Coal-mine underground intelligent jetting backfill mining system

A coal mine and equipment technology, applied in the field of coal mine intelligent jet filling mining equipment, can solve the problems of increasing the risk of dust explosion, large dust, and small processing capacity, and achieve the goal of simplifying the filling process, prolonging the service life and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but this does not mean to limit the protection scope of the present invention.

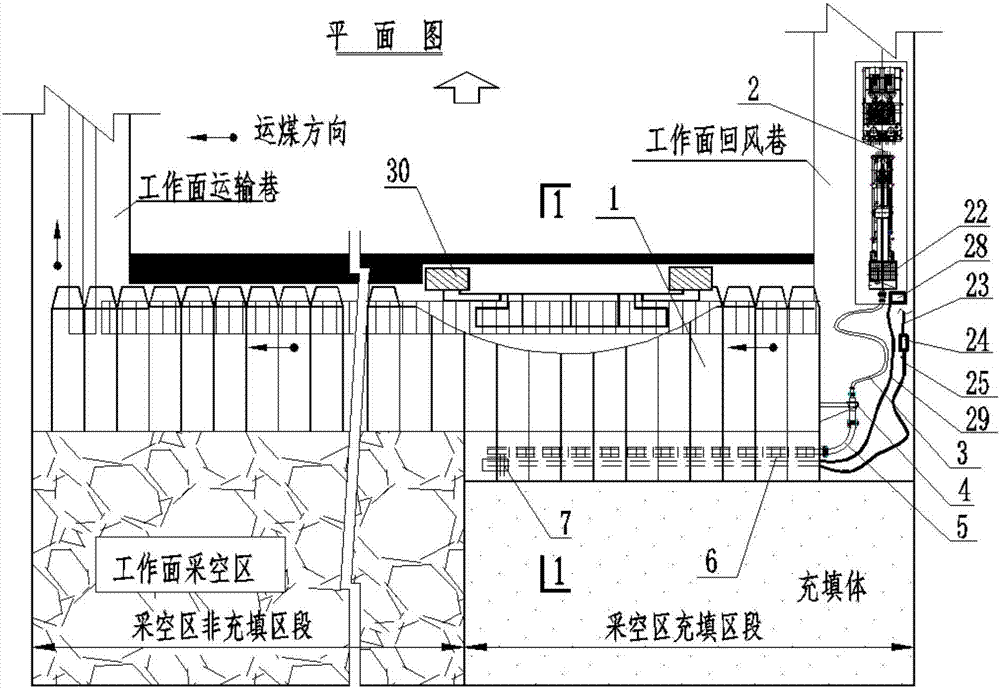

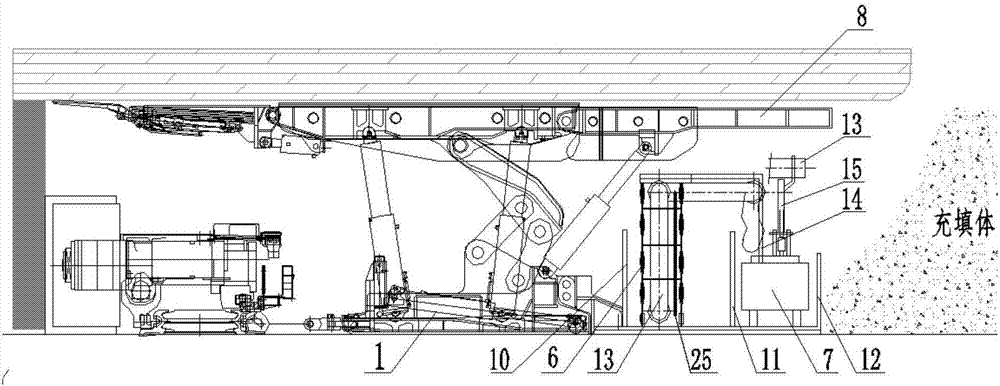

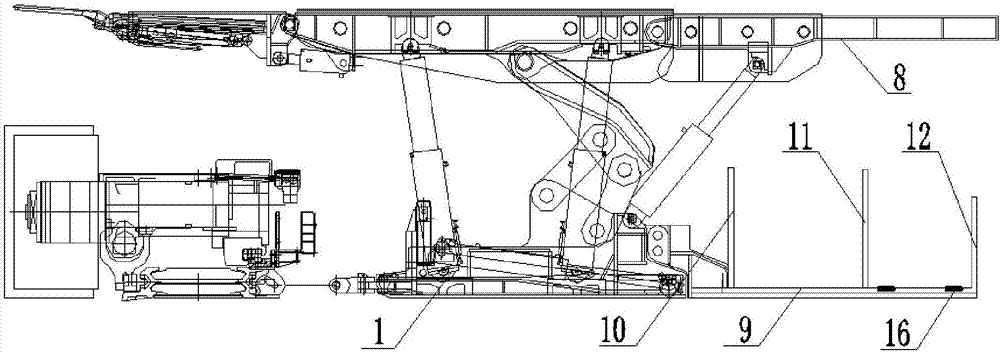

[0039] Such as figure 1 , Figure 4As shown, the filling pump 2 is set in the return air lane of the working face, about 100m away from the end of the working face; the outlet of the filling pump 2 is connected with the steel braided pipe 3, and the steel braided pipe 3 can maintain a certain bending under high pressure conditions; the steel braided pipe 3 The end of the pipe 3 is fixed on the first group of filling support 1 in the return air lane of the working face through the straight pipe seat 4, and the straight pipe seat 4 is connected to the 90° wear-resistant elbow 5 through the flange; the 90° wear-resistant elbow 5 is connected to the distribution pipe 13 connected. During work, the prepared slurry is sent into the receiving hopper 22 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com