Patents

Literature

133 results about "Flour dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filter material and use

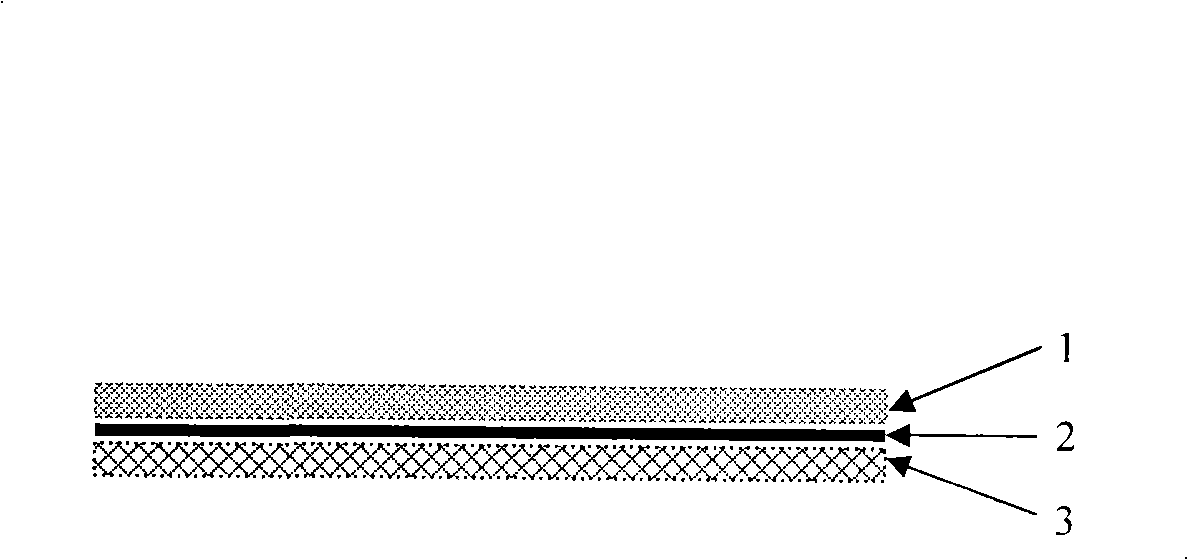

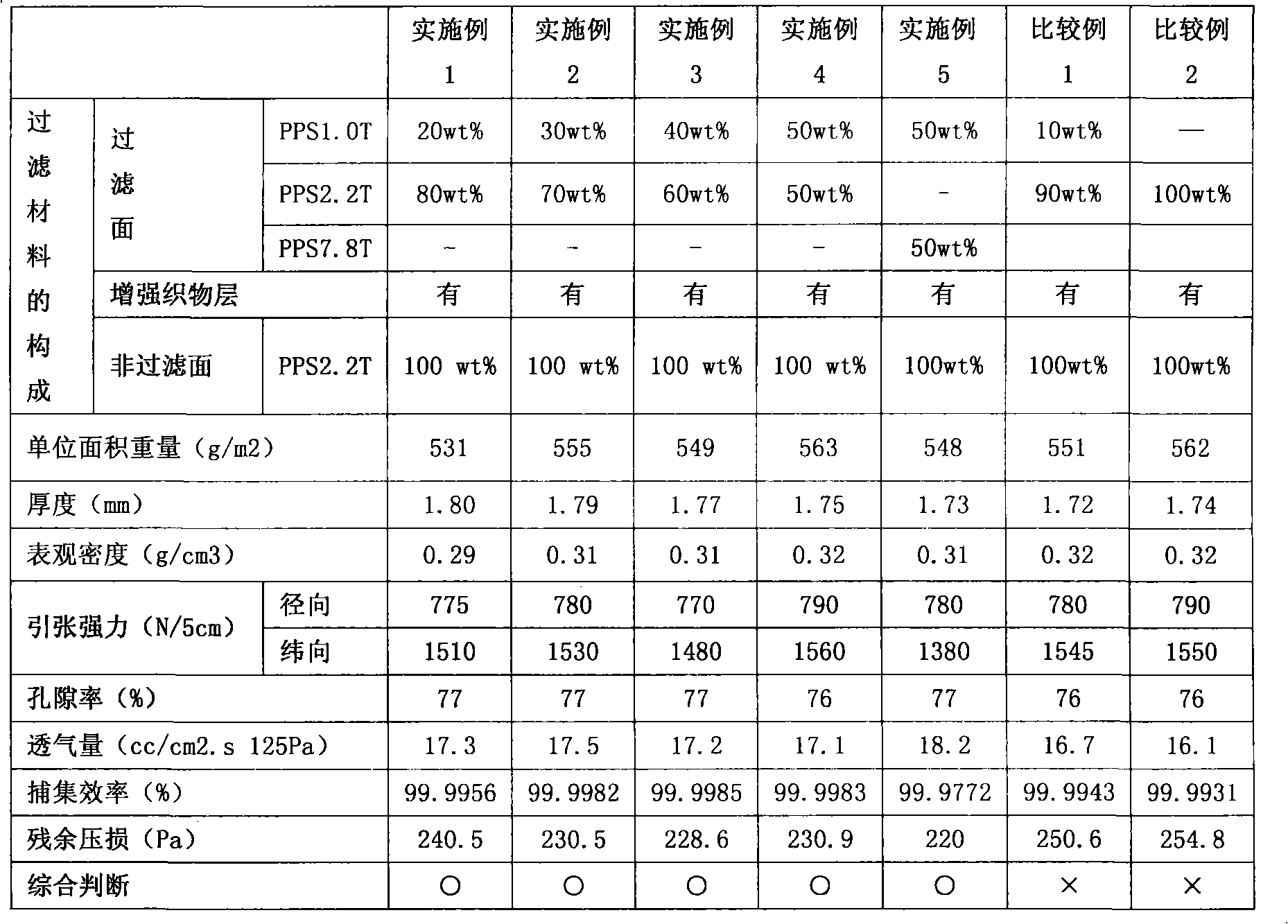

InactiveCN101406780AImprove capture efficiencyAvoid damageDispersed particle filtrationLayered productsFiberSurface layer

The invention discloses a filter material and application thereof. The filter material has a three-layer structure, namely, a filter surface layer, an unfilterable surface layer and a middle fabric reinforced layer, wherein the filter surface layer is a fiber net formed by mixing 10 to 90 weight percent of heat resistant fiber of which the average diameter is below 10 mu m, and 10 to 90 weight percent of the heat resistant fiber of which is the average diameter between 10 and 20 mu m; the unfilterable surface layer is the fiber net formed by the heat resistant fiber of which the average diameter is between 10 and 20 mu m; and the middle layer is a fabric reinforced layer. The filter material has the advantages of high dust collecting efficiency, small raise of pressure loss after the dust on the surface of the filter material is removed, and prolonged service life of the filter material because damage of the filter material caused by blowing times of compressed air is reduced due to long dust cleaning period. The filter material can be used for preparing filter bags and the like.

Owner:TORAY IND INC

Method for preparation of polytetrafluorethylene microporous film for the processing of high-temperature fume and flour dust

InactiveCN101081356ASimple processReduce manufacturing costSemi-permeable membranesDispersed particle separationPolymer scienceBurn treatment

The present invention discloses one kind of microporous teflon film for treating high temperature fume and dust and its preparation process. The preparation process includes mixing powdered teflon resin and powdered catalyst, adding liquid lubricant to the mixture, extruding, rolling, longitudinally stretching, transversely stretching, heat setting and other steps. The microporous teflon film for treating high temperature fume and dust has simple preparation process and low cost. It has pore size of 0.5-5 micron and dioxins eliminating rate at 200 deg.c as high as 95-98 %. It may be applied widely for high temperature tail gas treatment in refuse burning treatment plant, refuse burning power plant, coal burning power plant, cement mill, etc.

Owner:ZHEJIANG SCI-TECH UNIV

Aerogel composite material with surface subjected to dust-free treatment and preparation method

The invention relates to an aerogel composite material with a surface subjected to dust-free treatment and a preparation method thereof, in particular to a method using an aerogel felt, an aerogel plate, an aerogel cylinder and an aerogel shaped piece as the base material and coating the substrate surface with compact coating so as to avoid shedding of aerogel surface dust. The method is simple and practicable, can effectively solve the problem of easy generation of dust on the aerogel surface, significantly improves the working environment, and can satisfy the use condition of aerogel in clean space. By adopting different ratios, a rigid coating and a flexible coating can be obtained, high temperature and low temperature application can also be achieved, compound proportioning of an inorganic film-forming agent and an organic film-forming agent also can give consideration to flexibility and fire resistance, and significantly improves the adaptability of the coating paste to different types of aerogel materials. The aerogel subjected to dust-free treatment can be applied to heat preservation of various industrial equipment and pipeline, and also can be applied to thermal insulation of high speed rail, vessels, electronics and pharmaceutical workshops and building field.

Owner:浙江圣润纳米科技有限公司

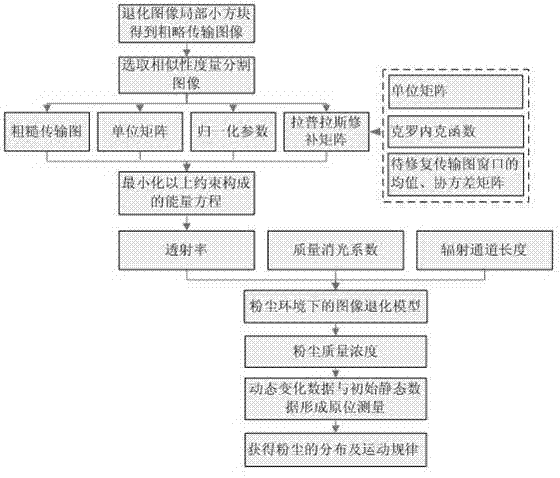

Monitoring and measuring method for dust concentration in working faces in underground coal mine

ActiveCN102353622AOvercoming airspace sampling flawsQuick measurementParticle suspension analysisMining engineeringRadiation length

The invention provides a monitoring and measuring method for dust concentration in working faces in an underground coal mine, and the method overcomes the problems of a slow speed in sampling dust, complicated sampling and incapability of satisfying requirements of safe production on-line monitoring in the prior art. The monitoring and measuring method comprises the following steps: (1) acquiringa rough transmission diagram having a blocking effect based on a degraded image in a working face dust environment; (2) carrying out refined processing on the rough transmission diagram so as to obtain transmissivity corresponding to each pixel point in the diagram; (3) calculating an absorption factor and a scattering factors, calculating an absorption coefficient and a scattering coefficient, and calculating an extinction coefficient; (4) measuring the length of a radiation channel; (5) calculating mass concentration of dust and a changing process of dust concentration based on the transmissivity, the extinction coefficient and radiation length. The beneficial effects of the invention are as follows: rapid measuring is realized; the requirement for real time dynamic measurement is met; the method is of important significance for implementation of corresponding dustproof measures in the underground coal mine. Appropriate dedusting methods can be employed according to different environments when distribution and motion rules of dust in coal mining working faces are mastered.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

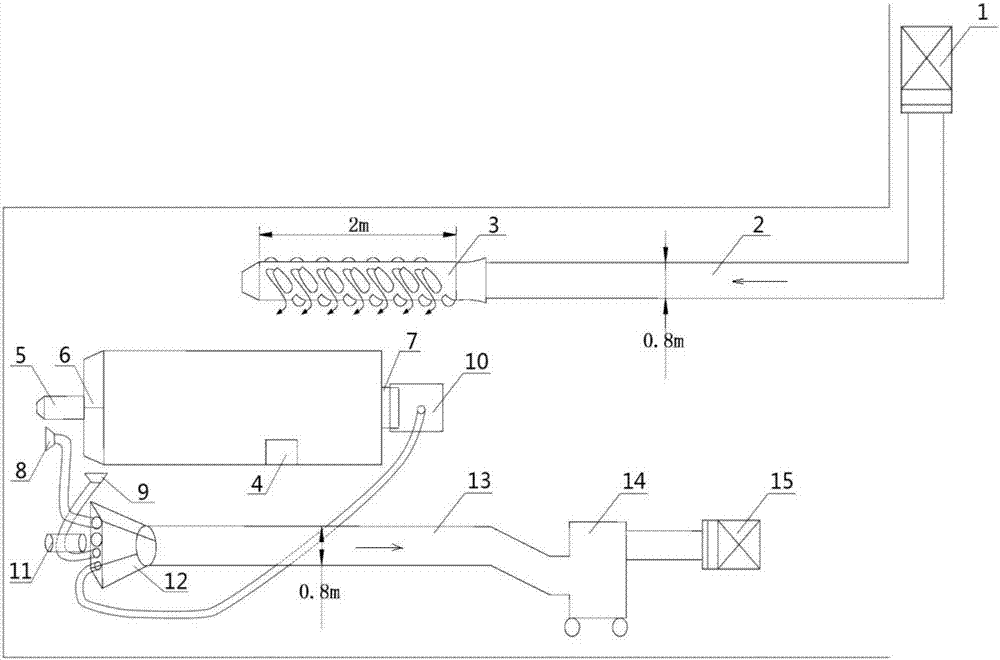

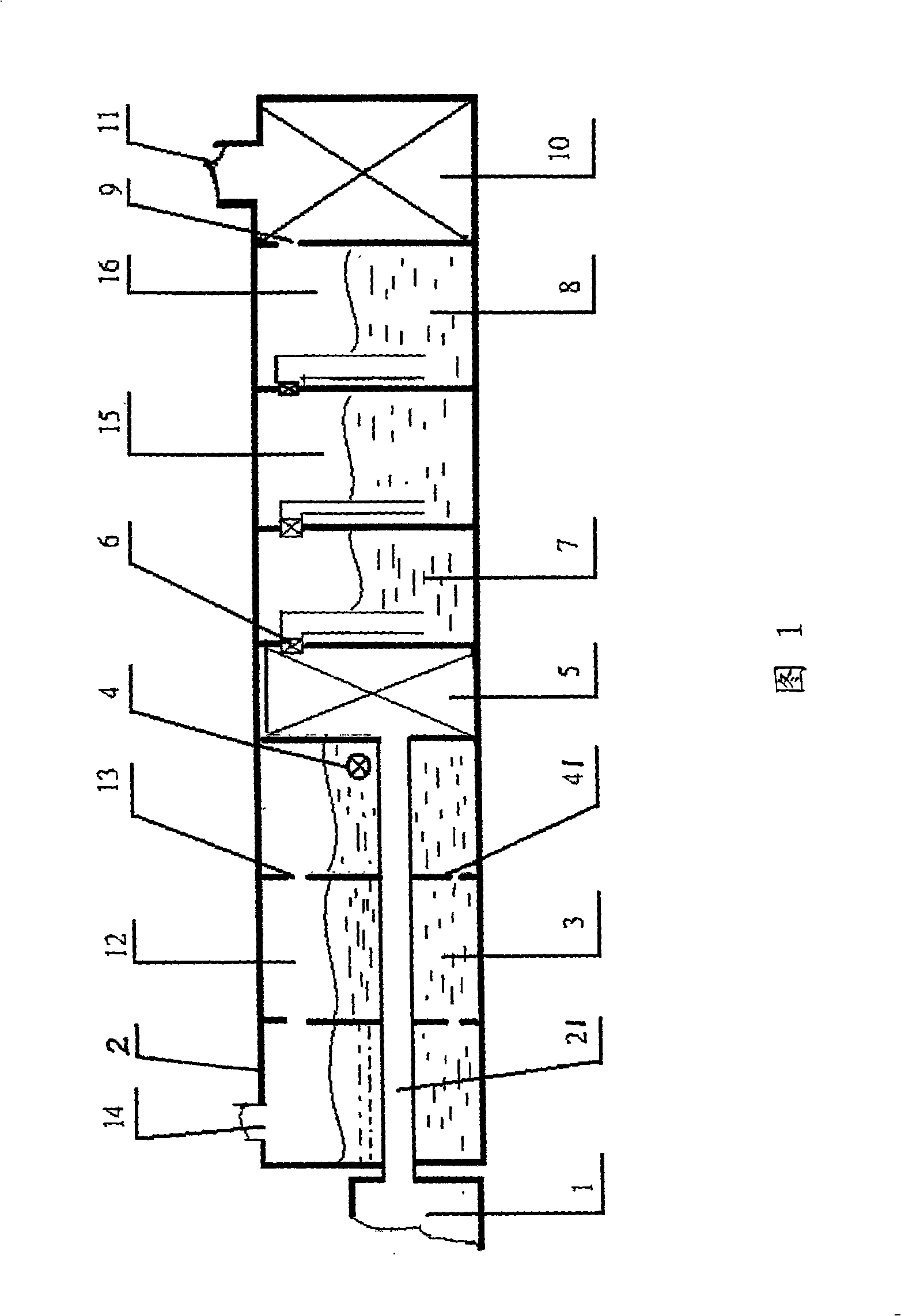

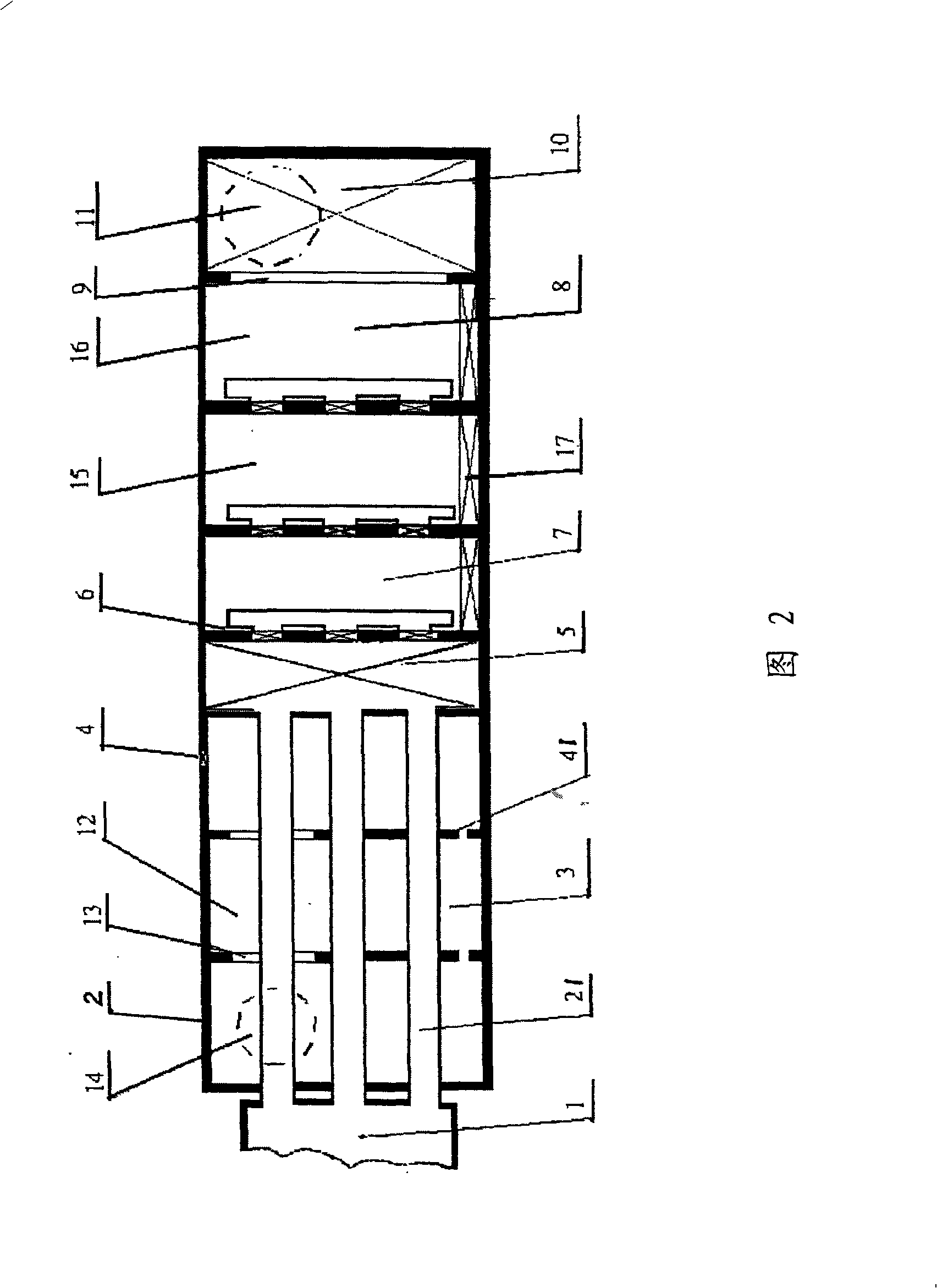

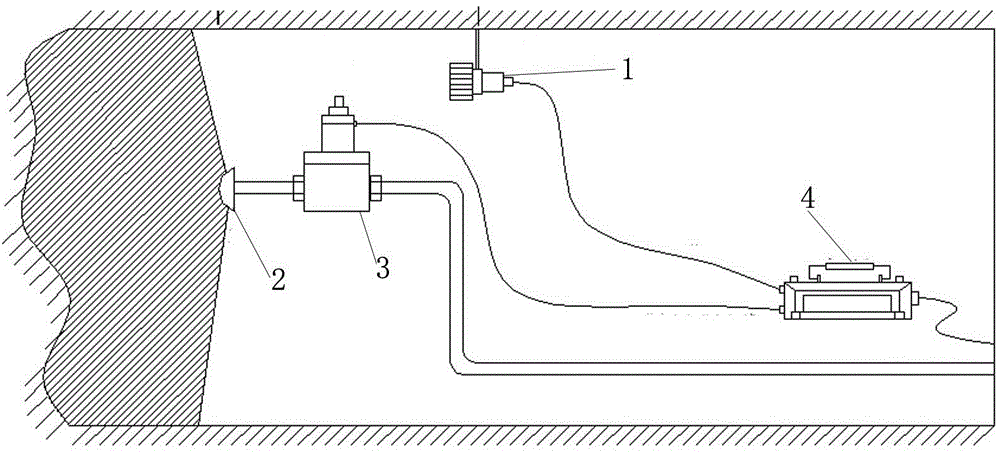

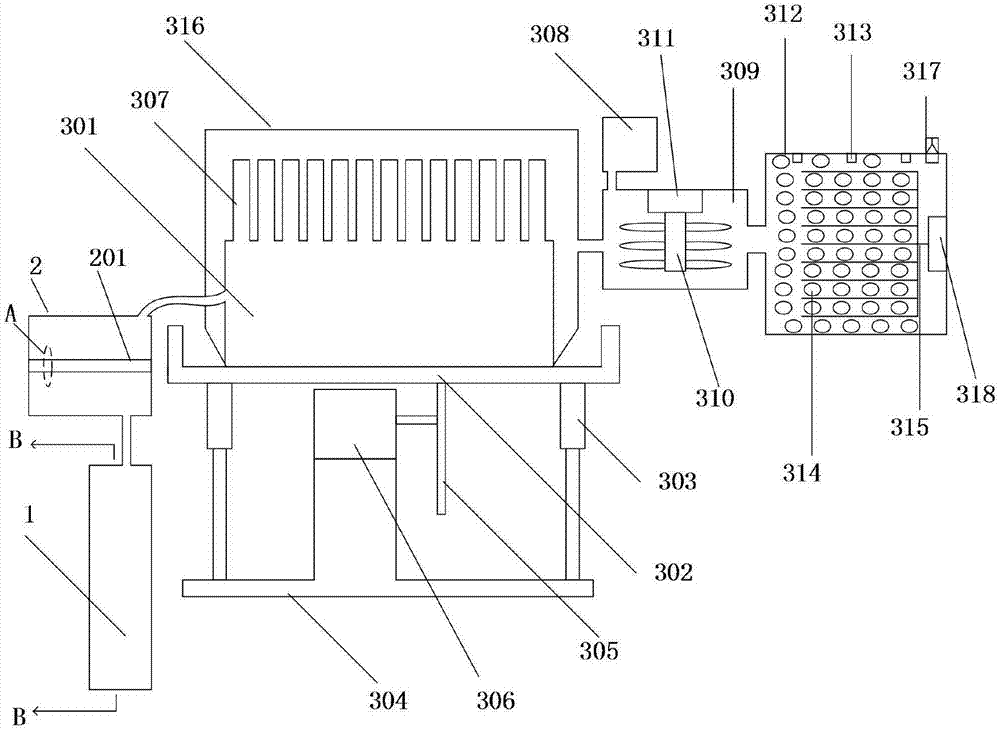

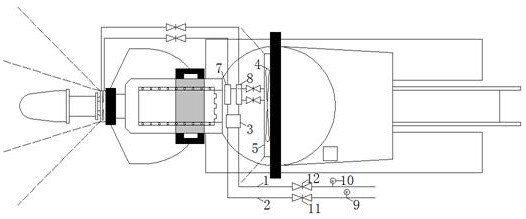

Dust removing system for fully-mechanized coal mining workface

PendingCN107218074AImprove working environmentReduce dust concentrationDust removalFire preventionMining engineeringDust control

