Patents

Literature

160results about How to "Reduce the likelihood of an explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

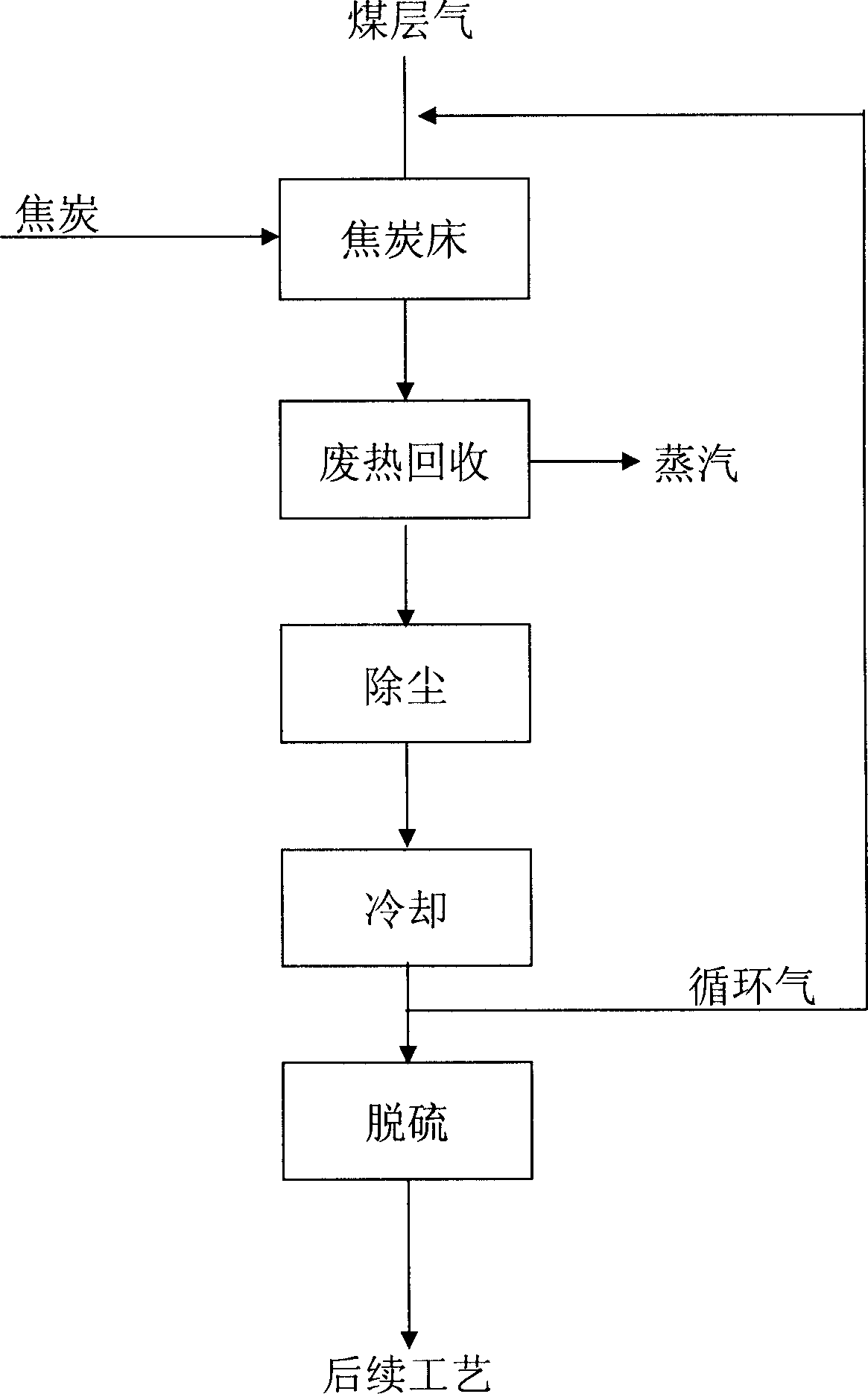

Coal bed gas coke deoxidization technique

The invention discloses the coal bed gas coke deoxidization technology, comprising the following steps: deoxidizing coal bed gas with coke and anthracite coal, keeping the temperature between 600-1000Deg.C, then dedusting, and cooling; adjusting the oxygen content in deoxidation reactor to 5-9%. The technology can keep reaction temperature, remove oxygen of coal bed gas, reduce methane cracking, and improve safety.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

