Exhaust gas purifying device and purification method thereof

An exhaust gas purification device and a technology for exhaust gas purification, which are used in exhaust devices, chemical instruments and methods, mufflers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

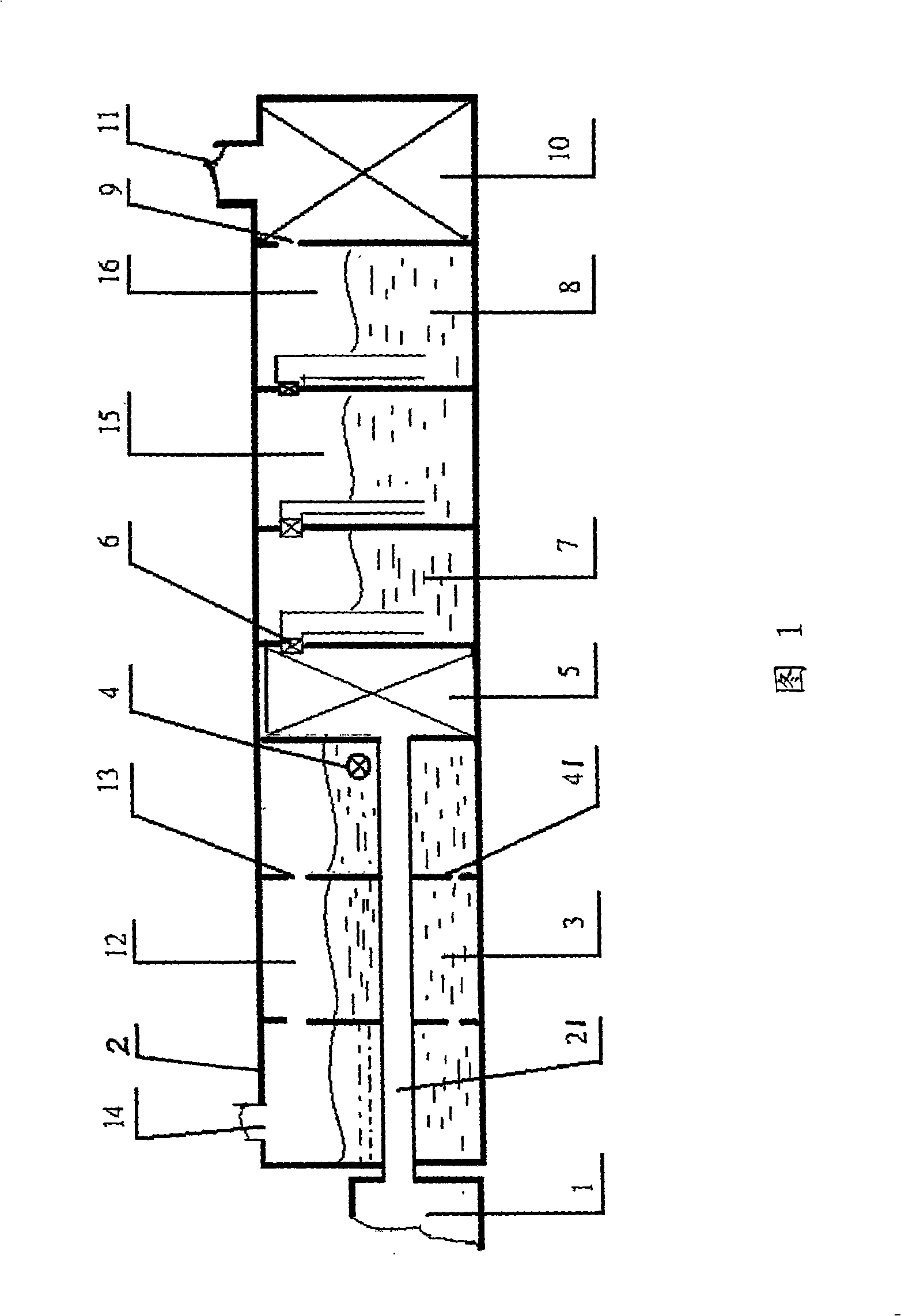

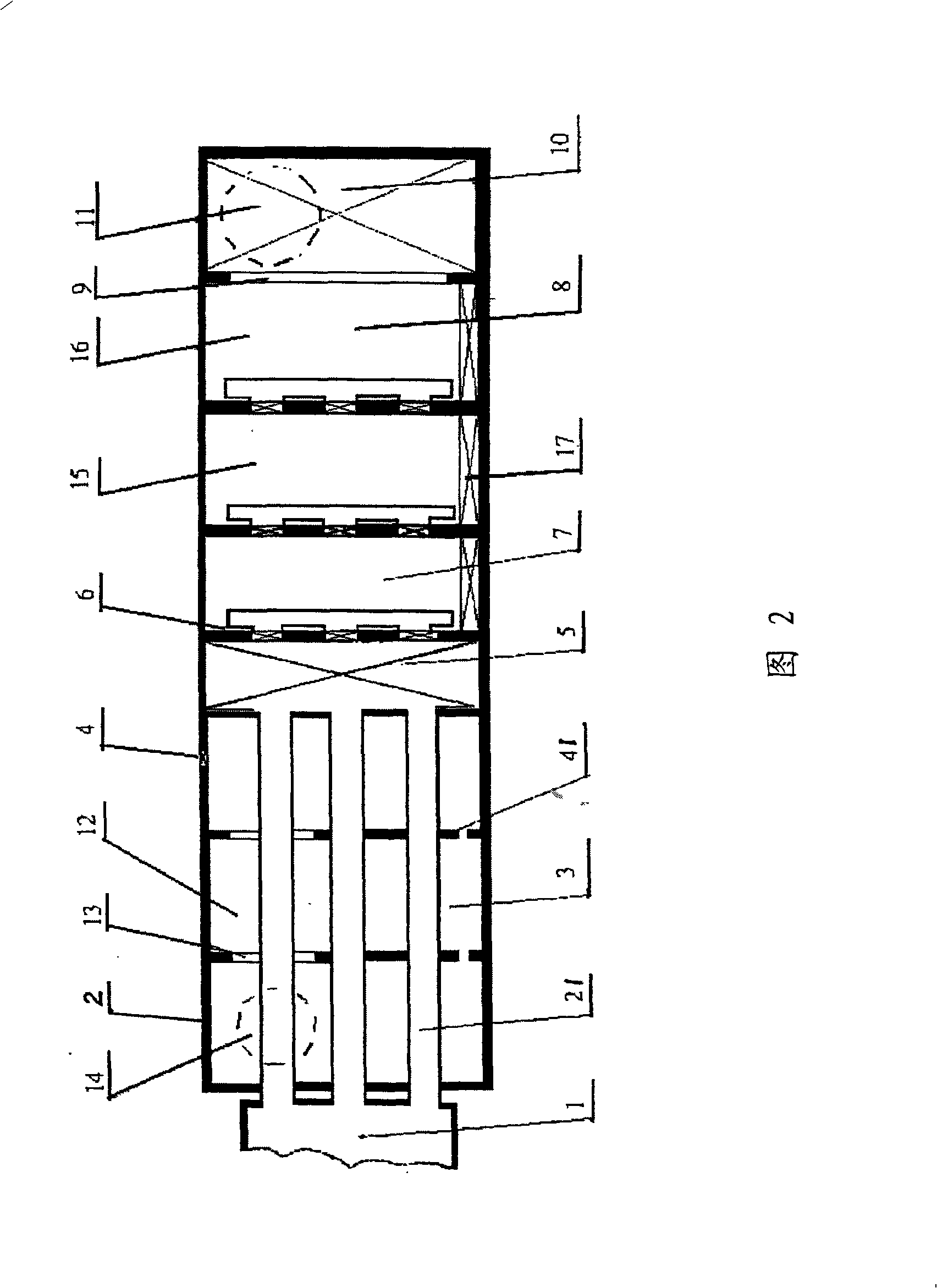

[0013] As shown in FIG. 1 , the exhaust gas purification device of the present invention includes: a cooling unit 2 , a dust removal unit 5 and an absorption unit 15 . The exhaust gas cooling unit 2 includes: a cooling chamber 12 containing a cooling liquid 3 , such as cooling water; and an exhaust gas transmission pipe 21 passing through the cooling chamber, wherein high-temperature exhaust gas is transmitted. The exhaust gas transmission pipe 21 is immersed in the cooling liquid 3 so that the high-temperature exhaust gas transmitted therein can exchange heat with the external cooling liquid to cool the high-temperature exhaust gas. A plurality of exhaust gas transmission pipes 21 may also be arranged in the cooling chamber 12, as shown in FIG. 2, three exhaust gas transmission pipes are arranged in the cooling chamber 12, and each exhaust gas transmission pipe is immersed in the cooling liquid. The cooling chamber 12 may also be provided with a cooling liquid level regulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com