Dust removal device for removing dust and adherends on surface of steel belt and operation method

A technology of dust removal device and operation method, which is applied in the direction of workpiece cleaning device, workpiece surface treatment equipment, metal rolling, etc., which can solve the problems of easy scratching of the surface, accumulation of magnesium oxide hardening, and decline of purging effect, etc., and achieves good treatment effect , not easy to scratch, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

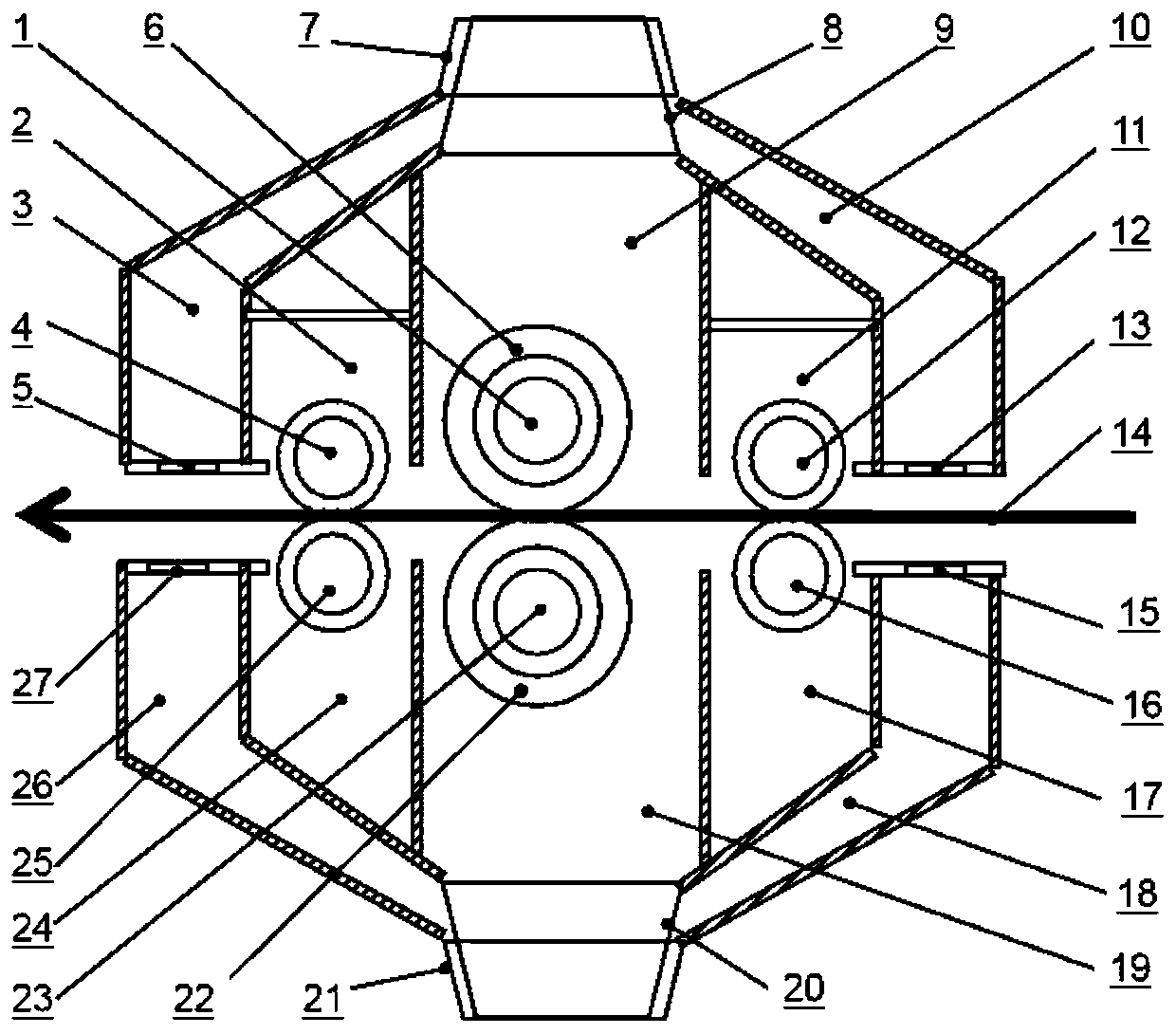

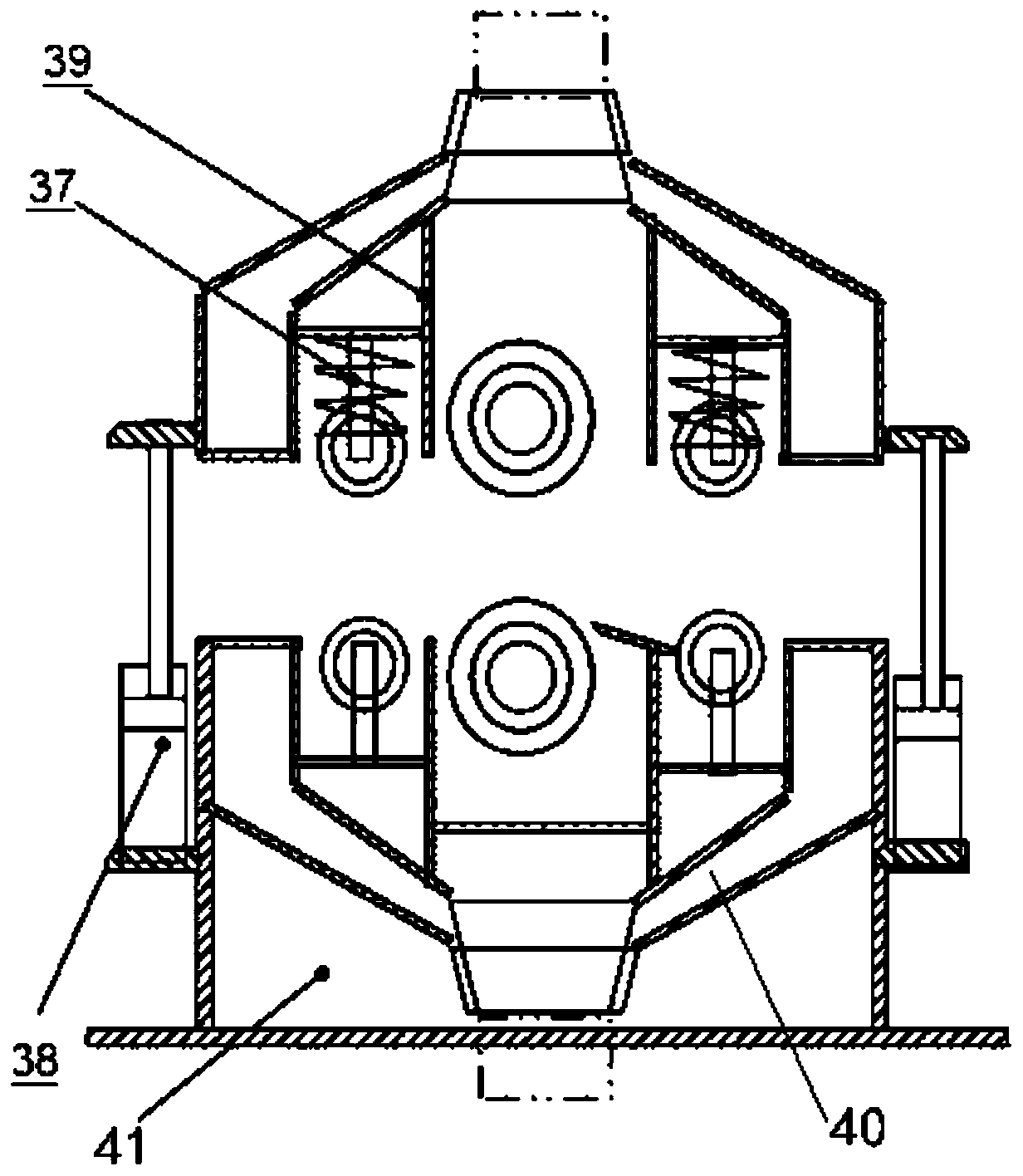

[0040] The invention discloses a dust removal device for removing dust and adherents on the surface of a steel strip, such as figure 1 As shown, it includes an upper brush roller 6, a lower brush roller 22, an upper sealing roller, and a lower sealing roller positioned at the upper and lower sides of the steel strip 14 and arranged parallel to each other. The upper sealing roller and the lower sealing roller are two groups, respectively located at On both sides of the upper brush roll and / or the lower brush roll, wherein, the preferred upper brush roll 6 and the lower brush roll 22 of the present invention are connected to the center of rotation perpendicular to the steel belt. Similarly, the rotation of each group of upper seal rolls and lower seal rolls The center connection line is also perpendicular to the steel belt 14, and the shape and size of the two sets of sealing rollers are identical, while the size of the brush rollers is greater than that of the sealing rollers; ...

