Flour quantitative weighing equipment

A technology for weighing and flour, applied in the directions of weighing, measuring devices, cleaning devices, etc., can solve the problems of cumbersome weighing process of flour, easy to be affected by moisture, etc., to achieve the effect of easy taking out and weighing, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

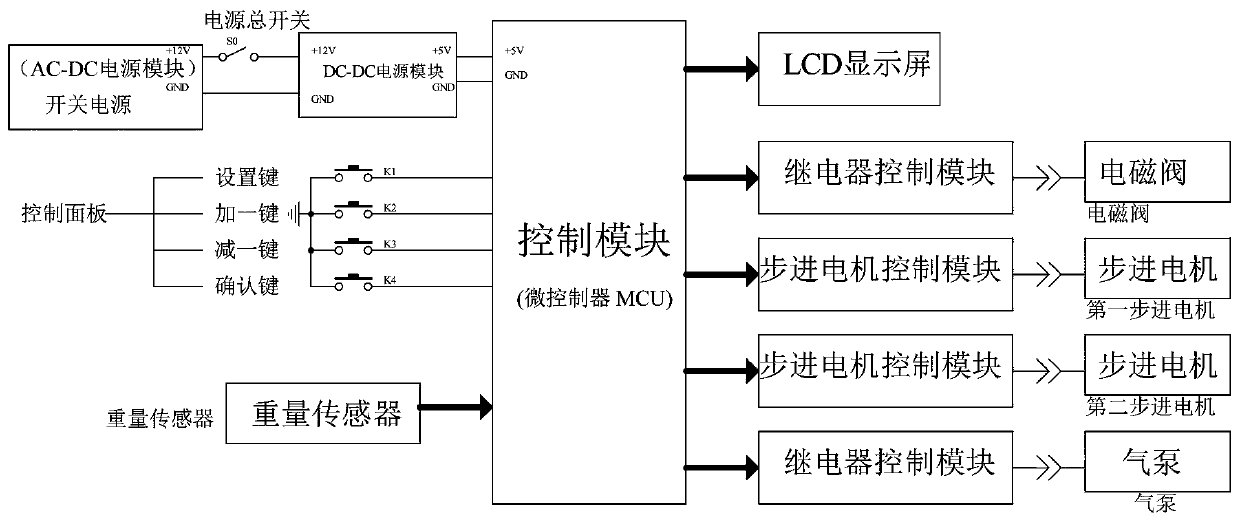

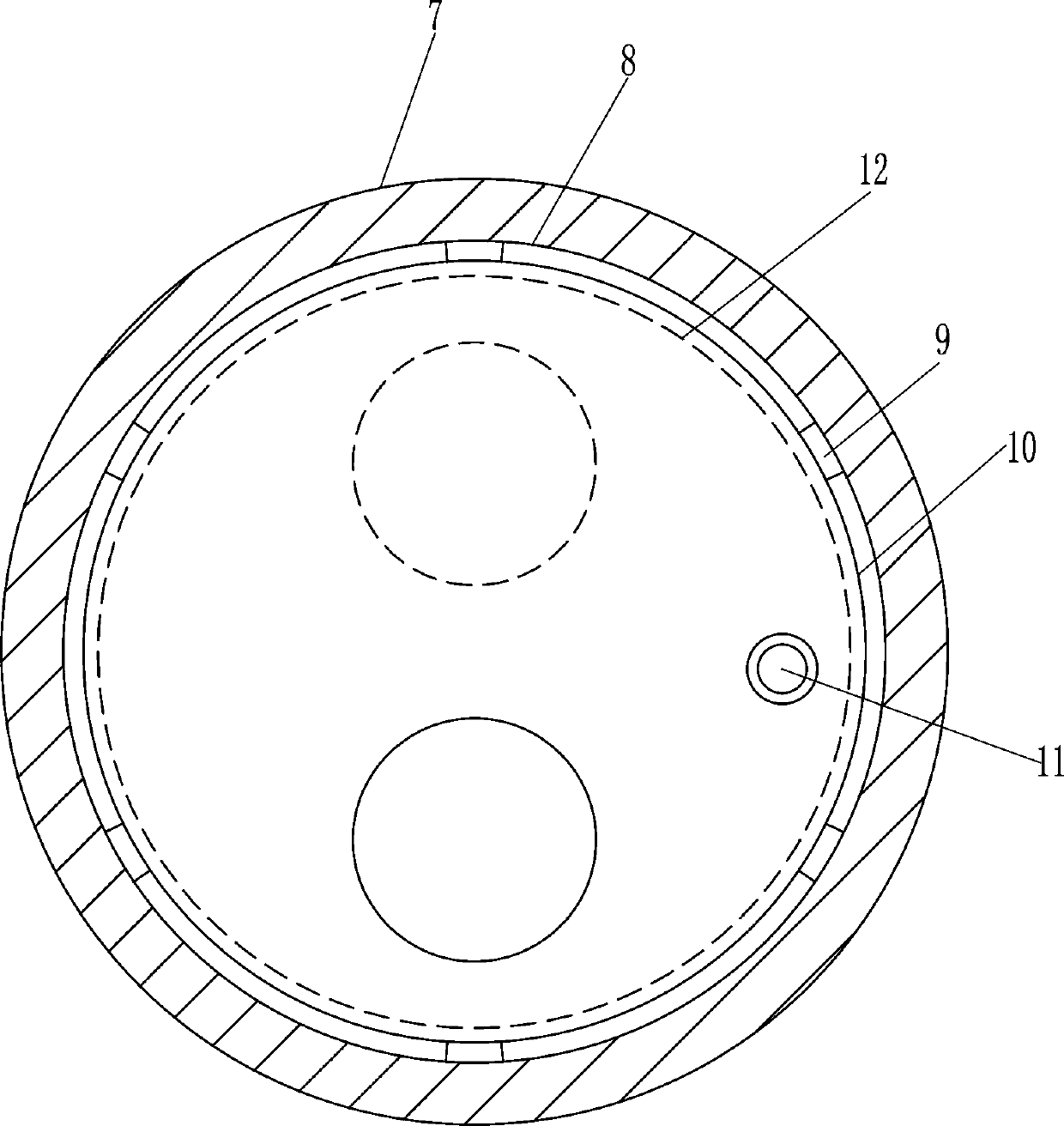

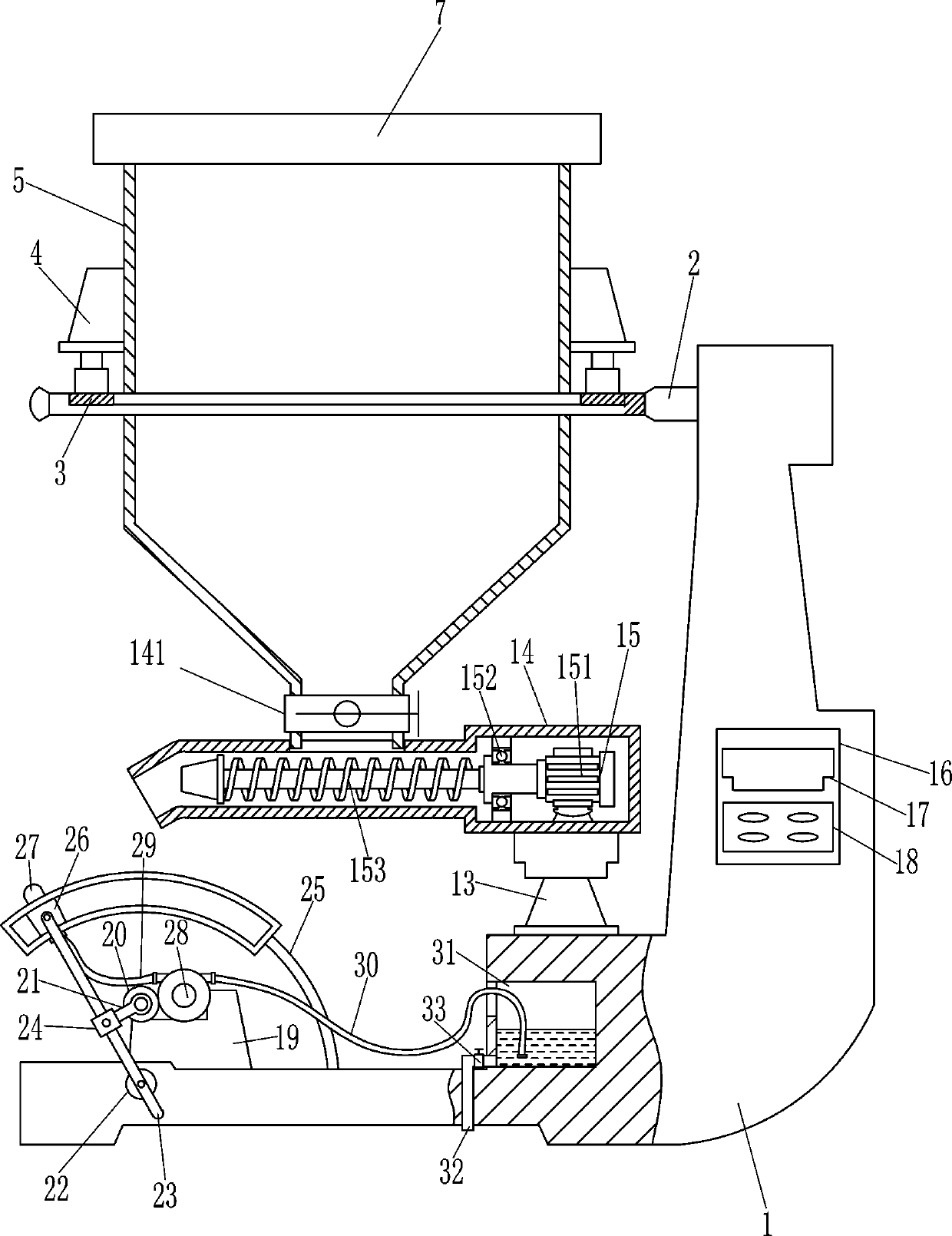

[0019] A flour quantitative weighing equipment, such as Figure 1-5 As shown, it includes a base 1, a support plate 2, a weight sensor 3, a support rod 4, a material storage frame 5, a mounting ring 7, a first arc-shaped slider 9, a first opening disc 10, a first rotating rod 11, The second opening disc 12, the first support seat 13, the discharge pipe 14, the solenoid valve 141, the discharge device 15, the control box 16, the LCD display screen 17 and the control panel 18, the top of the base 1 is equipped with a support plate 2, The base 1 is connected with the support plate 2 by welding, the support plate 2 is equipped with a weight sensor 3, the weight sensor 3 is connected with