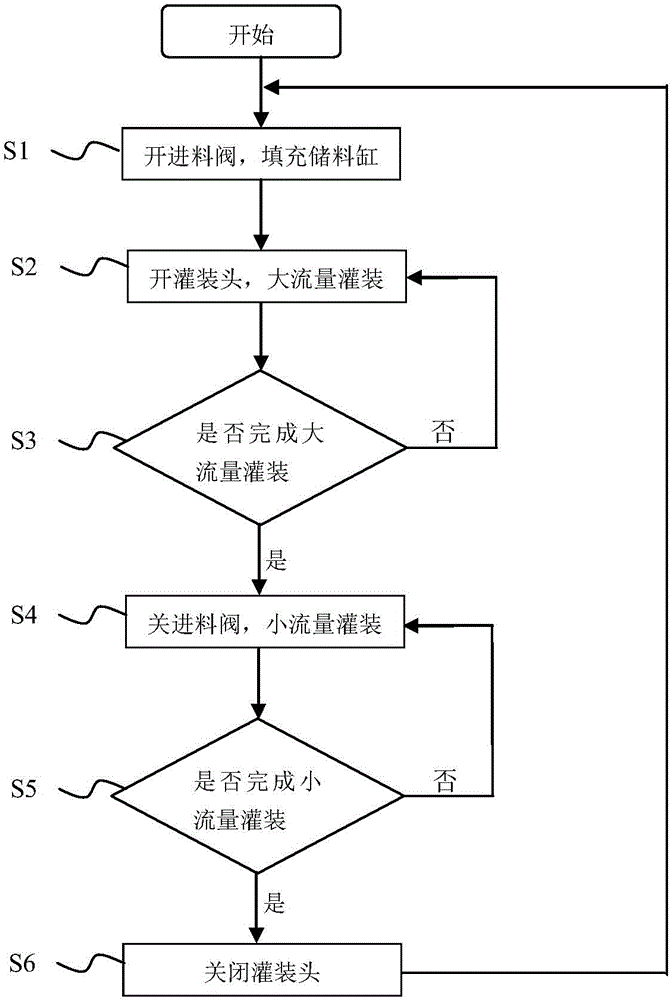

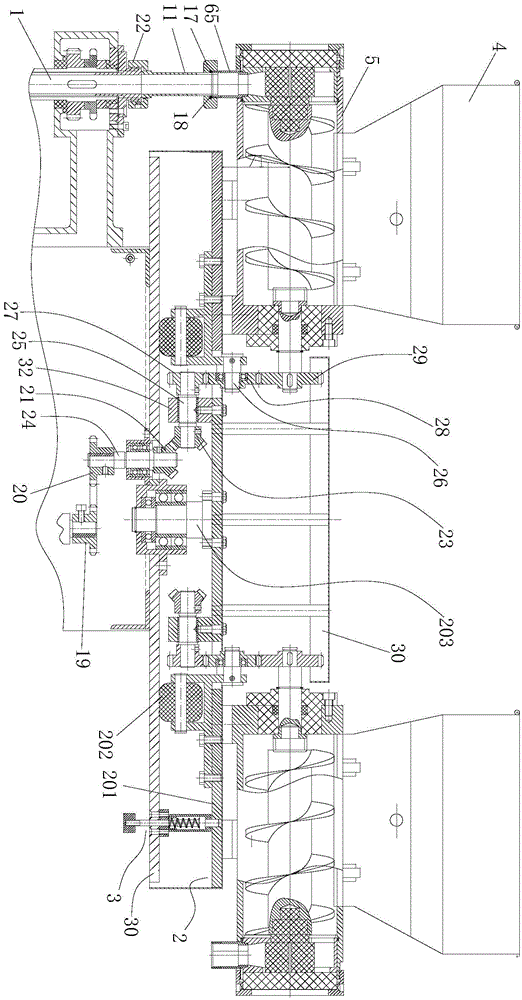

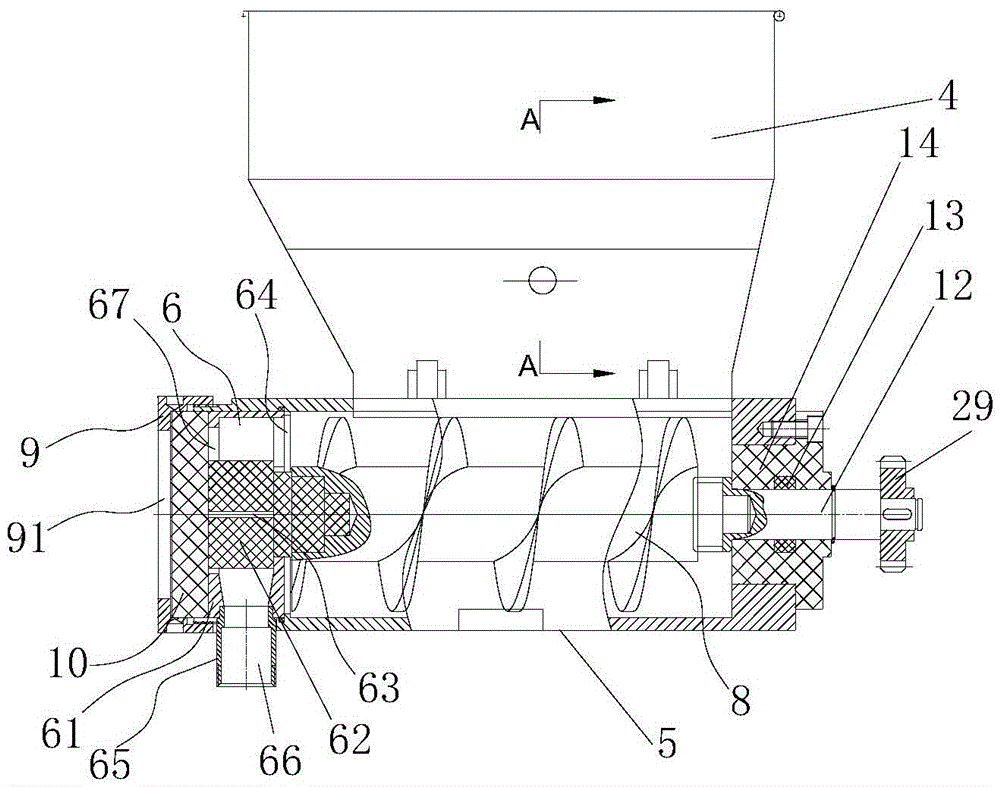

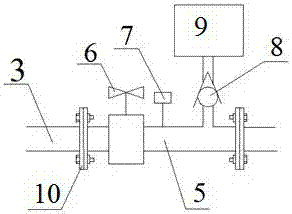

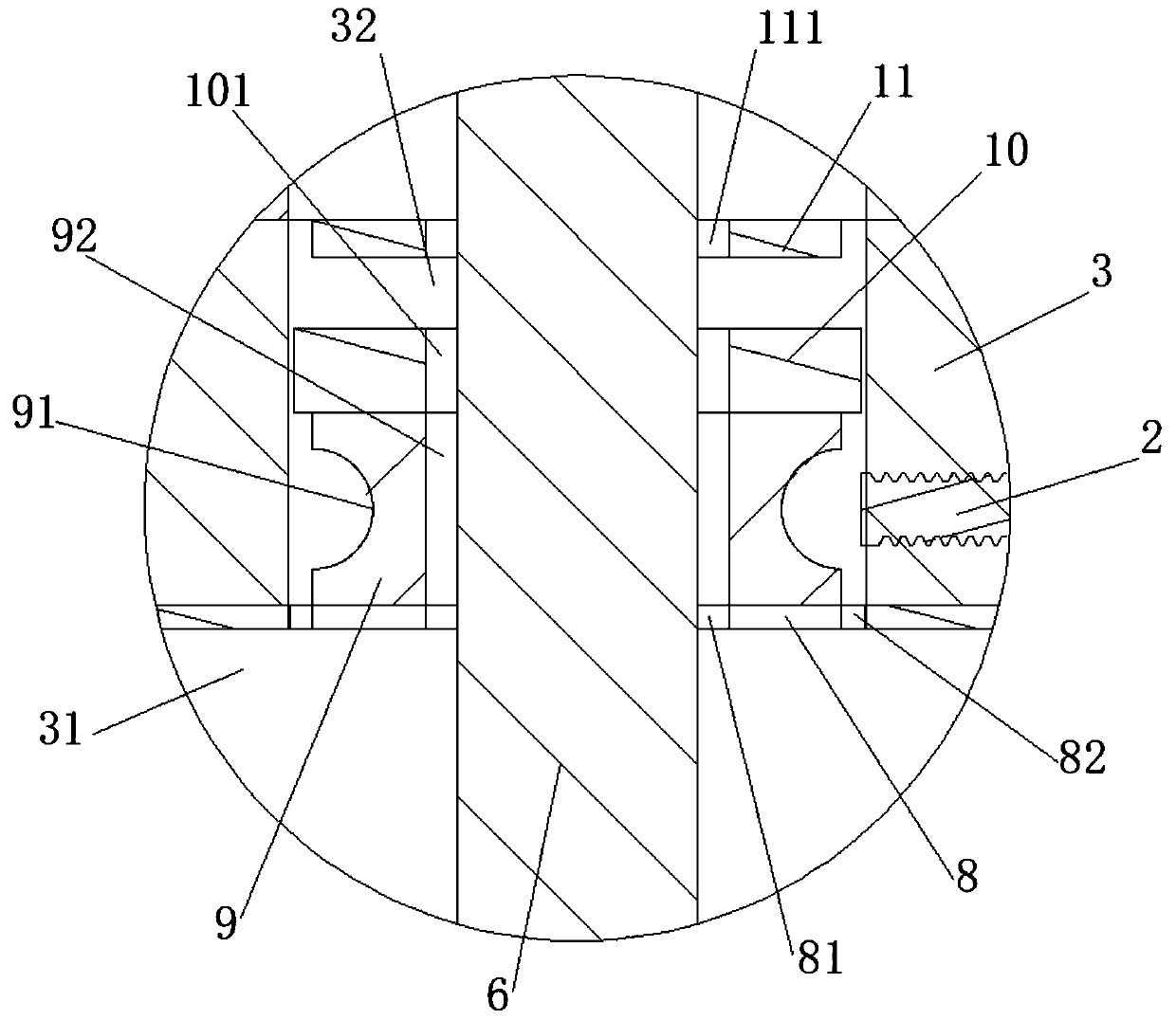

Liquid material filling control device and method

The invention relates to a liquid material filling control device and method. The device comprises a filling head (1), a material inlet pipe (6) and a material storage cylinder (3); a material inlet valve (7) is installed in the middle of the material inlet pipe (6); one end of the material inlet pipe (6) is connected with the filling head (1); to-be-filled materials are fed through the other end of the material inlet pipe (6); the material inlet valve (7) controls the materials to flow or stop in the material inlet pipe (6); a branch is designed between a flange (5) and the material inlet valve (7) and on the material inlet pipe (6) and connected with the material storage cylinder (3) through a threaded pipe (4); the material storage cylinder (3) comprises an air cavity (A) and a material cavity (B) which are sealed and isolated through pistons (2); the air cavity (A) is connected with a control valve (9) through an air pipe (8); the material cavity (B) is communicated with the material inlet pipe (6); the control valve (9) guides in or cuts off industrial instrument air or atmosphere. By means of the liquid material filling control device and method, speed and accuracy of the filling process are improved, the filling process is simplified, and material waste is reduced.

Owner:BEIJING AREOSTANARD NEW TECH +2

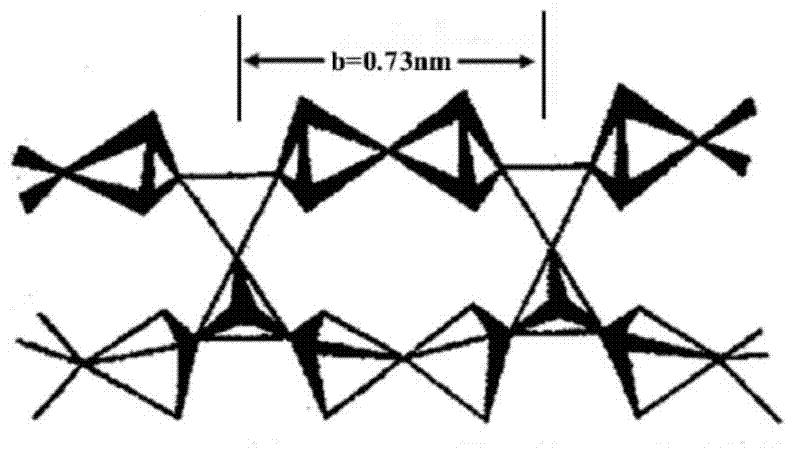

Application of synthetic calcium carbonate as high paper filler and preparation method of high paper filler

InactiveCN107287980AHigh total retentionHigh opacityInorganic compound additionFiberCalcium silicate

The synthetic calcium carbonate, as the application of papermaking filler, belongs to the papermaking technical field. The plant pulp fiber material is as the skeleton, synthetic calcium silicate power is as the filler, and the high paper filler is produced by paper-making technics. The synthetic calcium silicate power is as the hydrated calcium aluminate, and the object composition includes C-S-H polymer gel and tobermorite, and the brightness of synthetic calcium silicate power is greater than or equal to 90%, the specific surface area is greater or equal to 120 square meters per gram, the bulk density is from 0.12 grams per centimeter to 0.30 grams per centimeter, the oil-absorbed value is 120-200 milliliters per milligram, and the average grain diameter is (D50) from 12 microns to 40 microns . Meanwhile, the invention also discloses the preparation method of synthetic calcium carbonate: the synthetic calcium silicate power is the paper filler, then under the premise that paper properties are guaranteed, the usage of plant fiber can be decreased at the greatest extent. Replacing the traditional paper filler by synthetic calcium silicate power can not only reduce the usage of plant filler at the greatest extent, but also increase the retention rate of calcium carbonate, decrease the waste of filler and improve the paper ash content.