Embodiment 2

[0046] The present invention also discloses the dust removal method of the above-mentioned device, and the specific process is as follows:

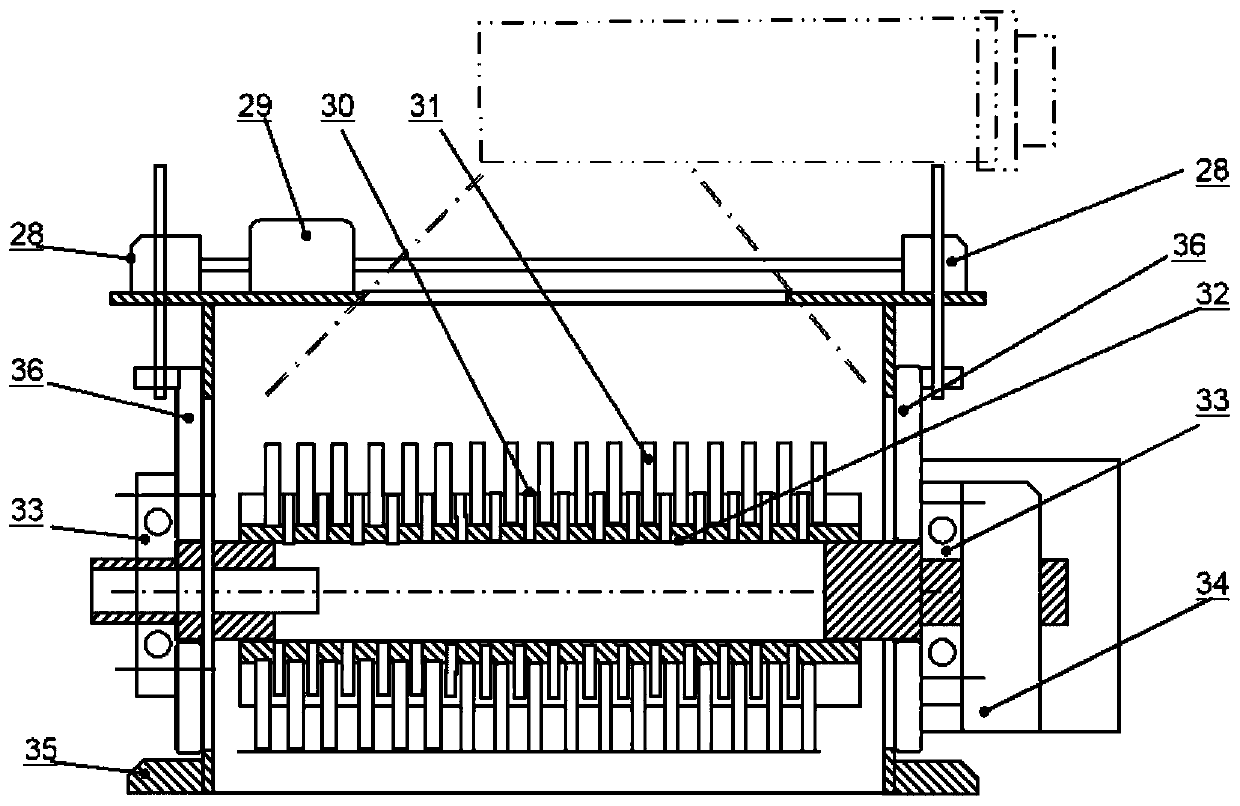

[0047] The upper brush roller 6 and the lower brush roller 22 mechanically sweep the dust and adherents on the surface of the steel strip 14, and the high-pressure airflow ejected from the injection hole 30 can not only cool and clean the brush wire 31, but also clean the steel strip 14. Purge; the formed magnesium oxide dust is discharged through the dust removal port 8 of the upper brush roller and the dust removal port 20 of the lower brush roller. Since the pressure in the closed chamber of the sealing roller is inconsistent with the pressure in the dust suction chamber of the brush roller, a small amount of dust will be released under the action of high-pressure airflow. Escape to the entrance and exit of the sealing roller, the energy of the airflow after passing the sealing roller is weakened, and then enter the dust suction chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com