Multi-item combined industrial dust removal equipment

A dust-removing equipment and a combined technology, applied in combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to achieve dust-removing effect, dust shaking, and dust-collecting air bag blockage, etc. Ensure smooth flow and ensure the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

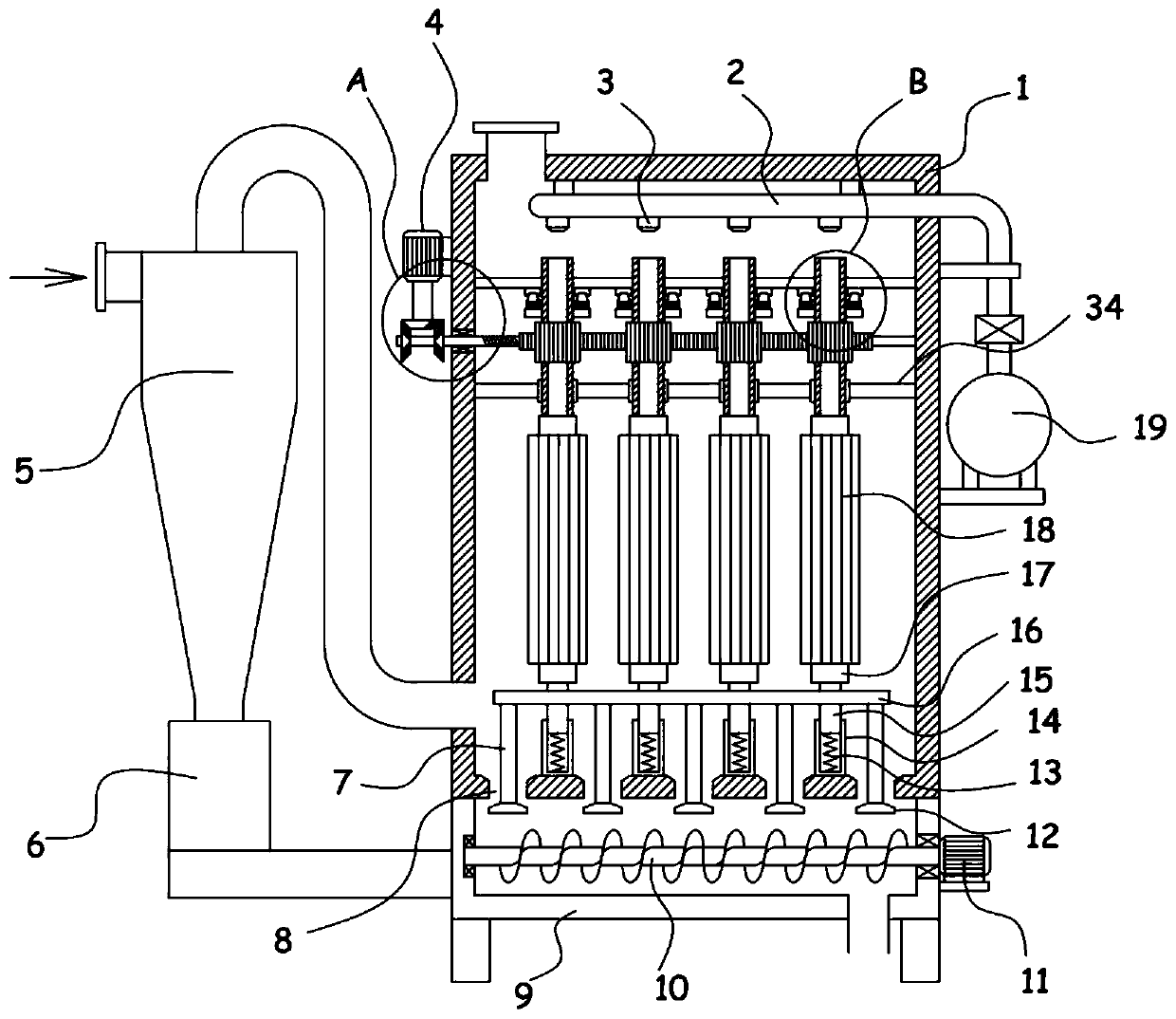

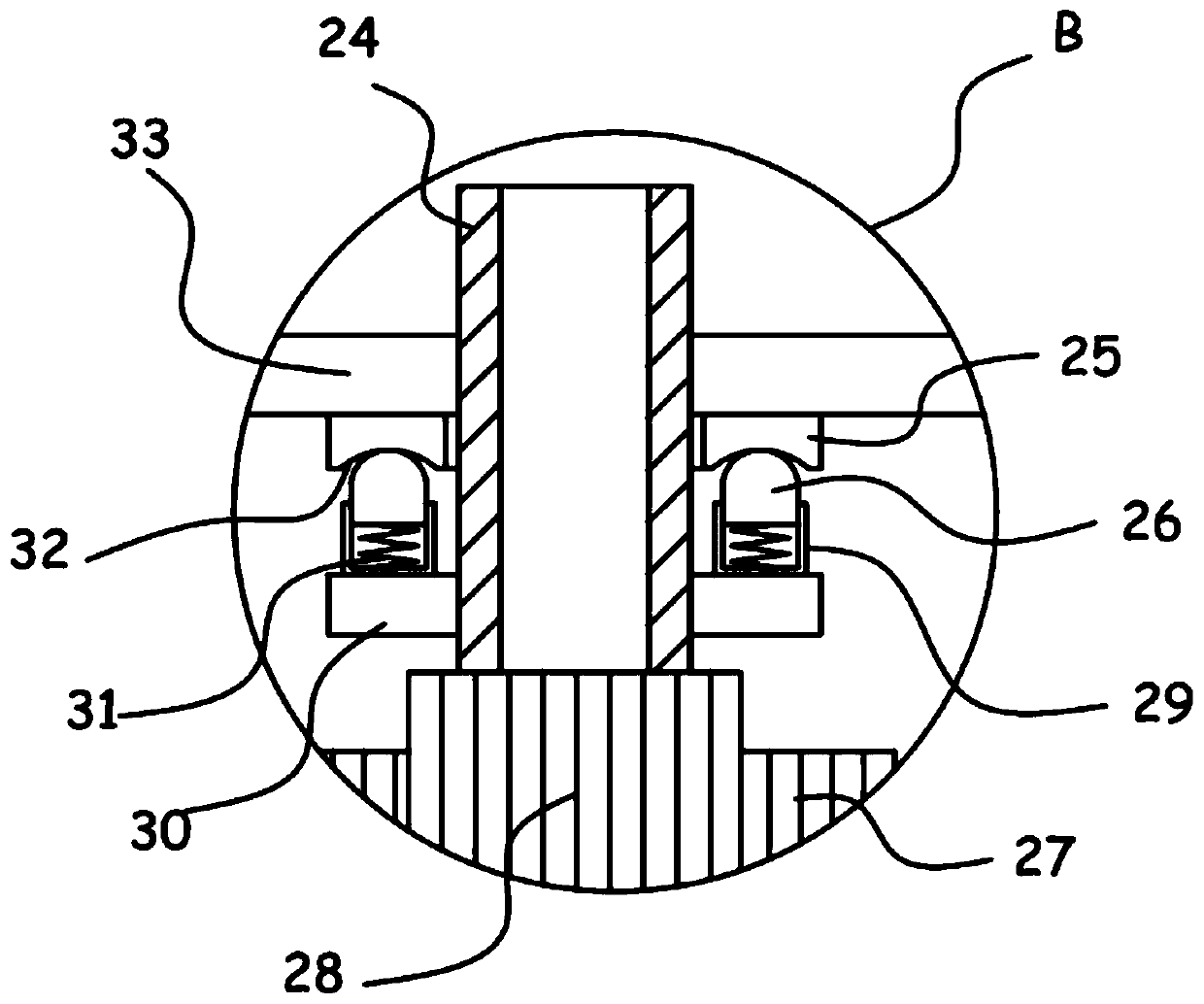

[0023] see Figure 1-4 , a multi-combined industrial dust removal equipment, including a dust removal box 1 and a cyclone separator 5, the bottom of the dust removal box 1 is equipped with a collection box 9 communicated through a blanking hole 8, and the top of the cyclone separator 5 extends to the In the dust removal box 1, an ash hopper 6 is installed at the bottom of the cyclone separator 5, and a sealing partition 34 is installed horizontally and fixedly in the dust removal box 1, and the sealing partition 34 is vertically slidably installed with several dust removal mechanisms distributed at equal intervals. The bottom of the dust removal box 1 is provided with a support guide assembly for supporting the dust removal mechanism. A horizontal plate 33 is horizontally fixed in the dust removal box 1. The dust removal mechanism includes an exhaust pipe 24 that vertically slides through the horizontal plate 33. The top of the exhaust pipe 24 is A purging mechanism is provide...