Owner:内蒙古普诺思新材料科技有限公司

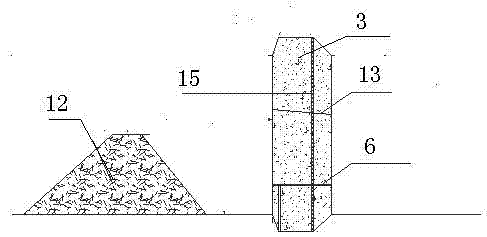

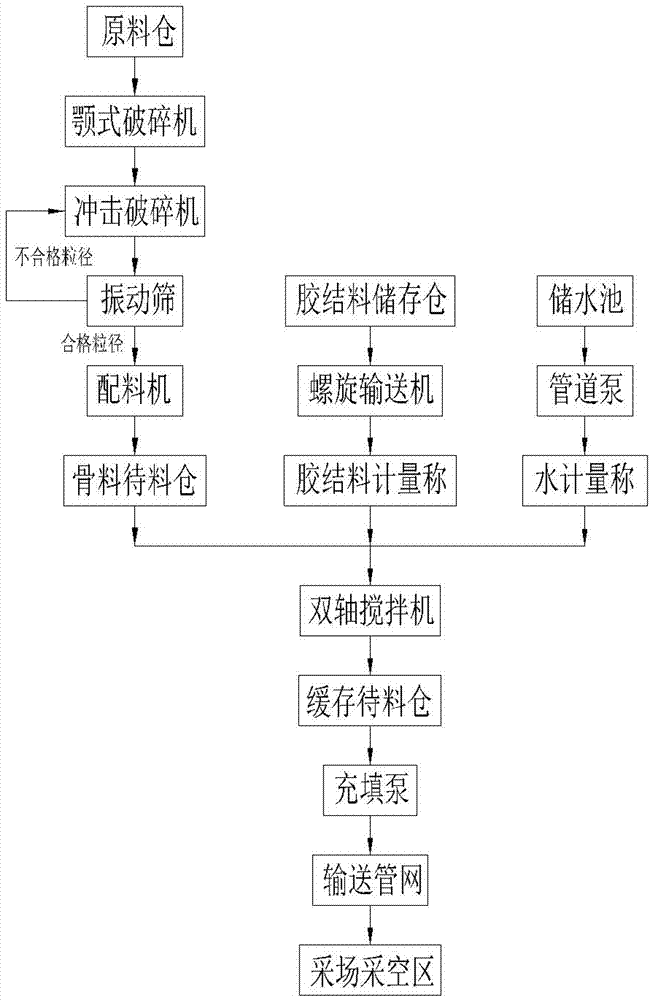

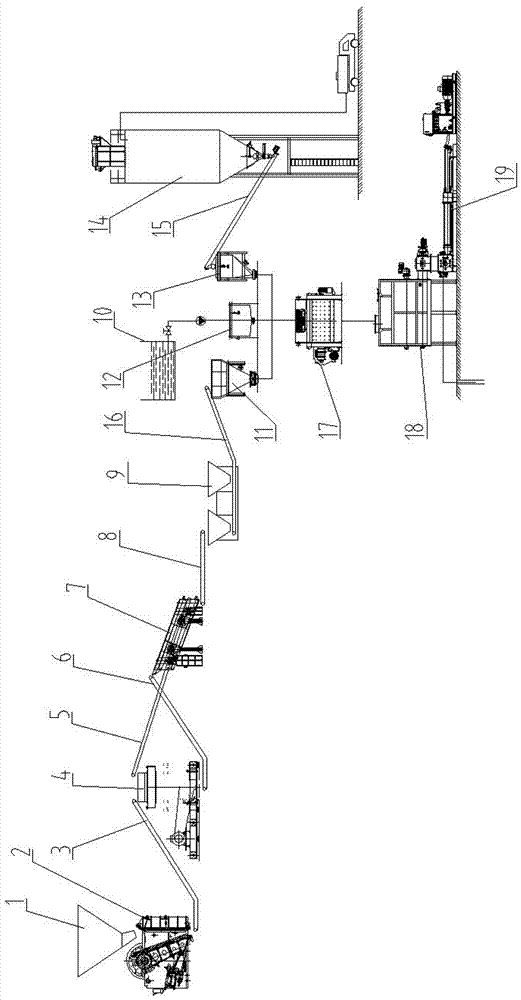

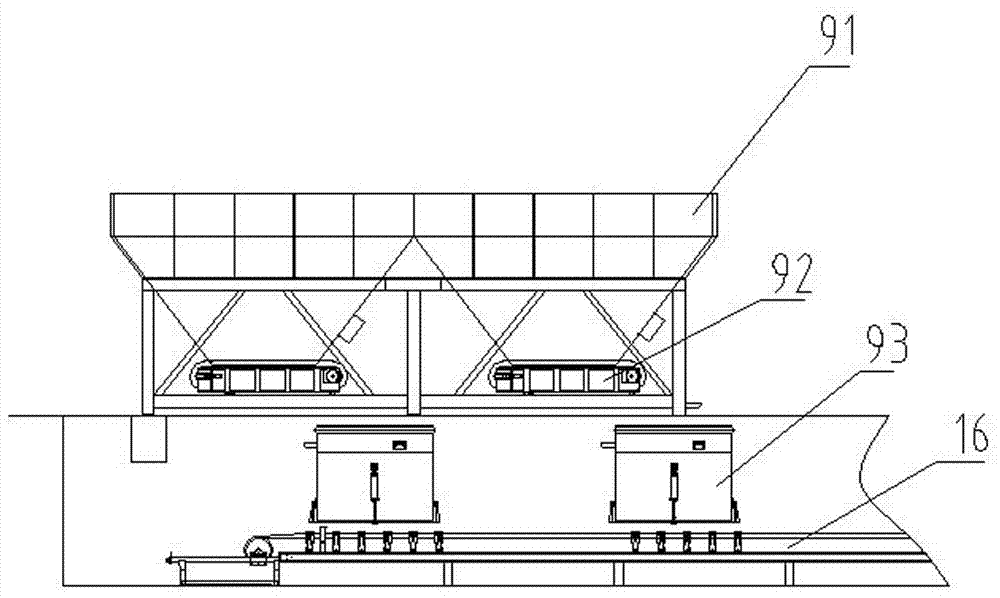

Method and system for filling underground goaf by filling material slurry prepared from weathering pit sand

InactiveCN106939796AWide variety of sourcesReduce precipitationMaterial fill-upHigh concentrationFilling materials

The invention discloses a method and system for filling an underground goaf by filling material slurry prepared from weathering pit sand. The method mainly comprises the following major three steps of firstly, preparing -10mm particle grade weathering pit sand; 2, enabling particle-grade-qualified hill sand, bonding materials and concentration adjusting water into a metering device to be metered through the respective material supply lines; supplying the materials into stirring equipment to be mixed; after uniform stirring, preparing the materials into high-concentration high-flowability structure flow filling material slurry; storing the materials into a buffer standby material cabin; 3, conveying the filling material slurry to an underground goaf to be filled at the pressure of the filling pump through a filling drill hole and an underground filling pipe net. The coal mine filling mining safe requirements can be met; the environment protection is facilitated. The resources of filling materials are wide; the materials can be obtained in nearest places or on the spot; the filling process flow process is simple; the equipment operation is reliable; the investment is low; the filling cost is low; the economic benefits are good. The high-concentration hill sand bonding filling process is used; the water secretion quantity and the separation of the bonding materials can be reduced; the intensity of the filling body is high.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

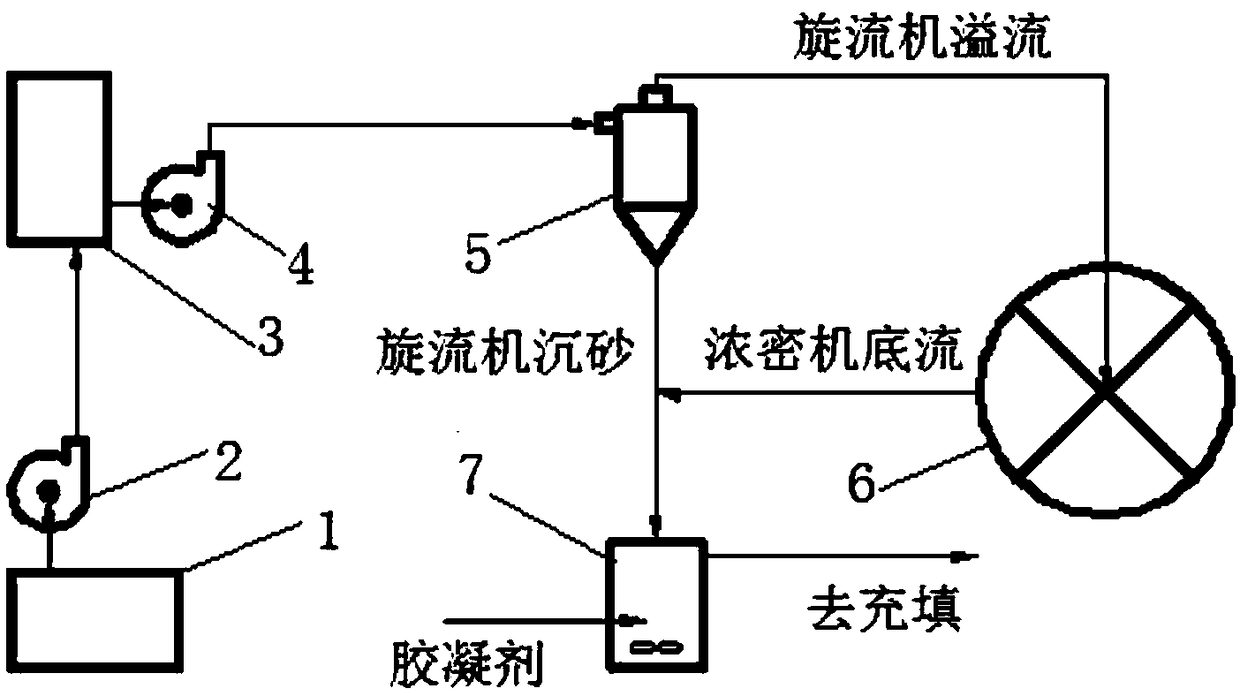

Ore pulp thickening and dewatering method and device

PendingCN108746159AControl concentrationAccelerated settlementSolid waste disposalVortex flow apparatusHigh concentrationPulp and paper industry

The invention discloses an ore pulp thickening and dewatering method and device. The ore pulp thickening and dewatering method and the device are applicable to thickening and dewatering of various types of ore pulp of mines. Pulp materials are subjected to overall classification and thickening by a cyclone, and settled sand of the cyclone directly flows to a high-concentration stirring drum, overflow of the cyclone is thickened through a thickener and sent to the high-concentration stirring drum to mix with the settled sand of the cyclone, so that satisfactory filler pulp is obtained directly.A filling process is simplified, and vicious cycle and influences of fine particle materials in the ore pulp thickening process are eliminated.

