Device and method for dry-type collaborative purification and indirect cooling of fixed bed gas oily dust

A fixed bed and gas technology, applied in chemical instruments and methods, combustible gas purification, combustible gas purification/transformation, etc., can solve the problem of large investment in fine dust removal and water treatment facilities, increased investment and raw material consumption, and general cooling dust removal effect and other problems, to achieve the effect of solving the problem of difficult ammonia nitrogen treatment and water balance, good gas purification effect, and solving huge equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

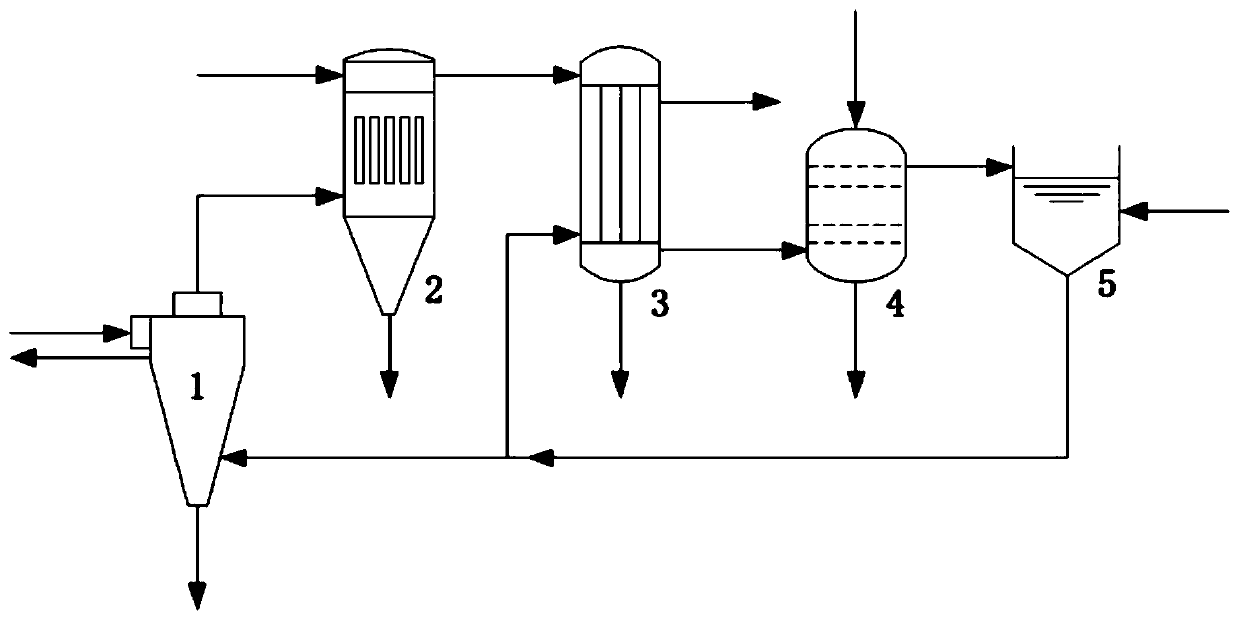

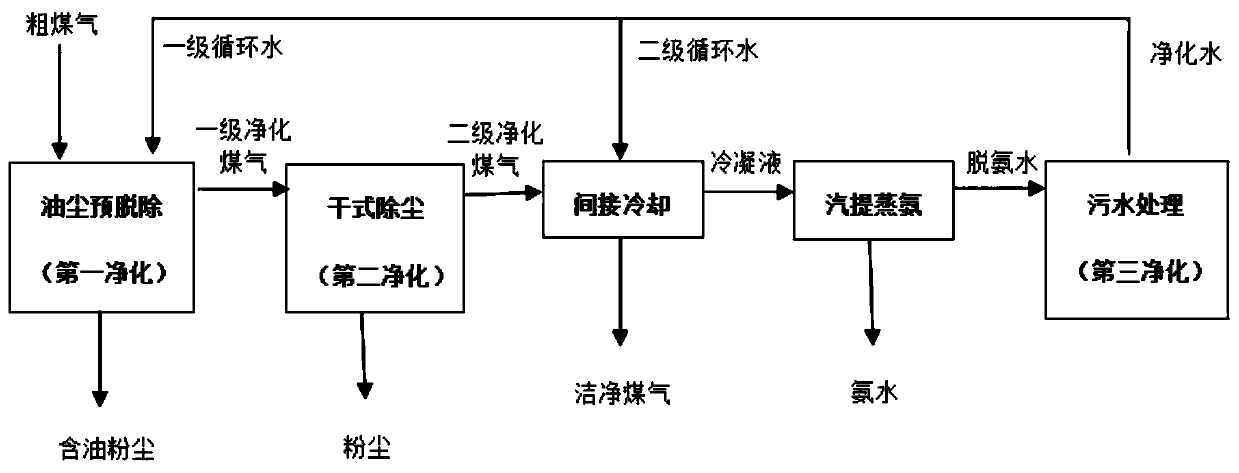

[0063] use figure 1 The shown fixed bed gas oil dust dry synergy purification and indirect cooling device, according to figure 2 The process flow shown is for the treatment of crude gas from a batch fixed-bed gasifier in a factory. The moisture content of the crude gas is 35wt%, and the dust content is 20g / Nm 3 , the tar content is 10mg / Nm 3 , the specific ingredients are shown in Table 1.

[0064] Table 1 Crude gas composition

[0065] Element CO H 2

CH 4

CO 2

N 2

O 2

total Content (dry basis) 28% 43% 1.3% 8.3% 19.1% 0.3% 100%

[0066] The oil and dust pre-removal device 1 in the fixed-bed coal gas, oil and dust dry-type collaborative purification and indirect cooling device is a cold-wall cyclone separator, and a membrane wall is arranged outside the shell, and the dry-type dust collector 2 is a filter-type dust collector. The filter material used is PTFE+PTFE coated cloth bag, and the indirect cooler 3 is specifical...

Embodiment 2