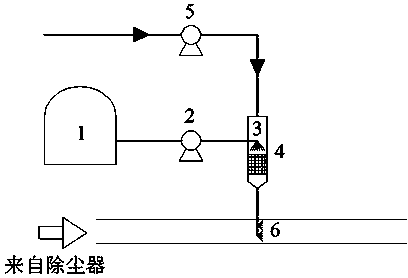

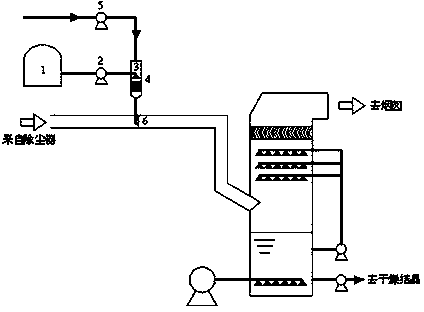

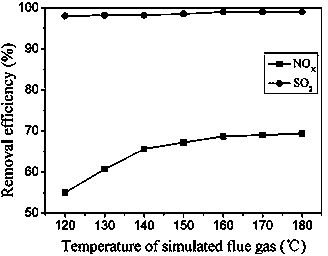

Device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation

ActiveCN103463978AHigh removal rateImprove oxidation efficiencyDispersed particle separationAir quality improvementPtru catalystCatalytic decomposition

The invention provides a device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation (H2O2). The H2O2 is sprayed into an H2O2 catalytic decomposition device through an injection pump and reacts with catalysts, a large amount of active matter is generated, the active matter is injected into a smoke channel along with a bypass air flow from an air blower in a blowing mode and reacts with sulfur dioxide (SO2) and oxynitride (NOX) in smoke to generate sulfuric acid and nitric acid. The sulfuric acid, the nitric acid and pollutants left in the smoke enter an ammonia absorption tower, and finally two kinds of important chemical fertilizer, namely ammonium sulfate and ammonium nitrate are generated. The device and method are suitable for smoke simultaneous desulfurization and denitrification in large, medium and small size boiler and reconstruction application of built combustion equipment, and the NOX and SO2 can be removed at the same time.