Owner:安徽金安矿业有限公司 +1

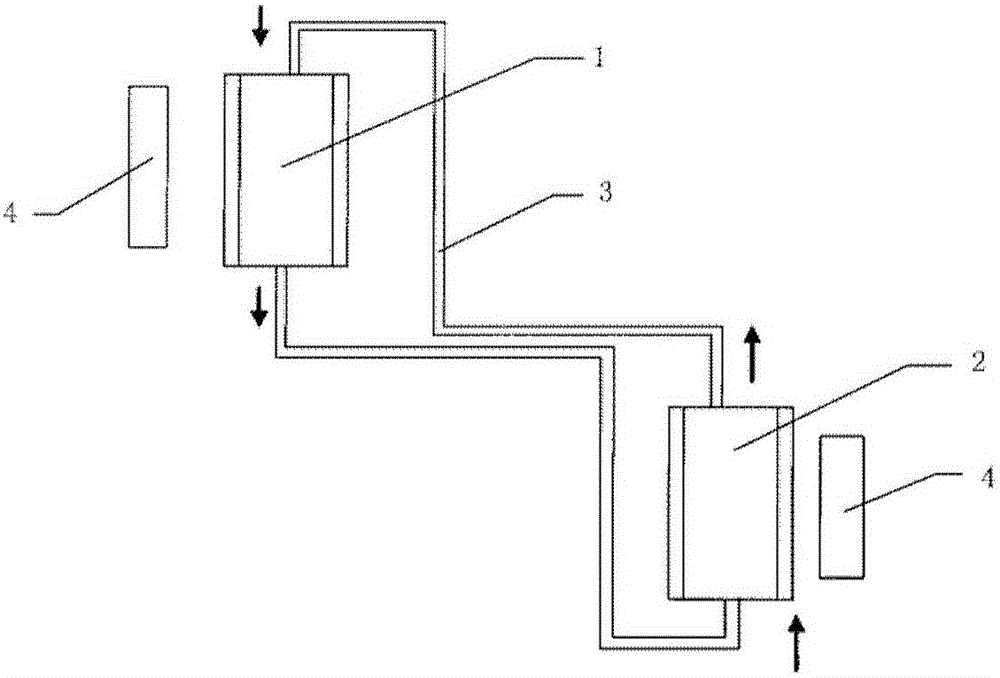

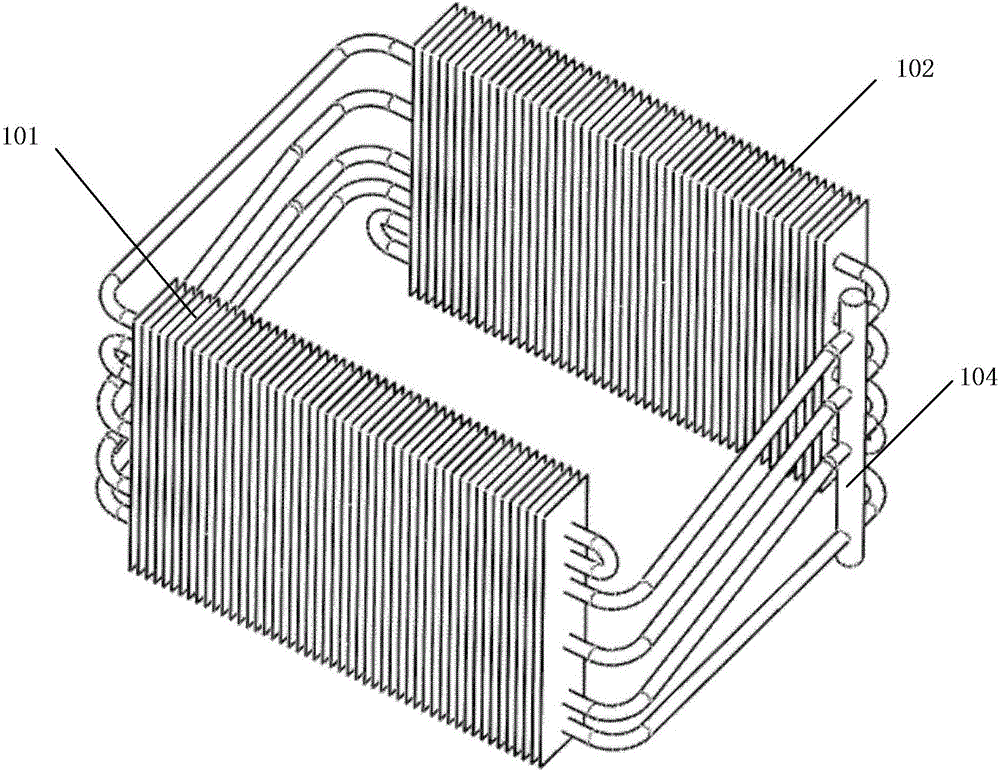

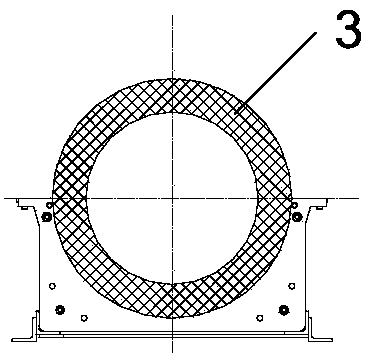

Annular heat pipe array heat exchanger and heat exchange system comprising annular heat pipe array heat exchanger

ActiveCN105737361ALow flow resistanceReduce energy consumptionIndirect heat exchangersSpace heating and ventilation detailsPlate heat exchangerData center

The invention relates to an annular heat pipe array heat exchanger. The annular heat pipe array heat exchanger comprises a condensation end and an evaporation end, and the condensation end and the evaporation end each comprises a plurality of horizontal pipes; the heat exchanger further comprises two multi-way pipes, and the two multi-way pipes are oppositely arranged; each multi-way pipe is connected to the horizontal pipes of the condensation end and the evaporation end to form a plurality of closed loops; and the two multi-way pipes include the first multi-way pipe and the second multi-way pipe. The invention further discloses a heat exchange system comprising the annular heat pipe array heat exchanger. According to the annular heat pipe array heat exchanger, the conditions that the outdoor temperature in Spring, Autumn and Winter is low and power consumption is less are used, heat inside the space is transferred to an outdoor place, a large amount of air-conditioning energy consumption is saved, and the annular heat pipe array heat exchanger can be applied to heat exchange in a data center or an equipment cabinet.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

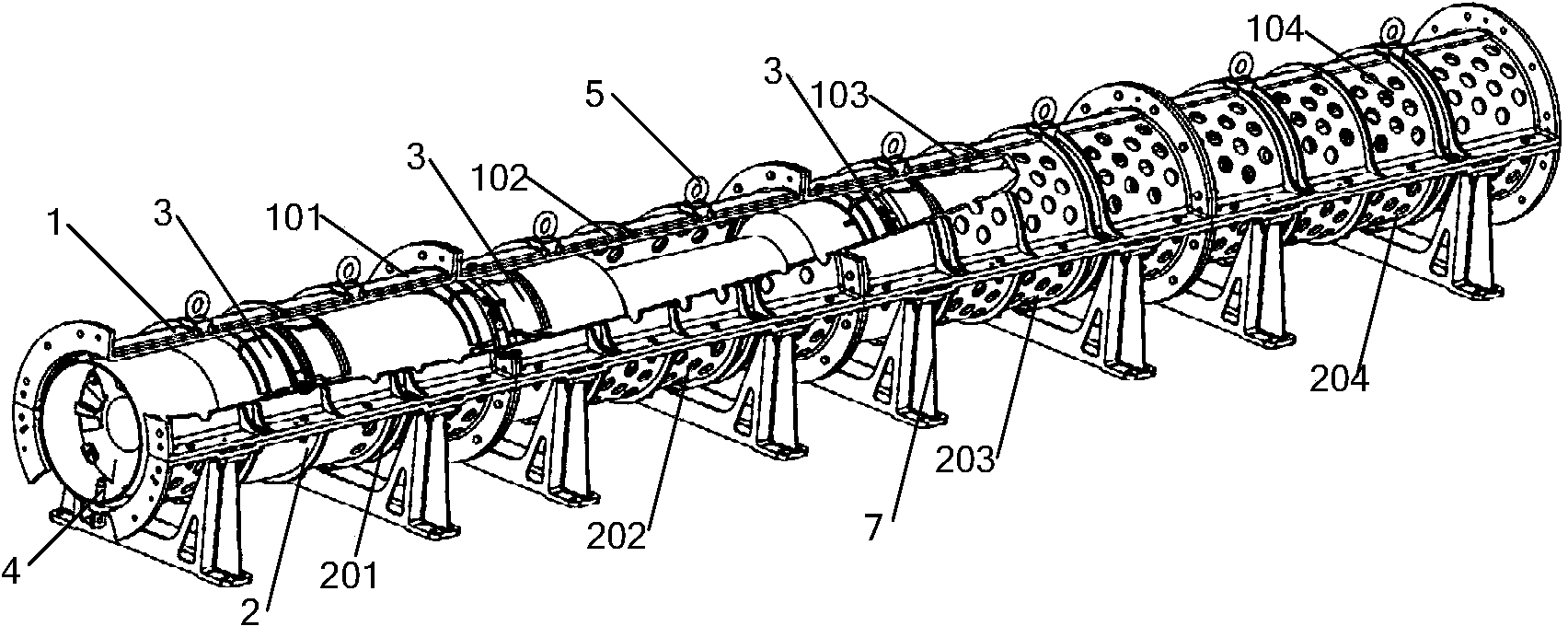

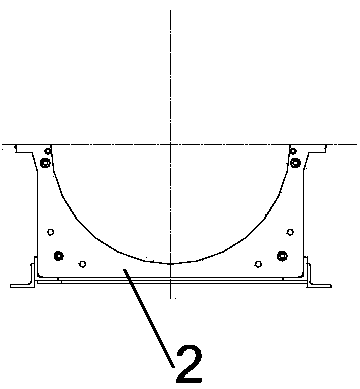

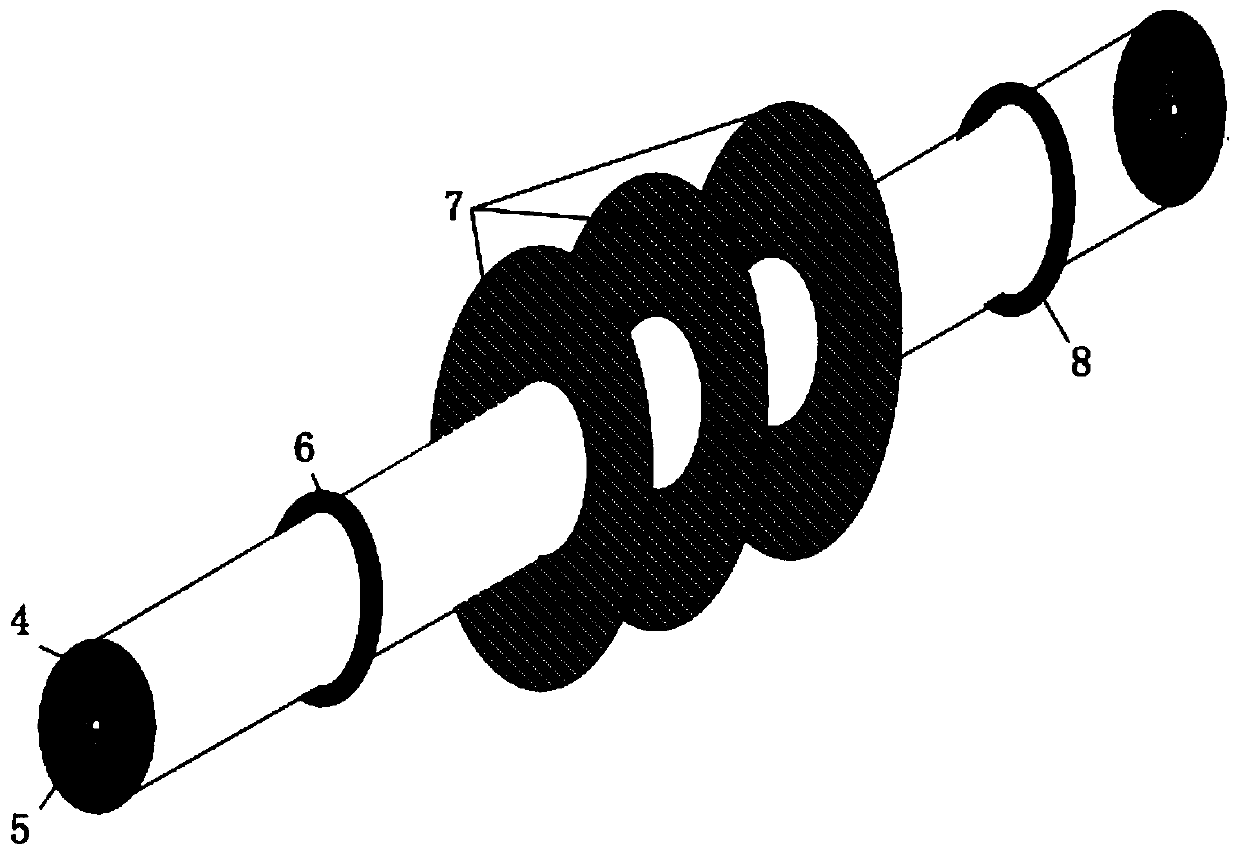

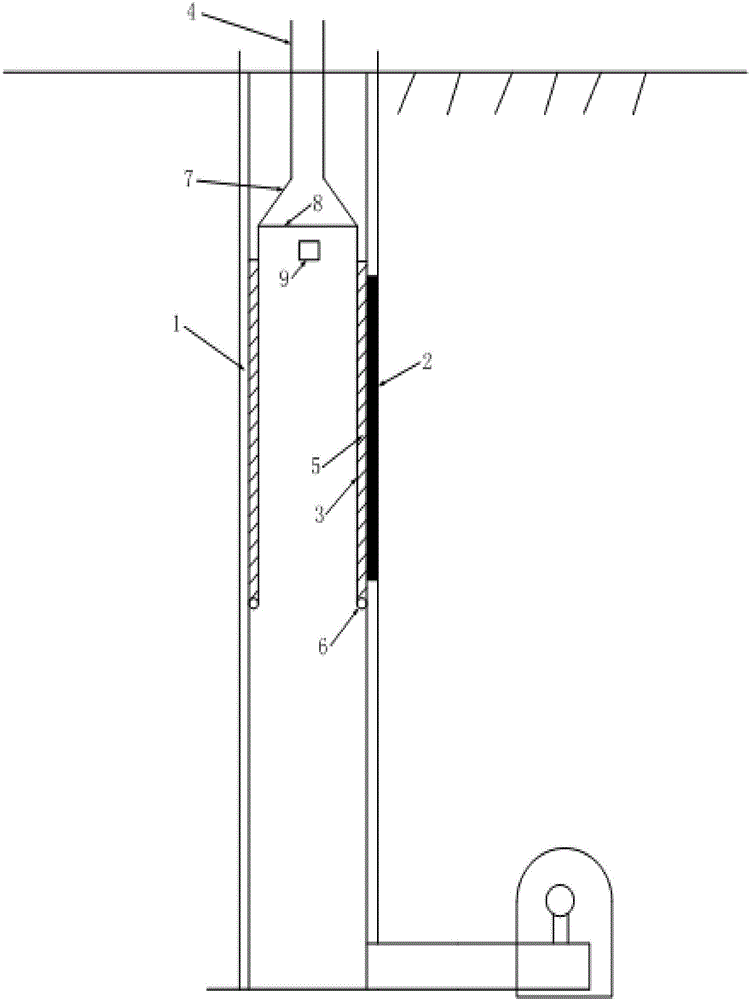

Underwater horizontal hot launching device

ActiveCN104266545AAchieve axial positioningImplementation orientationRocket launchersInter layerMarine engineering

The invention discloses an underwater horizontal hot launching device. The underwater horizontal hot launching device comprises an upper half emitting tube shell (1), a lower half emitting tube shell (2), a plurality of adapter module (3), an axial position pin (4) and a hanging ring (5); the upper half emitting tube shell (1) is formed by connecting four upper shell sections (101-104) through butt joint; the lower half emitting tube shell (2) is formed by four lower shell sections (201-204); every adapter module (3) is composed of at least four adapters (30), and gaps are formed between every two neighboring adapters; every adapter is composed of an outer layer (301) in contact with the wall of an emitting tube, a middle layer and an inner layer (303) in contact with a vessel to be launched (8); the outer surface of every adapter (30) is provided with a ring groove (30) for mounting a strap. The underwater horizontal hot launching device is used of guiding and positioning during launching of underwater vessels, and meanwhile, solves the problem of loading inconvenience of the underwater vessels with a high slenderness ratio and accordingly omits complex design of loading equipment.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