The invention discloses a dust removing system for a fully-mechanized coal mining workface. The system includes a dust control system installed on one side of a roadheader, a dust suction system and a dust collecting system installed on the other side of the roadheader, wherein the dust control system comprises a press-in type fan, a press-in type air duct and a wall-attached air duct which are connected with each other in turns; the dust suction system comprises a first suction hood for sucking dust on the cutting head position of the roadheader, a second suction hood for sucking dust on the insertion board position of the roadheader, a third suction hood for sucking dust on the break-of-bulk-point position of a scraper conveyor and belt conveyor, a dust suction air duct and a suction hood assembly box, and the first suction hood, the second suction hood, the third suction hood and the dust suction air duct are all connected to the suction hood assembly box; the dust collecting system comprises an extraction type air duct, a dust remover and an extraction type fan which are connected with each other in turns, and the extraction type air duct is connected to the suction hood assembly box. The dust removing system for the fully-mechanized coal mining workface can effectively control diffusing and spreading of dust in underground roadways, has a good dust suction effect and high dust collecting efficiency, and can greatly reduce the dust concentration of the fully-mechanized coal mining workface.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

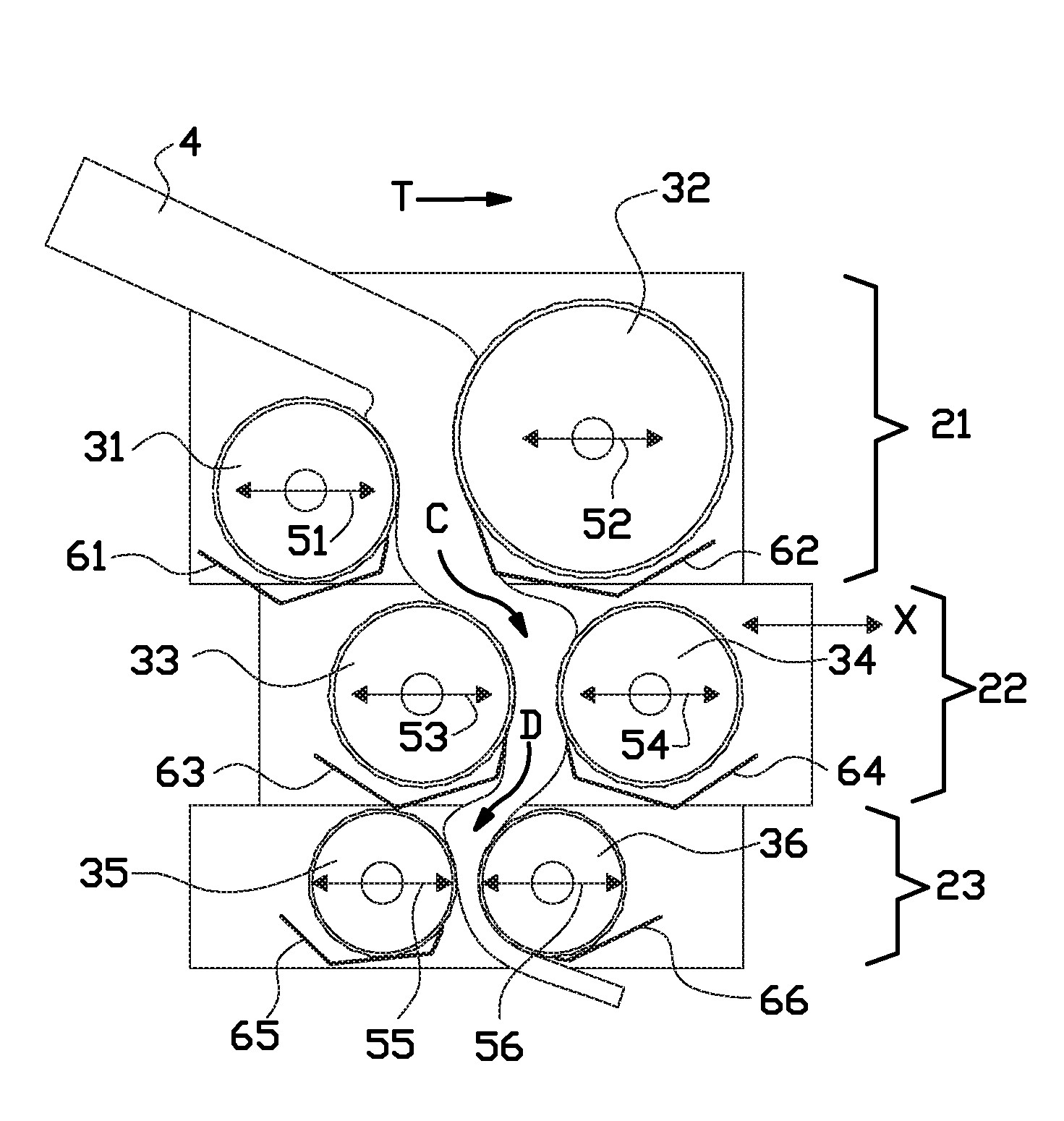

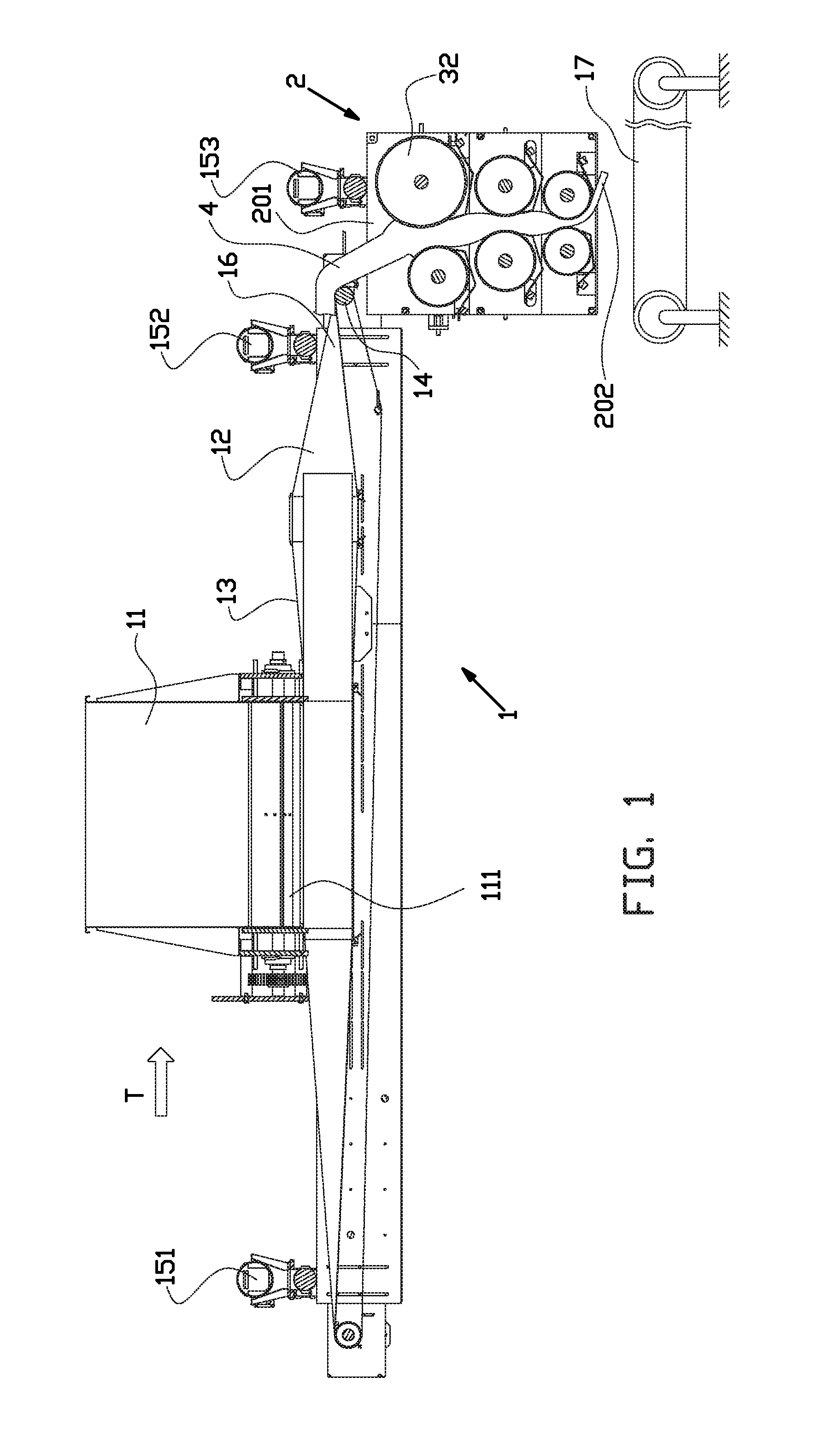

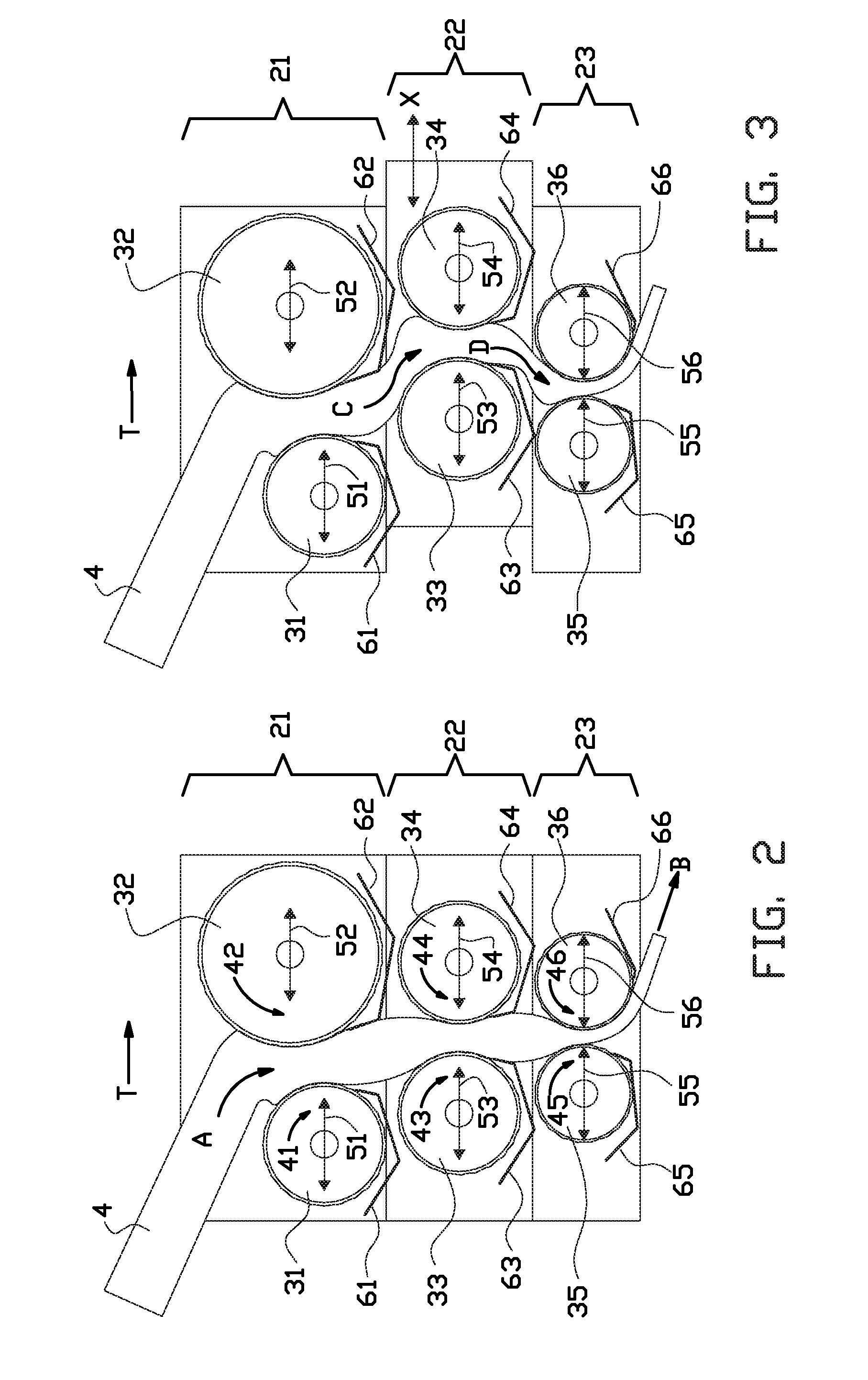

Adjustable dough roller device

InactiveUS8734143B2Minimize changesMinimize damageDough treatmentDough-sheeters/rolling-machines/rolling-pinsEngineeringLeather belt

Owner:JOHAN HENDRIK BERNARD KAAK

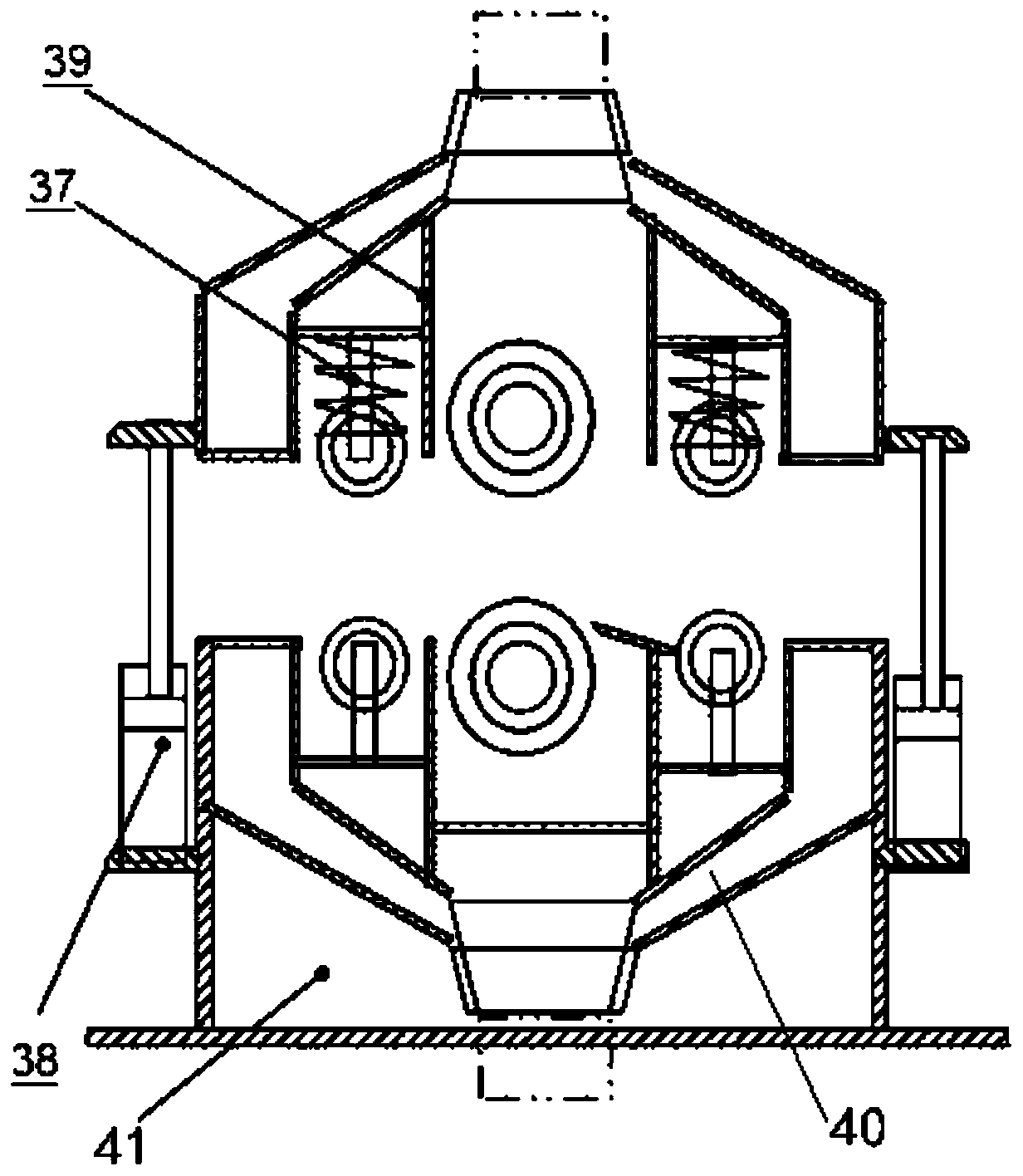

Movable dust removal equipment for industrial factory building

InactiveCN111346449AExtended service lifeFast cleaningDispersed particle filtrationTransportation and packagingActivated carbon filtrationDust control

The invention relates to the technical field of industrial factory building dust removal, and in particular, relates to movable dust removal equipment for an industrial factory building, wherein the movable dust removal equipment comprises a machine box body, the interior of the machine box body is sequentially divided into a power cavity, a reverse blowing cavity, a filtering cavity and a collecting cavity from top to bottom through two transverse partition plates, an air outlet pipe is arranged at the top of the power cavity, and an activated carbon filter is arranged on the air outlet pipe;a centrifugal fan communicated with the air outlet pipe is arranged in the power cavity, and the bottom end of the centrifugal fan is communicated with an air collecting disc; a filter cartridge typefilter and an ash removal device are arranged in the filter cavity, the left outer wall and the right outer wall of the filter cavity are communicated with air inlets, and electronic air valves are arranged in the air inlets; an ash collecting drawer is slidably mounted in the collecting cavity, and an ash falling hole is formed in the transverse partition plate between the collecting cavity andthe filtering cavity; walking wheels are fixedly mounted at four corners of the lower end surface of the bottom end of the machine box body; dust on the surface of the filter element can be cleaned while the filter element filters gas, and meanwhile, the filter element can be matched with the reverse blowing system to accelerate the cleaning speed of industrial dust.

Owner:界首尚嘉工业设计有限公司

Tree planting method at magnesite flour dust polluted area hillside fields and tree pit filler

InactiveCN101366354ASufficient raw materialsLow priceThomas phosphate fertilisersFertilising methodsPhosphogypsumPollution

The invention relates to a plant cultivation method, in particular to a tree planting method and a tree pit filling for magnesite dust polluted area slope land, which solves the problems that the magnesite dust polluted area slope land is low in forest coverage rate and serious in water and soil loss phenomenon. The filling per pit comprises 50 to 80 portions of organic material, 5 to 10 portions of phosphogypsum, 0.5 to 1.0 portion of industrial sulphur and 0.5 to 1 portion of slow-release urea or slow-release compound fertilizer, and the weight of the filling accounts for 5 to 15 percent of the sum of tree pit soil and the filling. The method adopts scale-pit reverse-slope stepped soil preparation, wherein each planting pit is 40 to 60 cm long, 40 to 60 cm wide and 50 to 70 cm deep; and in-situ soil or foreign soil is utilized and mixed with the filling for planting trees in the slope land. In the invention, the tree pit filling is low in price and free from pollution, and the tree planting method is simple and easy to apply and has the effects of improving the survival rate and growth rate of tree seedlings, restoring soil and vegetation and reducing water and soil loss.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Working surface dust treating and preventing method based on working surface on-site coal dust diffusion regulation

InactiveCN109630187ASolve difficultySolve efficiency problemsMining devicesDust removalHigh concentrationCoal dust

The invention discloses a working surface dust treating and preventing method based on a working surface on-site coal dust diffusion regulation. A supporting frame negative pressure secondary dust removing device, a coal mining machine negative pressure secondary dust removing device and a wet-type rolling blind dust preventing net, wherein the supporting frame negative pressure secondary dust removing device and the coal mining machine negative pressure secondary dust removing device perform mist spraying dust reducing according to an entrainment mechanism of a water jet, a negative pressurearea can be formed to entrain high concentration dust aggregates in a working area to improve the dust reduction efficiency, the wet-type rolling blind dust preventing net sprays water mist onto a filter net to form a filter membrane under the action of the tension on the surface of water, the bumping probability between dust in air flows and the filter membrane is increased to improve the dust capturing efficiency, the location and manner of three dust reduction measures are designed according to on-site numerical simulation and the distribution of wind flows and the dust, and cooperative using is conducted to achieve the purpose of reducing the dust concentration of the working surface. The method has the advantages that the dust reducing efficiency is improved, and the dust concentration on large-mining-height comprehensive-mining working surface is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

