Liquid pipeline silencing system based on underwater wide-low-frequency sound insulation metal-based metamaterial design

A technology for liquid pipelines and sound insulation materials, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipes, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

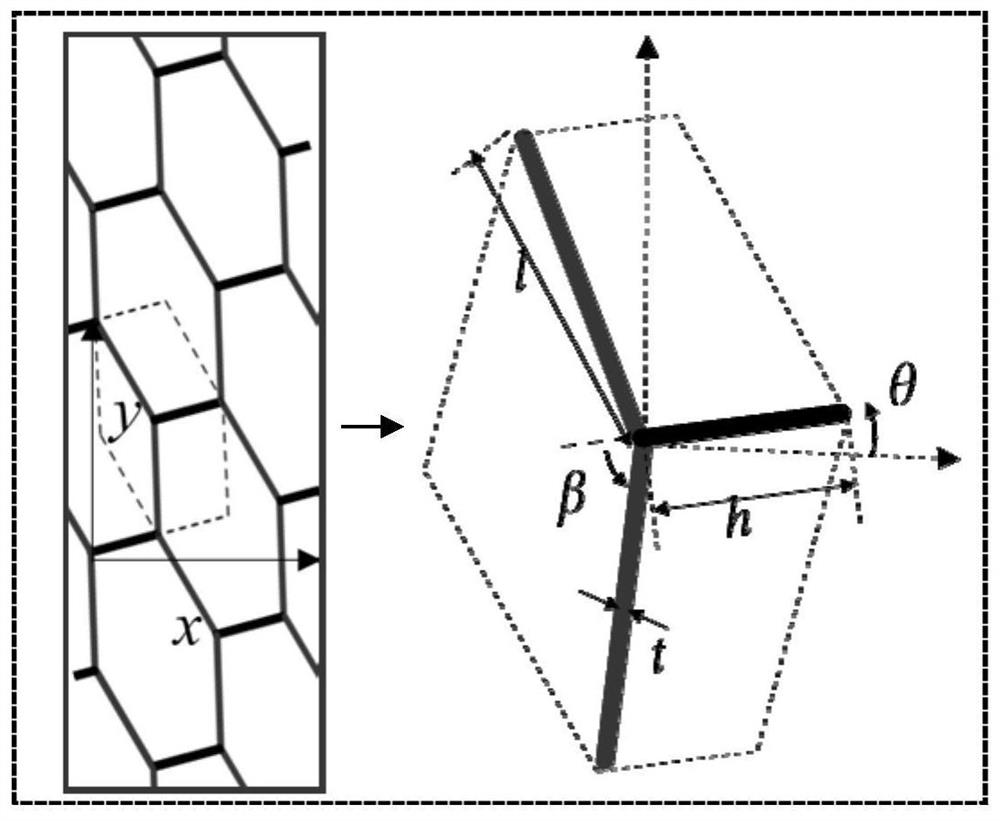

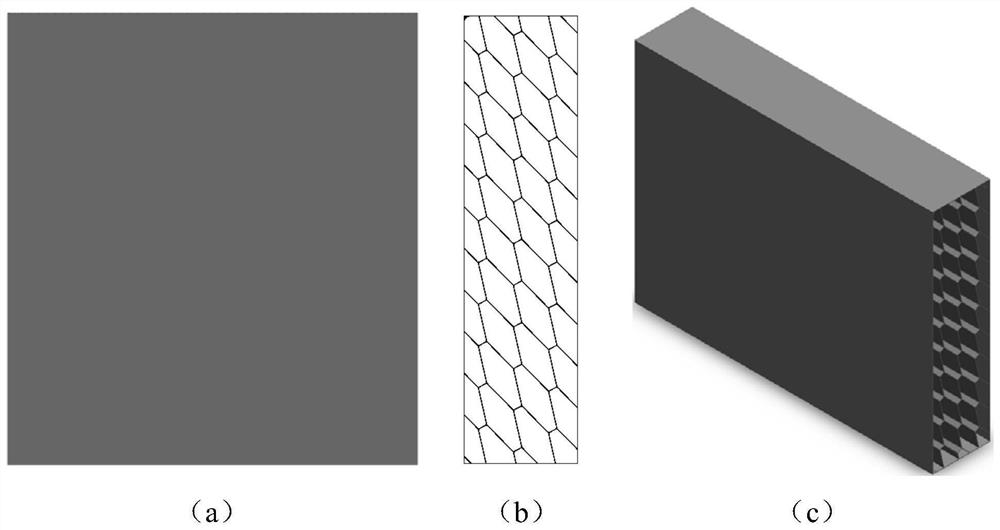

[0056] A liquid pipeline noise reduction system designed based on underwater wide and low frequency sound insulation metal-based metamaterials. Its noise reduction effect is realized based on wide and low frequency underwater sound insulation materials: relying on the principle of impedance mismatch, the material has extremely low impedance , it has a better effect on wide and low frequency underwater sound.

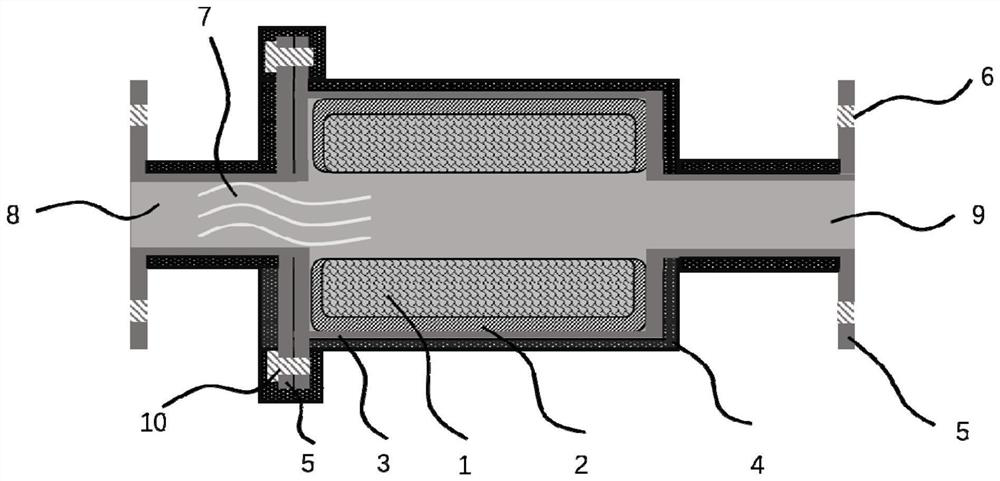

[0057] Such as Figure 3-4 and Figure 6-7 As shown, the overall structure of the liquid pipeline muffler system is divided into five parts, which are respectively the inlet cylinder tube 8 at the head end of the muffler system connected to the upper water inlet pipe and the connecting flange 5, which are connected to the lower outlet pipe The outlet cylindrical through pipe 9 and the connecting flange 5 at the end of the muffler system, and the square main structure 3 for muffler. The square main structure 3 contains a cavity inside, and the inside of the cavity is cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com