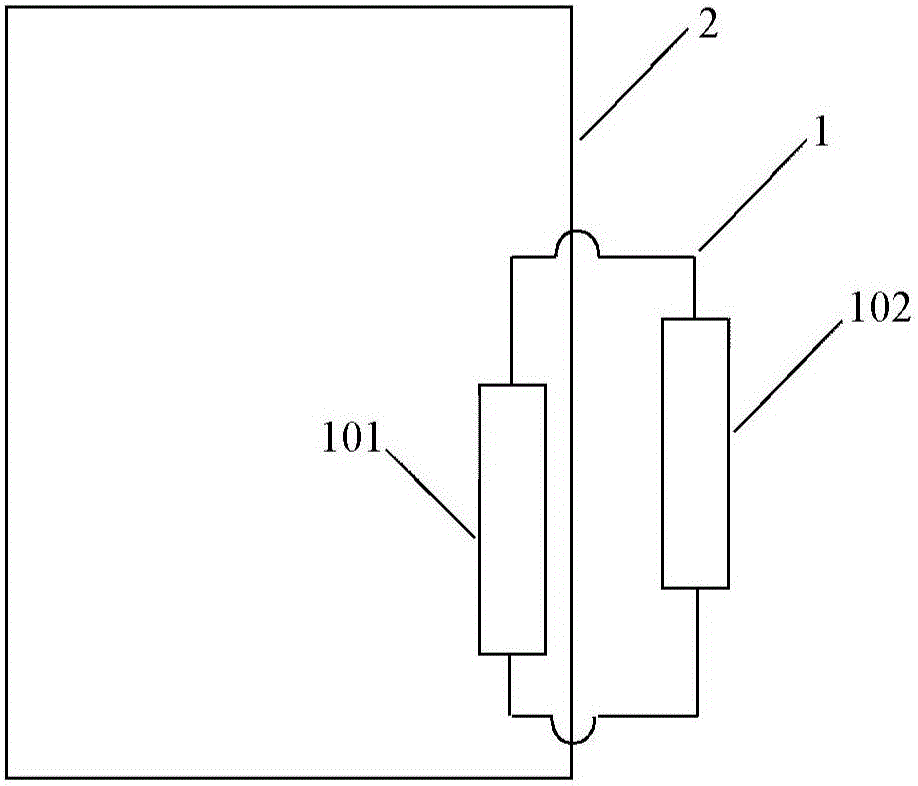

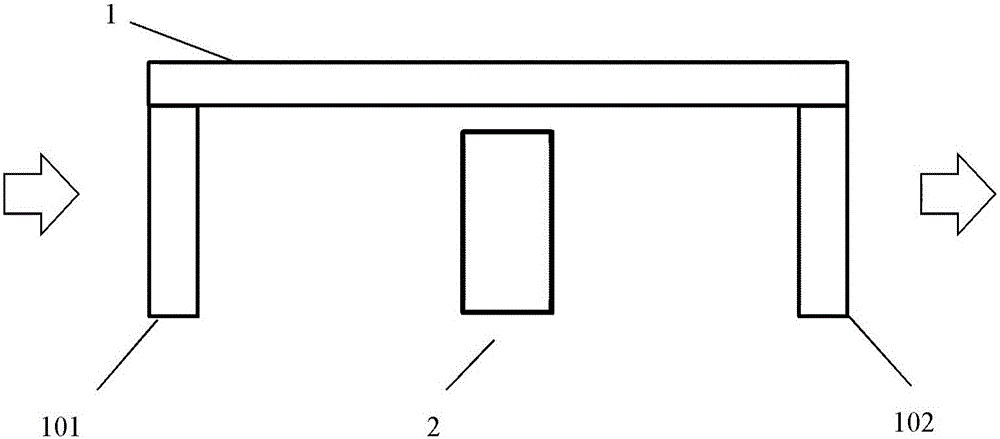

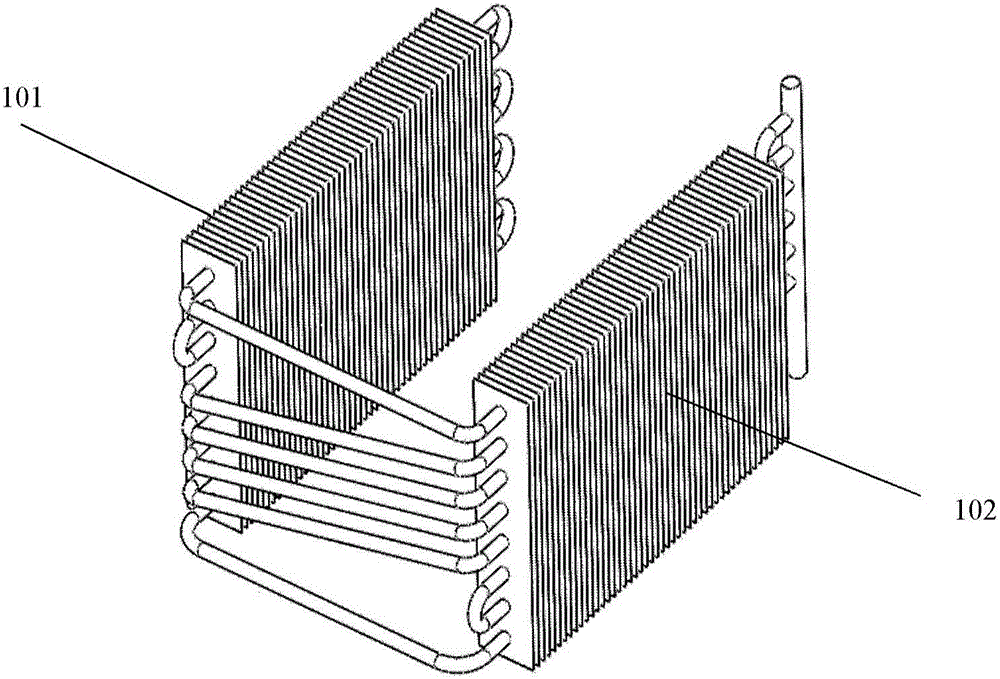

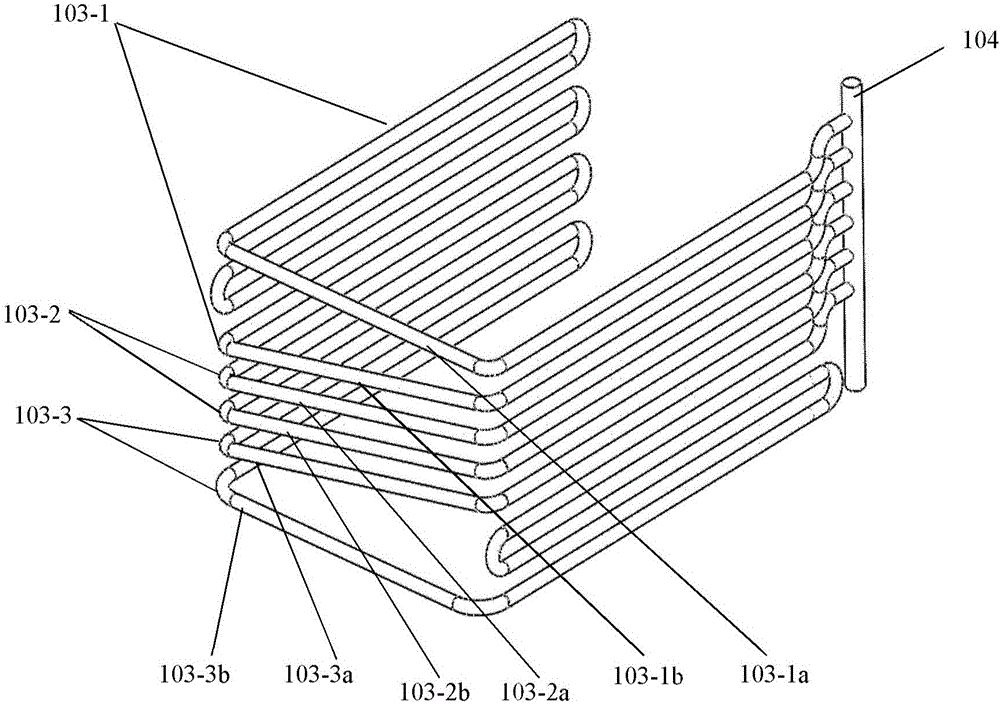

U-shaped heat pipe array device and air conditioning system with the same

InactiveCN105758238ALess convective interferenceLow flow resistanceIndirect heat exchangersSpace heating and ventilation detailsRoom temperatureEvaporation

The invention discloses a U-shaped heat pipe array device. The U-shaped heat pipe array device comprises two straight arm parts and a bend part for connecting the two straight arm parts. The two straight arm parts serve a condensation end and an evaporation end and each comprise multiple horizontal pipes; the bend part is a multi-way pipe and used for connecting the horizontal pipes of the condensation end and the horizontal pipes of the evaporation end; a perpendicular primary pipe is further arranged at the end, far away from the bend part, of the condensation end, and is communicated with the multiple horizontal pipes of the condensation end; every two corresponding end openings in the portions, far away from the bend part, of the horizontal pipes of the evaporation end are connected through a connecting pipe. According to the U-shaped heat pipe array device, in air conditioning of the air conditioner industry, the refrigeration industry, the dehumidification industry, the drying industry and the like, as low-temperature cold sources do not need to be prepared for dehumidifying during room temperature control, the use ratio of energy and the comfort degree of the room are increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

