Dust removing device for wheat flour processing factory

A processing plant, dust technology, applied in the field of dust removal equipment in flour processing plants, can solve the problems of personal injury, dust explosion, air turbidity, etc., reduce the possibility of dust explosion, and benefit the effect of physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

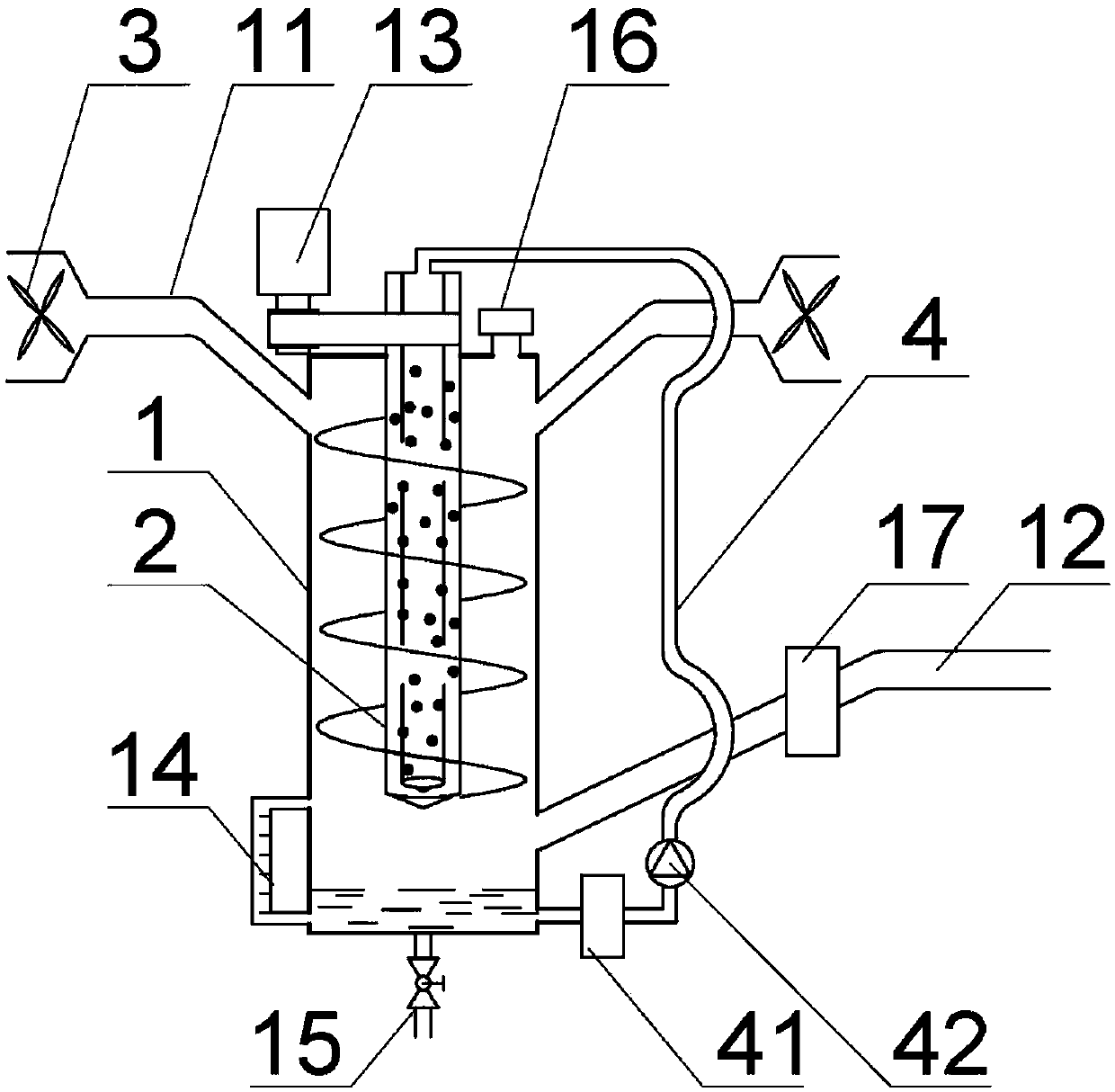

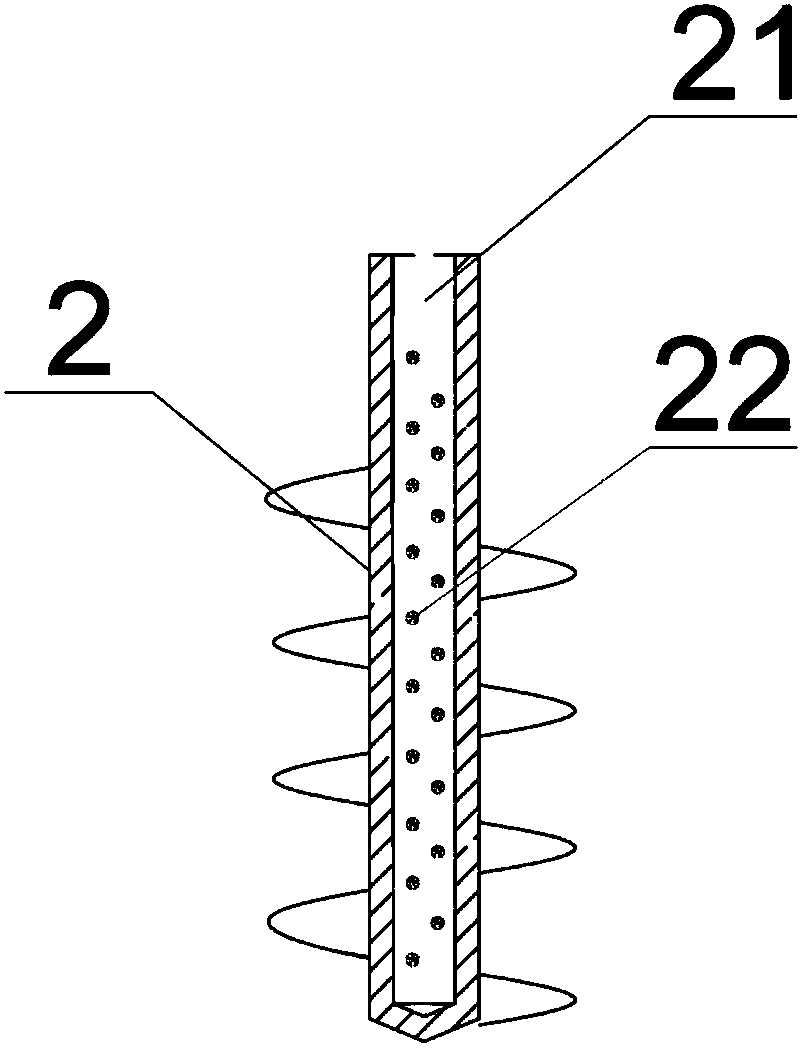

[0016] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a dust removal device in a flour processing plant proposed by the present invention; figure 2 It is a cross-sectional view of the air-supply dragon of a dust removal device in a flour mill proposed by the present invention.

[0017] refer to Figure 1-2 , a dust removal device for a flour processing plant proposed by the present invention, comprising a dust removal box 1 and an air supply auger 2, the dust removal box 1 is a columnar cavity 21 structure, and the air supply auger 2 is vertically and rotatably installed in the dust removal box 1 Inside, a motor 13 is fixed on the dust removal box 1, and the motor 13 drives the air supply auger 2 to rotate. The interior of the air supply auger 2 rotating shaft is provided with an axial cavity 21 for accommodating water, and the air supply auger 2 rotating shaft is provided with A plurality of atomizing holes 22, the atomizing holes 22 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com