Embodiment 2

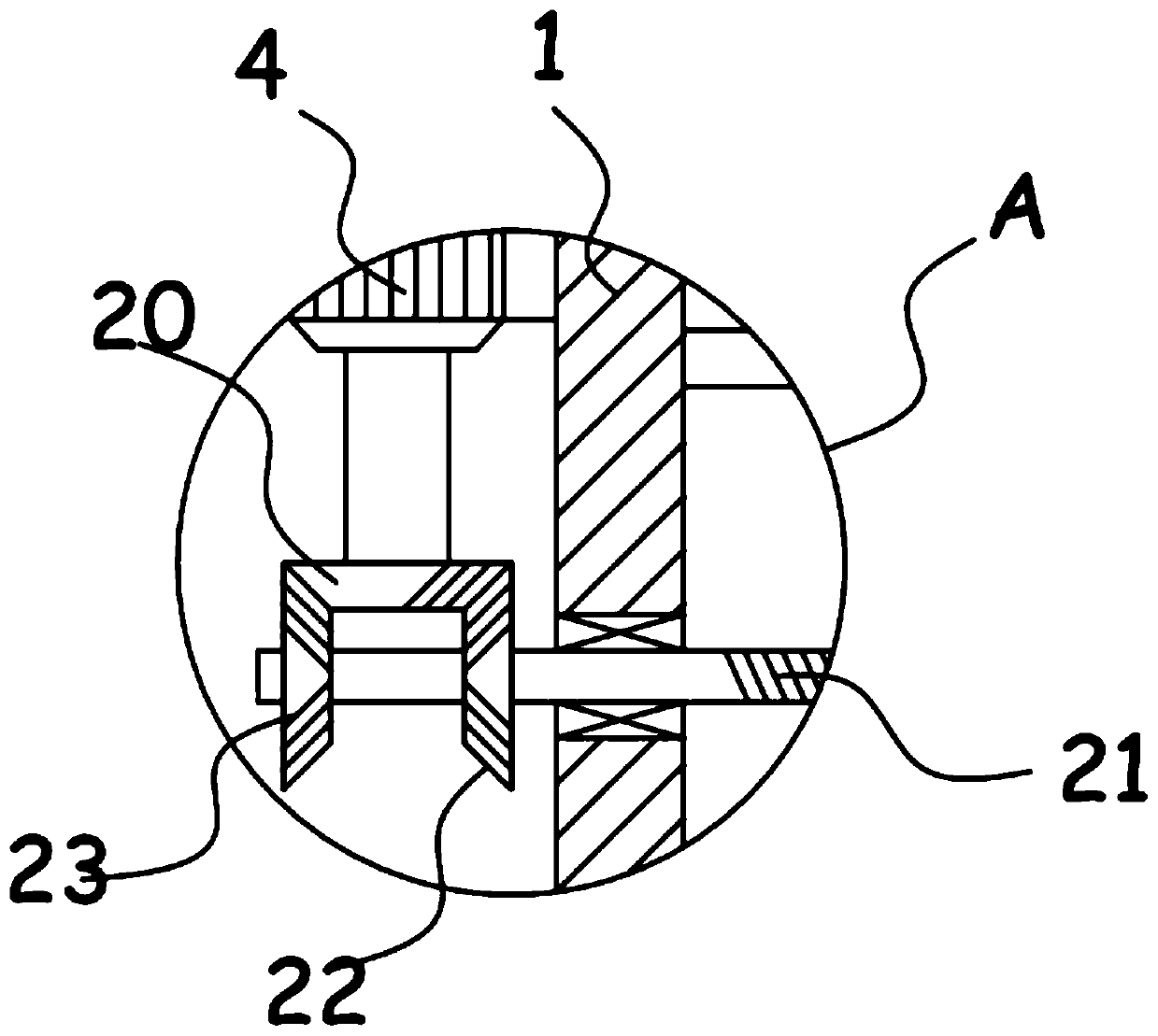

[0030] On the basis of Embodiment 1, in addition, the rotating mechanism of the device includes a rack 27 slidingly installed in the dust removal box 1, and the rack 27 is meshed with a gear 28 sleeved and fixed on the exhaust pipe 24. The screw rod 21 extending to the outside of the dust removal box 1 is installed on the internal thread connection of the rack 27. The screw rod 21 is sleeved with a bevel gear I22 and a bevel gear II23, and the bevel gear I22 and the bevel gear II23 are alternately meshed and connected to be driven by the motor I4. The incomplete bevel gear 20.

[0031] The motor I4 can drive the incomplete bevel gear 20 to rotate, and the incomplete bevel gear 20 can be meshed and connected with the bevel gear I22 and the bevel gear II23 alternately. At this time, the screw rod 21 realizes forward and reverse alternately, that is, the screw rod 21 drives the rack 27 to reciprocate horizontally. Sliding, the gear rack 27 drives the gear 28 to alternately rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com