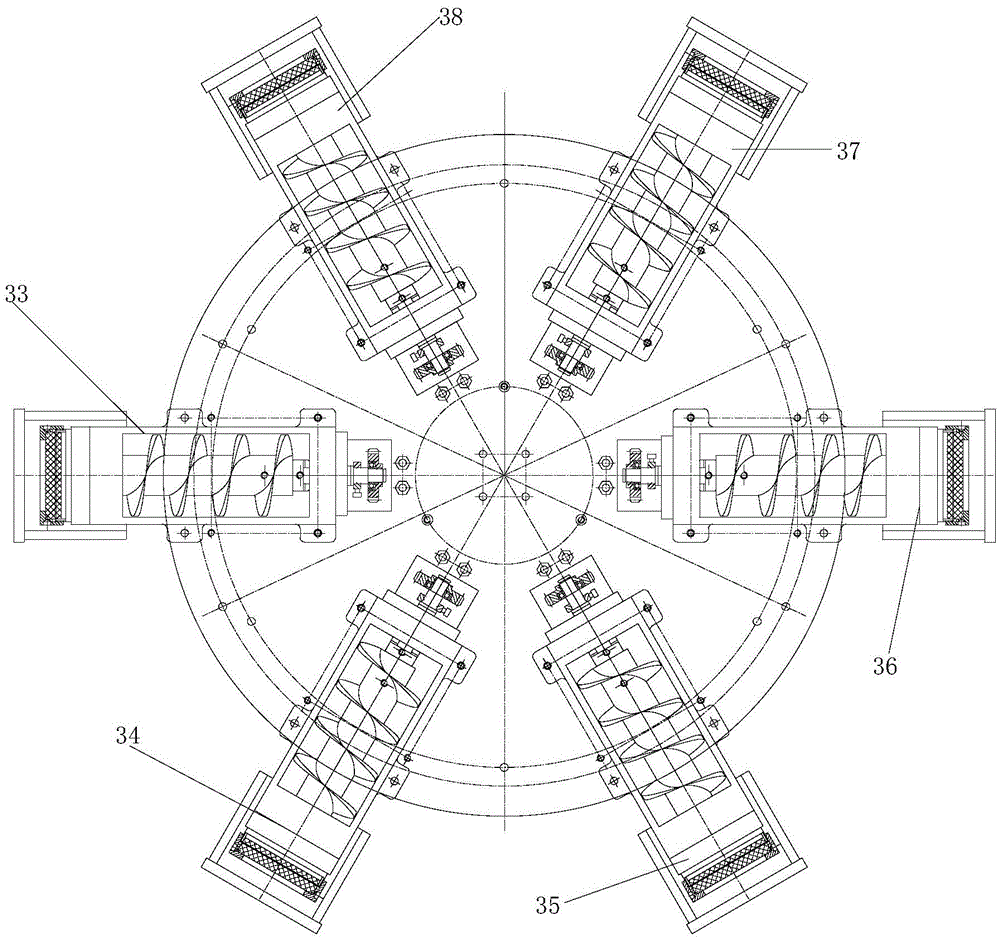

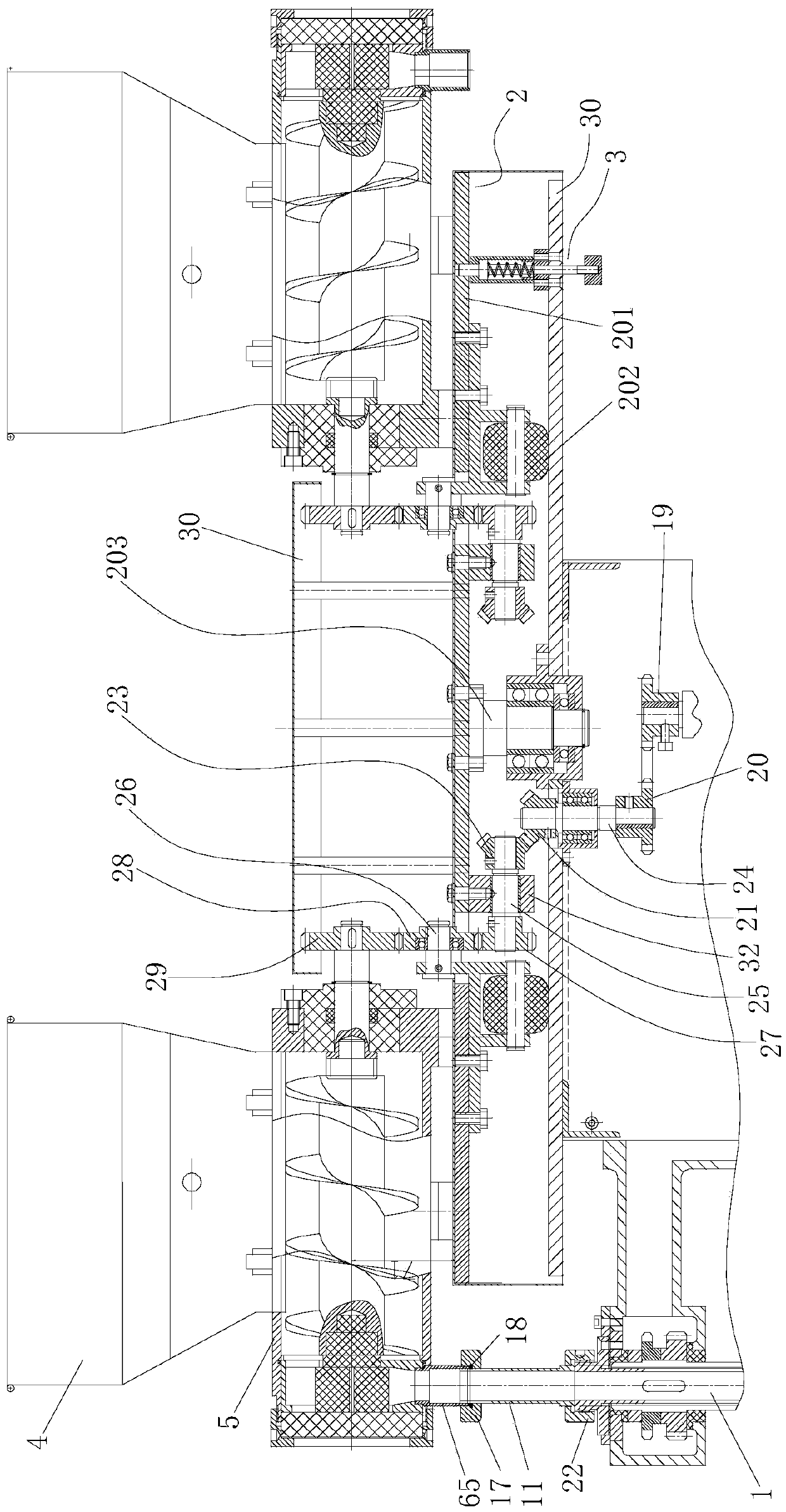

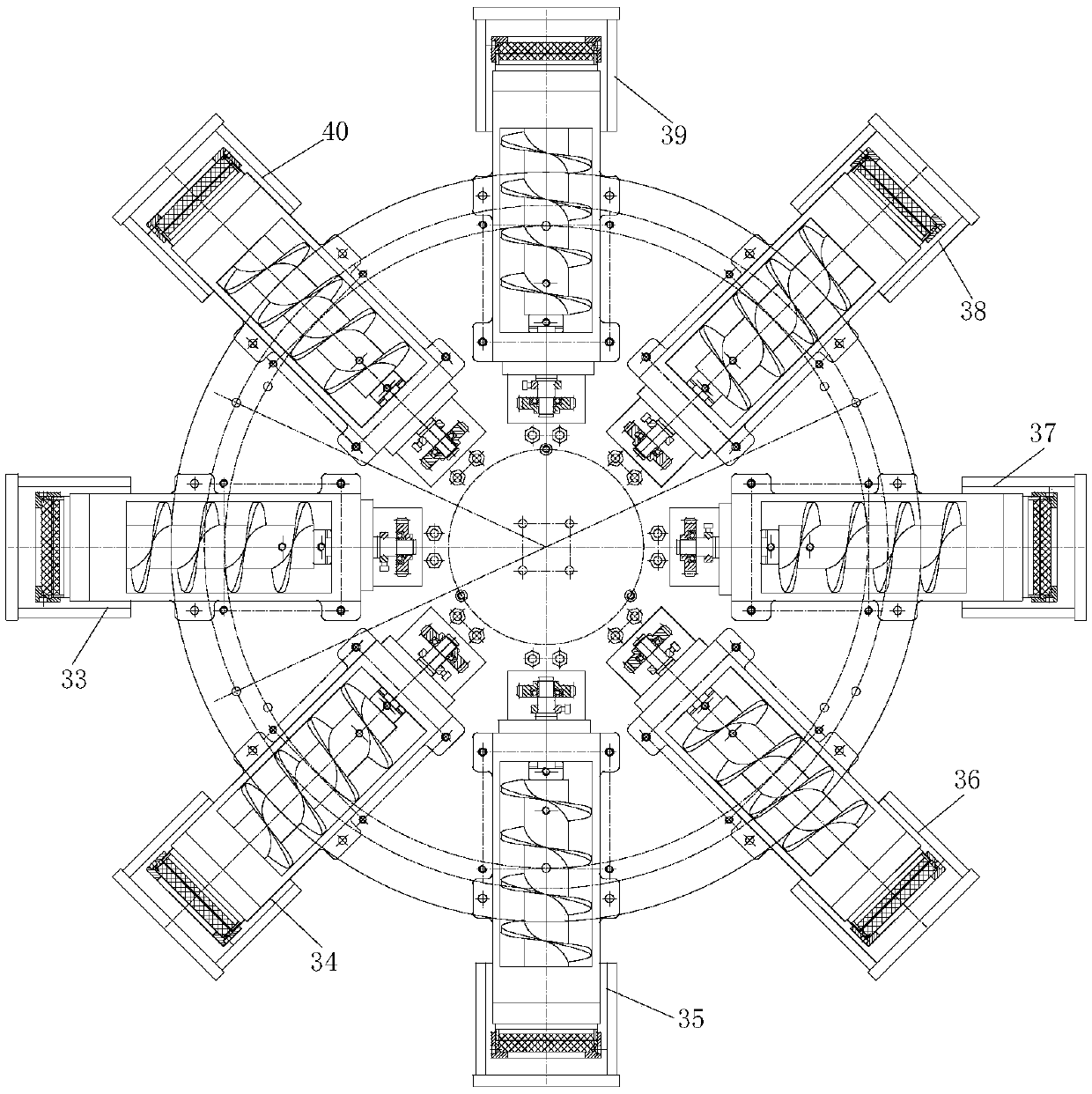

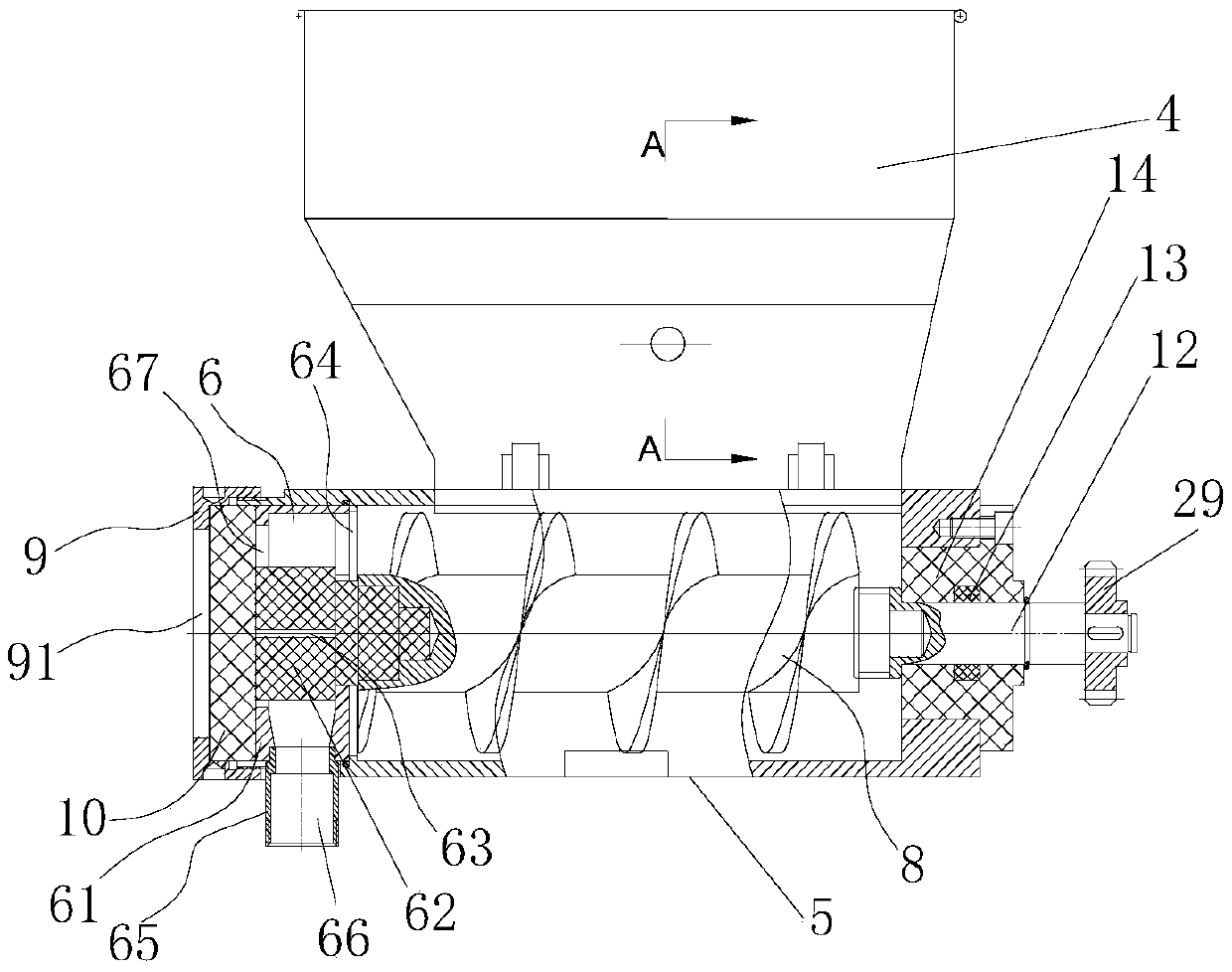

Chinese style pastry maker movable six-stuffing conveying system

ActiveCN105532779AImprove the mixing effectEasy to change stuffingDough processingPastry makerEngineering

The invention discloses a Chinese style pastry maker movable six-stuffing conveying system. The system comprises a stuffing bottom board, a stuffing surface board and stuffing conveying assemblies; the stuffing surface board is arranged on the stuffing bottom board in a rotatable manner; and the stuffing assemblies are used for conveying stuffings, and are circumferentially distributed on the stuffing surface board, and the quantity of the stuffing assemblies is 6. The Chinese style pastry maker movable six-stuffing conveying system allows the stuffing surface board to be arranged on the stuffing bottom board in a rotatable manner, so the stuffing conveying surface board is conveniently pushed to drive the stuffing conveying assemblies on the stuffing surface board to move to an assigned position in order to be connected with a stuffing tube on a pastry maker, so the stuffing changing convenience is improved, and the stuffing changing process is simple and convenient; and the stuffing conveying system adopts a horizontal stuffing auger structure, so the stuffing stirring effect is improved.

Owner:WUHU BREAKFAST 4050 RIVERSIDE ENG CO LTD

Filling material containing lepidolite slag as well as preparation method and application thereof

InactiveCN111606614ASolve the problems of easy flow and poor accumulation effectEasy to pumpSolid waste managementMaterial fill-upSlagFilling materials

The invention relates to a filling material for lepidolite slag as well as a preparation method and application of the filling material, and belongs to the technical field of the filling of lepidoliteslag. Slurry formed by mixing the prepared filling material with water has the viscosity close to that of water, is easy to pump (the pumping distance can reach 100-500 m), excellent in thixotropy and short in initial setting time (shorter than 60 s), and overcomes the defects of long initial setting time of a product, proneness of the slurry to flowing, and poor accumulation effect in the priorart. According to the filling material prepared by the invention, 100% consolidation is realized, the highest compressive strength can reach 5MPa, and the problems of poor consolidation performance and low compressive strength of the product in the prior art are solved. According to the high-water-content filling material prepared by the method, complex auxiliary treatment such as filling templatesupporting is not needed in a construction process, and a filling process is simple, and the high-water-content filling material is particularly suitable for meeting a rapid filling requirement underemergency conditions in mines.