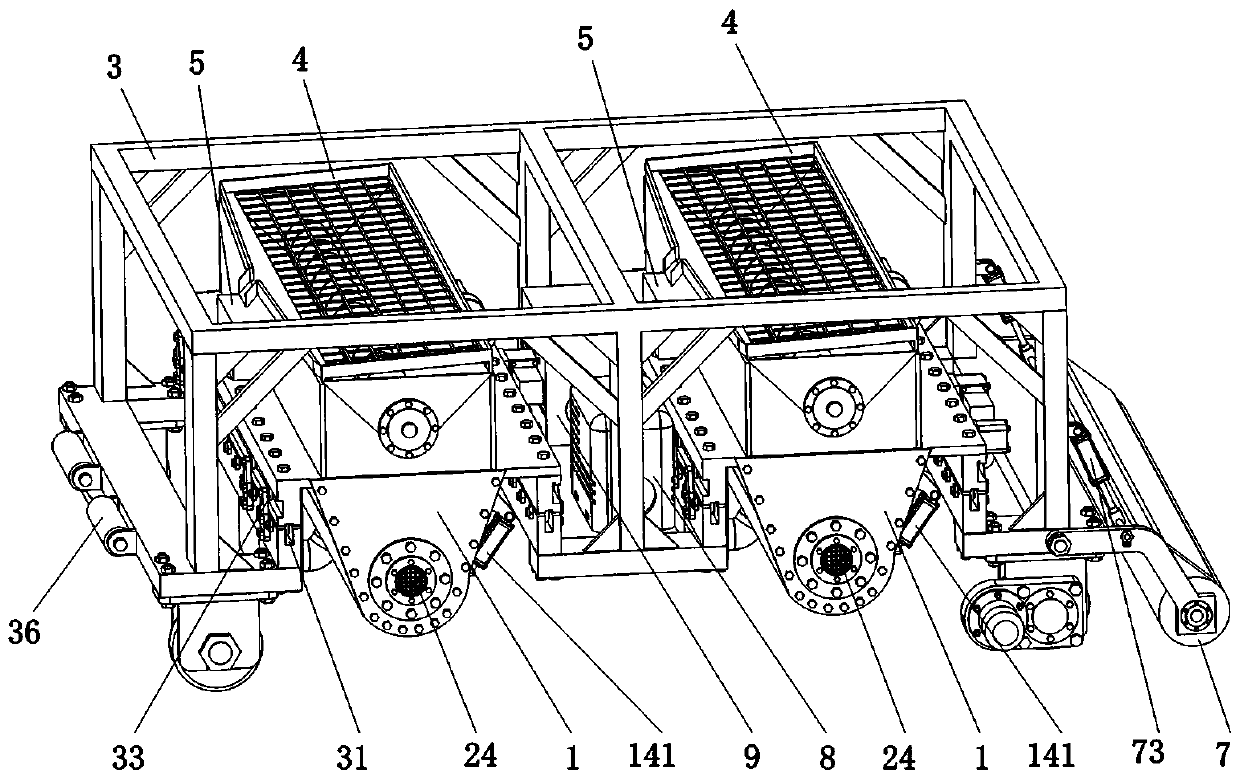

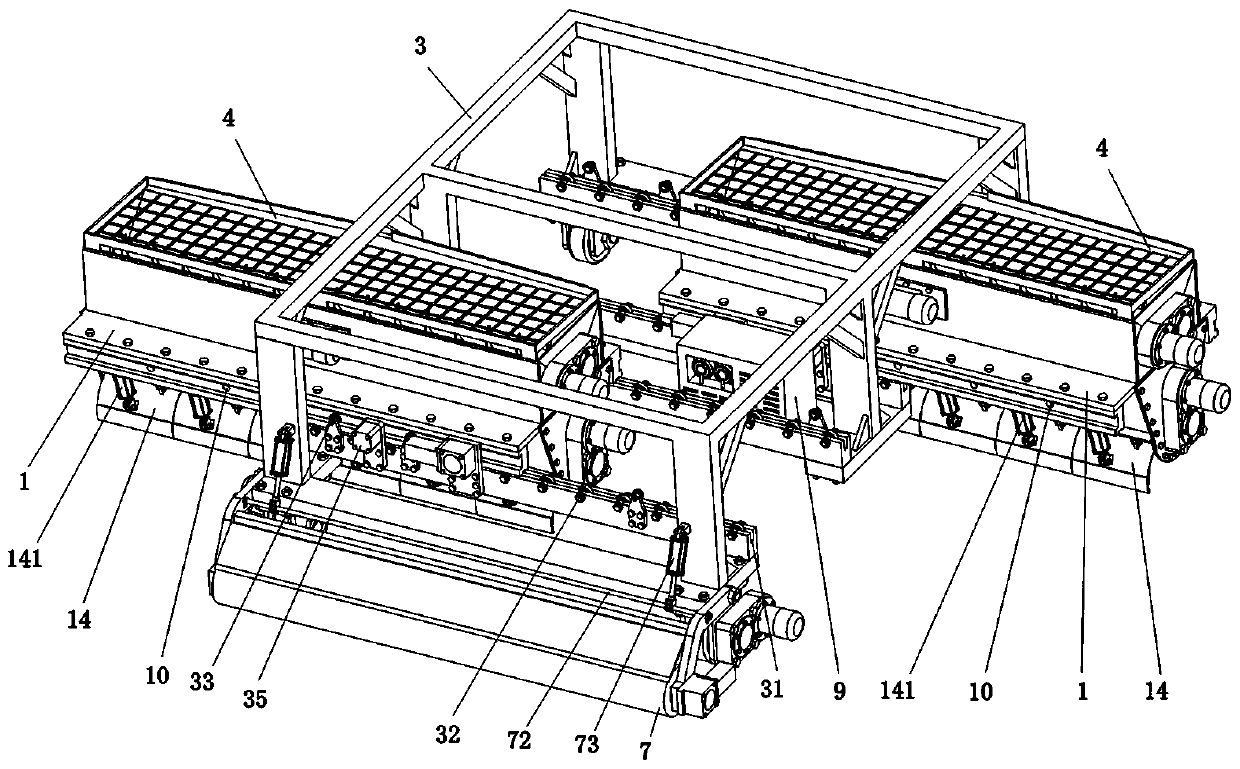

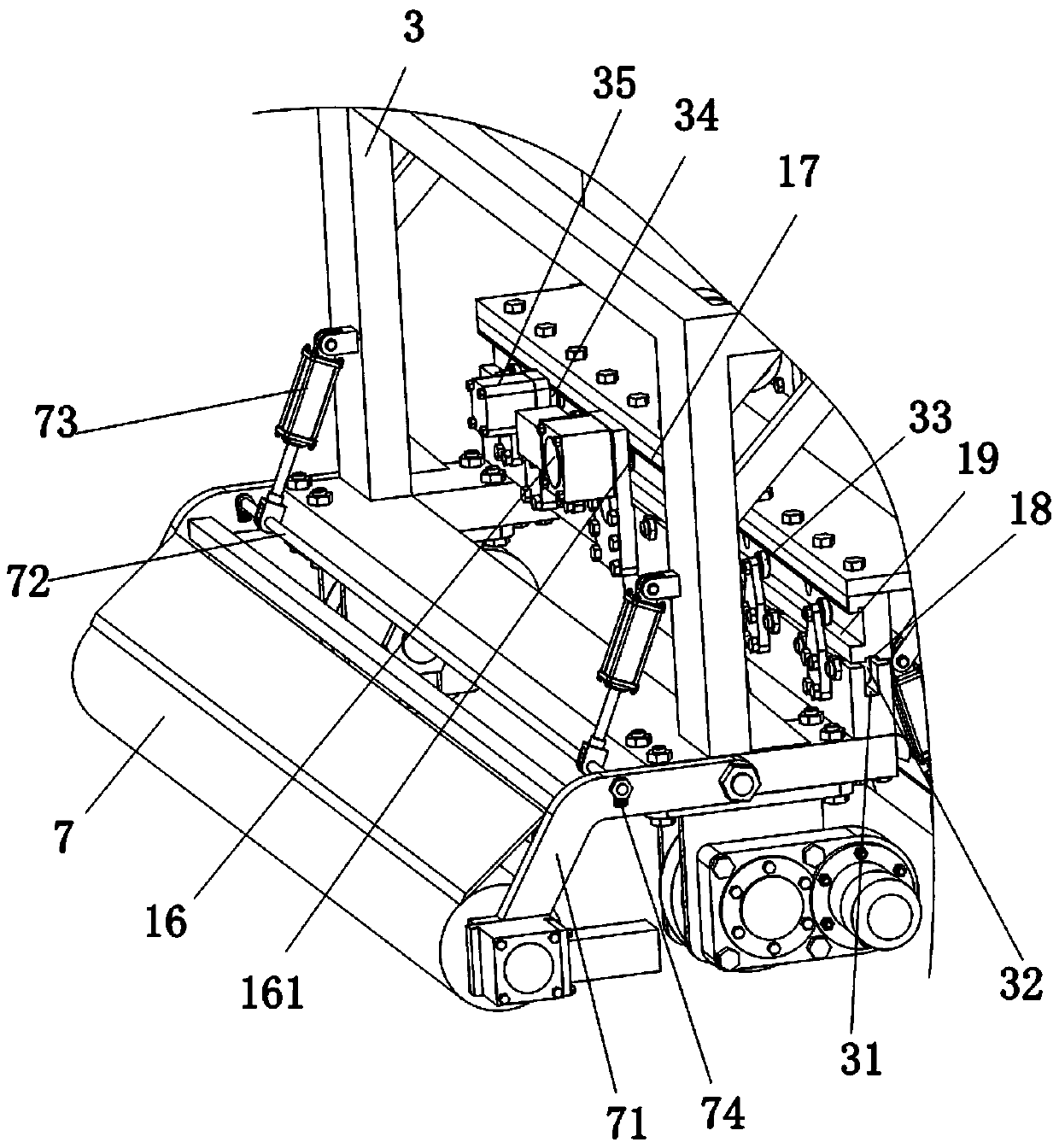

Broken stone spreader for road construction

ActiveCN111472239AReduce pollutionImprove adhesion strengthRoads maintainenceArchitectural engineeringCrushed stone

The invention relates to a broken stone spreader for road construction, which belongs to the technical field of road construction, and is characterized in that two groups of spreaders are arranged ona walking rack in parallel front and back, and slide left and right along the walking rack by virtue of a matched driving device to form a spreading width adjusting structure; the spreader adopts a material bin separation structure, broken stones uniformly fall to a discharge port of a blanking bin by means of an auger of a material receiving bin, then, under the driving of a rotary material distributing roller, the broken stones are shifted by material shifting plates to be spread to the ground through the discharging port, and the material carrying amount of each time is the volume between the two material shifting plates. The material shifting plates and dust leaking holes communicated with inner holes of the material shifting plates are evenly distributed on the periphery of the rotarymaterial distributing roller, the two adjacent material shifting plates of the rotary material distributing roller are in contact fit with the arc-shaped bottom supporting plate of the discharging port to form a closed space, and the closed space is communicated with a dust remover arranged on the walking rack through dust removing holes in the arc-shaped bottom supporting plate. Dust on the surfaces of the broken stones is absorbed while the broken stones are spread, the wrapping strength of the broken stone and asphalt is improved, the construction quality is guaranteed, and dust pollutionis reduced.

Owner:KAIFENG UNIV

Exhaust gas purifying device and purification method thereof

InactiveCN101280926AGas treatmentInternal combustion piston enginesPurification methodsHazardous substance

The invention discloses a waste gas purifier, including a cooling unit with a cooling room for containing liquid coolant and a waste gas transfer tube penetrating the cooling room and immerged into the liquid coolant, the cooling unit is used for cooling waste gas inputted into the transfer tube; a dust removing unit arranged on backward position side of the cooling unit for removing harmful substance and flour dust contained in the waste gas; a absorption unit arranged on backward position side of the dust removing unit and containing the absorption liquid, for removing carbonic anhydride and precipitate from the waste gas by reacting the absorption liquid with the carbonic anhydride and precipitate in the waste gas to generate precipitate; and a purification unit arranged on backward position side of the absorption unit and containing purified water for removing remained harmful substance and flour dust in the waste gas. The invention also discloses an exhaust gas cleaning method.

Owner:卢冠均

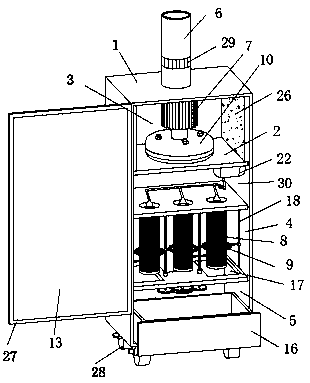

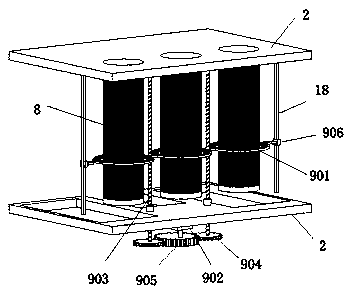

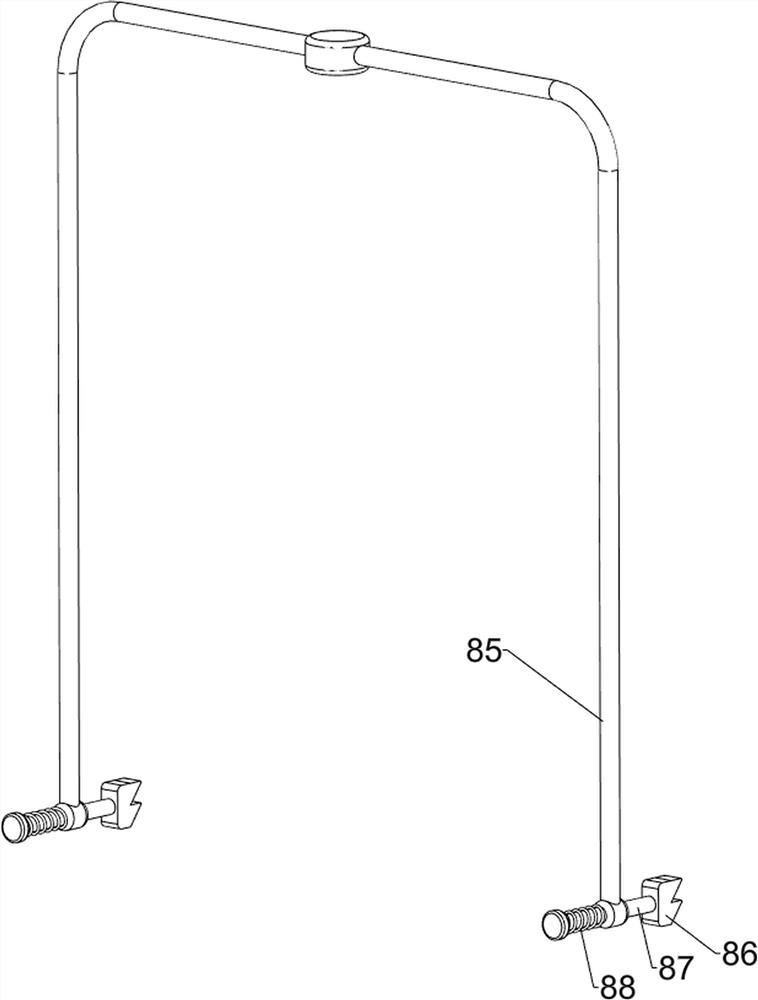

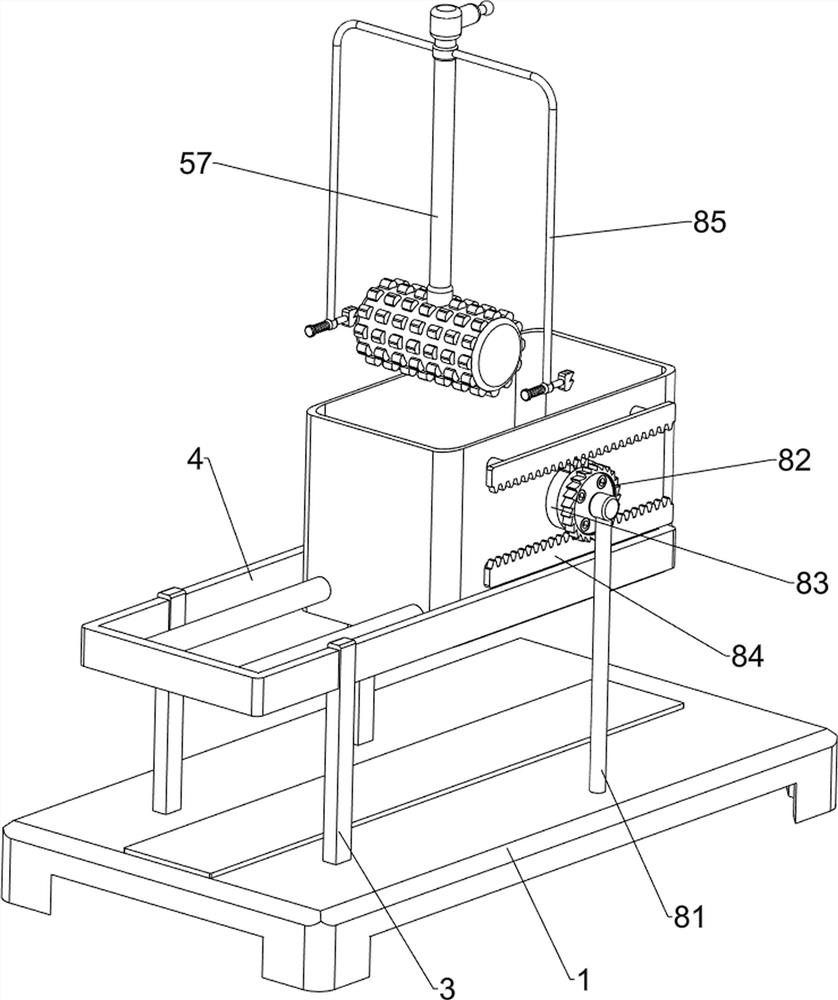

Automatic dust removal equipment

InactiveCN110975492AGood effectReduce the frequency of dust removalCombination devicesThermodynamicsDust control

