Method for treating dust on coal mine heading face by using aerial fog turbulent flow fluid

A technology for excavating working face and turbulent flow, which is applied in the fields of dust prevention, mining equipment, earth-moving drilling and mining, etc., can solve the problems of short service life, time-consuming and laborious replacement and cleaning, and restrictions on the promotion and application of water spray equipment, so as to optimize the dust removal effect and solve the The effect of high water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

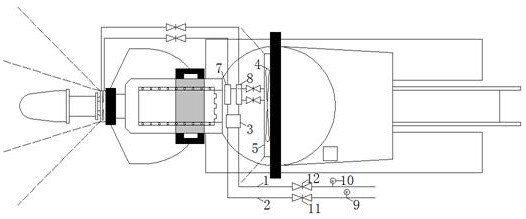

Embodiment approach 1

[0029] One uses low-pressure compressed air as the main power source, supplemented by atmospheric pressure water to wet and modify the gas, and sprays the gas and liquid two-phase fluid mixture and atomization on the coal mine fully mechanized roadway excavation face, through continuous turbulent vortex splitting and energy transmission, the aerosol turbulent jet in the limited space, the aerosol turbulent jet is respectively installed at the cantilever section of the roadheader and the frame of the body of the roadheader through the annular ejector fixing component and the gate post type fixing component; the annular The ejector fixing assembly and the gatepost type fixing assembly are equipped with a universal valve for adjusting the spray angle of the aerosol turbulent jet; the pressure water circuit and the pressure air circuit are used as the power source of the aerosol turbulence device, and the gas pressure regulating valve and the water pressure The regulating valves ar...

Embodiment approach 2

[0040] One uses low-pressure compressed air as the main power source, supplemented by atmospheric pressure water to wet and modify the gas, and sprays the gas and liquid two-phase fluid mixture and atomization on the coal mine fully mechanized roadway excavation face, through continuous turbulent vortex splitting and energy transmission, the aerosol turbulent jet in the limited space, the aerosol turbulent jet is respectively installed at the cantilever section of the roadheader and the frame of the body of the roadheader through the annular ejector fixing component and the gate post type fixing component; the annular The ejector fixing assembly and the gatepost type fixing assembly are equipped with a universal valve for adjusting the spray angle of the aerosol turbulent jet; the pressure water circuit and the pressure air circuit are used as the power source of the aerosol turbulence device, and the gas pressure regulating valve and the water pressure The regulating valves ar...

Embodiment approach 3

[0051] One uses low-pressure compressed air as the main power source, supplemented by atmospheric pressure water to wet and modify the gas, and sprays the gas and liquid two-phase fluid mixture and atomization on the coal mine fully mechanized roadway excavation face, through continuous turbulent vortex splitting and energy transmission, the aerosol turbulent jet in the limited space, the aerosol turbulent jet is respectively installed at the cantilever section of the roadheader and the frame of the body of the roadheader through the annular ejector fixing component and the gate post type fixing component; the annular The ejector fixing assembly and the gatepost type fixing assembly are equipped with a universal valve for adjusting the spray angle of the aerosol turbulent jet; the pressure water circuit and the pressure air circuit are used as the power source of the aerosol turbulence device, and the gas pressure regulating valve and the water pressure The regulating valves ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com