[0075] use figure 1 The shown fixed bed gas oil dust dry synergy purification and indirect cooling device, according to figure 2 The process flow shown is for the treatment of crude gas from a batch fixed-bed gasifier in a factory. The moisture content of the crude gas is 30wt%, and the dust content is 40g / Nm 3 , the tar content is 30mg / Nm 3 , the specific ingredients are shown in Table 2.

[0076] Table 2 Crude gas composition

[0077] Element CO H 2

CH 4

CO 2

N 2

O 2

total Content (dry basis) 39% 42% 2.0% 16% 0.4% 0.6% 100%

[0078] The oil and dust pre-removal device 1 in the fixed-bed coal gas, oil and dust dry-type collaborative purification and indirect cooling device is a cold-wall cyclone separator, and a water jacket is arranged outside the shell, and the dry-type dust collector 2 is a filter-type dust collector. The filter material used is PTFE+PTFE coated cloth bag, and the indirect cooler 3 is specifically ...

Embodiment 3

[0087] use figure 1 The shown fixed bed gas oil dust dry synergy purification and indirect cooling device, according to figure 2 The process flow shown is for the treatment of crude gas from a batch fixed-bed gasifier in a factory. The moisture content of the crude gas is 15wt%, and the dust content is 30g / Nm 3 , the tar content is 20mg / Nm 3 , the specific ingredients are shown in Table 3.

[0088] Table 3 Crude gas composition

[0089] Element CO H 2

CH 4

CO 2

N 2

O 2

total Content (dry basis) 31% 38% 2.5% 8.1% 20.1% 0.3% 100%

[0090] The oil and dust pre-removal device 1 in the fixed bed gas oil dust dry collaborative purification and indirect cooling device is a cold wall cyclone separator, and a coil is arranged outside the shell, and the dry dust collector 2 is a filter dust collector , the filter material used is PTFE+PTFE coated cloth bag, and the indirect cooler 3 is specifically a heat pipe heat exchanger.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com