Owner:NANJING UNIV OF SCI & TECH

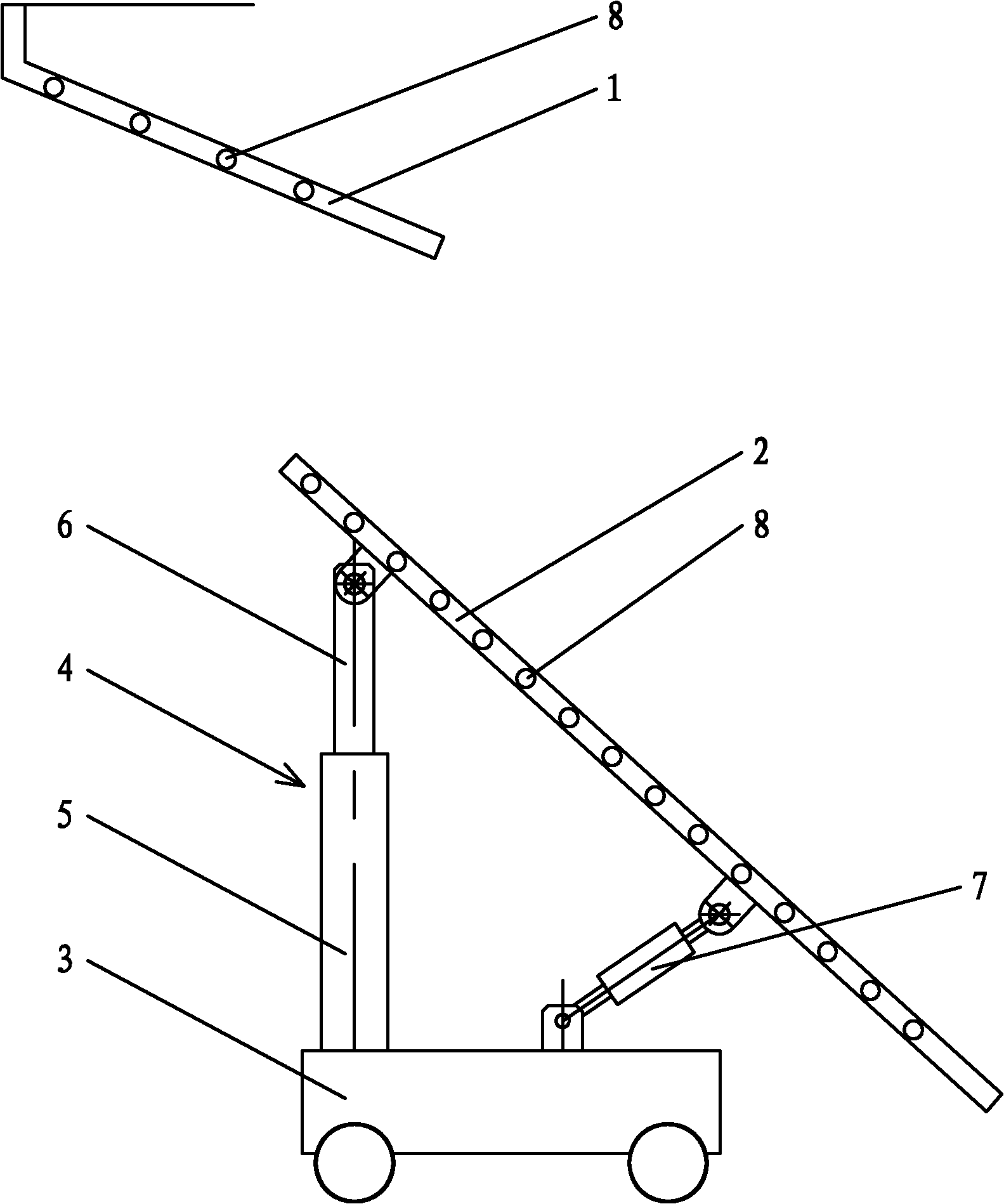

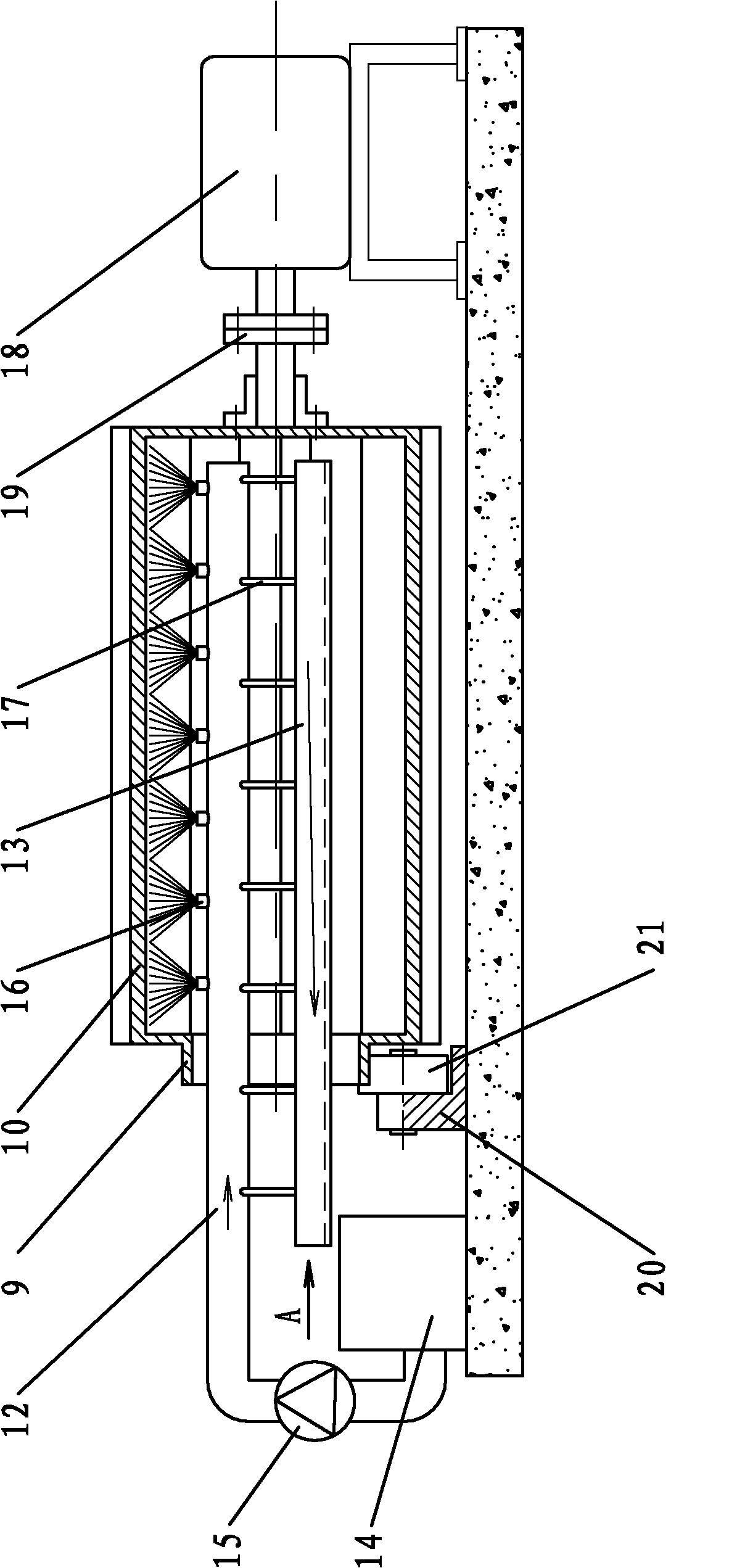

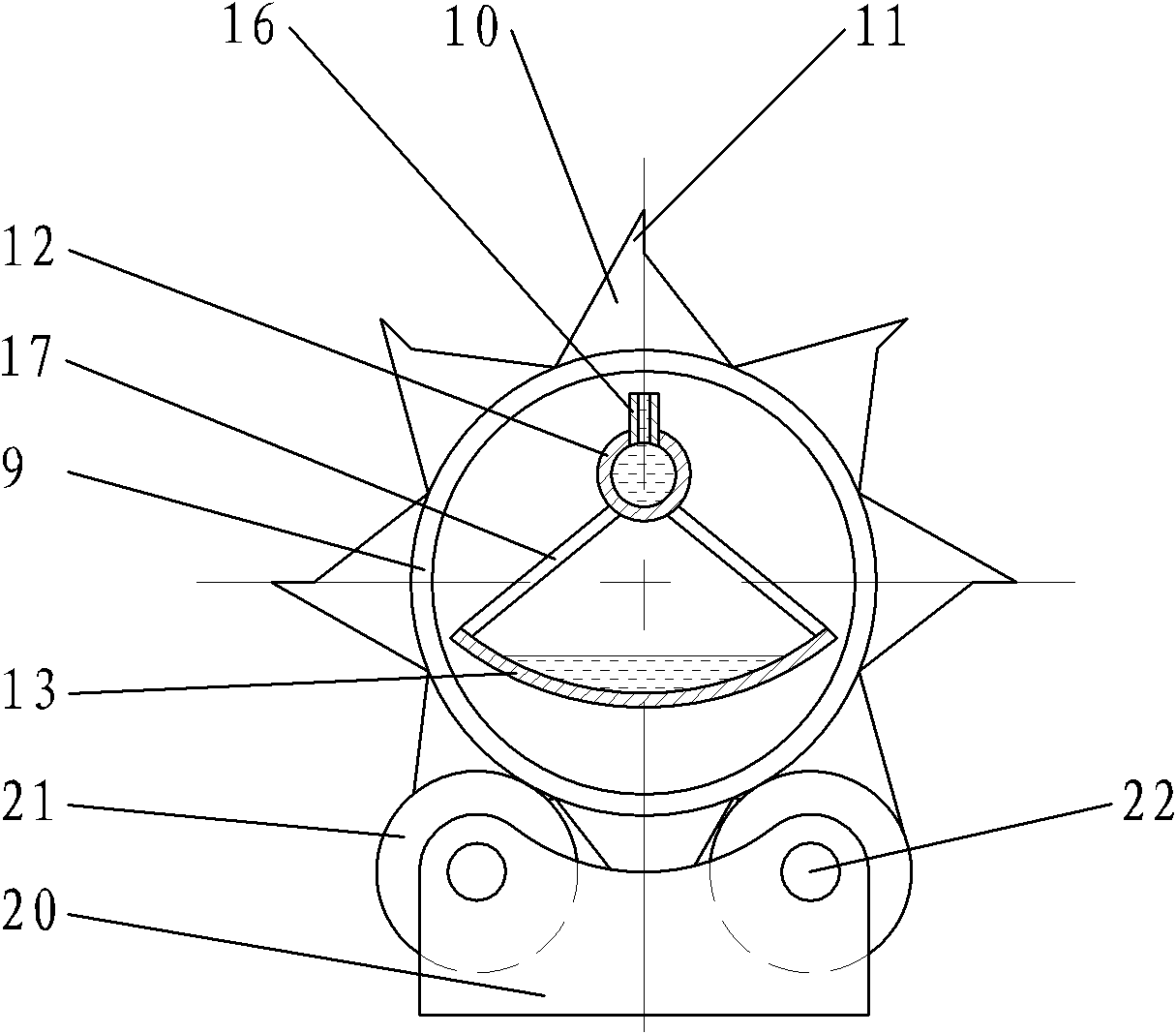

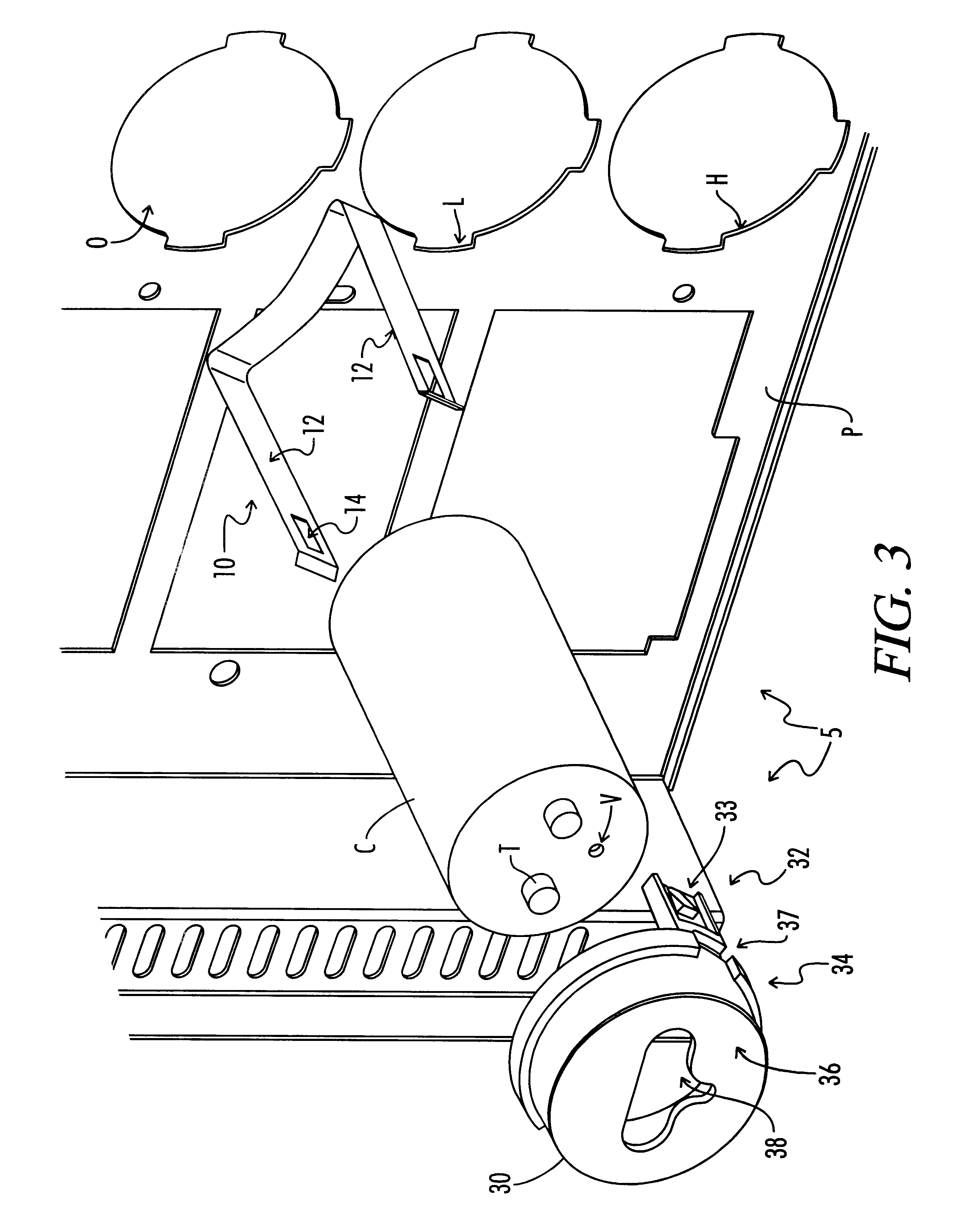

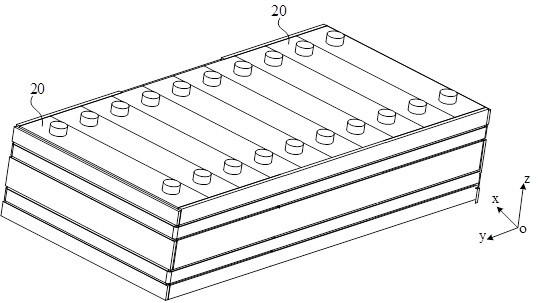

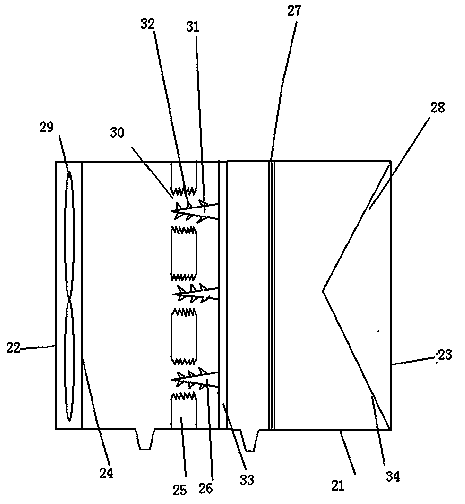

Dry granulation and afterheat recovery system of blast-furnace slag

ActiveCN101914640ASmall particle sizeAvoid it happening againRecycling and recovery technologiesProcess efficiency improvementSlagEnergy consumption

The invention discloses a dry granulation and afterheat recovery system of blast-furnace slag and relates to a blast-furnace slag treatment system, aiming to provide a dry granulation and afterheat recovery system of blast-furnace slag, which has the advantages of low energy consumption, low water consumption, low harmful gas emission, high afterheat recovery rate and stable running. The dry granulation and afterheat recovery system of the blast-furnace slag comprises a tunable swelling slag bead chute, a swelling slag bead throwing roller and a swelling slag bead afterheat recovery device, wherein the tunable swelling slag bead chute comprises an upper swelling slot and a lower swelling slot; the swelling slag bead throwing roller comprises a roller body with a power device; the swelling slag bead afterheat recovery device comprises a channel structure and a heat exchange system, and the channel structure comprises a top wall, a front side wall, a rear side wall and a bottom wall; the roller body of the swelling slag bead throwing roller is positioned below the lower end of the lower swelling slot of the tunable swelling slag bead chute; the channel structure of the swelling slag bead afterheat recovery device corresponds to the roller body; and the left end of the bottom wall is positioned within the throwing range of the swelling slag bead throwing roller.