Owner:JIANGXI UNIV OF SCI & TECH

Coaxial TSV-structure pinboard and fabrication method thereof

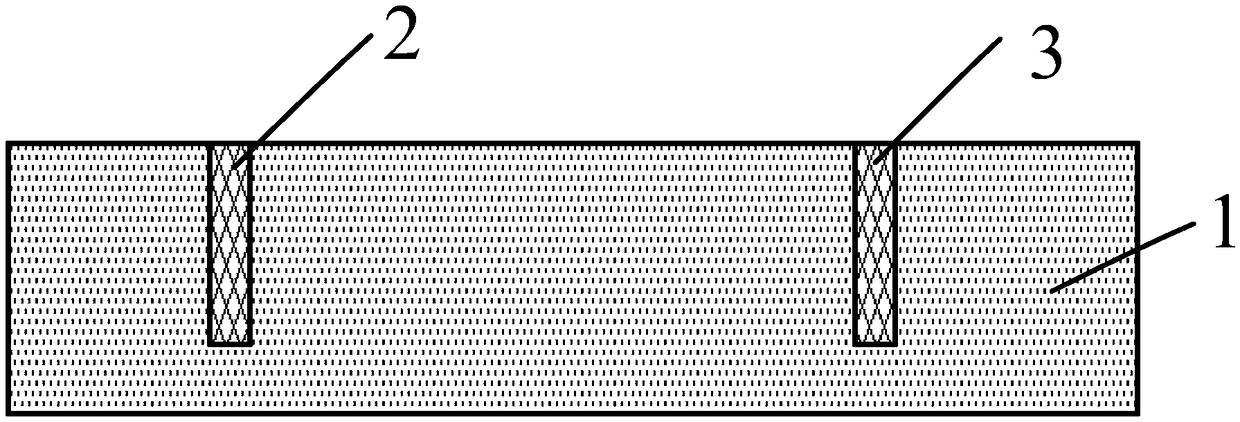

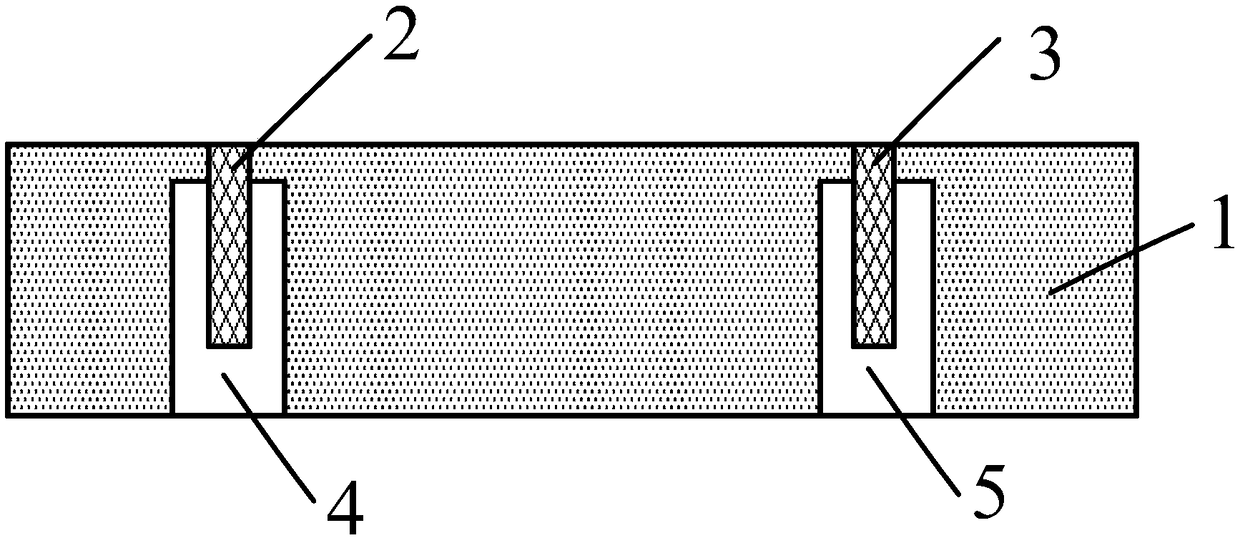

ActiveCN109461699ASimple filling processControllable repeatabilitySemiconductor/solid-state device detailsSolid-state devicesPre treatmentTransmission line

The invention discloses a coaxial TSV-structure pinboard and a fabrication method thereof. The fabrication method comprises the steps of pre-processing a silicon wafer, wherein the silicon wafer is provided with a front surface and a rear surface which are corresponding to each other; processing an inner-ring copper cylinder structure on the front surface; fabricating a silicon blind hole with a large external diameter in a back surface by taking a metal copper cylinder of the inner-ring copper cylinder structure as a center; processing and forming an outer-ring metal layer on a surface of a side wall of the silicon blind hole; filling and curing an intermediate dielectric layer in the silicon blind hole with the outer-ring metal layer; processing the front surface and the rear surface until the surface is planarized, processing the front surface until the intermediate dielectric layer is exposed, and processing the rear surface until the metal copper cylinder of the inner-ring coppercylinder structure is exposed; and processing a coaxial TSV hole bonding pad and a coaxial TSV hole interconnection transmission line on the front surface and the back surface to form a silicon pinboard with a TSV coaxial structure. By the fabrication method, the polymer medium filling process is simplified, the fabrication method is controllable and is good in repeatability, and mass production and fabrication is favorably achieved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Tunable plasma photonic crystal fiber device

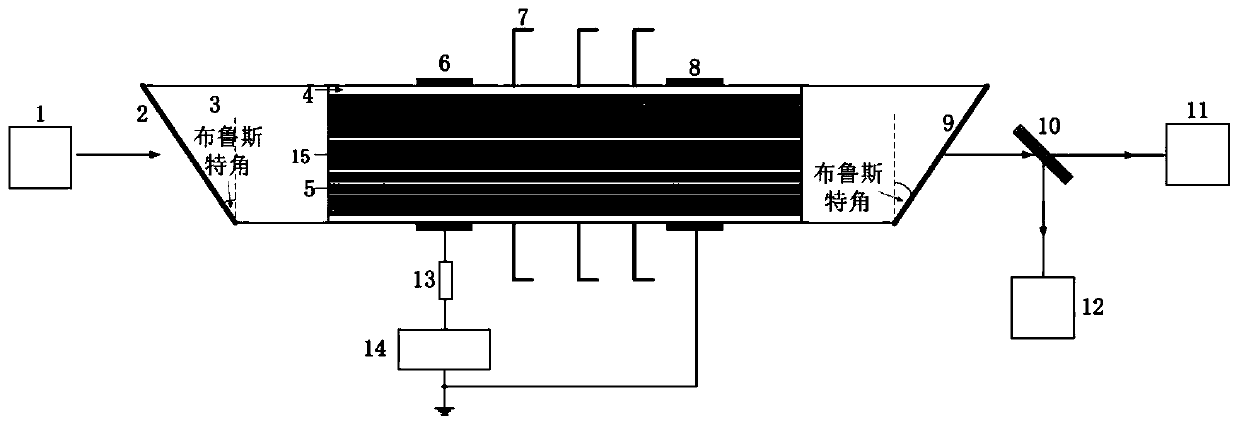

InactiveCN110794510ASimple filling processReconfigurableOptical waveguide light guideMicrostructured optical fibreVoltage pulseOptical communication

The invention discloses a tunable plasma photonic crystal fiber device. The tunable plasma photonic crystal fiber device comprises a photonic crystal fiber, a high-voltage pulse power supply, a protective resistor, a high-voltage electrode, an insulating piece, a ground electrode, an incident Brewster window and an outgoing Brewster window; an infrared laser enters the photonic crystal fiber through the incident Brewster window and is emitted from the outgoing Brewster window, the high-voltage pulse power supply applies a pulse voltage to the high-voltage electrode, and low-temperature plasmais obtained in a hollow hole filled with inert working gas in a form of dielectric barrier porous discharge to realize the photonic crystal fiber filled with the plasma; and by changing pulse parameters of the high-voltage power supply, the gas pressure of the inert working gas or an electrode spacing, characteristic physical parameters and the gas temperature of the plasma can be adjusted, and infrared band gap characteristics of the photonic crystal fiber can be tuned in a wide range. The tunable plasma photonic crystal fiber device has the advantages of continuous tuning, reconfigurability,wide tuning frequency band and high response speed, and has broad industrial application prospects in the optical communication aspect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

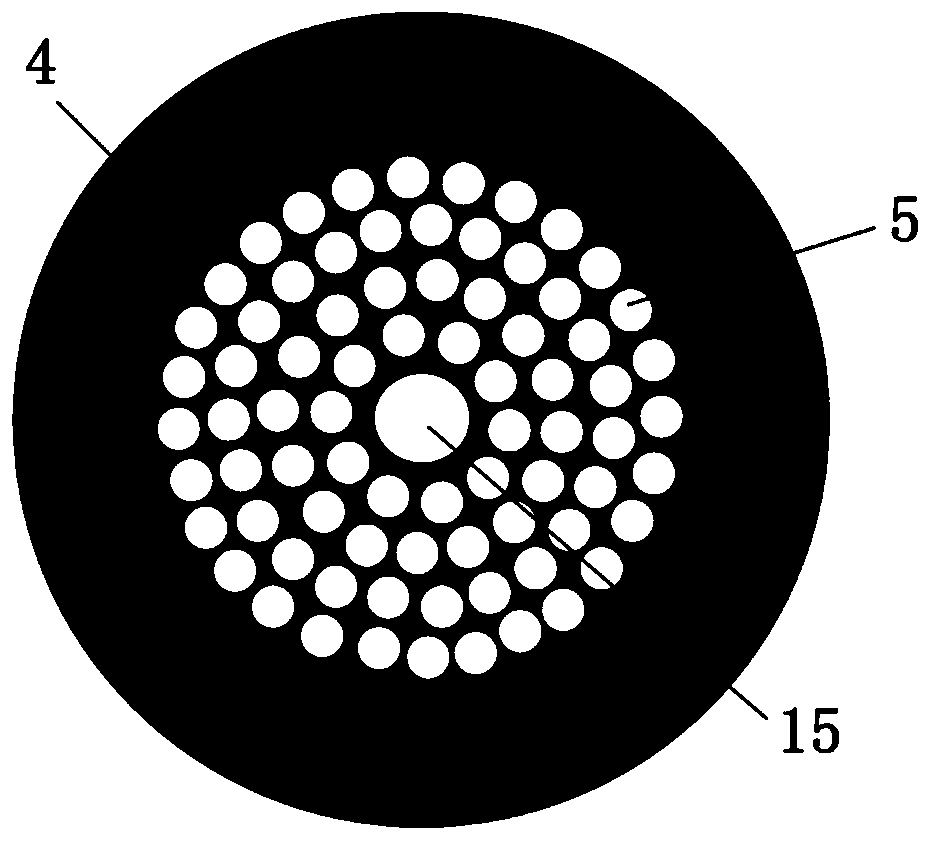

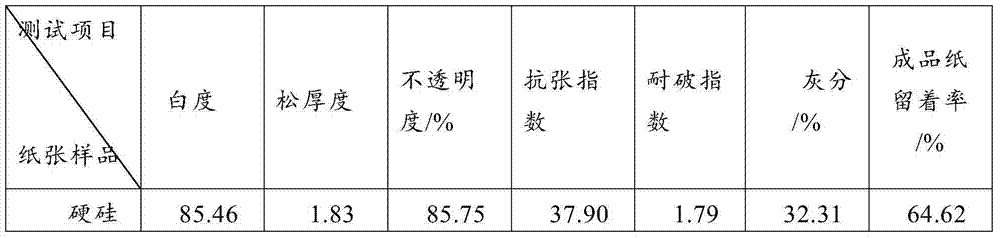

Application of xonotlite as paper making filler

ActiveCN103669104AImprove performanceSimple filling processReinforcing agents additionPaper/cardboardPaper sheetWater soluble

The invention discloses application of xonotlite as a paper making filler. High-filler-content paper is produced with 40-60 percent of plant pulp fibrous raw material serving as a framework, 40-60 percent of the xonotlite serving as the paper making filler and a water-soluble macromolecular multipolymer serving as a reinforcing agent according to the conventional paper making process method. Compared with the conventional paper making method, the method adopted in the invention has the advantages that the xonotlite is taken as the paper making filler, so that the phenomenon of powder falling of the filler on a paper making surface is avoided in a paper making process, the retention rate of the filler is generally 55-85 percent after being loaded onto a net of a paper machine, being 20-50 percent higher than that of the conventional paper making filler, and waste of the filler is reduced effectively; paper produced with the method has the advantages of low extension rate, high opacity, high smoothness, no pollution, degradability, recyclability, low cost and the like.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

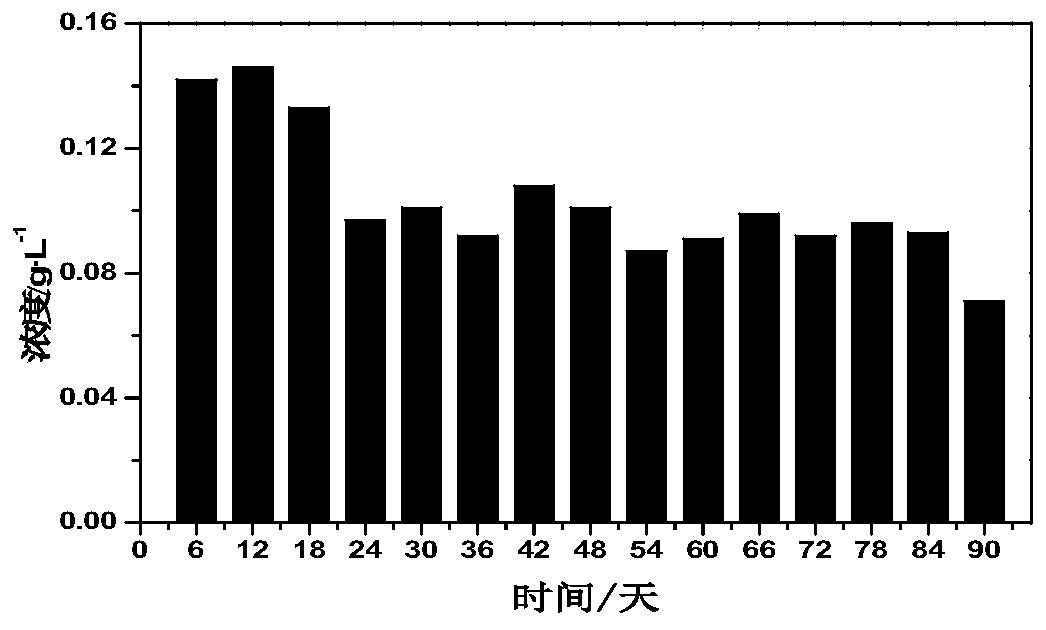

Slow-release corrosion and scale inhibitor capsule for oil wells and preparation method thereof

InactiveCN111286312ASimple filling processSink fastDrilling compositionBorehole/well accessoriesCross linkerAqueous solubility

The invention provides a double-film controlled-release corrosion and scale inhibition capsule and a preparation method thereof. The preparation method comprises the following steps: uniformly mixinga corrosion and scale inhibition integrated agent, an inorganic carrier and a density weighting agent, kneading the mixture, and drying the mixture to obtain a loading integrated agent; kneading the integrated loading agent, an aqueous solution of a coating agent A and an aqueous solution of a cross-linking agent, then preparing a particle ball by adopting an extrusion method, and drying the particle ball to form a capsule core; and spraying and coating the capsule core with an aqueous solution of a coating agent B and an aqueous solution of a cross-linking agent to form a first layer of film,then spraying the aqueous solution of the coating agent A and the aqueous solution of the cross-linking agent to form a second layer of film, and performing drying to obtain the slow-release corrosion and scale inhibitor capsule for oil wells. The capsule anti-scaling particle filling process is simple, a tubular column is not moved, and the capsule anti-scaling particle can be put into a wellbore pocket through an oil sleeve annulus at a time. Meanwhile, the density of the added weighting agent is larger than that of water, the weighting agent does not flow away along with wellbore liquid soas to guarantee rapid sinking of the capsule, and the purpose of slow release is achieved by slowly dissolving the water-soluble capsule shell into water.

