Multi-stage series gas-liquid flow equalizer

A flow equalizer and gas-liquid technology, which is applied in the field of multi-stage series gas-liquid flow equalizers, can solve the problems of low working efficiency, shortened life of the heat exchanger, and uneven distribution of the coiled heat exchanger, and achieve structural Simple, space-saving, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

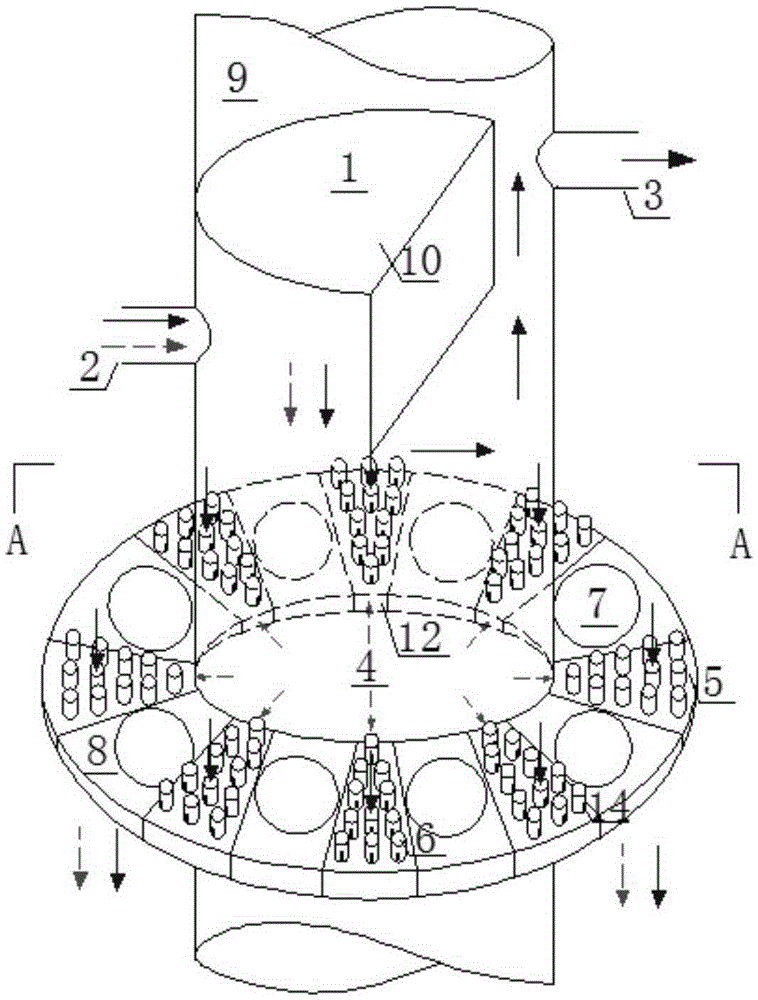

[0032] Such as figure 1 As shown, the multi-stage series gas-liquid two-phase flow equalizer provided by the present invention includes a core tube 9, and a gas-liquid two-phase inlet 2 and a gas-phase outlet 3 are arranged on the side wall of the core tube 9, And the gas-liquid two-phase inlet 2 and the gas-phase outlet 3 are arranged oppositely; a baffle 10 is arranged in the core tube 9, and the baffle 10 is arranged between the gas-liquid two-phase inlet 2 and the gas-phase outlet 3; The flow plate 10 is composed of two horizontal and vertical plates perpendicular to each other, forming a separator 1 in the core tube 9 .