Owner:江苏唐问节能环保科技有限公司

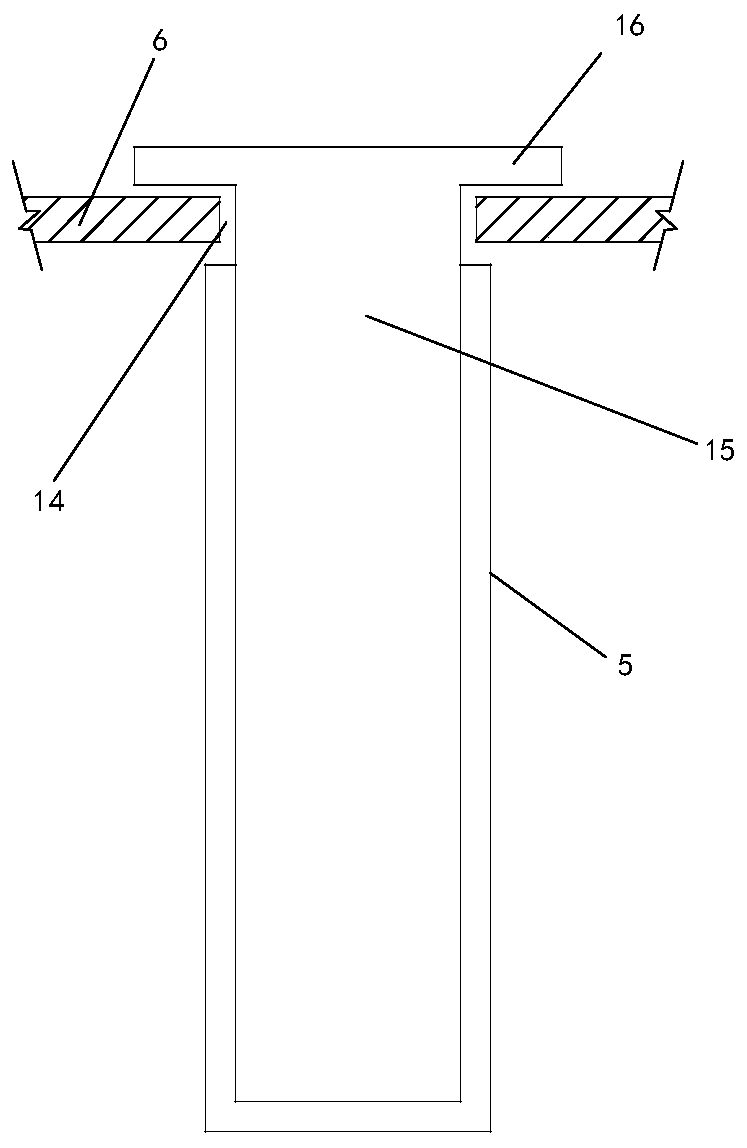

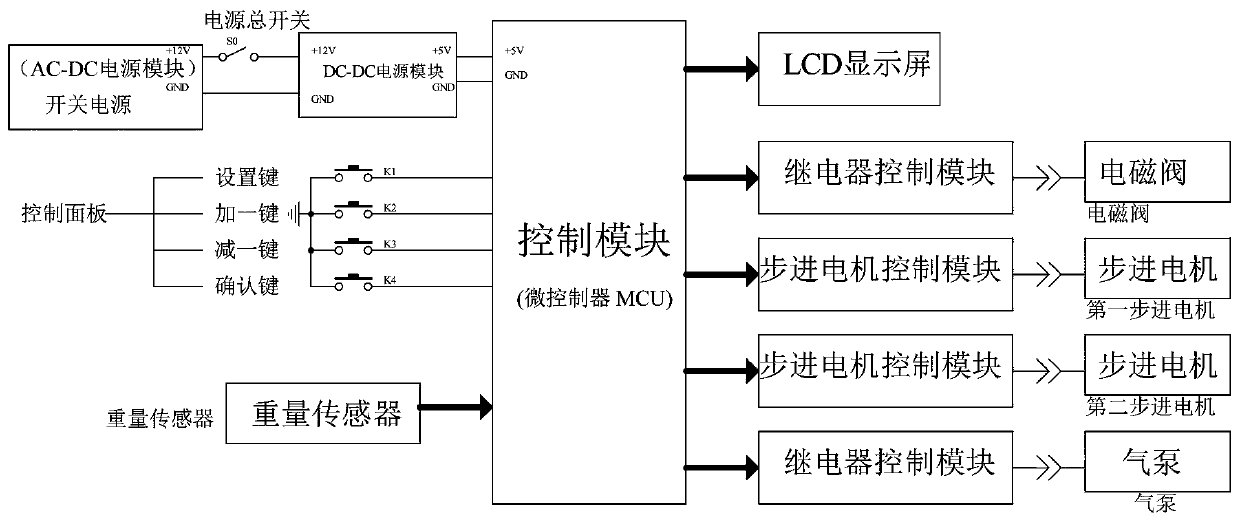

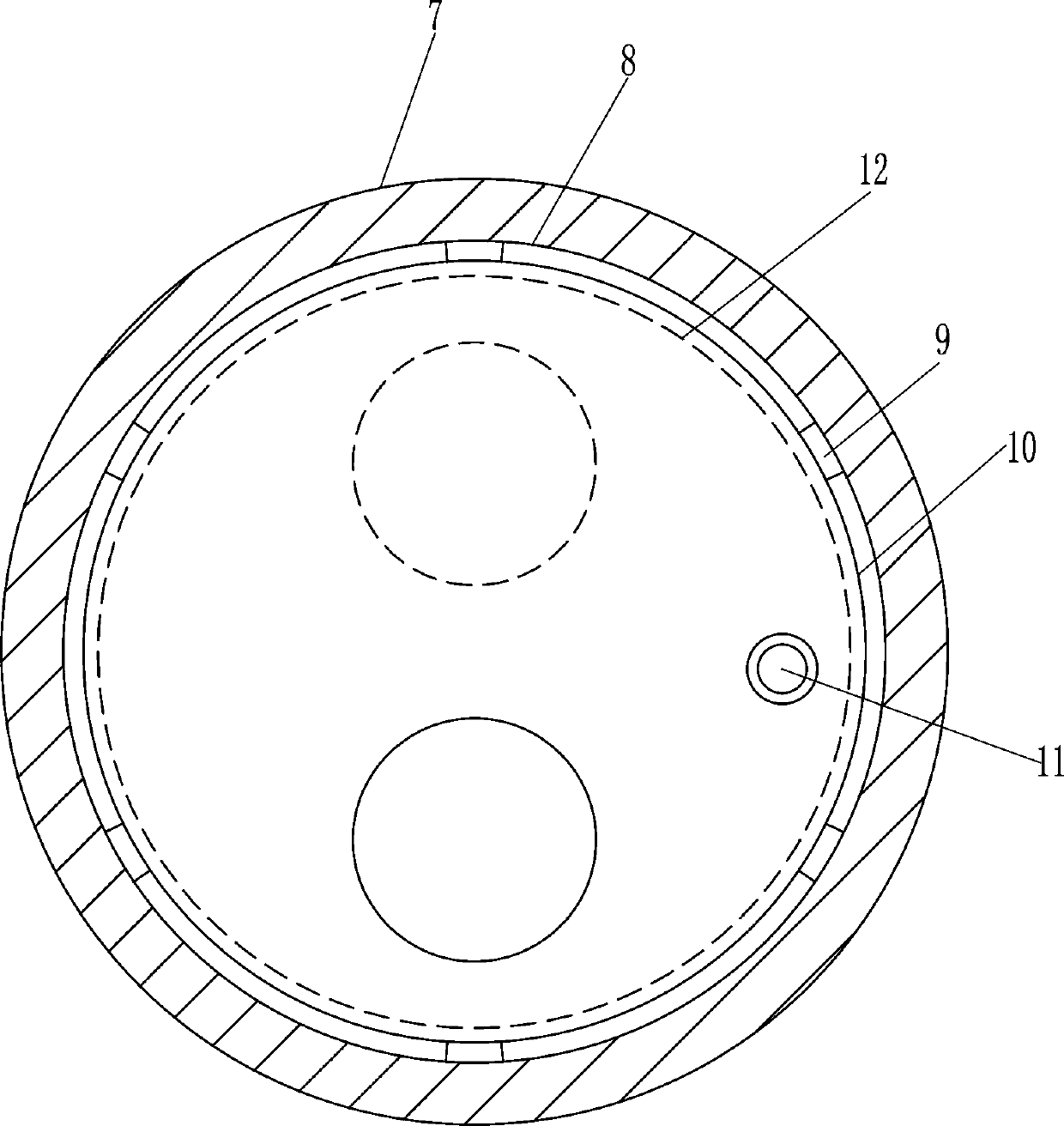

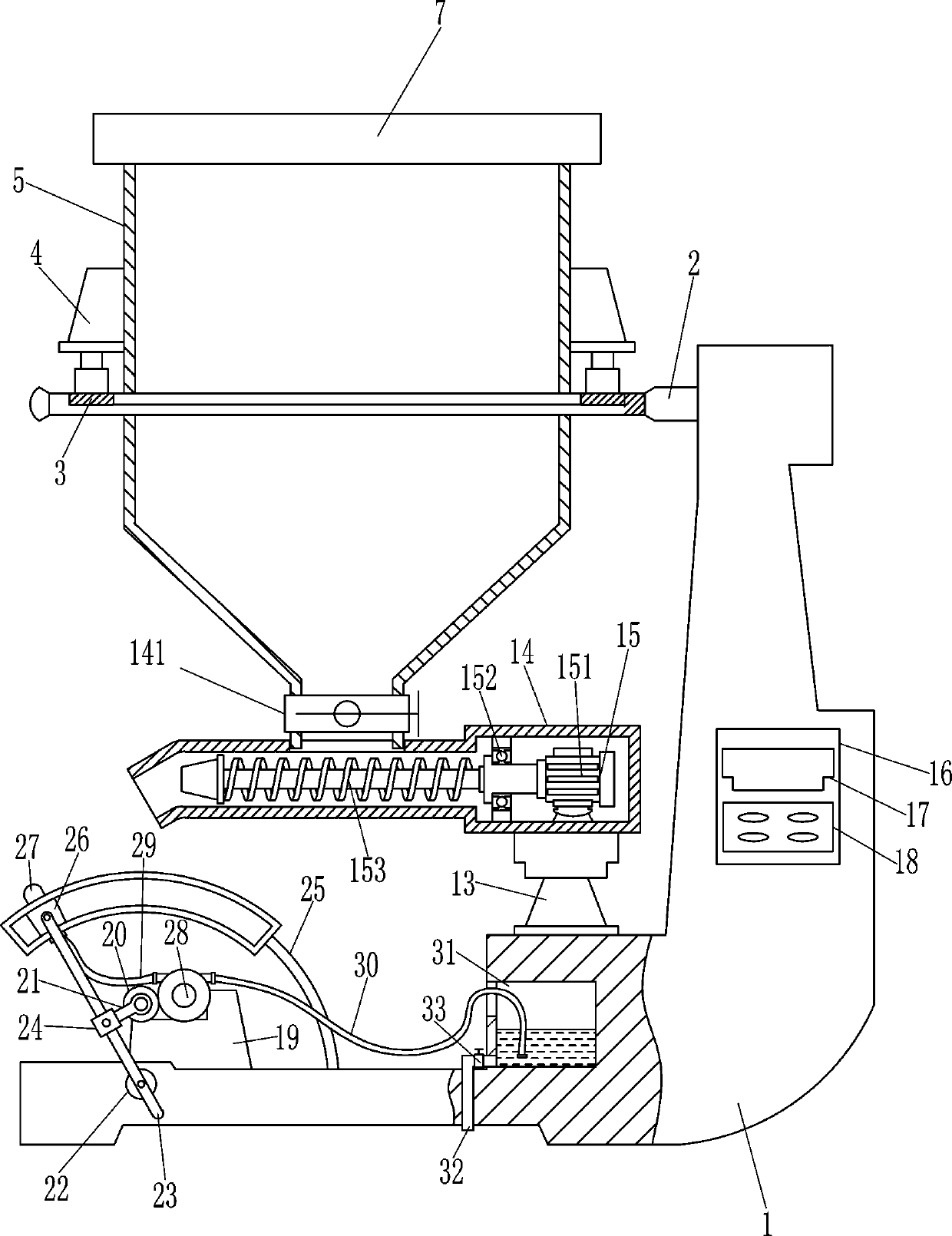

Flour quantitative weighing equipment

The invention relates to flour weighing equipment, in particular to flour quantitative weighing equipment. The flour quantitative weighing equipment can achieve the technical purposes that flour can be stored in a drying environment and is convenient to take out and weigh. According to the technical scheme, the flour quantitative weighing equipment comprises a base, a supporting plate, weight sensors, supporting rods, a material storage frame and the like. The supporting plate is arranged at the upper part of the base, and the weight sensors are arranged on the supporting plate. According to the equipment, the effects that the flour can be stored in the drying environment and is convenient to take out and weigh are achieved; the material storage frame, a first open disc, a second open discand the like are arranged, can facilitate addition of flour and can make the flour stored in the dry environment. A discharging device can facilitate discharge of the flour. A control panel, an LCD screen and the like are arranged so that intelligent weighing can be achieved, and the accurate flour weighing process can be completed at a time. A filtering cover which swings left and right can absorb flour dust in the air.

Owner:山东未来城建筑工程有限公司

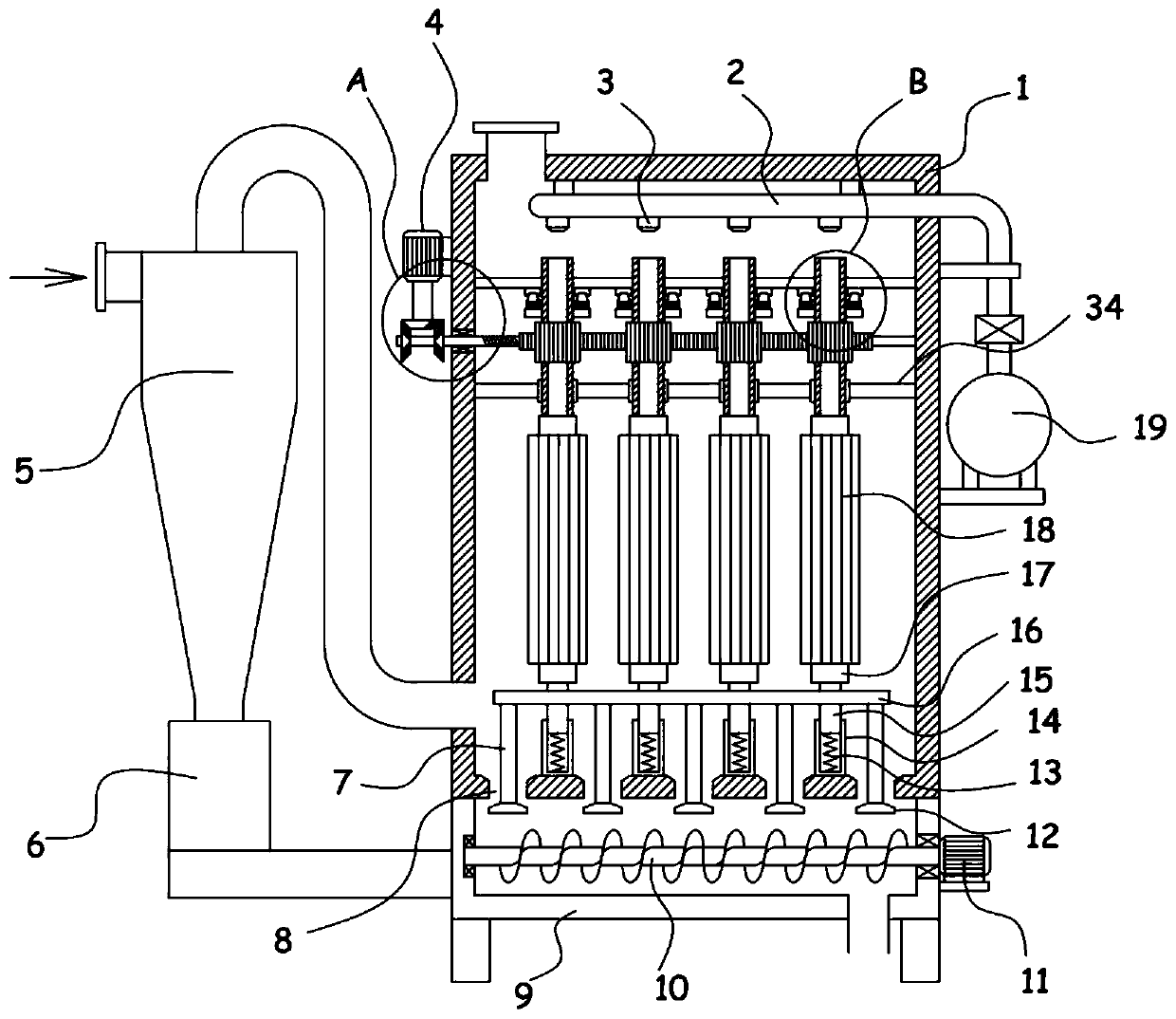

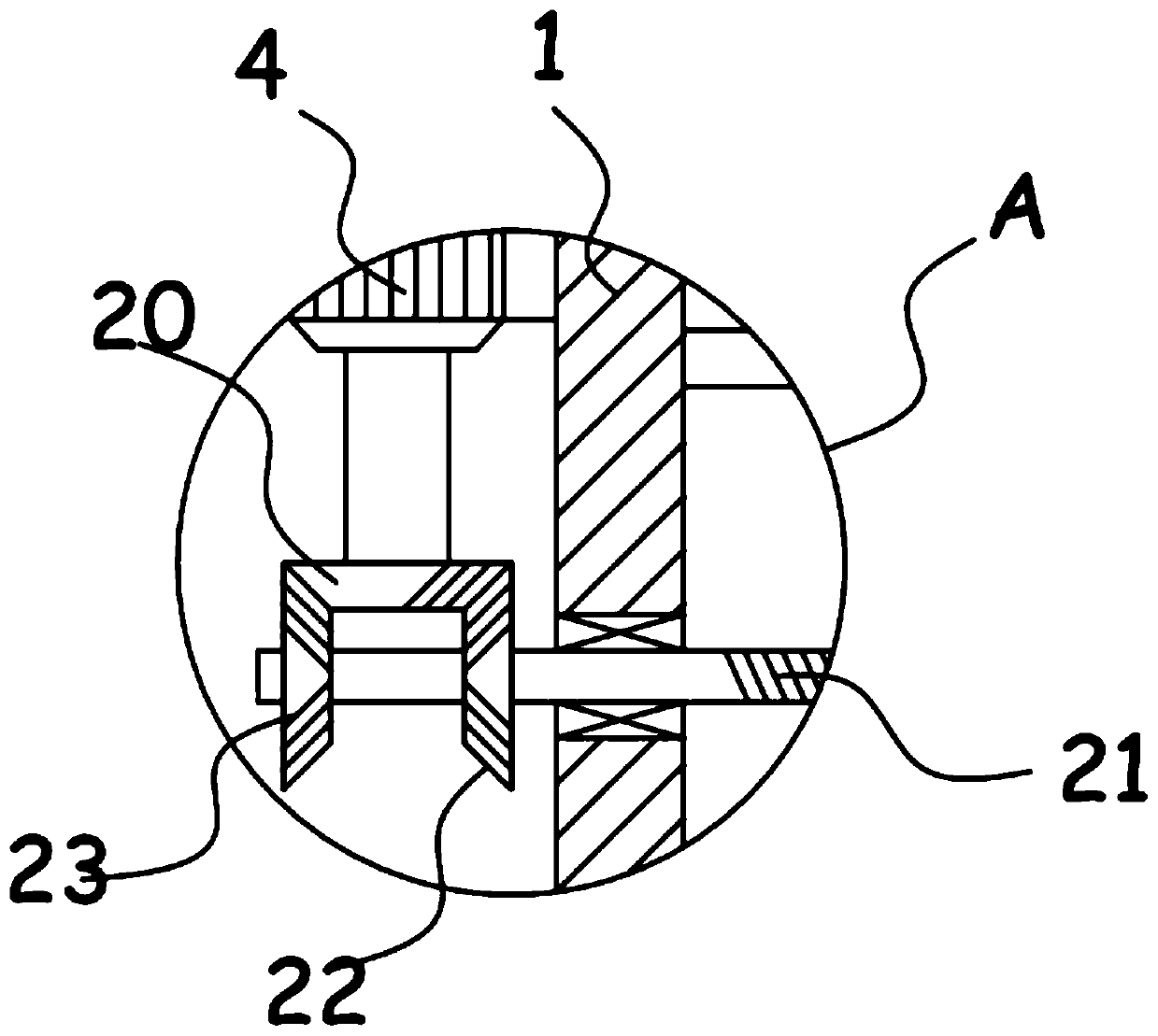

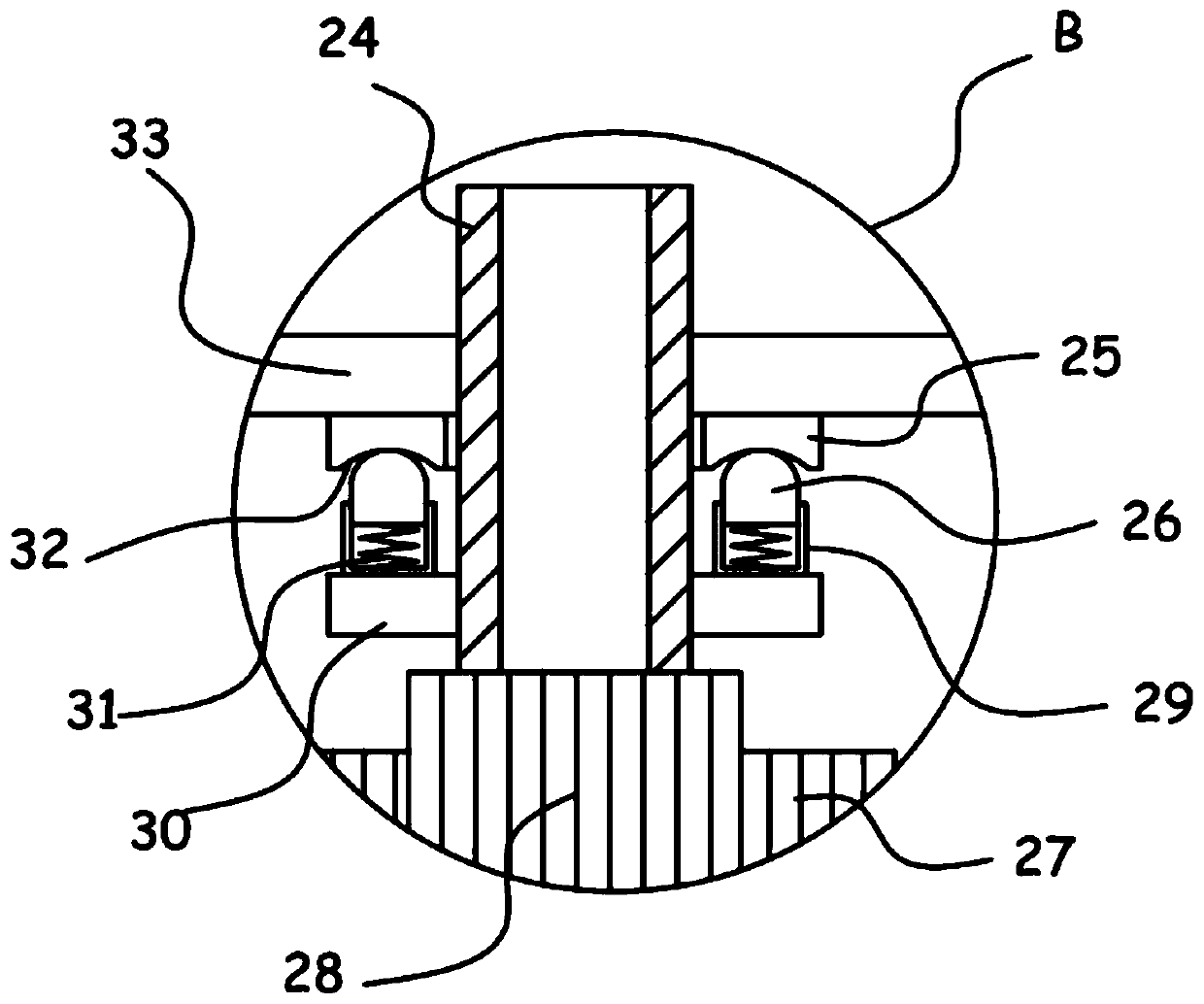

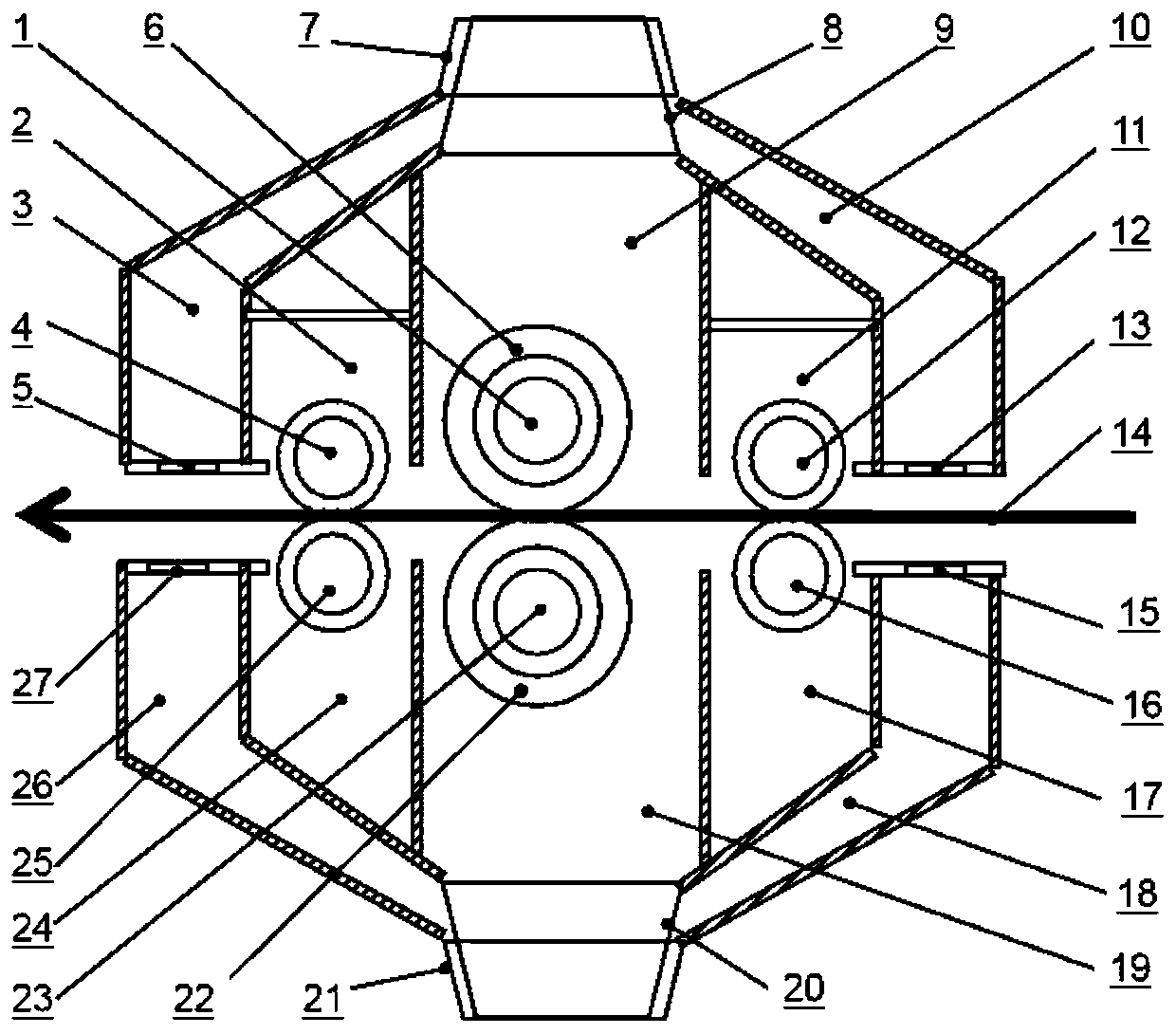

Multi-item combined industrial dust removal equipment

InactiveCN111450650ASpeed up the fallFacilitate shake offCombination devicesDispersed particle filtrationDust controlProcess engineering

The invention discloses multi-item combined type industrial dust removal equipment and relates to the technical field of industrial dust removal. The multi-item combined type industrial dust removal equipment comprises a dust removal box and a cyclone separator, a collecting box communicated through a discharging hole is installed at the bottom of the dust removal box, a supporting guide assemblyused for supporting a dust removal mechanism is arranged at the bottom of the dust removal box, a horizontal plate is horizontally fixed in the dust removal box, the dust removal mechanism comprises an exhaust pipe vertically and slidably penetrating through a horizontal plate, and a purging mechanism is arranged at the top of the exhaust pipe. According to the invention, a pleated cloth bag in the dust removal mechanism is used for blocking dust in air flow, the arranged blowing mechanism can blow air flow from the interior of the pleated cloth bag to the exterior of the pleated cloth bag, the effect of purging and removing dust on the outer surface of the pleated cloth bag is achieved, the pleated cloth bag can be expanded in the period, falling of dust is accelerated, the rotating mechanism can drive the pleated cloth bag to rotate in a reciprocating mode, the dust on the pleated cloth bag is thrown off from the pleated cloth bag, the cleanliness of the surface of the pleated clothbag can be well guaranteed, and the dust removal effect is greatly improved.

Owner:叶霏

Powder milling device for chemical production

PendingCN112427069AAchieving a grinding effectImprove cleanlinessCleaning using toolsGrain treatmentsPowder millRaw material

The invention relates to a powder milling device, in particular to a powder milling device for chemical production. The invention provides the powder milling device for chemical production, which is delicate, is better in powder milling effect, automatically cleans the dust on the surface of a milling part, and is beneficial for powder collection. The powder milling device for chemical productioncomprises a base, a grinding mechanism and a clearing mechanism, wherein a slide frame for collecting powder-shaped chemical raw materials is arranged on the base in a sliding mode; the grinding mechanism for chemical raw material grinding is arranged on the base; the clearing mechanism for clearing accumulated powder on the grinding mechanism is arranged on the base; and the clearing mechanism isconnected to the grinding mechanism. A first movable block slides up and down along a roller to drive a pressure hammer to slide up and down, and the pressure hammer cracks the chemical raw materialsin a discharge frame below while moving downwards, so that the effect of grinding the chemical raw materials is achieved.