Owner:PETROCHINA CO LTD

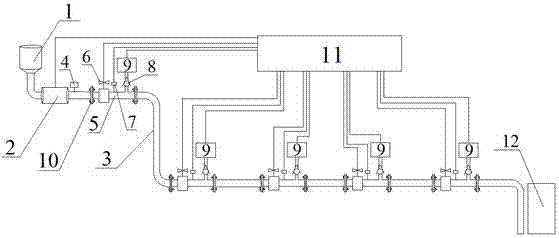

Device and method for conveying pastes by utilizing high pressure air

ActiveCN107191222ASolve the complex cleaning processIncrease profitMaterial fill-upEngineeringOperability

The invention discloses a device and method for conveying pastes by utilizing high pressure air. The device for conveying the pastes by utilizing the high pressure air comprises a material slurry hopper, a filling pump, high pressure air conveying devices, a flowmeter and a PLC controller. The material slurry hopper is connected with a filling pipeline. The filling pump is arranged below the material slurry hopper. The flowmeter is arranged on the filling pipeline in the outlet direction of the filling pump. The outlet end of the filling pump is connected with one high pressure air conveying device. The filling pipeline is provided with one or more high pressure air conveying devices. According to the device for conveying the pastes by utilizing the high pressure air, the high pressure air is used as the thrust, so that the pastes are always kept in the plug-flow state in the pipeline in the conveying process, and relative movement of the interior of a column core does not happen; and through the arrangement of the multiple high pressure air conveying devices in the filling pipeline, the pastes in the pipeline are pushed and sent to the filling working surface in a relay mode. The method for conveying the pastes by utilizing the high pressure air is simple and easy to implement and high in operability, the filling technology is more simplified, and the conveying of mine filling material slurry is achieved well.

Owner:TAIYUAN UNIV OF TECH

Movable type eight-stuffing transporting system of Chinese style pastry making machine

The invention discloses a movable type eight-stuffing transporting system of a Chinese style pastry making machine. The system comprises a stuffing base plate, a stuffing face plate and stuffing transporting assemblies; the stuffing face plate is rotatably arranged on the stuffing base plate; the stuffing transporting assemblies are used for transporting the stuffing, and eight stuffing transporting assemblies are distributed on the stuffing face plate in circumferential distribution. The stuffing face plate of the movable type eight-stuffing transporting system of the Chinese style pastry making machine is rotatably arranged on the stuffing base plate for facilitating stuffing change, and the stuffing face plate is pushed to drive the stuffing transporting assemblies thereon to rotate to designated positions, so that one stuffing transporting assembly is connected to a stuffing tube of the Chinese style pastry making machine, convenience of stuffing change is improved, and the stuffing changing process is simple and convenient; at the same time, a horizontal stuffing auger structure is used, in order to improve effect for stirring the stuffing.

Owner:WUHU BREAKFAST 4050 RIVERSIDE ENG CO LTD

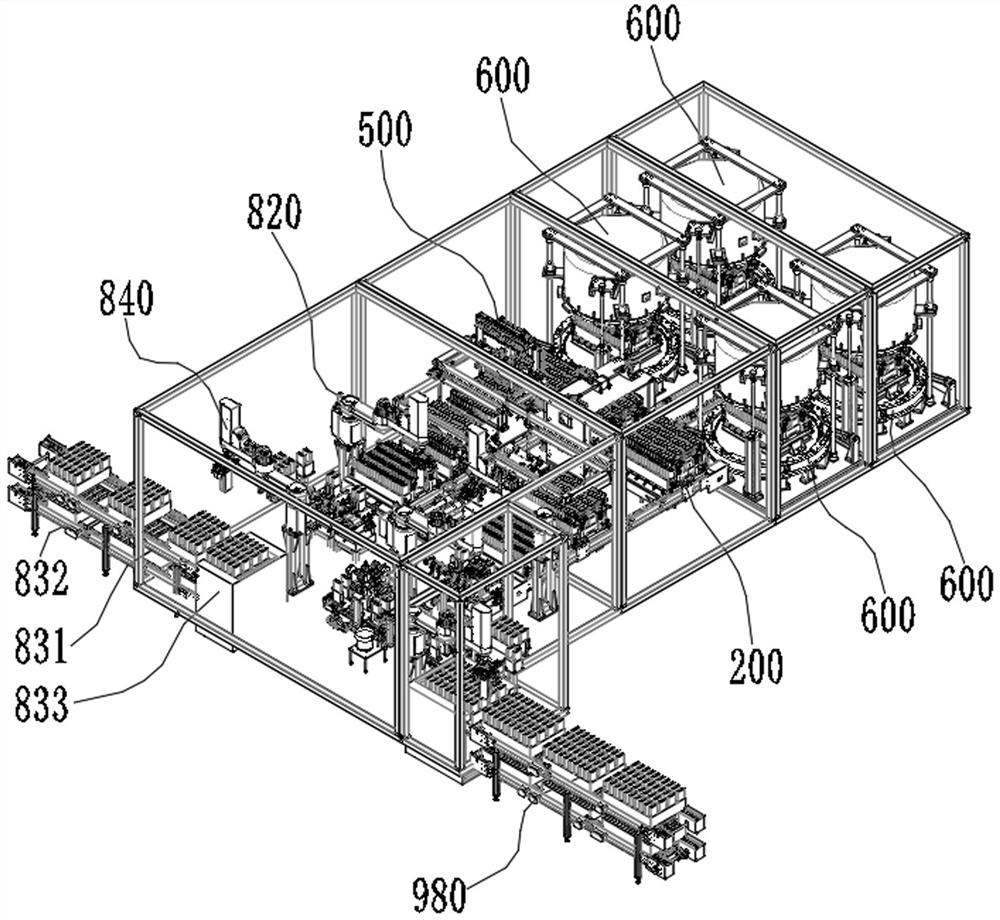

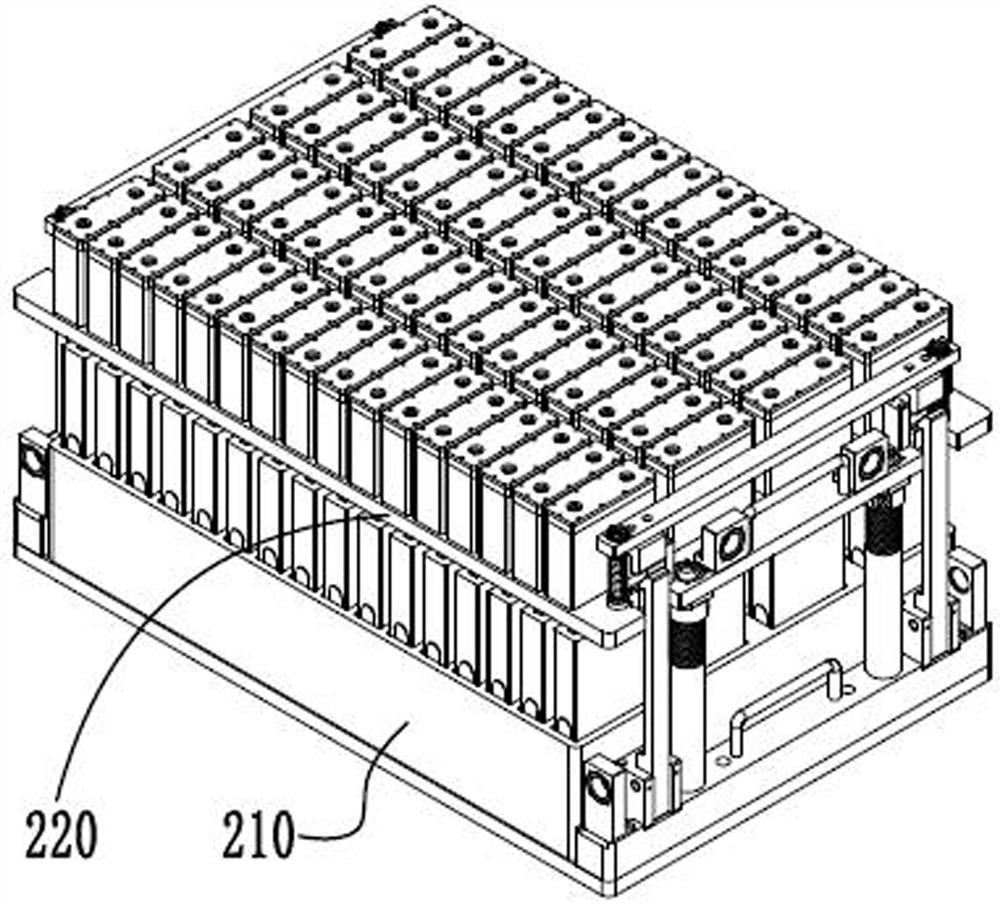

Liquid injection machine

ActiveCN114792870AShorten the manufacturing cycleReduce manufacturing costFinal product manufactureCell component detailsElectrolytic agentElectrical battery

The invention belongs to the technical field of battery liquid injection, and discloses a liquid injection machine which comprises a material conveying line, liquid injection clamps, a mold separating and closing device, a liquid injection device, a bell jar device and a carrying device, the material conveying line comprises a first conveying mechanism and a second conveying mechanism, and the liquid injection clamps comprise the first liquid injection clamp and the second liquid injection clamp. And when the first liquid injection clamp and the second liquid injection clamp are oppositely closed, the liquid injection cup is communicated with the battery, and the mold separating and closing device can oppositely close or separate the first liquid injection clamp and the second liquid injection clamp. According to the liquid injection machine provided by the invention, the first liquid injection clamp and the second liquid injection clamp are subjected to mold closing, liquid injection is performed through the liquid injection device, after liquid injection is completed, the liquid injection clamps are transferred to the bell jar device through the carrying device for standing, in the process that the electrolyte is absorbed into the battery, the electrolyte in the liquid injection cup can be supplemented into the battery, secondary liquid injection of the battery is not needed, and the production efficiency is improved. And the liquid injection process can be effectively simplified, the manufacturing period of the battery is shortened, and the production cost of the battery is reduced.