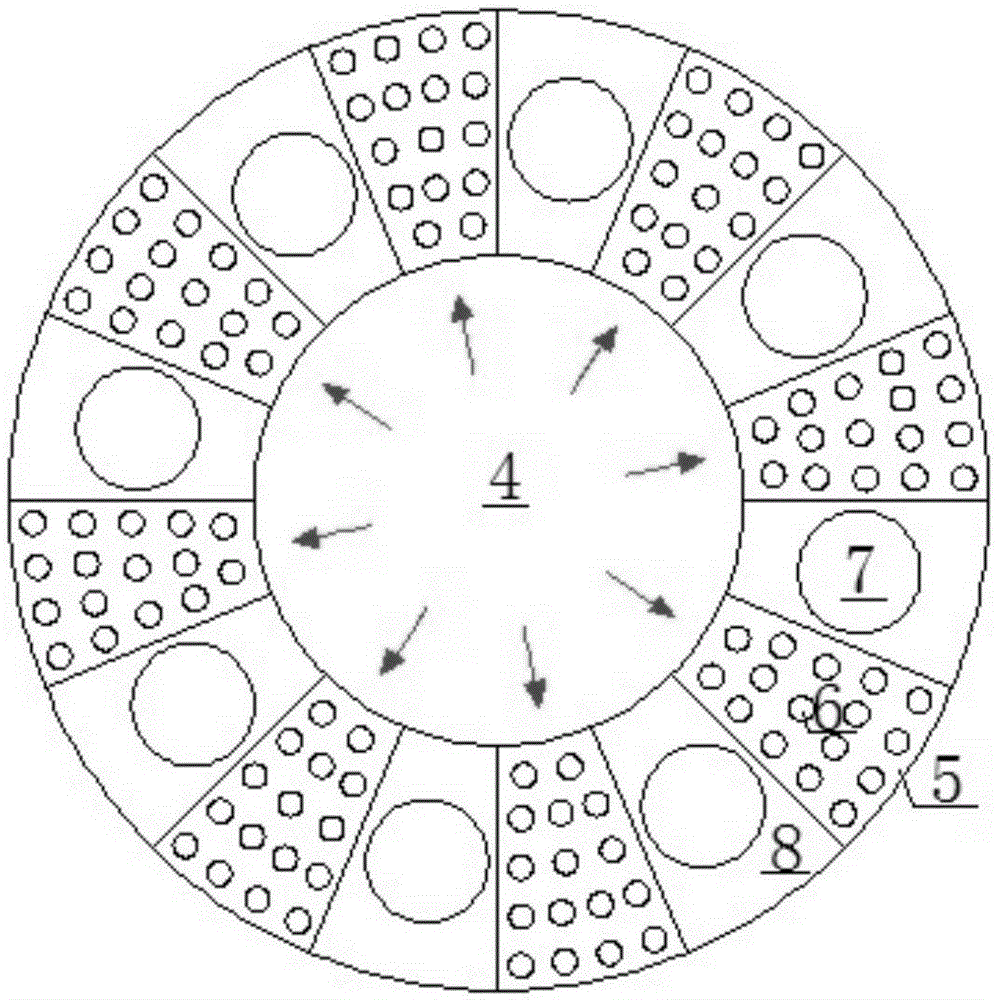

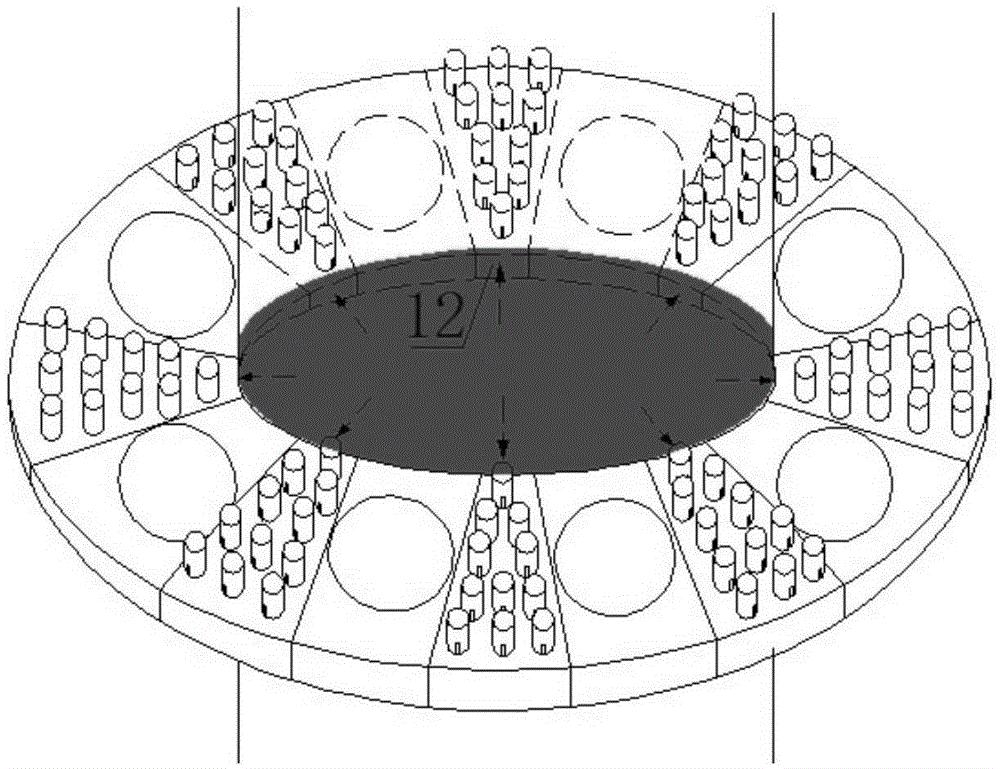

[0033] Such as Figure 1 ~ Figure 3 As shown, a disc 4 is arranged in the cavity of the core tube 9 , the disc 4 is arranged along the radial direction of the core tube 9 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com