Power type white LED based on fluorescence lens

A power type, LED chip technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems such as the packaging method does not break through the LED chip, the phosphor crystal structure is complex, and the promotion and application are hindered, and the thermal stability is superior. , Improve the luminous efficiency and thermal stability, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

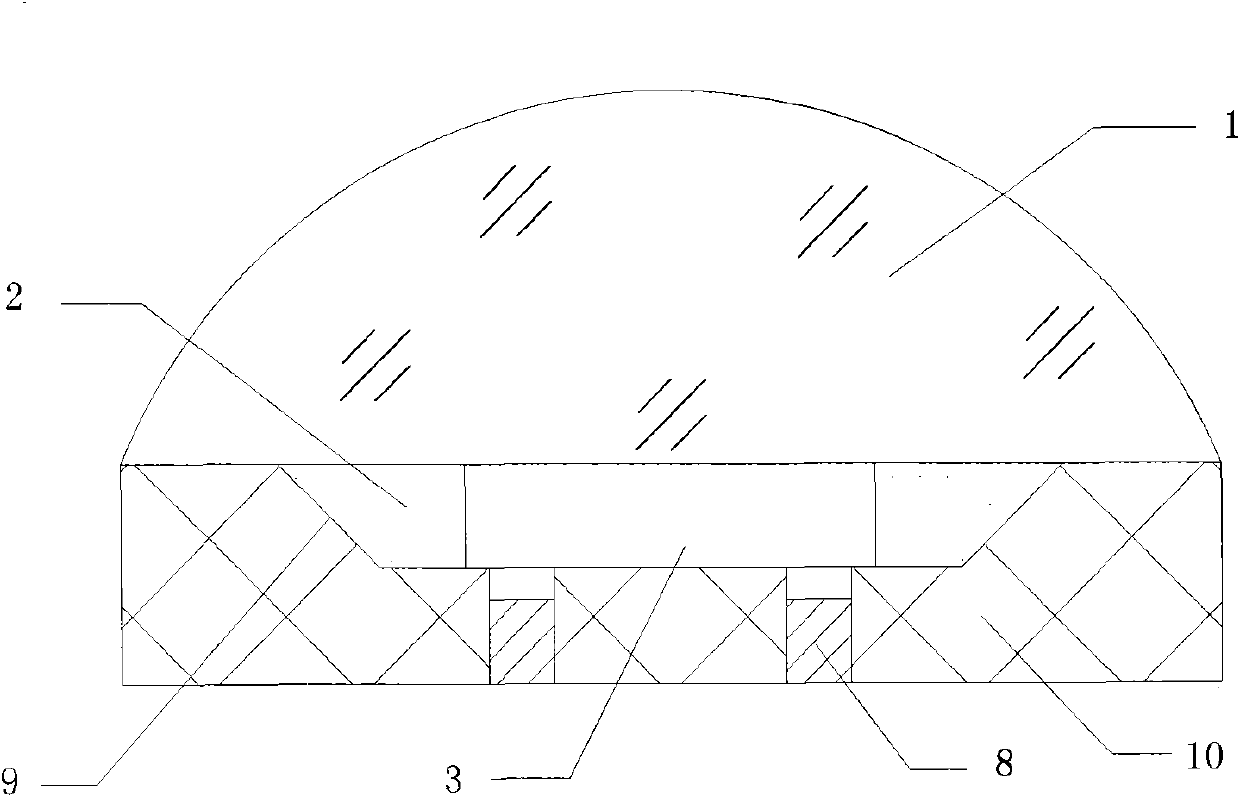

[0012] see figure 1 , in the traditional white LED packaging structure, the heat generated by the blue LED chip 7 during operation will have a greater impact on the phosphor-doped LED optical epoxy resin adhesive layer 6 . Under the action of heat, the phosphor in the adhesive layer 6 is prone to adverse changes, resulting in low overall thermal stability of the white LED, prone to problems such as color coordinate drift, luminous efficiency, and luminous flux decline.