Owner:尹家琴

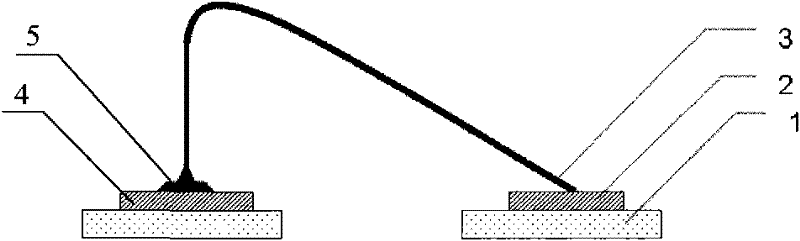

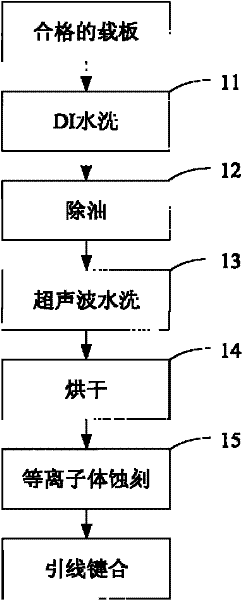

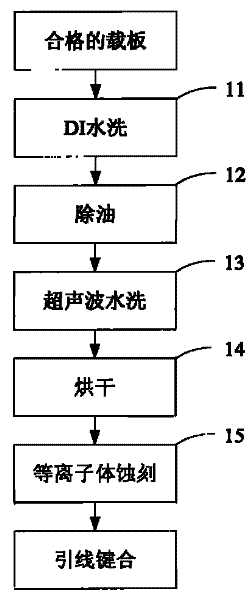

Method for improving wire bonding performance

ActiveCN102446778AImprove bonding abilityImprove bindingSolid-state devicesSemiconductor/solid-state device manufacturingSulfideEngineering

Owner:NEW FOUNDER HLDG DEV LLC

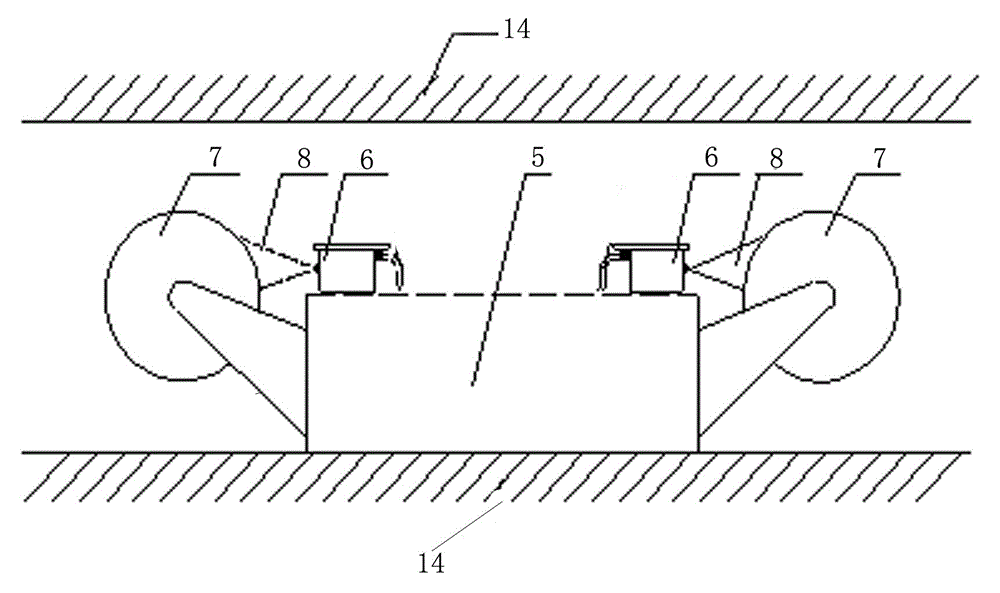

Automatic Dust Reduction Method of Flour Dust Overrun in Fully Mechanized Mining

ActiveCN103291348BExpand the spraying rangeImprove atomization effectDust removalFire preventionMining engineeringAtomizer nozzle

The invention relates to the field of coal mine ventilation and safety, in particular to a fully mechanized coal mining face dust overrunning automatic dust suppression method. The fully mechanized coal mining face dust overrunning automatic dust suppression method solves the technical problem that the dust suppression effect of the prior fully mechanized coal mining face is not ideal, and comprises the step of conducting dust suppression through a fully mechanized coal mining face dust suppression system and a coal cutter dust suppression system. The fully mechanized coal mining face dust suppression system comprises a plurality of dust concentration sensors arranged on a hydraulic support in the arrangement direction of the hydraulic support according to the gap of 20+1m and a plurality of first atomizer nozzles arranged on the front beams of the hydraulic supports. Electrically operated valves are all connected to the first atomizer nozzles through pipelines. According to the fully mechanized coal mining face dust overrunning automatic dust suppression method, because two dust suppression systems are adopted to conduct dust suppression processing on dust generated in the coal cutting process of a coal cutter, dust suppression effect is greatly improved, working environment of underground personnel is effectively improved, and health and working safety of the personnel are protected.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

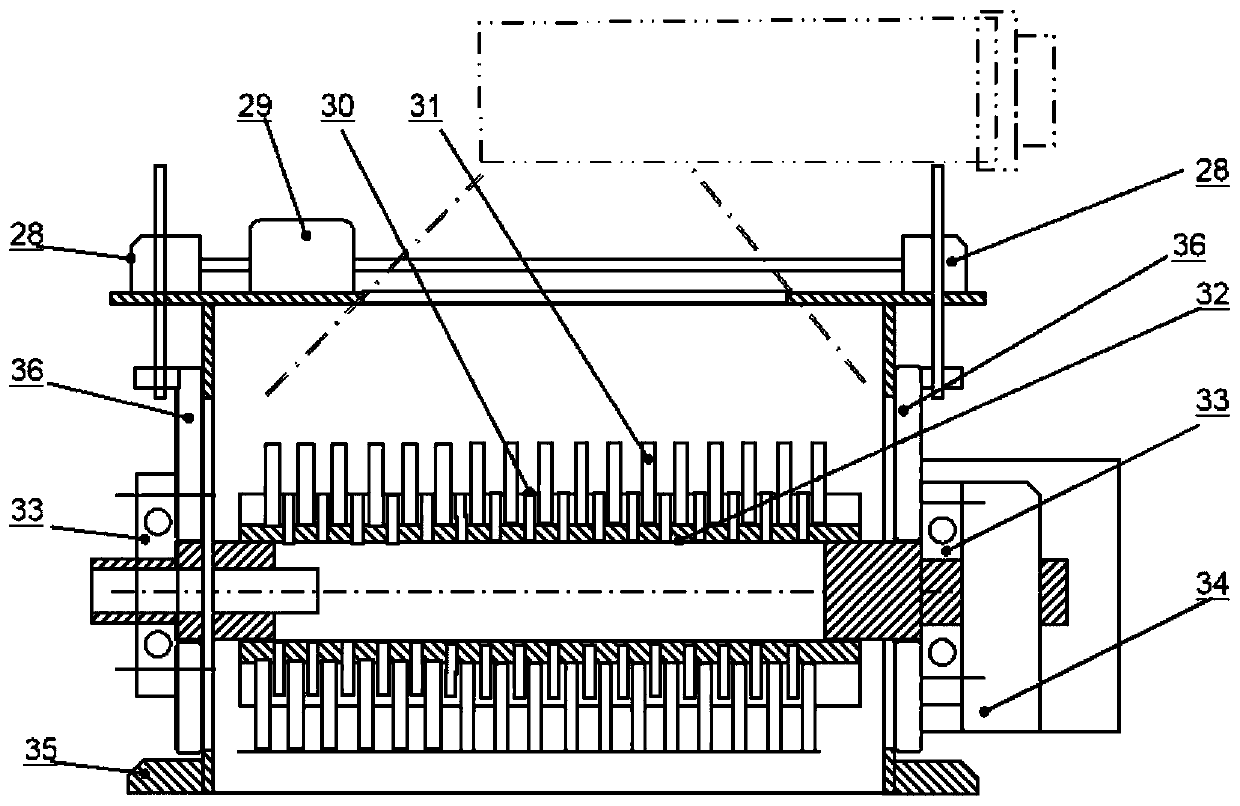

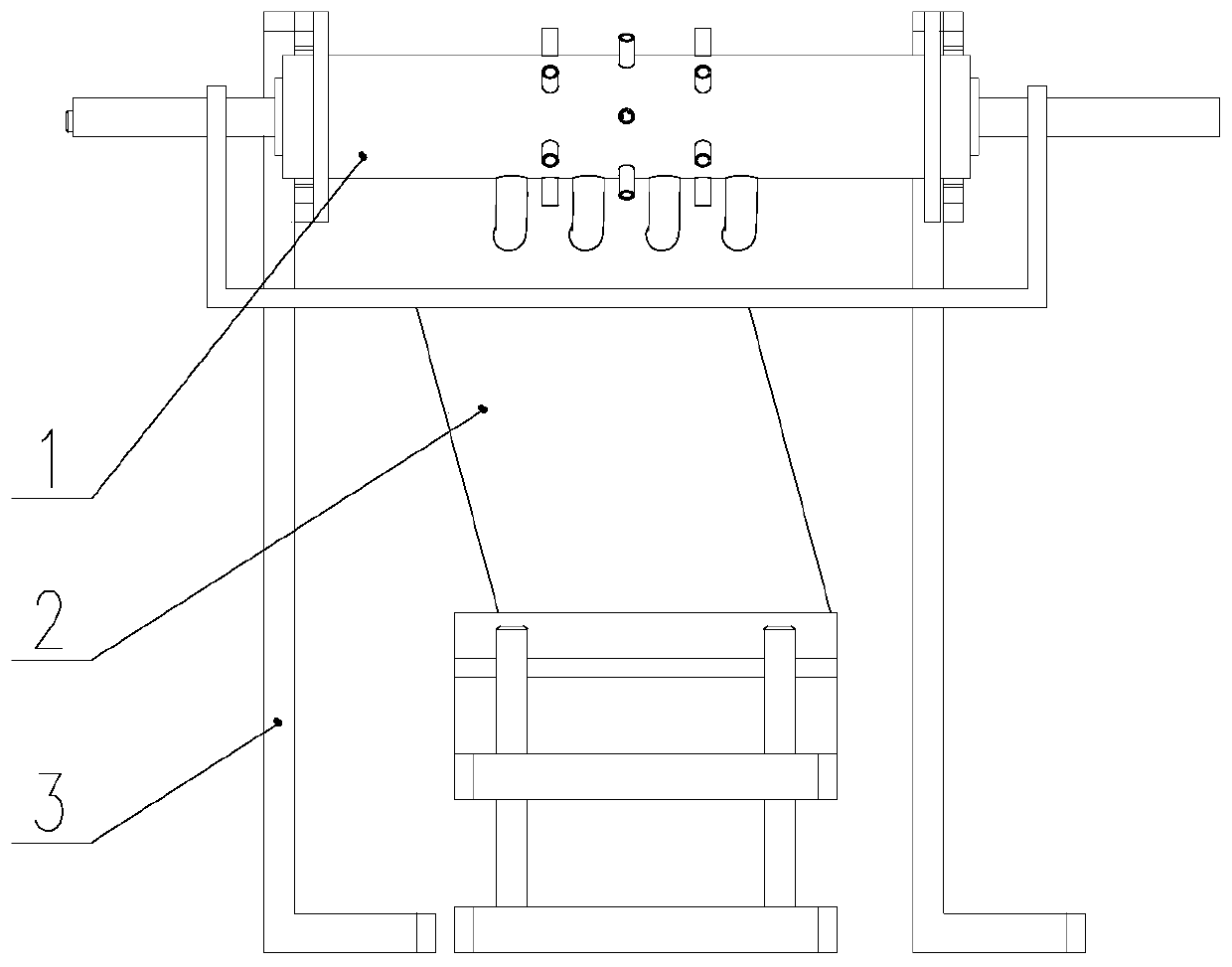

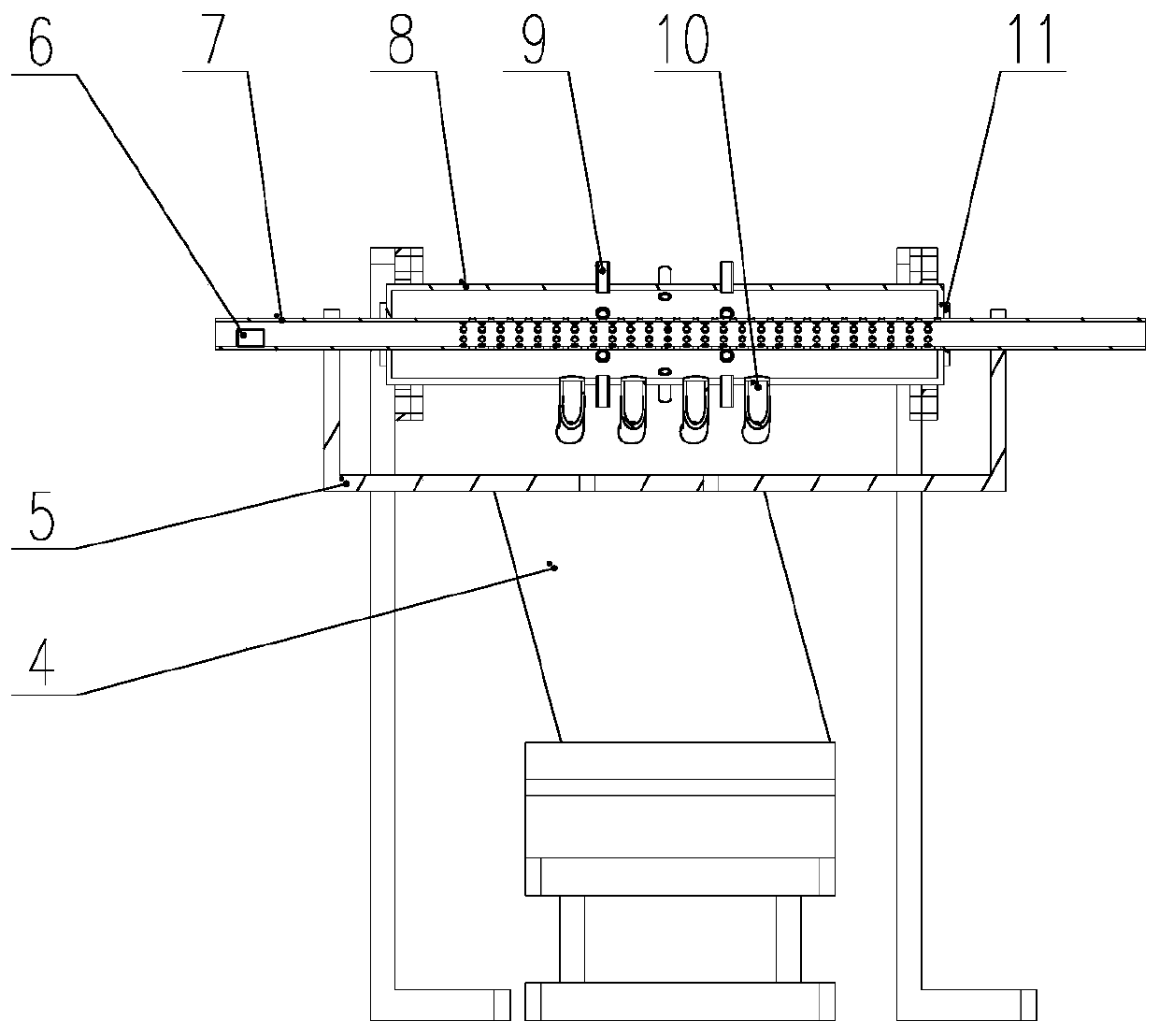

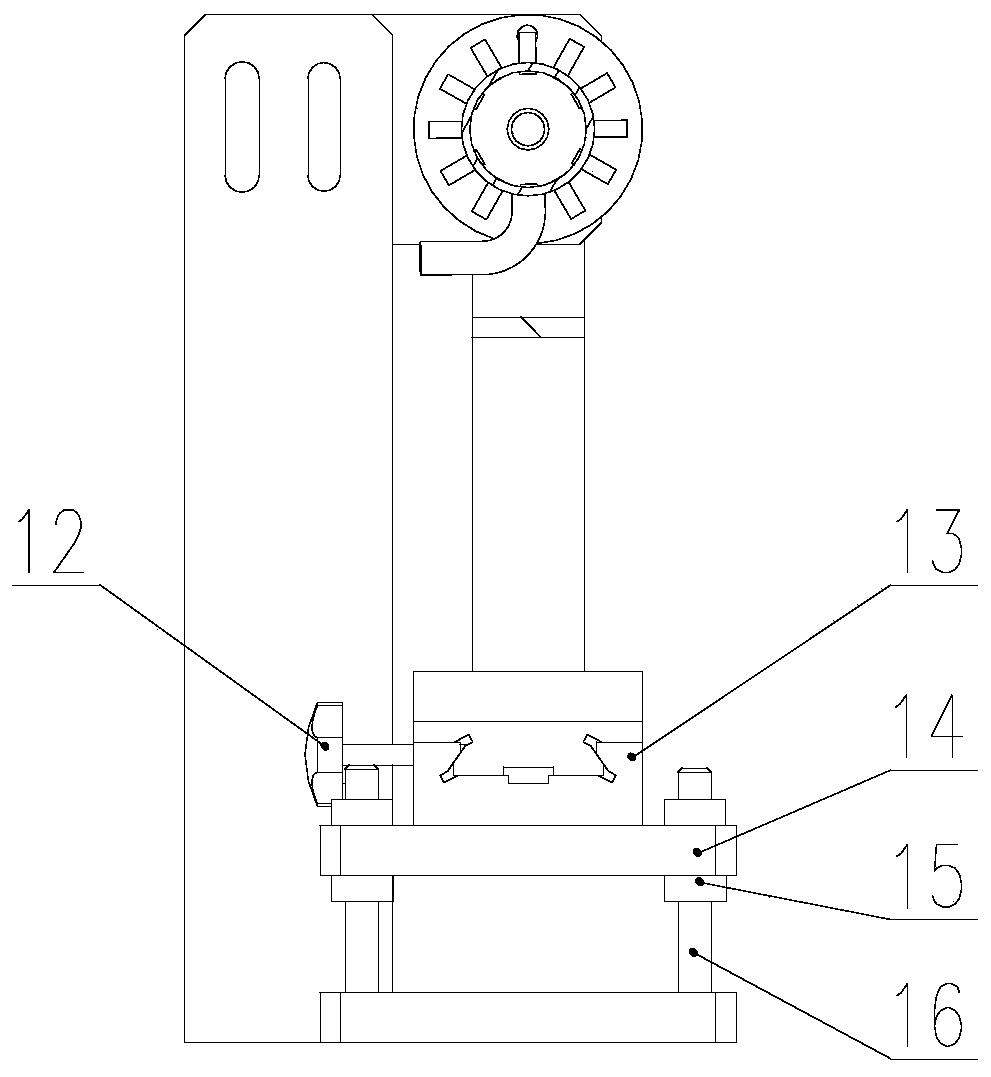

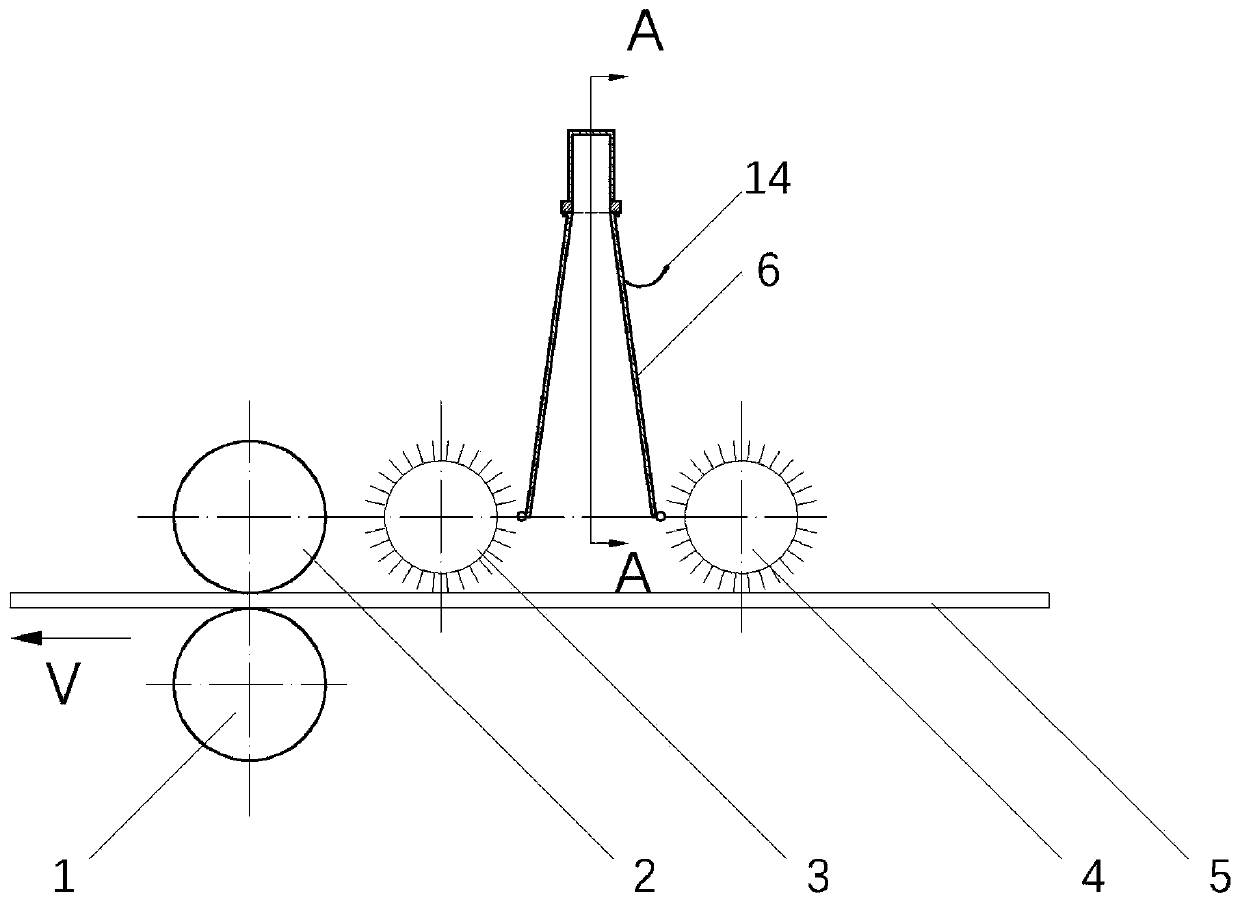

Dust removal device for removing dust and adherends on surface of steel belt and operation method

ActiveCN110899346AEasy to handleImprove sealingWork cleaning devicesMetal rolling arrangementsDust controlStructural engineering

The invention discloses a dust removal device for removing dust and adherends on the surface of a steel belt and an operation method, and belongs to the technical field of mechanical devices. The device comprises an upper brush roller, a lower brush roller, an upper sealing roller, a lower sealing roller, an upper box body collecting cover and a lower box body collecting cover which are located above and below the steel belt and are arranged in parallel; a driving mechanism for controlling the upper box body collecting cover to move far away from or close to the lower box body collecting coveris arranged on the lower box body collecting cover; when the upper box body collecting cover moves close to the lower box body collecting cover and is closed, a cavity is formed; the upper brush roller and the lower brush roller each comprise a roller shaft and brush wires located on the surface of the roller shaft; each roller shaft is a hollow shaft with one end provided with an air inlet connected with an external air source and the other end closed; and spraying holes are formed in the surfaces of the hollow shafts. With the dust removal device adopted, the removal rate of magnesium oxideon the surface of the steel plate can reach 95% or above by means of mechanical stripping and high-pressure airflow purging.