the support rod 4, the support rod 4 is connected with the material storage frame 5, and the top of the material storage frame 5 A mounting ring 7 is installed, and the inner wall of the mounting ring 7 is provided with an annular groove 8, and a first arc-shaped slider 9 is evenly slid in the ann...

Embodiment 2

[0021] A flour quantitative weighing equipment, such as Figure 1-5 As shown, it includes a base 1, a support plate 2, a weight sensor 3, a support rod 4, a material storage frame 5, a mounting ring 7, a first arc-shaped slider 9, a first opening disc 10, a first rotating rod 11, The second opening disc 12, the first support seat 13, the discharge pipe 14, the solenoid valve 141, the discharge device 15, the control box 16, the LCD display screen 17 and the control panel 18, the top of the base 1 is equipped with a support plate 2, A weight sensor 3 is installed on the support plate 2, a support rod 4 is connected to the weight sensor 3, a material storage frame 5 is connected to the support rod 4, a mounting ring 7 is installed on the top of the material storage frame 5, and a ring is formed on the inner wall of the mounting ring 7. Groove 8, the first arc-shaped slider 9 is evenly slidable in the annular groove 8, and the first opening disc 10 is connected between the first ...

Embodiment 3

[0024]A flour quantitative weighing equipment, such as Figure 1-5 As shown, it includes a base 1, a support plate 2, a weight sensor 3, a support rod 4, a material storage frame 5, a mounting ring 7, a first arc-shaped slider 9, a first opening disc 10, a first rotating rod 11, The second opening disc 12, the first support seat 13, the discharge pipe 14, the solenoid valve 141, the discharge device 15, the control box 16, the LCD display screen 17 and the control panel 18, the top of the base 1 is equipped with a support plate 2, A weight sensor 3 is installed on the support plate 2, a support rod 4 is connected to the weight sensor 3, a material storage frame 5 is connected to the support rod 4, a mounting ring 7 is installed on the top of the material storage frame 5, and a ring is formed on the inner wall of the mounting ring 7. Groove 8, the first arc-shaped slider 9 is evenly slidable in the annular groove 8, and the first opening disc 10 is connected between the first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com