A liquid pipeline noise reduction system based on underwater wide-frequency sound-insulating metal-based metamaterials

A technology of sound insulation material and liquid pipeline, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of low low frequency noise suppression efficiency and low impedance, and achieve low impedance, easy processing, basic simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

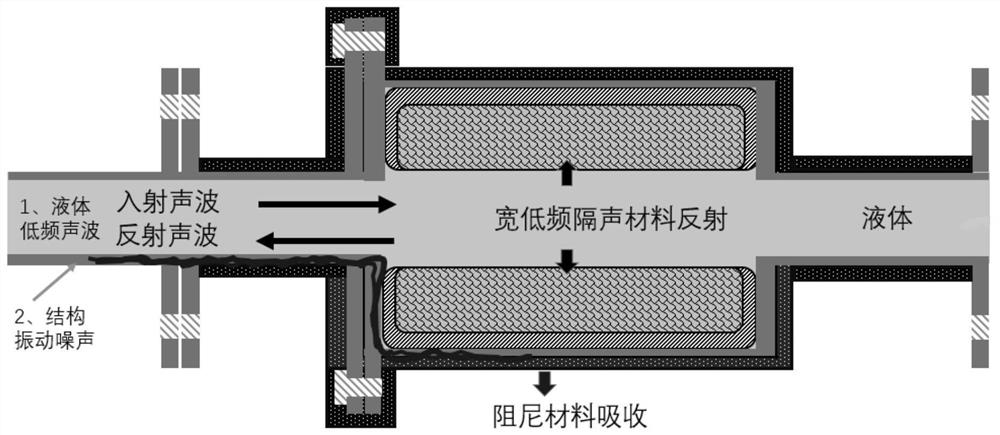

[0056] A liquid pipeline noise reduction system based on underwater wide-frequency sound-insulating metal-based metamaterials. Its sound-absorbing effect is realized based on wide-frequency and low-frequency underwater sound insulation materials: relying on the principle of impedance mismatch, the material has extremely low impedance. , it has better effect for wide and low frequency underwater sound.

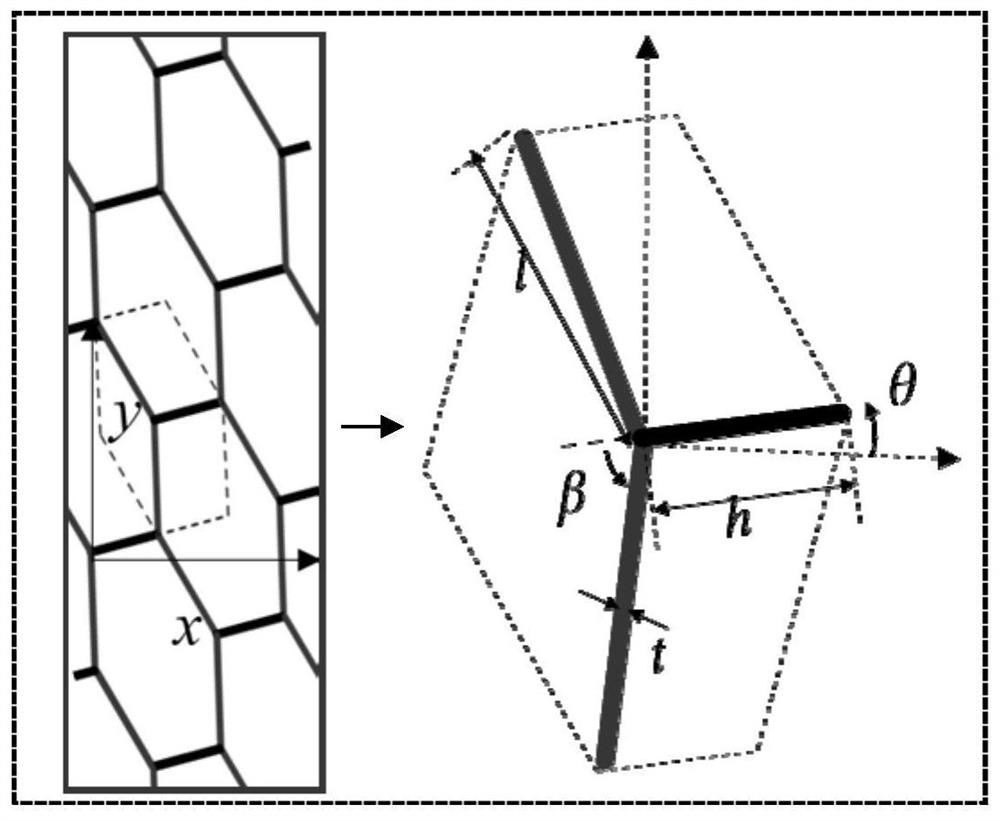

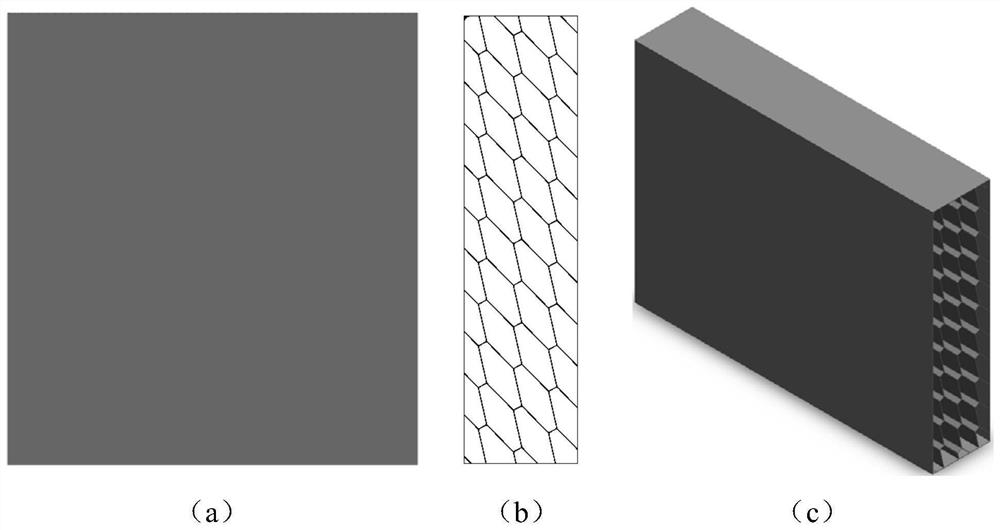

[0057] like Figure 3-4 and Figure 6-7 As shown, the overall structure of the liquid pipeline muffler system is divided into five parts, which are respectively a cylindrical through pipe 8 and a connecting flange 5 at the head end of the muffler system connected with the upper water inlet pipe, which are connected with the lower water outlet pipe. A cylindrical through pipe 9 and a connecting flange 5 at the end of the sound elimination system, and a square main body structure 3 for sound elimination. The square main body structure 3 contains a cavity, and the inside of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com