Owner:武汉钢铁有限公司

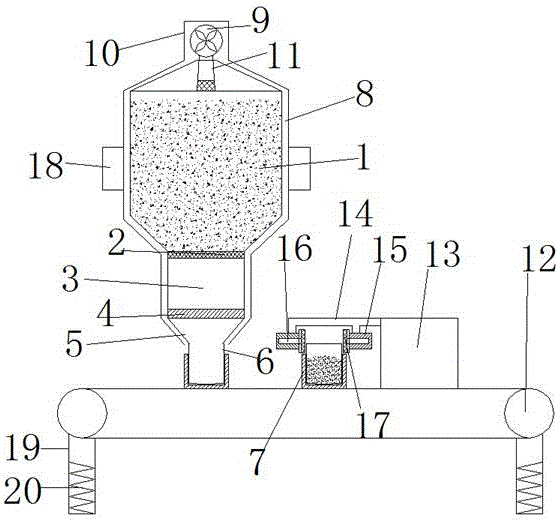

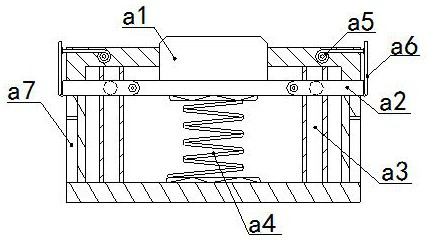

Efficient flour packing machine with damping device

InactiveCN106043747AReduce wasteAchieve environmental protection effectSolid materialWorking environmentEngineering

The invention discloses a high-efficiency flour packaging machine with a shock absorbing device, which comprises a flour bin, a flour discharge port, a weighing room, an electromagnetic switch, a discharge funnel, a packaging bag, a bagging cylinder, an outer cover, an exhaust fan, and an exhaust fan. Machine cover, dust exhaust pipe, transmission device, sealing machine support seat, connecting rod, driving cylinder, piston rod and heating plate, the high-efficiency flour packaging machine with shock absorbing device of the present invention, the flour bag that has completed quantitative loading is conveyed The device is transported to the sealing device for heat sealing, which realizes the integration of loading and sealing, greatly reduces the labor intensity, has good packaging effect and high efficiency, and can recycle the flour dust generated during the packaging process, greatly reducing It reduces the waste of flour, protects the environment, improves the working environment of operators, ensures the continuous packaging of flour, and avoids the occurrence of clogging. In addition, the vibration of the device is small when it is working, and the working stability is high.

Owner:李明波

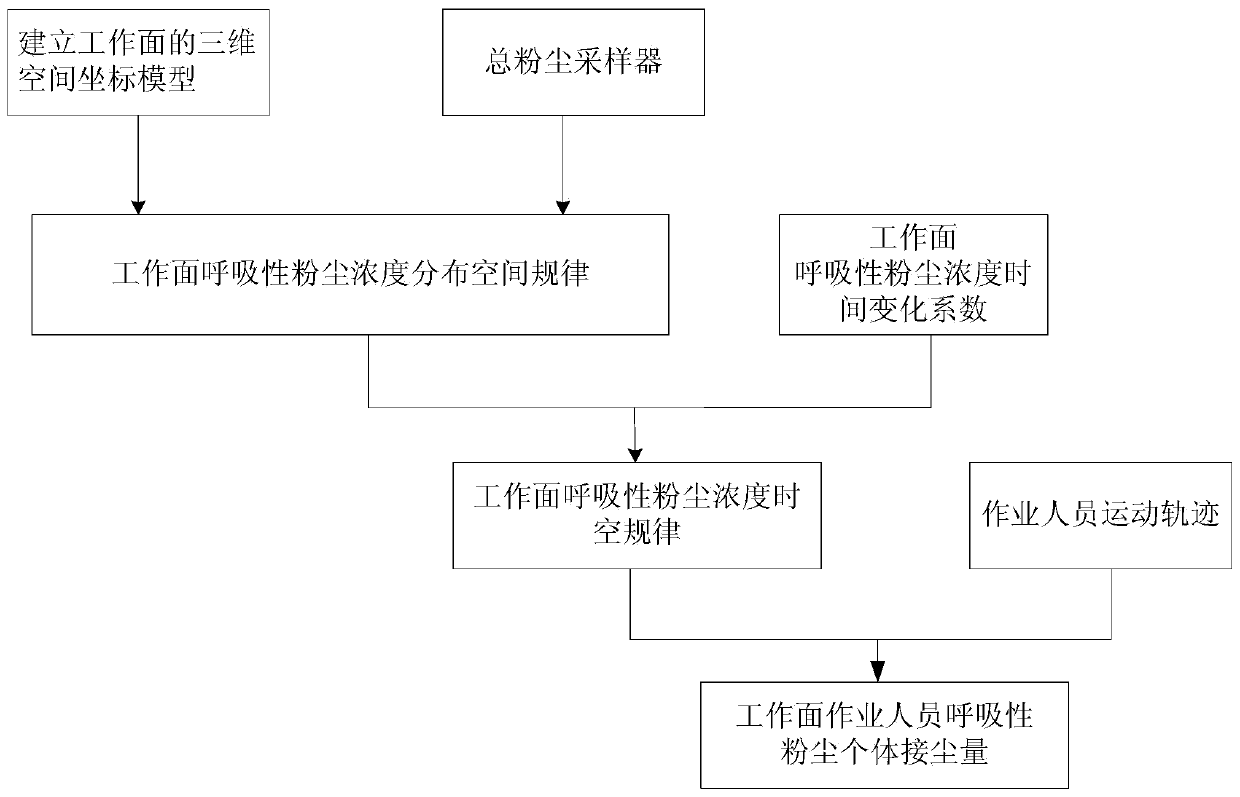

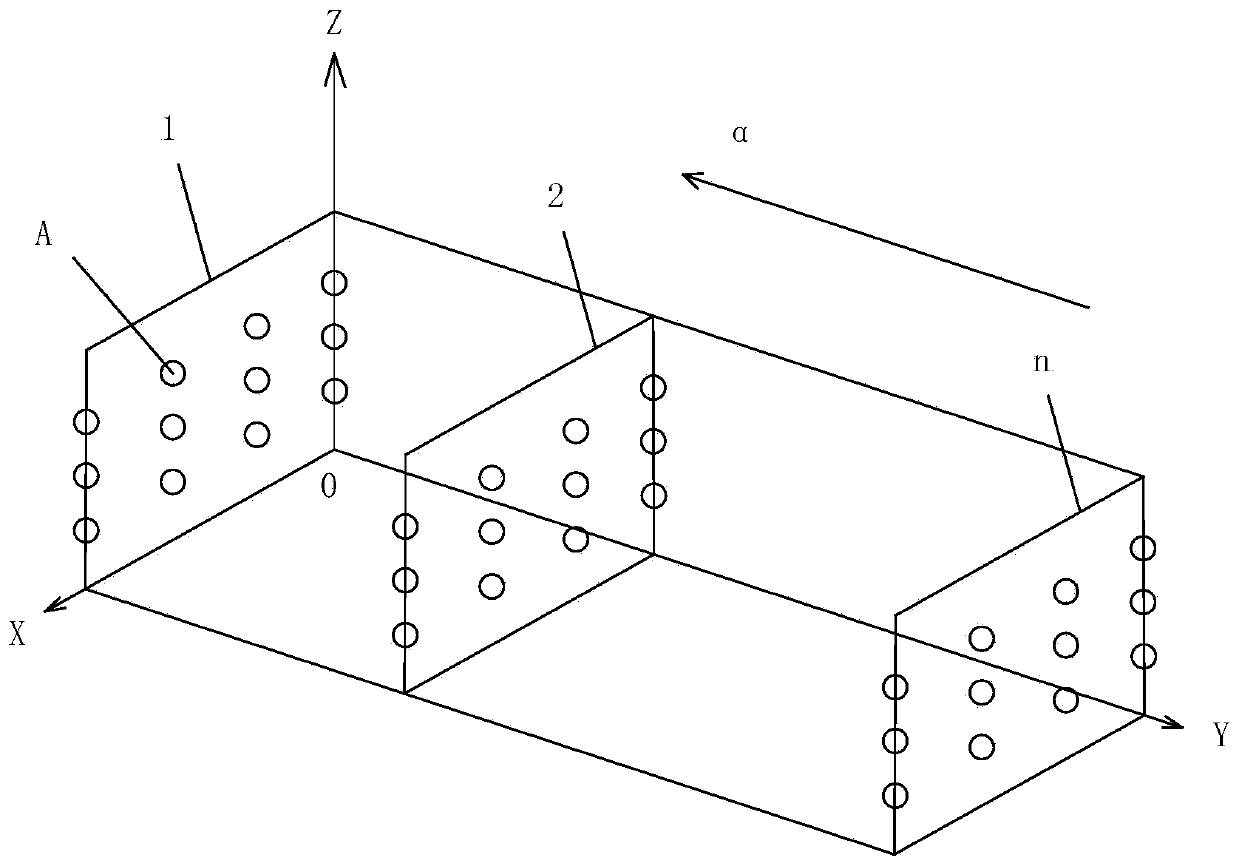

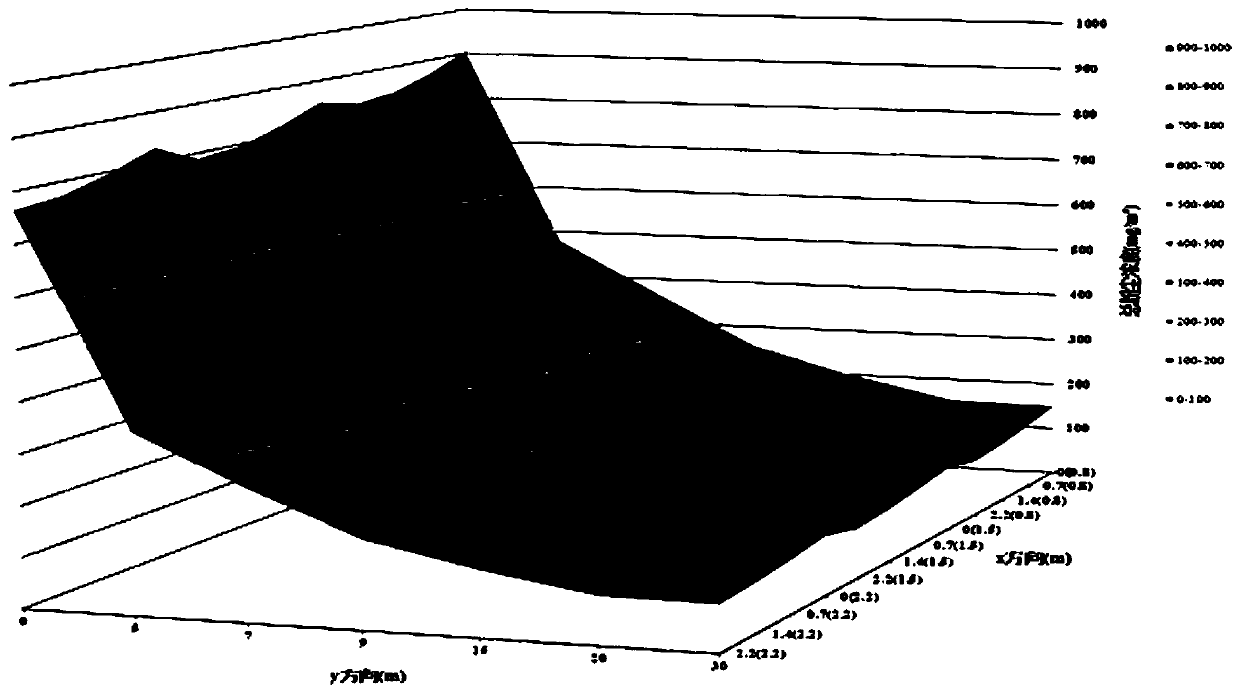

Mine working face dust hazard online monitoring system and method

ActiveCN111351731AAvoid harmImprove healthParticle size analysisDesign optimisation/simulationThree-dimensional spaceRespirable dust

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

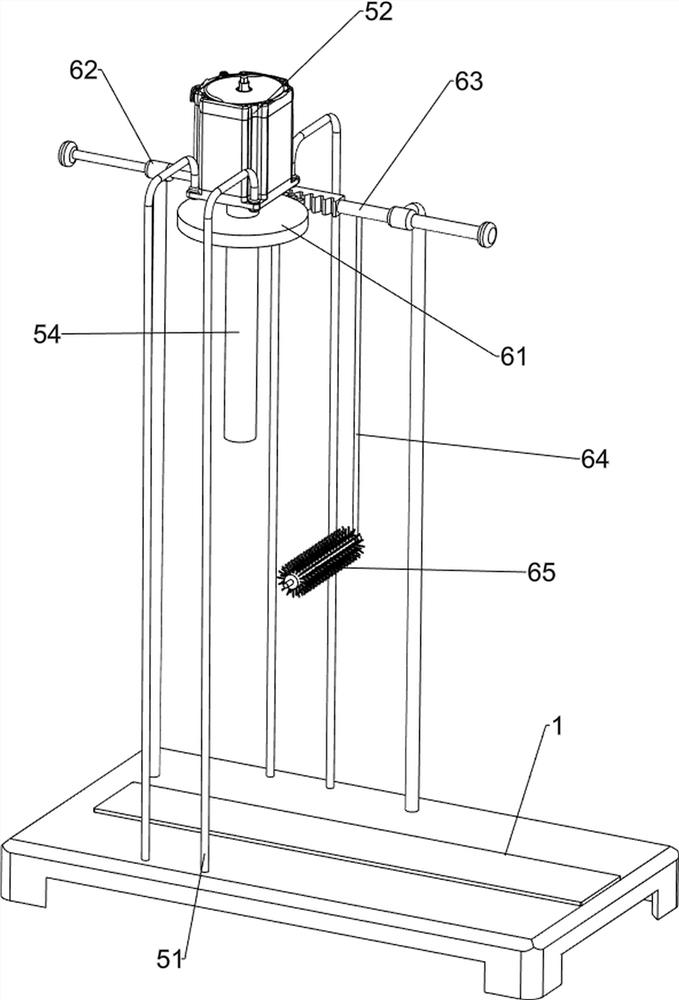

Dedusting and recycling device used in flour mill

The invention discloses a dedusting and recycling device used in a flour mill. The dedusting and recycling device comprises an air inlet assembly, a coarse filtering assembly and a dedusting assembly, wherein the air inlet assembly is connected with the coarse filtering assembly; the coarse filtering assembly is connected with the dedusting assembly; the air inlet assembly comprises an outer barrel and an inner barrel; the inner barrel is arranged inside the outer barrel; a first fan with an upward air outlet side is arranged inside the outer barrel; a second fan with a downward air outlet side is arranged inside the inner barrel; a dustproof brush is arranged on the edge of the bottom of the outer barrel; the coarse filtering assembly comprises a sieve plate; a filter hole is formed in the sieve plate; a thimble matched with the filter hole in shape is arranged on the right side of the filter hole; the dedusting assembly comprises a filter bag; an isolating hood sleeves the filter bag; a placing plate is arranged below the filter bag; a sleeve is arranged at the bottom of the placing plate; the bottom of the sleeve is fixed to a pedestal; the placing plate is pressed against an eccentric cam below; the eccentric cam is driven by a first motor. The coarse filtering assembly and the dedusting assembly of the dedusting and recycling device not only can effectively reduce flour dust in air, but also can recycle a part of the flour dust.

Owner:安徽天诚环保机械有限公司

Ceramic heating sheet machine

ActiveCN111761485AReduce accumulationGrinding carriagesAbrasive surface conditioning devicesRough surfaceEngineering

The invention discloses a ceramic heating sheet machine, which structurally comprises a machine body, a workbench, a distribution box and a top cover, wherein the workbench is fixed to the center position of the top of the machine body; a flat grinding machine grinds the surface of a heating plate and dust is attached to the surface of sandpaper; through the placement and removal of the heating plate, a cleaning device is in repeated contact with the surface of the sandpaper; the dust generated by grinding the heating plate on the surface of the sandpaper is collected, so that the accumulationof powder on the rough surface of the sandpaper on the surface is reduced, uneven points are arranged on the surface of the sandpaper, and the use of the heating plate is affected by the fact that the surface of the sandpaper is scratched by the points when the points are in contact with the heating plate; due to the fact that part of dust is easily attached to the surfaces of clamping blocks when the surfaces of the clamping blocks are in contact with small holes in the sandpaper, the dust attached to the surfaces of the clamping blocks is removed through clamping teeth inside side grooves,and the dust on the surfaces of the clamping blocks is reduced; and the volume of the clamping blocks becomes larger through continuous extrusion, the clamping blocks cannot enter the small holes in the sandpaper, the dust in the small holes is removed, and the removal of the dust on the surface of the sandpaper is affected.

Owner:徐州康纳高新材料科技有限公司

Self-cleaning device for belt conveyor and cleaning method of self-cleaning device

InactiveCN113477653AImprove cleaning efficiencyReduce wasteCombination devicesCleaningWorking environmentEnvironmental engineering

The invention relates to a self-cleaning device for a belt conveyor and a cleaning method of the self-cleaning device. The self-cleaning device comprises a material collecting component and at least one group of clearing components; and each group of clearing components comprises a first material clearing part, a second material clearing part which is arranged on one side of the first material clearing part in parallel, and a material collecting part. Through cooperation between the first material clearing part and the second material clearing part, the efficiency of clearing dust and attached materials on the surface of the conveying belt can be improved, the phenomenon that the dust and material residues still exist after cleaning is reduced, and normal work of the conveying belt and related parts is protected; the material collecting component can collect the cleared and fallen materials, so that the influence from the materials on the working environment and the health of workers can be reduced, the collected materials can be recycled, and the waste of the materials is reduced; and the dust can be adsorbed, settled and collected through a dust adsorbing and falling component, so that the influence from the dust on the working environment and the health of the workers is reduced, and potential safety hazards are reduced.

Owner:NANJING YUQUN COMM TECH CO LTD

Method for treating dust on coal mine heading face by using aerial fog turbulent flow fluid

InactiveCN112392535ASolve the problem of high water consumptionSolve efficiency problemsDust removalFire preventionMining engineeringCoal dust

The invention relates to a method for treating dust on a coal mine heading face by using aerial fog turbulent flow fluid. The method is used for removing dust on an underground coal mine fully-mechanized heading face and is characterized in that low-pressure compressed air is used as a main power source, normal-pressure water is used for wetting and modifying gas, and gas-liquid two-phase fluid ismixed, atomized and sprayed on the coal mine driving face. Through continuous turbulence vortex splitting and energy transmission, the driving face is covered, a dust fog removing area is formed on the coal wall of the driving face and repeatedly collides with dust generated in the production process of the driving face for multiple times, and fine dust particles are aggregated and coagulated infog drops and settle on the ground surface, so that dust dissipation and reentrainment do not occur in the space of the underground coal mine driving face. According to the method, underground coal dust explosion caused by dust flying on the driving face and malignant events caused by silicosis of workers are avoided, and application prospects and significance are very important. A device adoptedby the method is simple, reliable, easy to install, efficient in dust suppression and free of reentrainment.

