Space-time distribution detection method and detection system for coal mine fully-mechanized coal mining surface dust

A technology of spatiotemporal distribution and detection method, applied in measurement devices, analytical materials, particle suspension analysis, etc., can solve problems such as the inability to reflect the evolution of dust diffusion, the difficulty in reflecting the spatial distribution of dust, and the difficulty in judging the uneven distribution characteristics of dust in space and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

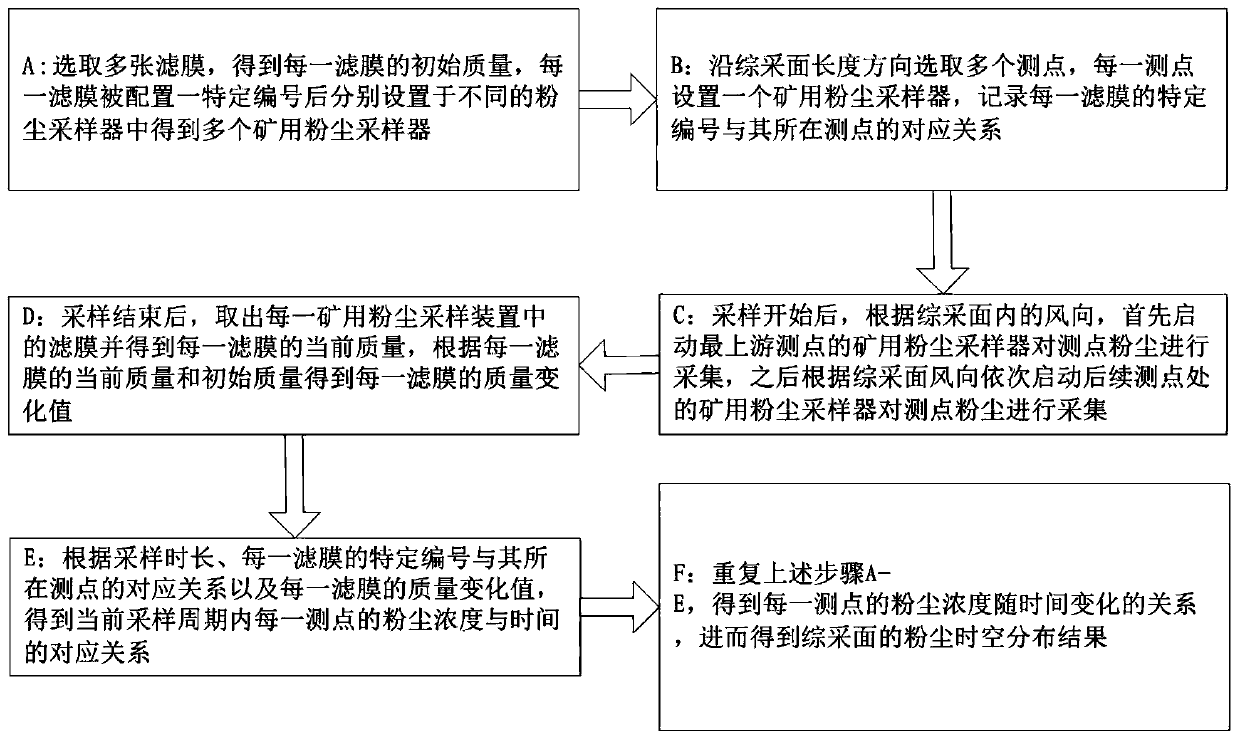

[0049] This embodiment provides a method for detecting the spatial and temporal distribution of fully mechanized coal mining dust, such as figure 1 shown, including the following steps:

[0050] A: Select multiple filter membranes to obtain the initial mass of each filter membrane. Each filter membrane is configured with a specific number and then set in different dust samplers to obtain multiple mine dust samplers; the filter membrane is preferred A brand new blank filter membrane can be selected, and the number of the filter membranes can be selected to be 6 or more. Wherein, the specific number is not particularly limited, and numbers, letters, etc. can be selected, for example: a, b, c, d, e, f....

[0051] B: Select multiple measuring points along the length of the fully mechanized mining face, set up a mining dust sampler at each measuring point, and record the specific number of each filter membrane and the corresponding relationship between the measuring points; the p...

Embodiment 2

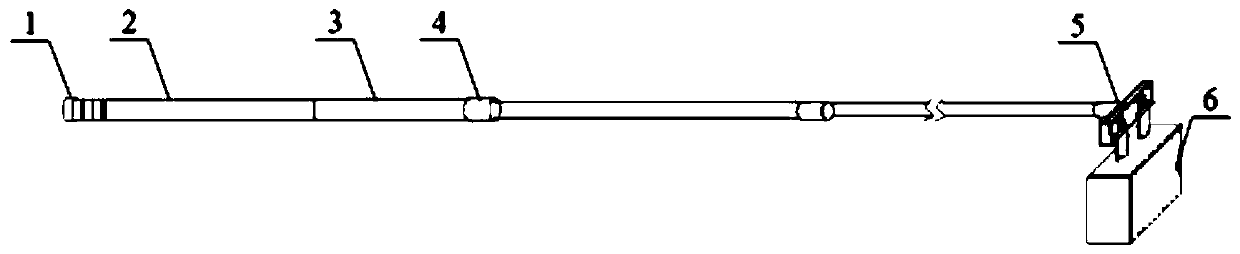

[0063] This embodiment also provides a detection system for realizing the time-space distribution detection method of fully mechanized coal mining flour and dust described in any of the schemes in Embodiment 1, including a dust sampler, a balance, a filter membrane, an anemometer, a distance measuring ruler and a controller . Wherein, the filter membrane is arranged in the dust sampler to obtain a mine dust sampler; the balance is used to measure the initial quality and current quality of the filter membrane; the anemometer is used to measure the wind speed of the fully mechanized mining face; The distance measuring ruler is used to measure the distance between different mine dust samplers; the controller is used to receive the wind speed of the fully mechanized mining face and the distance between different mine dust samplers, and start the different testers sequentially according to the preset sampling period. The mine dust sampler at the point; the controller is also used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com