Static strength and fatigue test device for tumbler type shaft housing as well as its method

A fatigue test and test device technology, applied in the field of rail transit, can solve the problems of distortion of the experimental data of the axle box, inability to obtain, ignoring the effect of the shock absorber, etc., to achieve the effect of standardization and improvement of rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

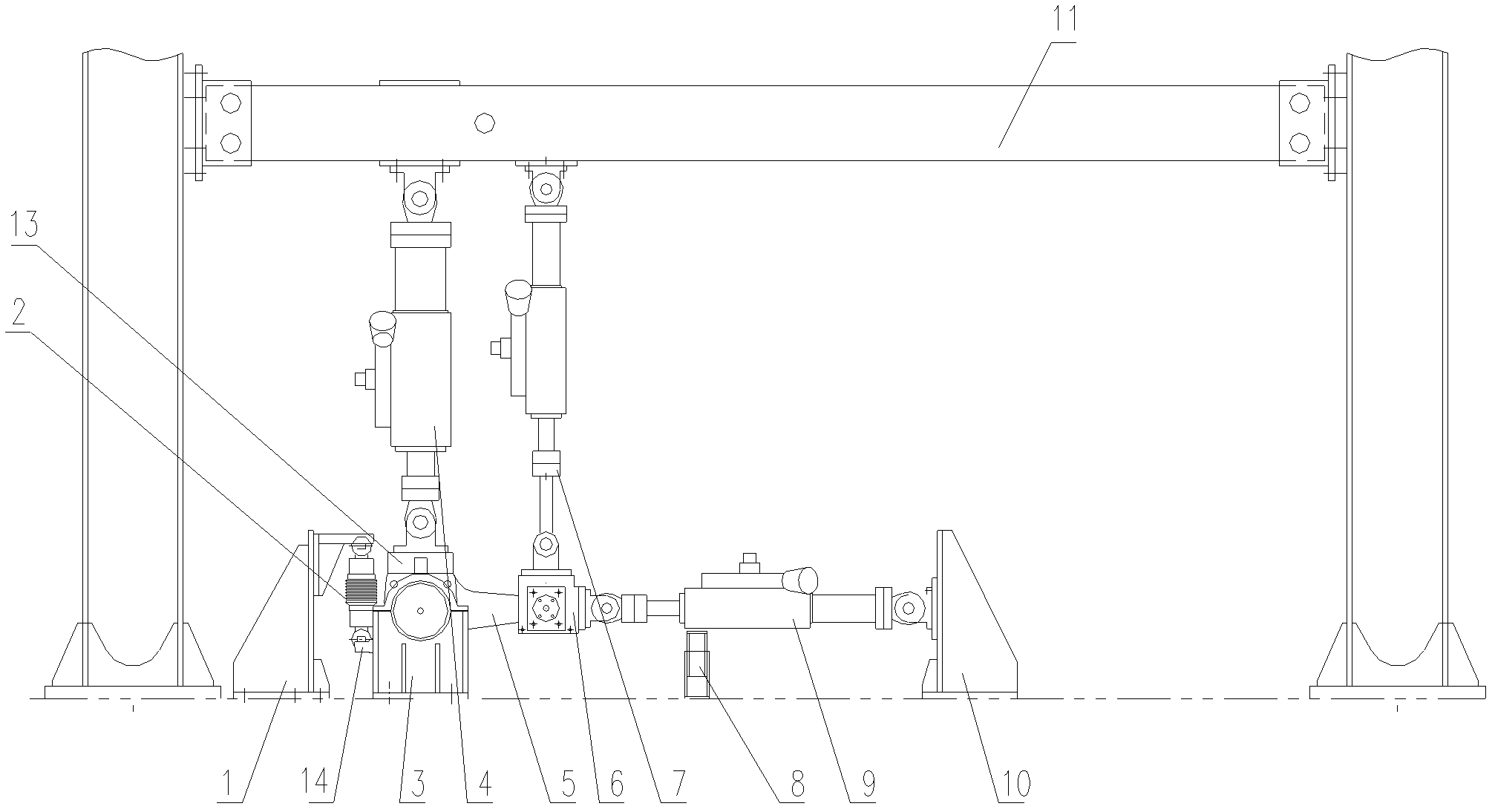

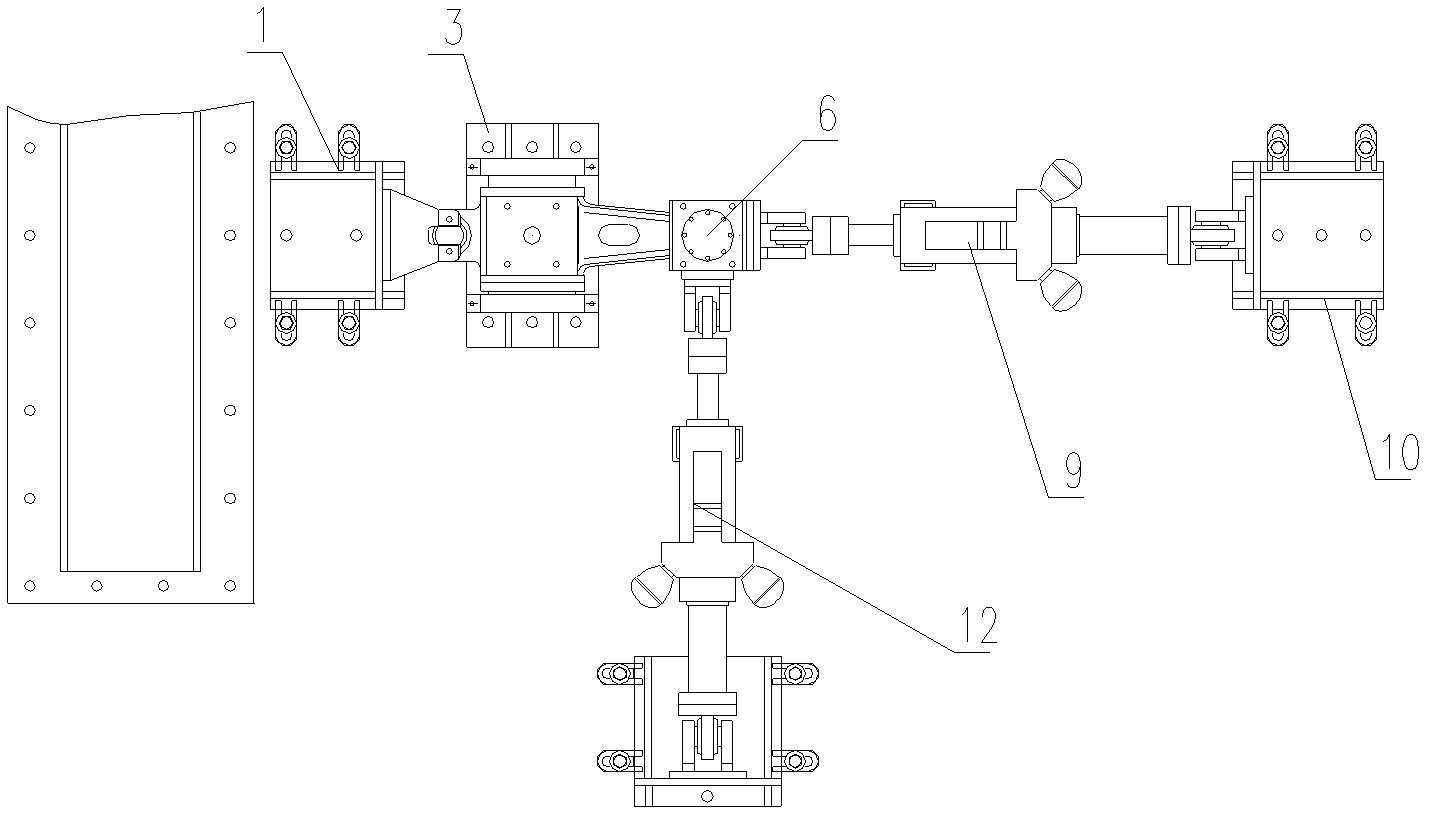

[0035] Example 1, such as figure 1 and figure 2 As shown, the test device for realizing the static strength and fatigue test of the pivoting arm type axle box mainly includes a loading beam 11 and an axle box seat 3 .

[0036] Wherein, the axle box body of the pivoting arm type axle box 5 is fixed on the axle box seat 3, and the axle box spring seat 13 on its top is connected to the first vertical actuator 4; The loading seat 6 , the second vertical actuator 7 , the lateral actuator 9 and the longitudinal actuator 12 are respectively connected to the node loading seat 6 .

[0037] A shock absorber 2 is loaded on the shock absorber seat 14 of the pivoting arm type axle box 5 , and the shock absorber 2 is installed on the shock absorber seat 1 .

[0038] An elastic support 8 is connected to the bottoms of the transverse actuator 9 and the longitudinal actuator 12 mounted on the support 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com