Owner:TAIYUAN UNIV OF TECH

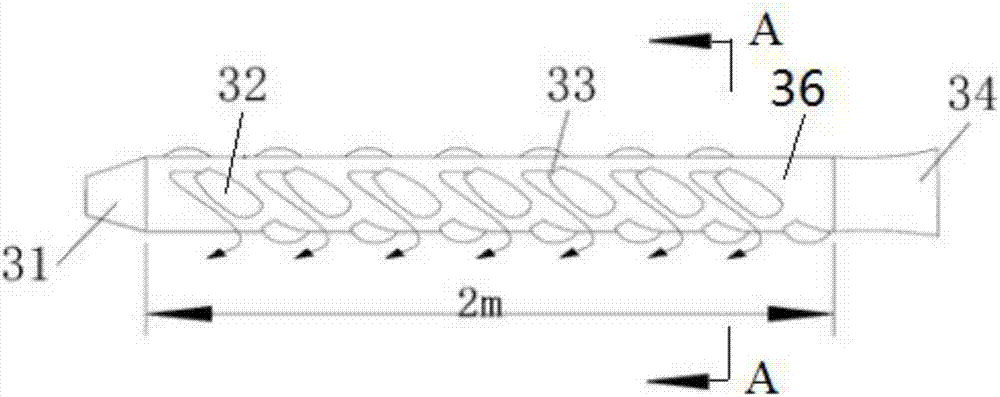

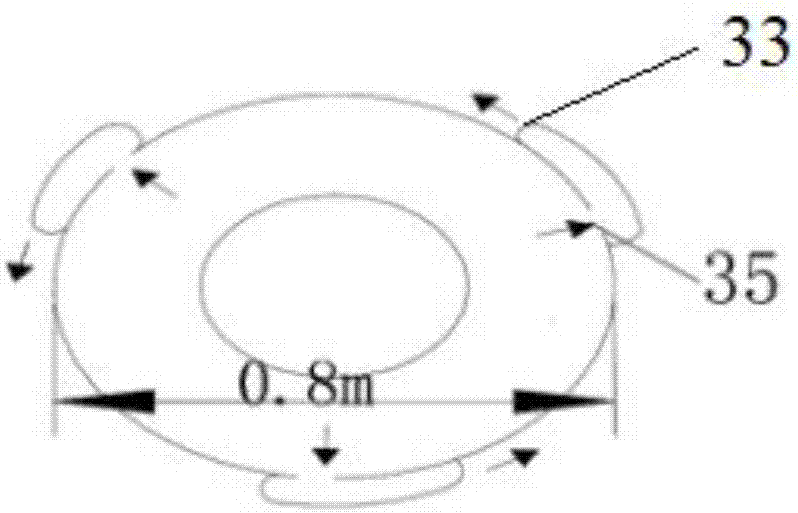

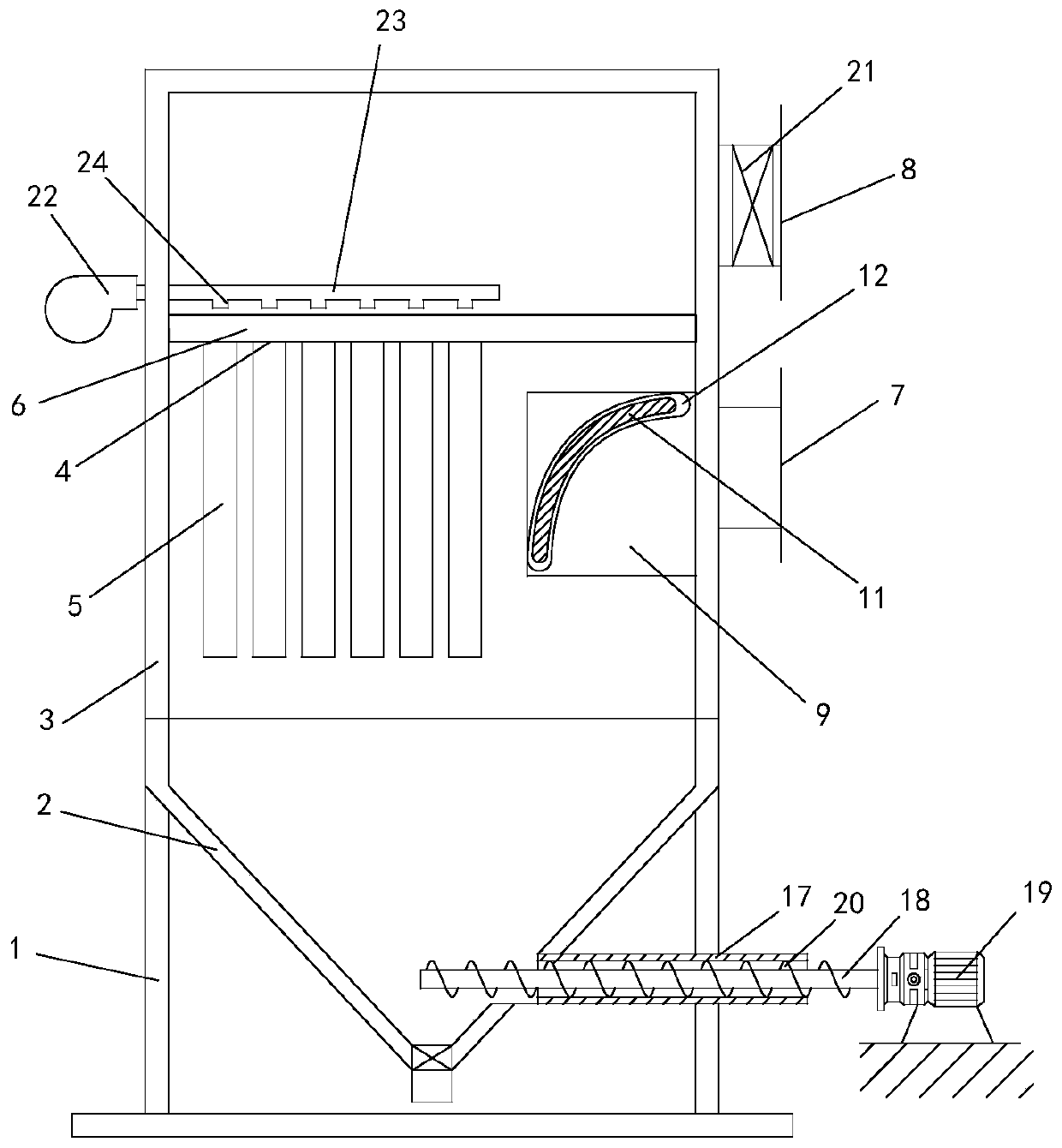

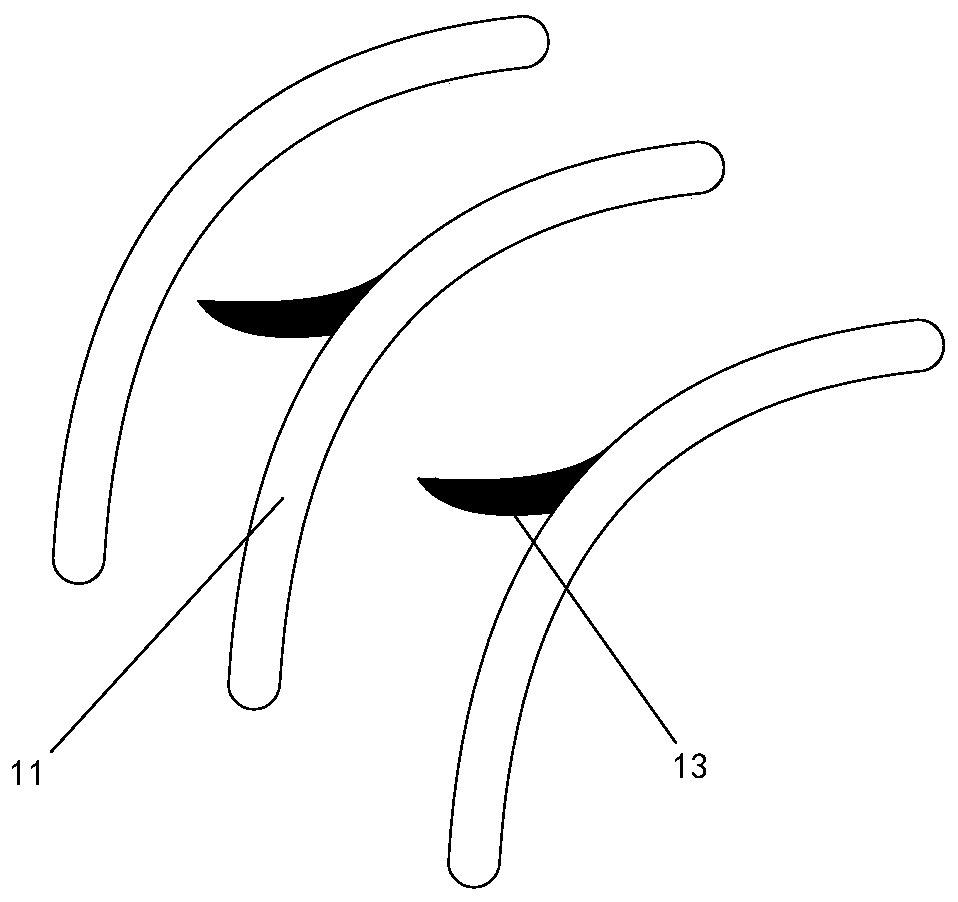

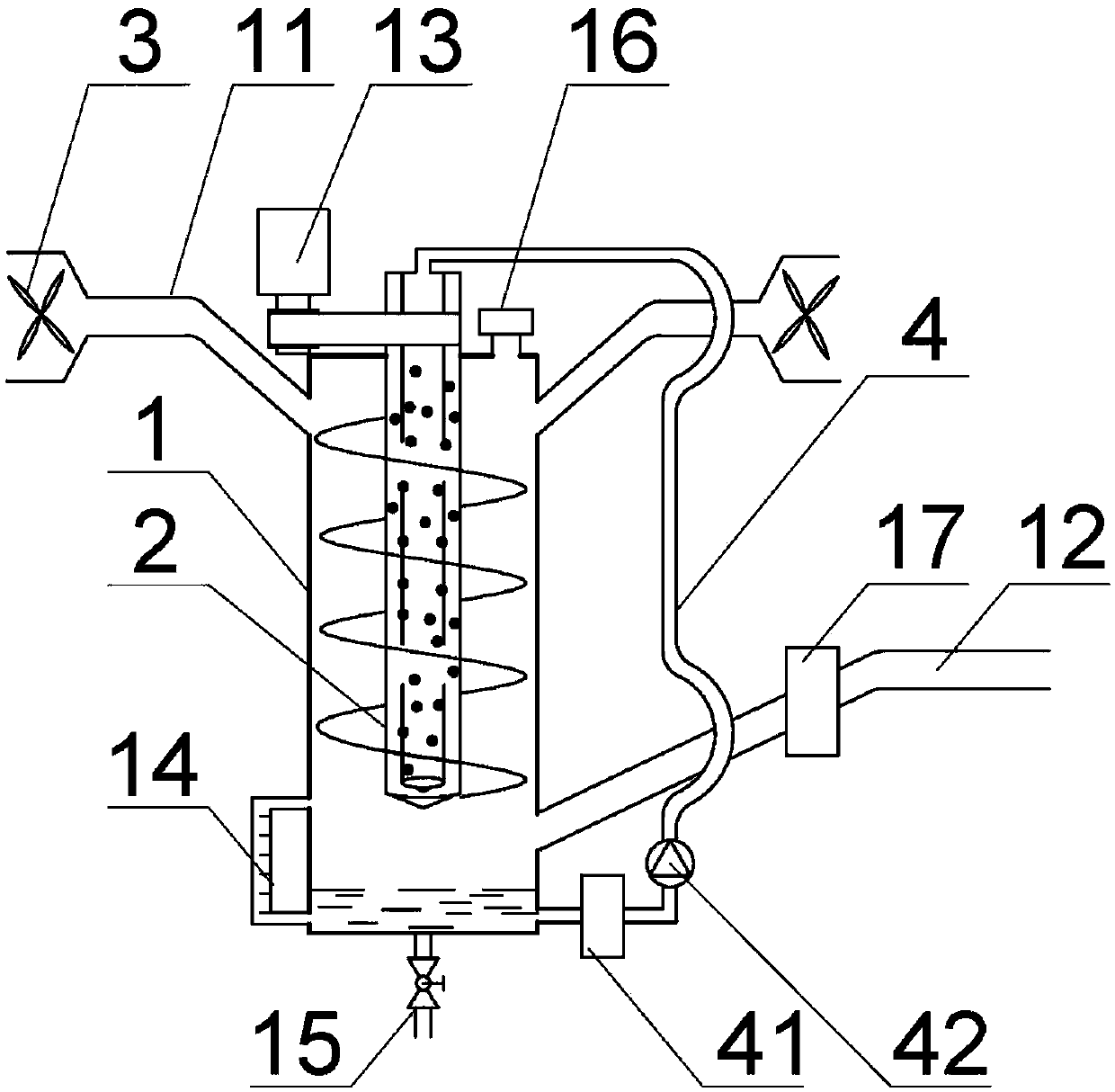

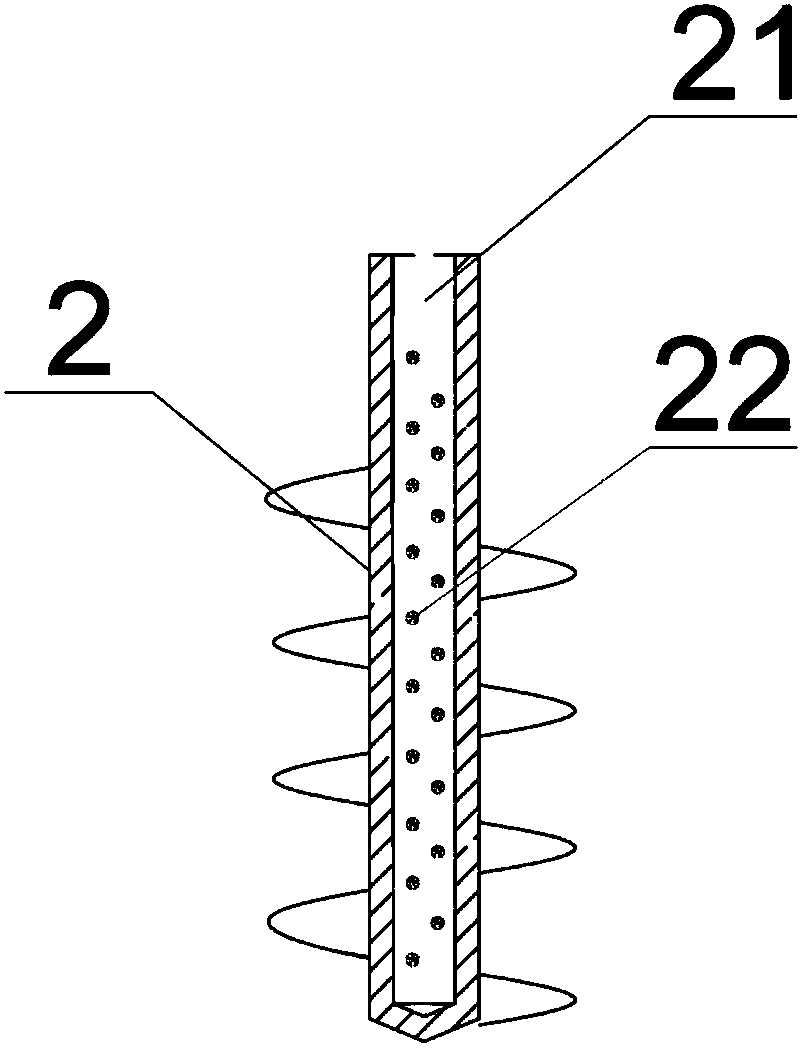

Dust removing device for wheat flour processing factory

PendingCN107754541AGood for physical and mental healthReduces the possibility of dust explosionsCombination devicesDust explosionEngineering

The invention discloses a dust removing device for a wheat flour processing factory. An air supply packing auger is rotationally arranged in a dust removing tank; an axial cavity for accommodating water is formed inside a rotating shaft of the air supply packing auger; a plurality of atomizing holes are formed in the rotating shaft of the air supply packing auger and communicated with the cavity;a plurality of air inlet pipelines are communicated with the dust removing tank and connected parts of the air inlet pipelines and the dust removing tank are close to the starting end of the air supply packing auger; an air outlet pipeline is communicated with the dust removing tank and a connected part of the air outlet pipeline and the dust removing tank is close to the tail end of the air supply packing auger; air containing wheat flour dust is sucked into the dust removing tank; the air supply packing auger in the dust removing tank rotates at high speed for spirally pushing the air to theair outlet pipeline; meanwhile, water in the cavity of the air supply packing auger is sprayed out from the atomizing holes; atomized water is combined with dust particles in the air; under the action of a centrifugal force, the dust particles are attached to the inner wall of the dust removing tank and flow to the bottom of the dust removing tank; the dust in exhausted gases subjected to dust removal is greatly reduced, so that physical and psychological health of workers in the factory is benefited, and the possibility of dust explosion is also reduced.

Owner:安徽省老家好食品有限公司

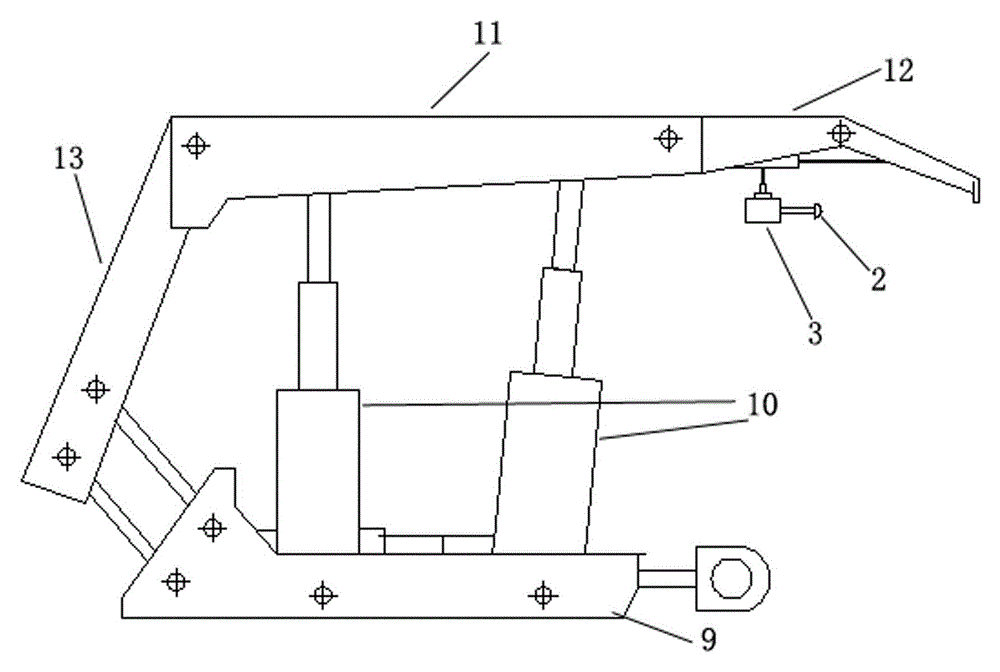

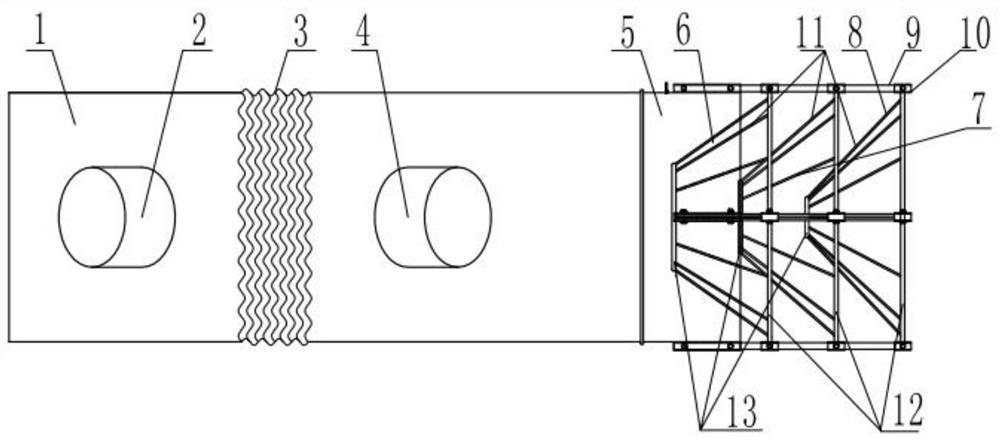

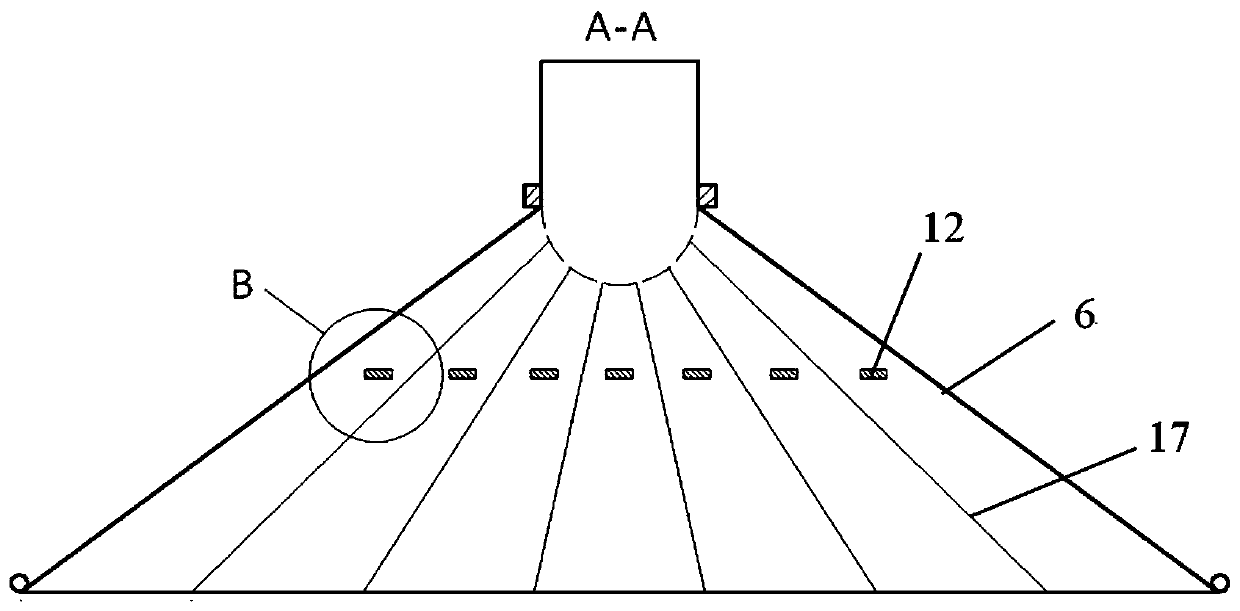

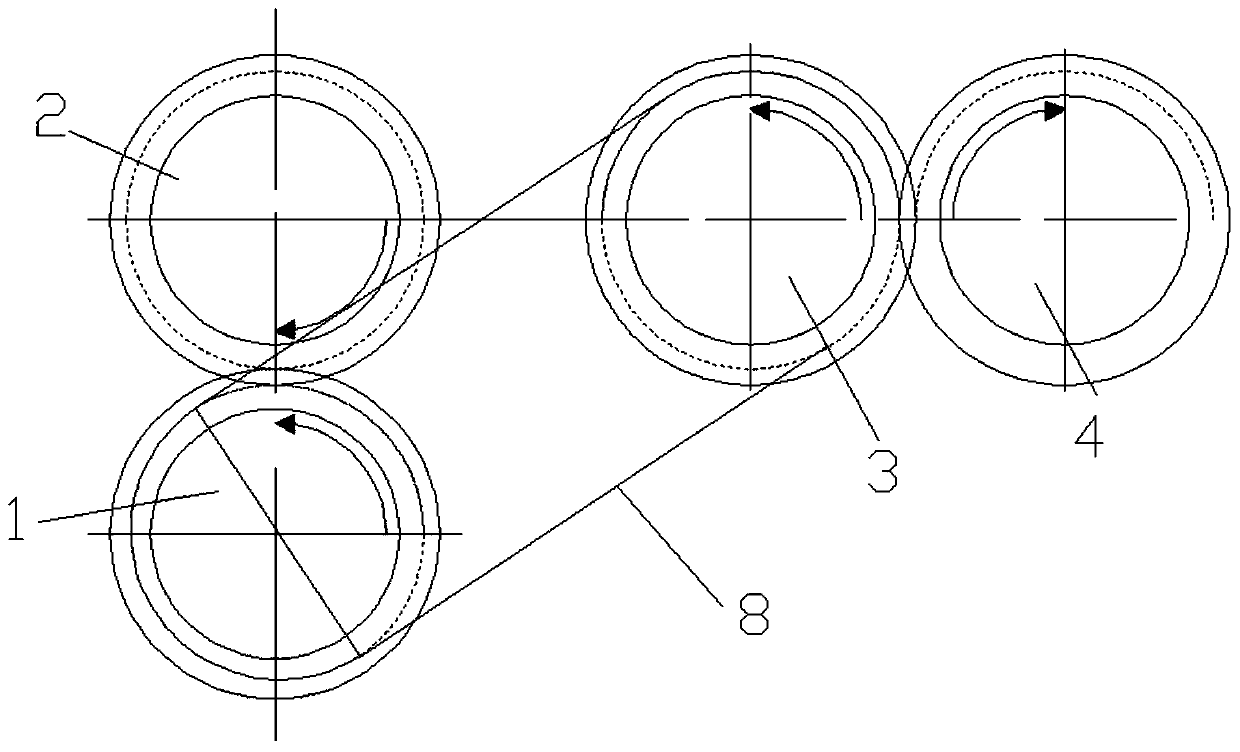

Umbrella-shaped air curtain air supply and dust control device for coal mine fully-mechanized excavation face

PendingCN112253210AAvoid accumulationImprove controlDust removalFire preventionMining engineeringDust control

The invention discloses an umbrella-shaped air curtain air supply and dust control device for a coal mine fully-mechanized excavation face. The device comprises an air supply device and an umbrella-shaped air curtain dust control device, wherein the air supply device is connected and fixed with the umbrella-shaped air curtain dust control device in series, the air supply device is provided with afirst inclined air outlet, and an outlet of the first inclined air outlet inclines towards an inlet of the air supply device; and the umbrella-shaped air curtain dust control device is used for carrying out regional dust control through an umbrella-shaped air curtain. According to the umbrella-shaped air curtain air supply and dust control device for the coal mine fully-mechanized excavation face,the problem that toxic and harmful gas is liable to accumulate in an overlapping area of air supply and dust removal due to lack of fresh air flow is solved, head-on dust is prevented from diffusingbackwards through the umbrella-shaped air curtain formed by the umbrella-shaped air curtain dust control device, regional dust control is achieved, therefore, disordered diffusion of dust on the fully-mechanized excavation face is effectively controlled, and the dust control effect is achieved.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