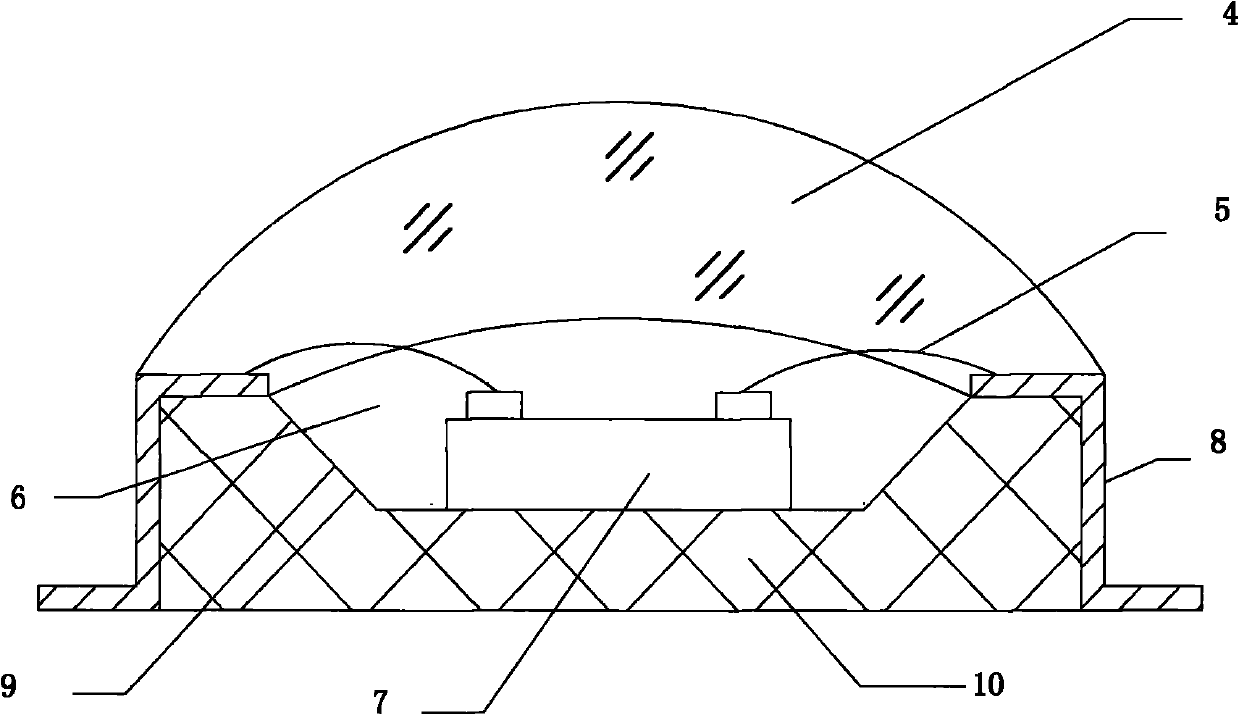

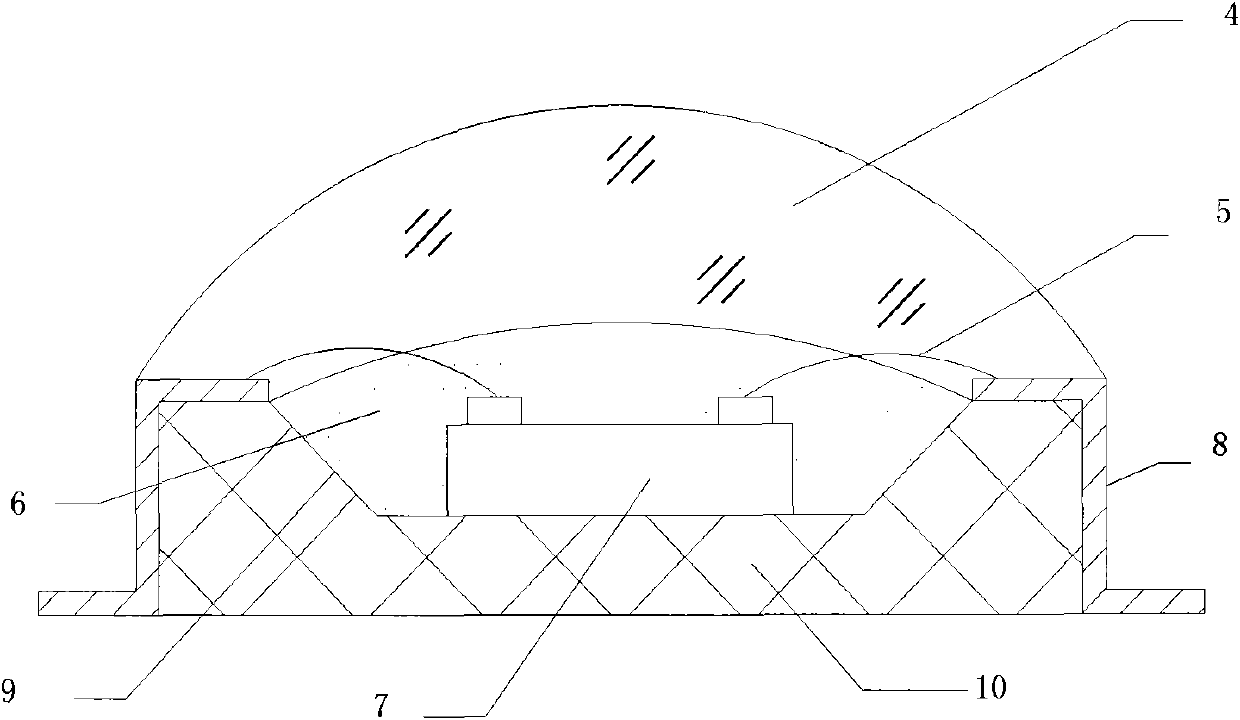

[0013] In order to solve the problem of low thermal stability of traditional white LEDs, the present invention proposes an innovative white LED packaging structure. see figure 2 , in the present invention, the LED packaging structure includes LED chips 3, electrodes 8, reflective cups 9, and heat sinks 10 in flip-chip packaging. The fluorescent lens 1 is used as a three-in-one functional device with fluorescent conversion, optical light distribution, and packaging protection; the reflector 9 and the flip-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com