Owner:南通科瑞恩智能装备有限公司

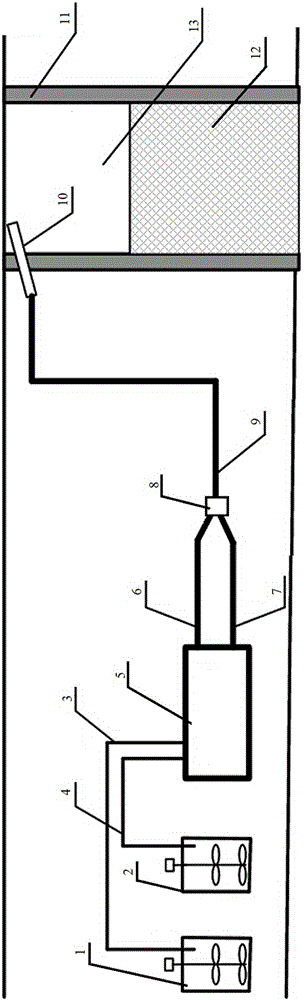

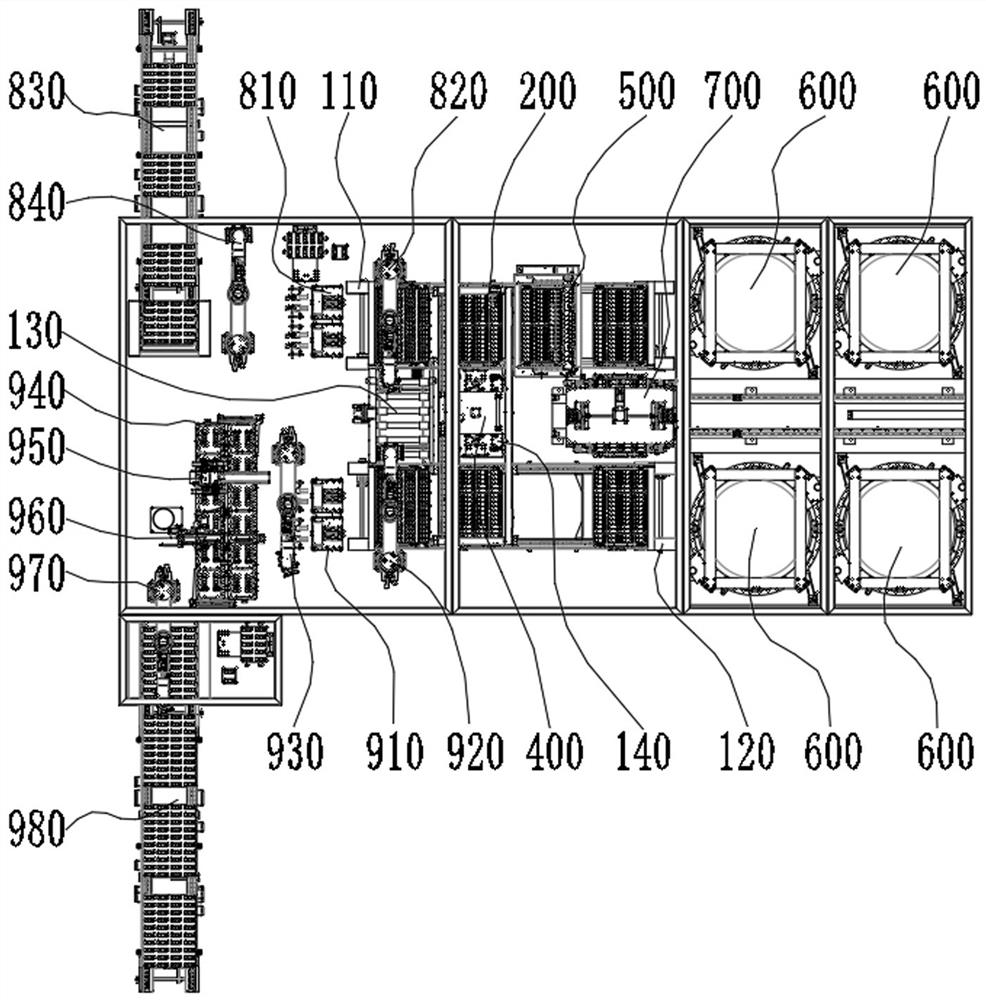

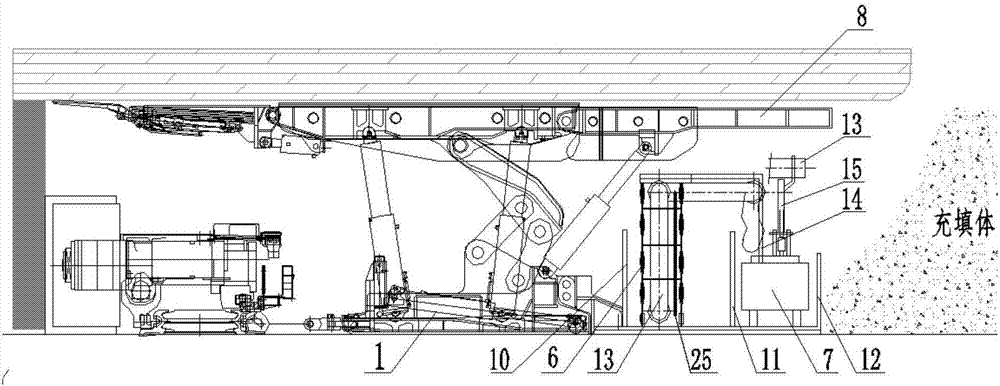

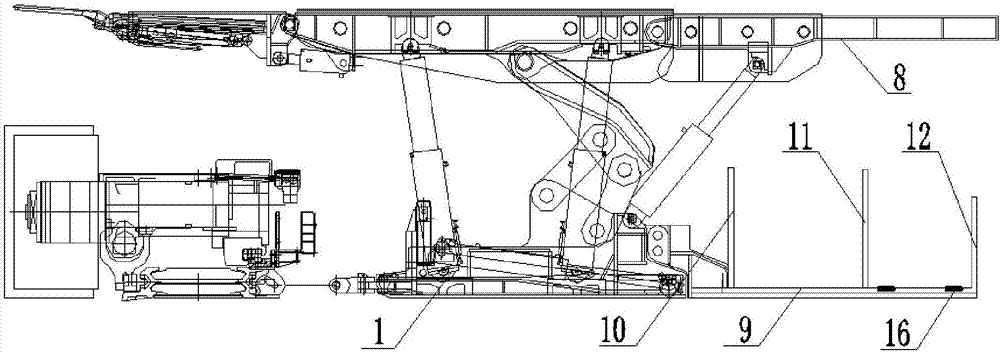

Coal-mine underground intelligent jetting backfill mining system

ActiveCN107131000ACapable of bearing pressureSimplify the filling processMaterial fill-upCycloneSlurry

The invention discloses a coal-mine underground intelligent jetting backfill mining system, which comprises a filling pump, a distributing pipe, a filling support, a steel tank chain, an intelligent self-propelled trolley, a traction arm, a manipulator a compressed air hose, an electric gate valve, a cyclone, an accelerator pump, an accelerator supply hose and the like. During operation, coal gangue, coal ash, cement and water are mixed according to proportions, so that slurry with high mass concentration is produced, and the filling pump is utilized to pump the slurry into a gob behind the support via a steel braided tube in the steel tank chain; a moving steel tank chain part is connected to the traction arm on the intelligent self-propelled trolley, a fixed distributing pipe outlet plate is connected to a fixed manipulator plate of the manipulator, both the intelligent self-propelled trolley and the steel tank chain run on a bottom bearing plate of the support, the steel tank chain can be carried by the intelligent self-propelled trolley to move to the left and the right, and the end of the distributing pipe can be carried by the manipulator to move up and down and swing within a small amplitude. Full-section jetting backfill in the gob is realized.

Owner:中煤能源研究院有限责任公司

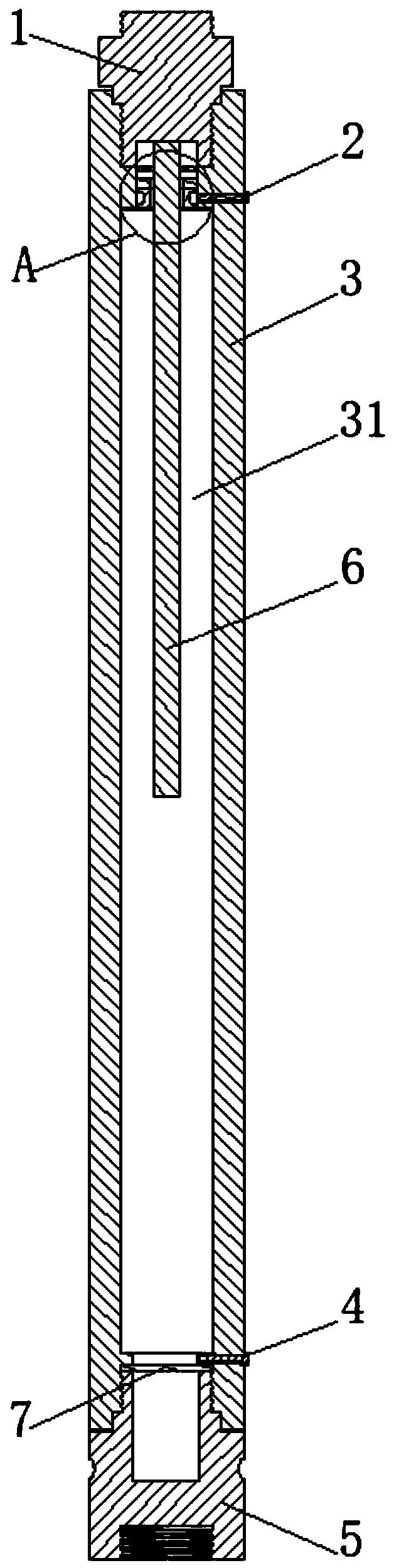

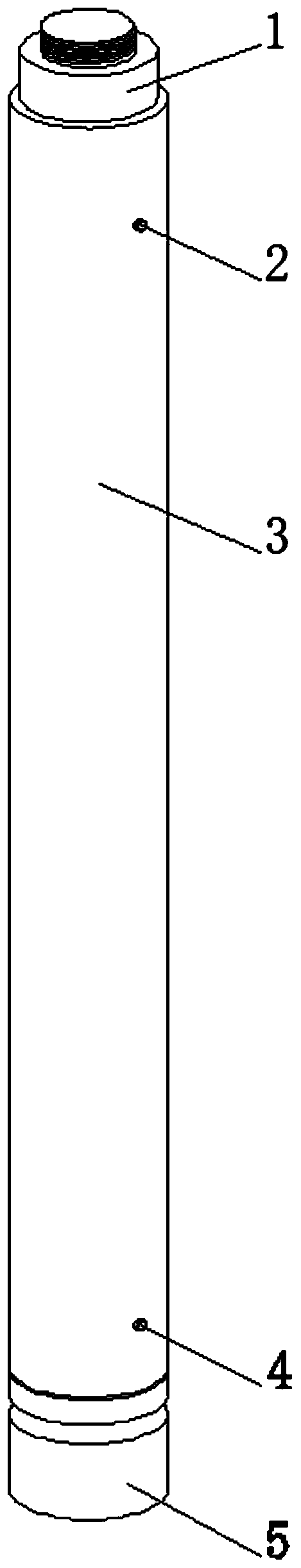

Carbon dioxide fracturing device

ActiveCN111396048AReduce airSimplify the filling processDisloding machinesBlasting cartridgesThermal dilatationEngineering

The invention relates to the field of carbon dioxide blasting, and particularly discloses a carbon dioxide fracturing device. The carbon dioxide fracturing device comprises a pipe body, a heating device arranged in the pipe body, a first connecting end arranged at the top end of the pipe body and a second connecting end arranged at the bottom end of the pipe body, wherein a cavity communicating with the first connecting end and the second connecting end is formed in the pipe body, a supporting piece is arranged at the top end of the pipe body, a thermal expansion material is arranged on the supporting piece, a sealing piece is arranged at the top end of the thermal expansion material, and the second connecting end communicates with a liquid carbon dioxide filling device. According to the carbon dioxide fracturing device, the cavity is filled with liquid carbon dioxide, and after the liquid carbon dioxide fills upwards from the bottom end of the cavity and is close to the first connecting end, and the thermal expansion material can be shrunk, so that the sealing piece blocks one end of the first connecting end, the filling process is simplified, air in the cavity is remarkably reduced, and the filling quality is improved.

Owner:广东中人工程集团有限公司

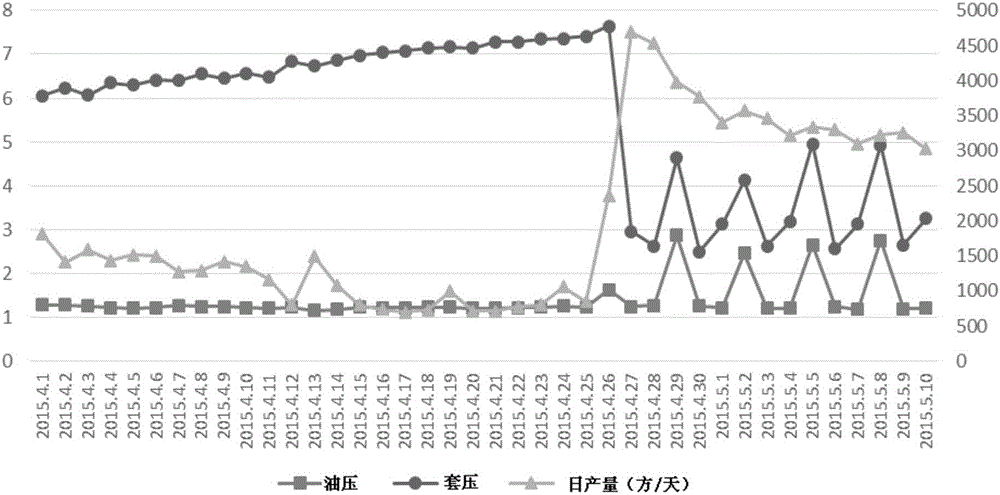

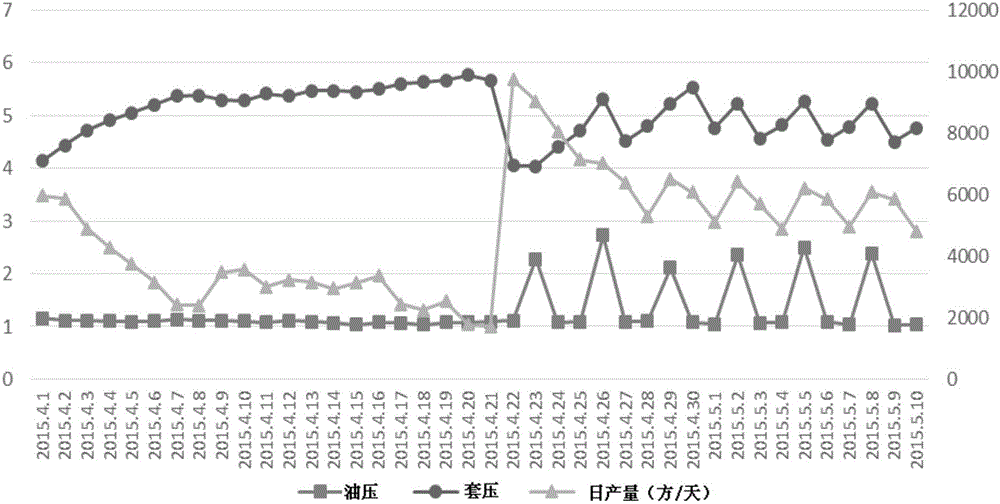

Mine sleeve repairing method

The invention discloses a mine sleeve repairing method. The repairing method comprises the steps that (1) a repairing pipe with the appropriate length is selected according to a damage position range of the mine sleeve; (2) the head end of a drill rod and the head end of the repairing pipe are detachably connected , and a through hole in the extending direction of the drill rod is formed in the drill rod; (3) the tail end of the repairing pipe is inserted in a pipeline of the mine sleeve, the position of the repairing pipe is adjusted to enable the repairing pipe to cover the damage position range, and the outer wall of the tail end of the repairing pipe is fixedly connected with the inner wall of the mine sleeve; and (4) a reinforcement agent is injected through the through hole until a gap between the outer wall of the repairing pipe and the inner wall of the mine sleeve is fully filled with the reinforcement agent, and after the reinforcement agent is solidified, a reinforced layer is formed. By adopting the mine sleeve repairing method, the repairing cost of the mine sleeve is effectively reduced, the conduction period is shortened significantly, and meanwhile, a repairing mode and a well cementing mode are simplified.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com