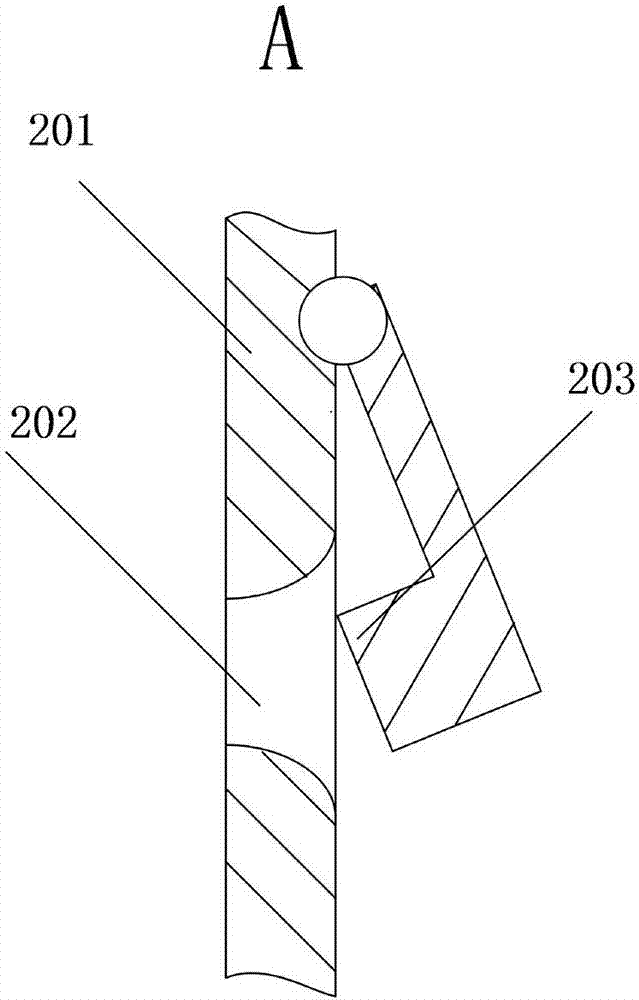

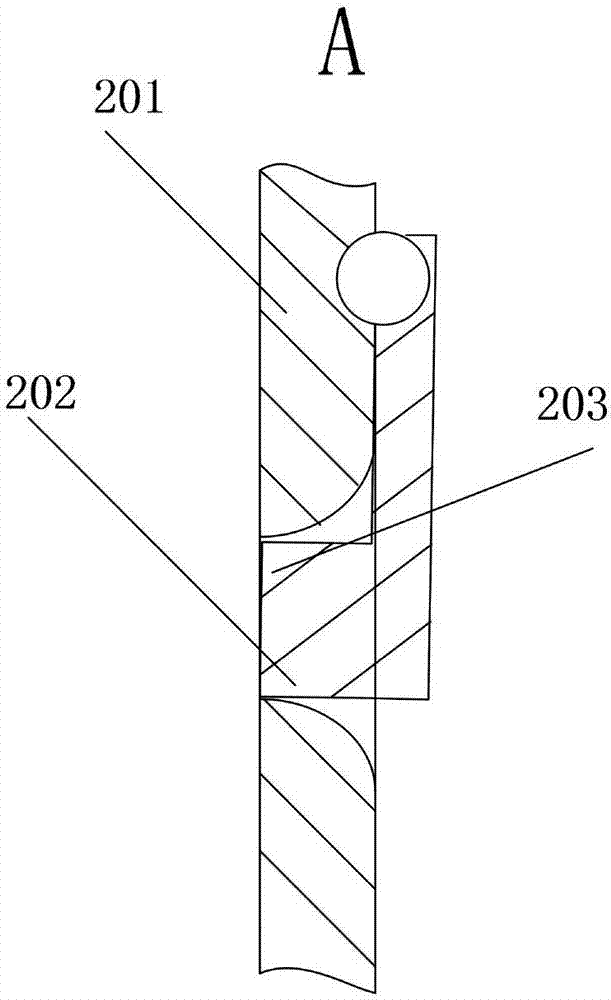

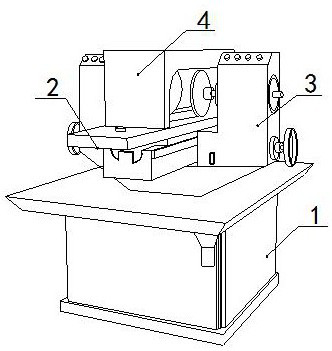

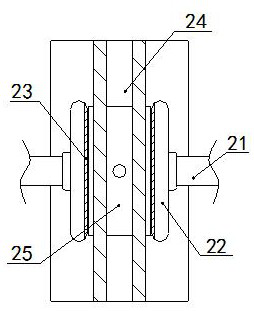

Processing technique for clutch facing

The invention relates to a processing technique for a clutch facing. The production method comprises the following steps of internal mixing, i.e., all raw materials are weighed according to respective weights and then are placed in a closed rubber mixing mill for internal mixing; mixed rubber sheeting, i.e., the internally-mixed mixed materials are sheeted through a rubber mixing mill; rolling, i.e., glass fiber yarn is placed on a goods shelf and dragged sequentially to a roller press through a dragger to be rolled with glue lines; winding, i.e., the glue lines are wound around finished sheets to form different regular concentric circles; hot pressing, i.e., a multi-layer thermal press is used for solidifying, and heat is supplied in a centralized mode; thermal treatment, i.e., a hot air circulation type thermal treatment device is adopted to make the facing be solidified more completely; surface grinding, i.e., external impurities are removed, and the materials are smoothed; drilling, i.e., a double-head automatic drilling machine is used for drilling holes according to drawing regulations; and cleaning, i.e., a facing cleaning machine is used for removing dust on the surface of the facing. The processing technique is simple, practical and reliable, and the quality of the produced clutch facing is substantially improved.

Owner:JIANGSU YAOYAO CASTING IND

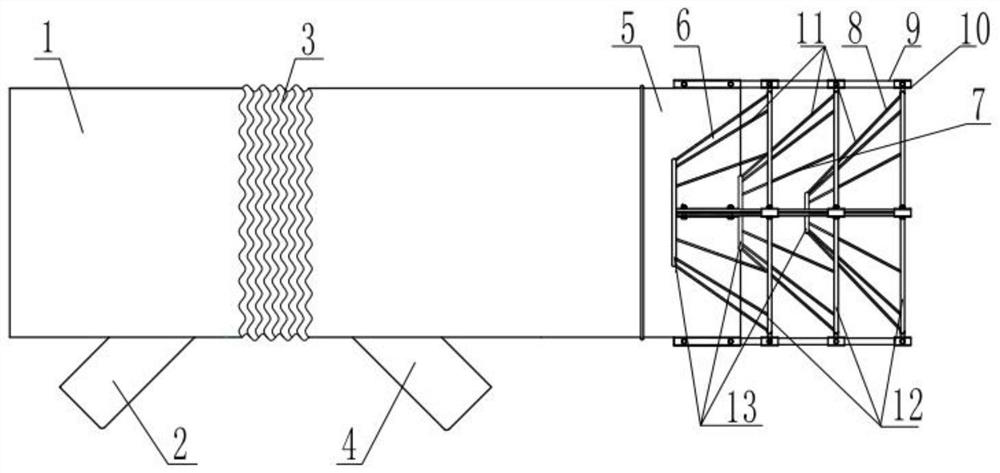

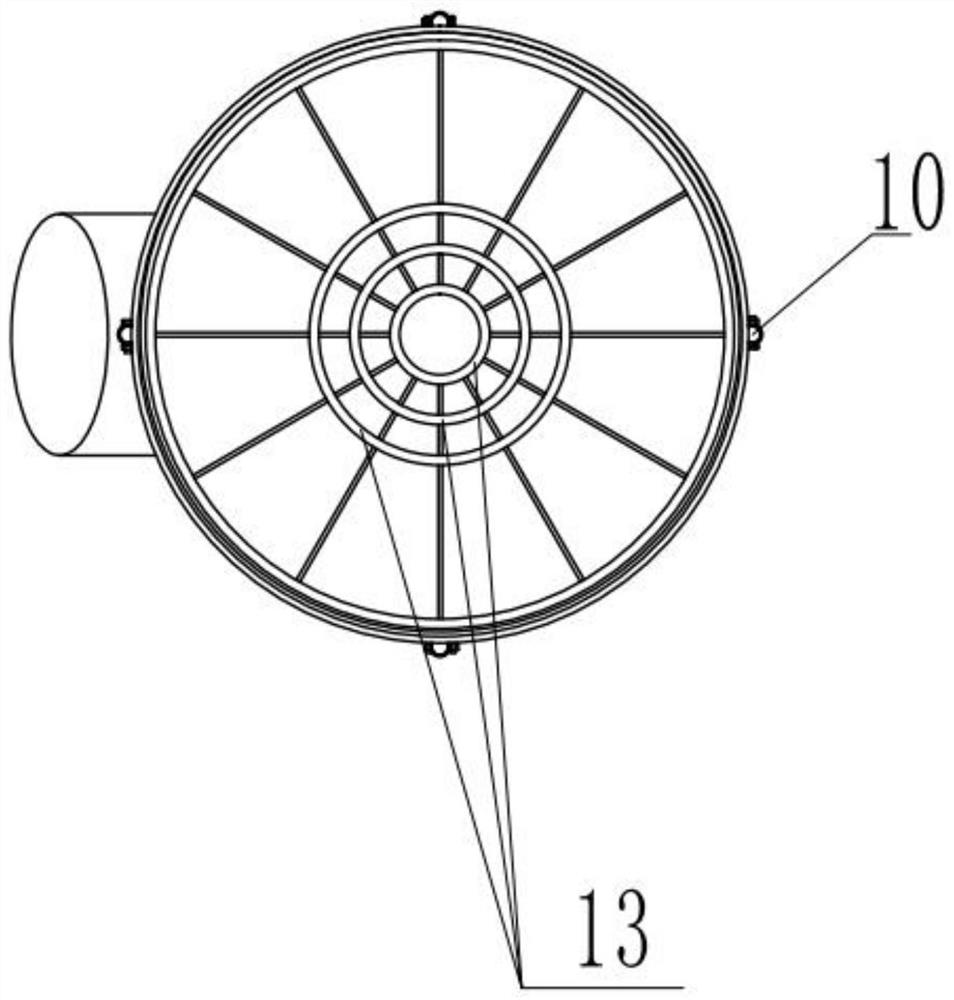

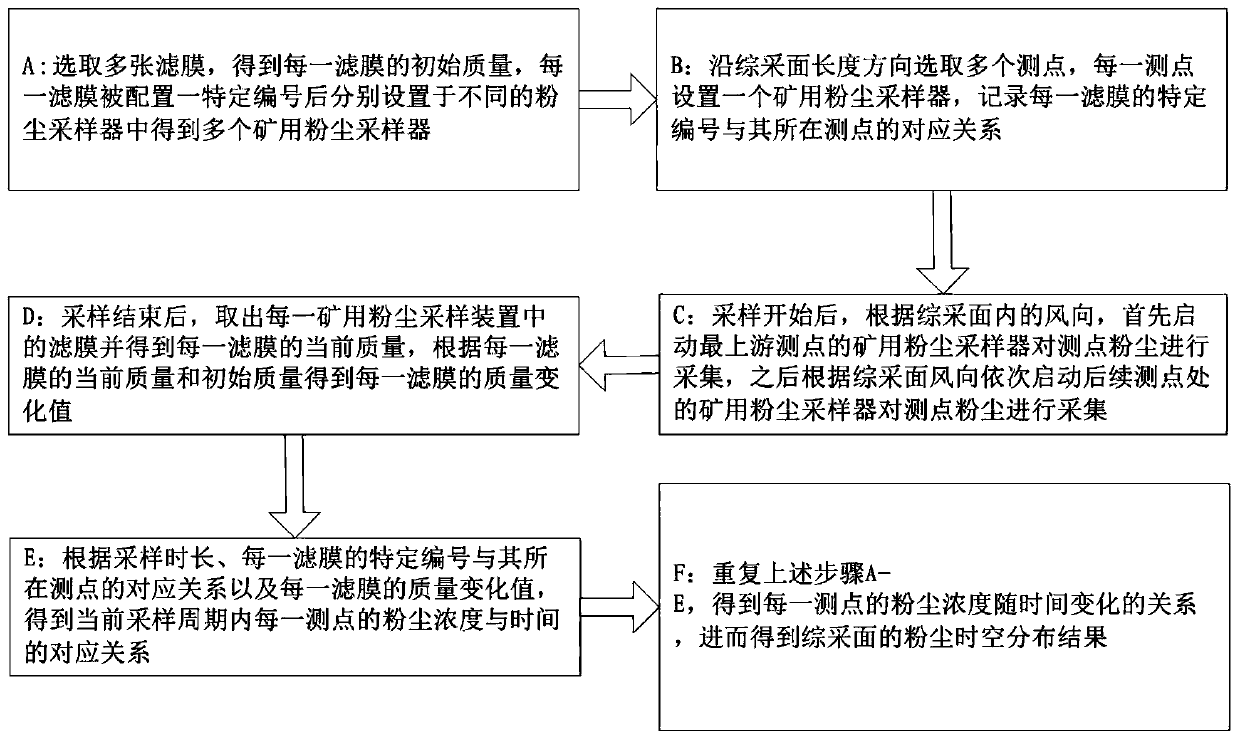

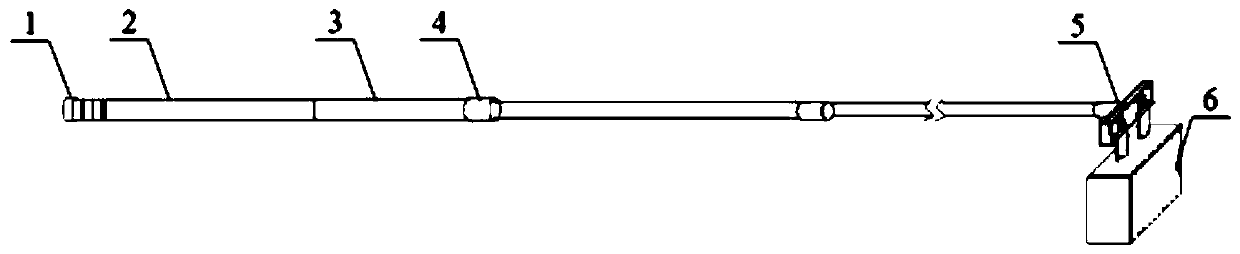

Space-time distribution detection method and detection system for coal mine fully-mechanized coal mining surface dust

InactiveCN111103221AScientific and reliable data supportParticle suspension analysisMining engineeringSurface dust

The invention provides a space-time distribution detection method and detection system for coal mine fully-mechanized coal mining surface dust. The method comprises the steps that a mining dust sampler is arranged at each measuring point, after sampling is started, the mining dust sampler at the most upstream measuring point is started to collect dust at the measuring point according to the wind direction in a fully mechanized coal mining face, and then the mining dust samplers at the subsequent measuring points are sequentially started to collect dust at the measuring points according to thewind direction of the fully mechanized coal mining face; after sampling is finished, the filter membrane is taken out in each mining dust sampler to obtain the current mass of each filter membrane andobtain the mass change value of each filter membrane according to the current mass and the initial mass of each filter membrane; the corresponding relation between the dust concentration of each measuring point and the time is further obtained in the current sampling period; and the steps are repeated to obtain the relationship of the dust concentration of each measuring point along with the timechange, thereby obtaining the dust space-time distribution result of the fully mechanized coal mining face. By means of the scheme, the evolution rule of the dust concentration at any position in thefully mechanized coal mining face along with time can be obtained.

Owner:SHENHUA SHENDONG COAL GRP

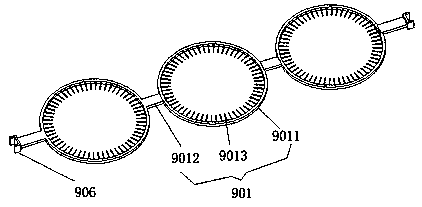

Pellet surface dust treatment device

ActiveCN111229725AMeet the process requirementsRealize online continuous processingCleaning using gasesEnvironmental engineeringRadioactive waste

The invention provides a pellet surface dust treatment device. The pellet surface dust treatment device comprises a dust blowing cavity, a pellet conveying device and a fixed support, wherein the pellet conveying device and the fixed support are connected with the dust blowing cavity; the pellet conveying device is used for continuously inputting and discharging pellets to the dust blowing cavity;and the dust blowing cavity is used for continuously purging the surfaces of the pellets conveyed into the dust blowing cavity. According to the treatment device, on-line continuous treatment of duston the surfaces of the pellets is realized; and in addition, the treatment device does not use any cleaning liquid, so that generation of radioactive waste liquid is avoided, and problems brought bya water washing mode are solved.

Owner:CHINA NUCLEAR POWER ENG CO LTD +1

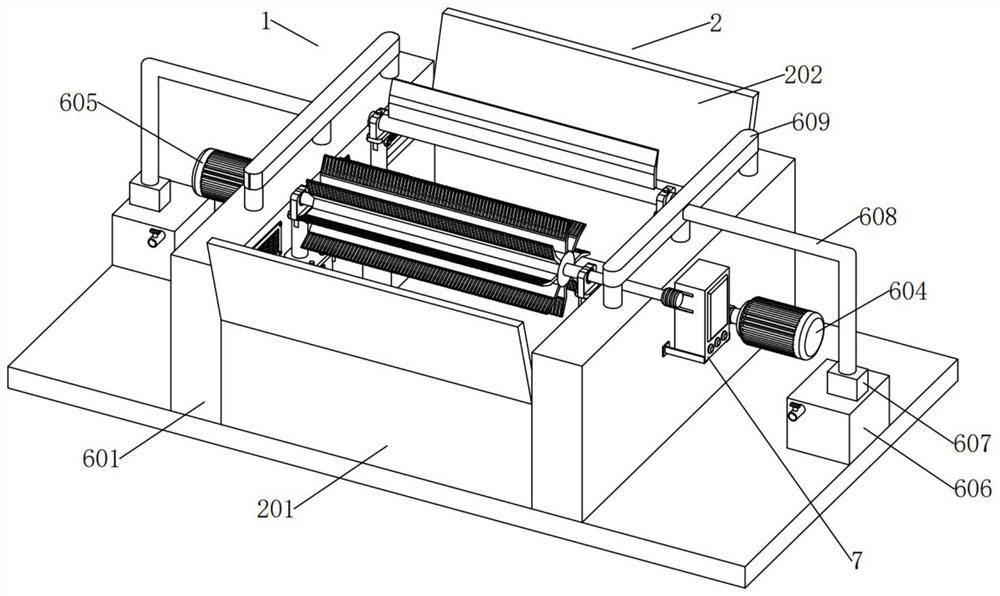

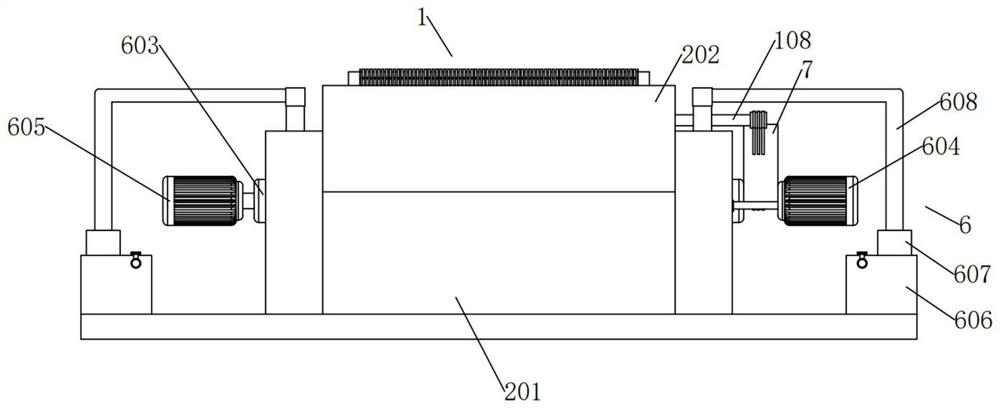

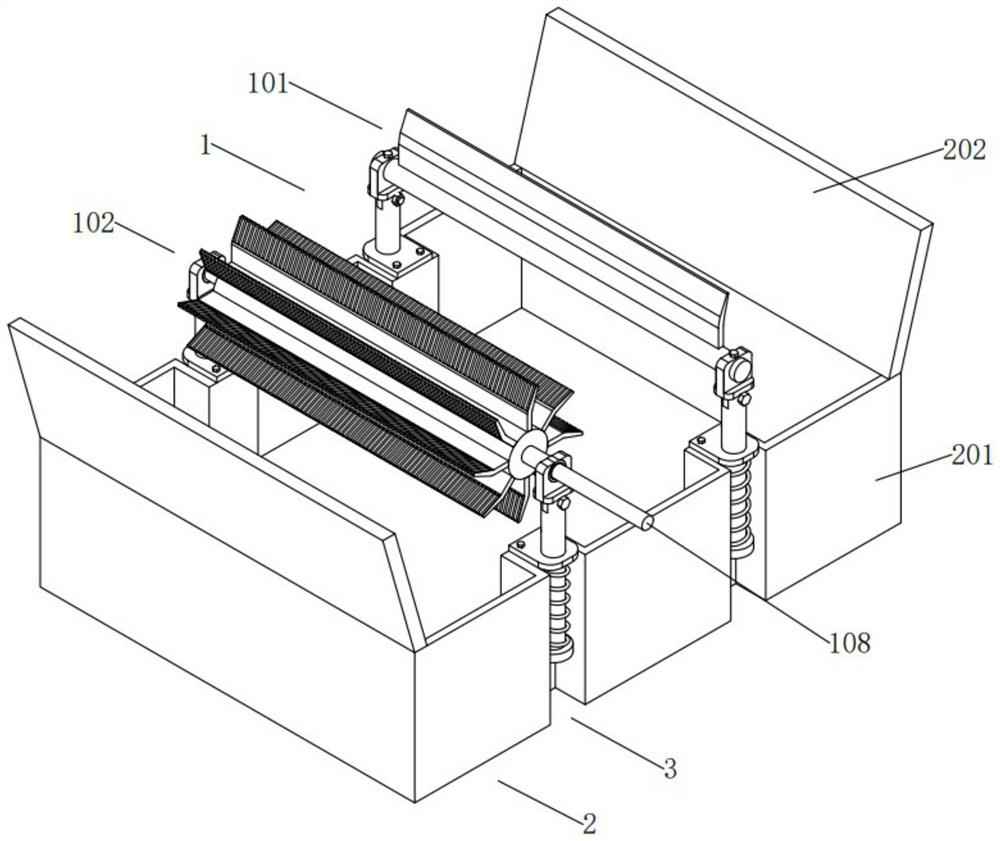

Surface dust removal device for corrugated paper on printer

ActiveCN111204124AImprove printing qualityUniform air volumePrinting press partsDust controlEngineering

The invention discloses a surface dust removal device for corrugated paper on a printer. The surface dust removal device comprises a corrugated paper conveying device, wherein the corrugated paper conveying device comprises a paper pressing roller and a paper conveying roller; the paper pressing roller and the paper conveying roller are vertically oppositely pressed; one side of the paper pressingroller is provided with a hair brush roller A, an air suction cavity and a hair brush roller B in sequence; and the hair brush roller A and the hair brush roller B mutually upwards oppositely roll. According to the surface dust removal device, the paper pressing roller and the paper conveying roller, which are vertically oppositely pressed, are adopted to convey the corrugated paper to be printed; the right side of the paper pressing roller is provided with the hair brush roller A, the air suction cavity and the hair brush roller B in sequence; the hair brush roller A and the hair brush roller B mutually upwards oppositely roll; after dust on the surface of the corrugated paper to be printed is gathered between the hair brush roller A and the hair brush roller B, the air suction cavity sucks out the gathered dust so as to completely remove the dust on the surface of the corrugated paper to be printed, and a situation that the printing of the corrugated paper is affected by impuritieson the surface of the corrugated paper so as to affect the printing quality of the corrugated paper is avoided.

Owner:江苏省朗晖实业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com