Ceramic heating sheet machine

A technology of ceramic heating plate and body, which is applied in the direction of grinding frame, metal processing equipment, grinding machine parts, etc., can solve the problems of affecting the use of heating plate and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

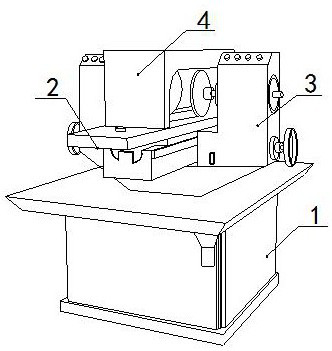

[0027] as attached figure 1 to attach Figure 5 Shown:

[0028] The invention provides a ceramic heating plate machine, the structure of which includes a body 1, a workbench 2, a power distribution box 3, and a top cover 4, the workbench 2 is fixed at the center of the top of the body 1, and the power distribution boxes 3 are respectively fixed On both sides of the workbench 2, the top cover 4 is installed on the top of the workbench 2.

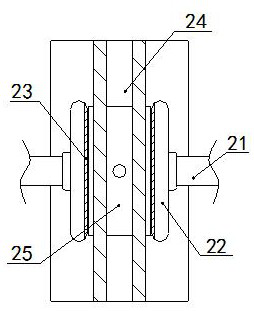

[0029] The workbench 2 is provided with a transmission shaft 21, a clamping plate 22, sandpaper 23, a limit groove 24, and a cleaning device 25. The transmission shaft 21 runs through the middle part of both sides of the workbench 2 respectively, and the clamping plate 22 and the transmission shaft The inner ends of 21 are connected, the sandpaper 23 is fixed on the inner side of the clamping plate 22, the limiting groove 24 is opened in the middle of the workbench 2, and the cleaning device 25 is set on the bottom of the limiting groove 24...

Embodiment 2

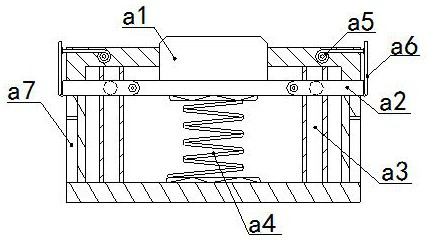

[0036] as attached Image 6 to attach Figure 8 Shown:

[0037] Wherein, the side groove a7 is provided with a buffer block d1, a clamping tooth d2, a push rod d3, and a connecting rod d4. Between the blocks d1, and the right side is fixed on the inner wall on the right side of the side groove a7, the latch d2 close to the buffer block d1 is connected by a push rod d4, and the top surface and bottom surface of the latch d2 are connected by a connecting rod d4 Sliding engagement, the push rod d3 is provided with two, inclined to connect with the locking teeth d2, so that the angle between the locking teeth d2 changes with the movement of the buffer block d1, so that the side plate a6 is fully in contact with the locking block b4, and there is It is beneficial to remove the dust on the block b4.

[0038] Wherein, the clamping tooth d2 is provided with a reset block r1, a clearing rod r2, a chip collecting groove r3, a clamping groove r4, and a slider r5, and the cleaning rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com