Owner:北京京能绿园节能科技有限公司

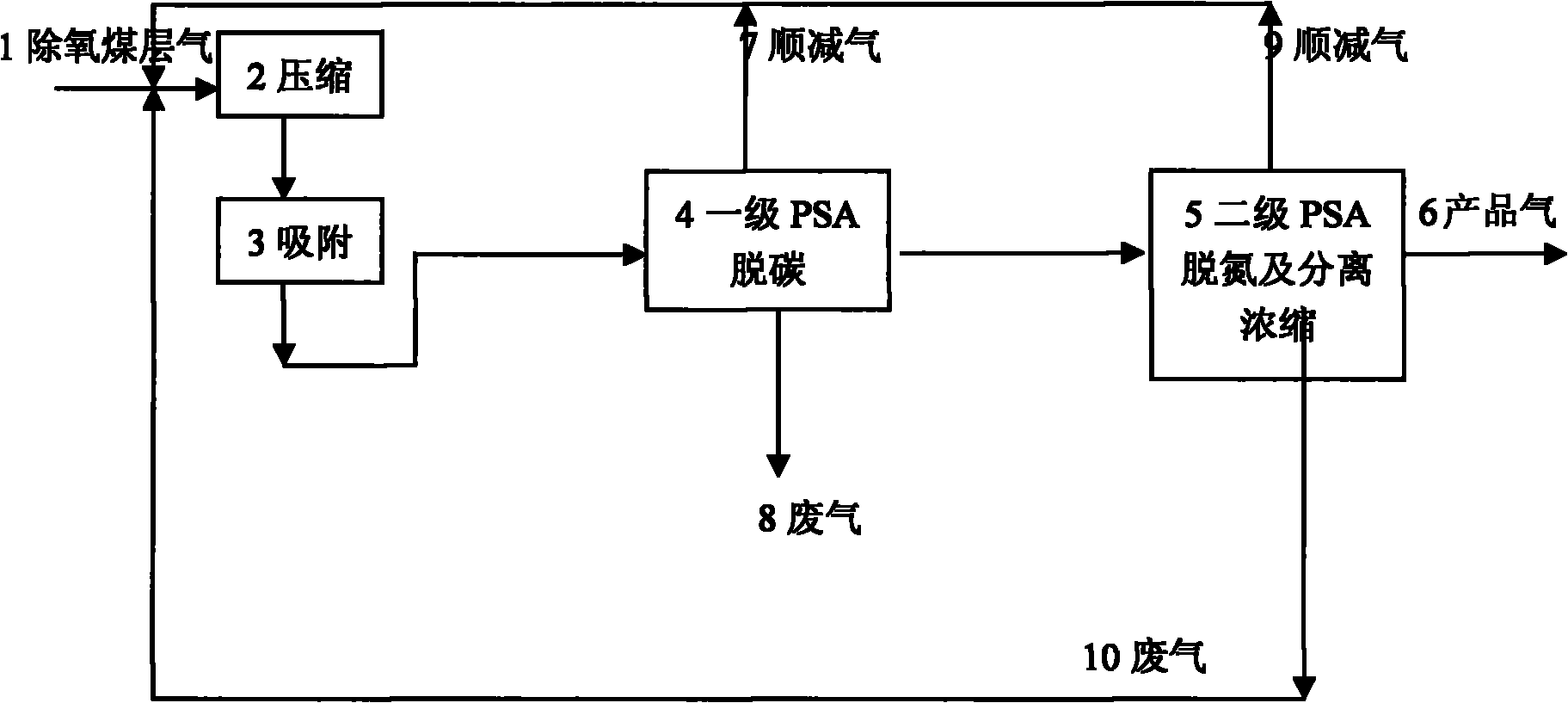

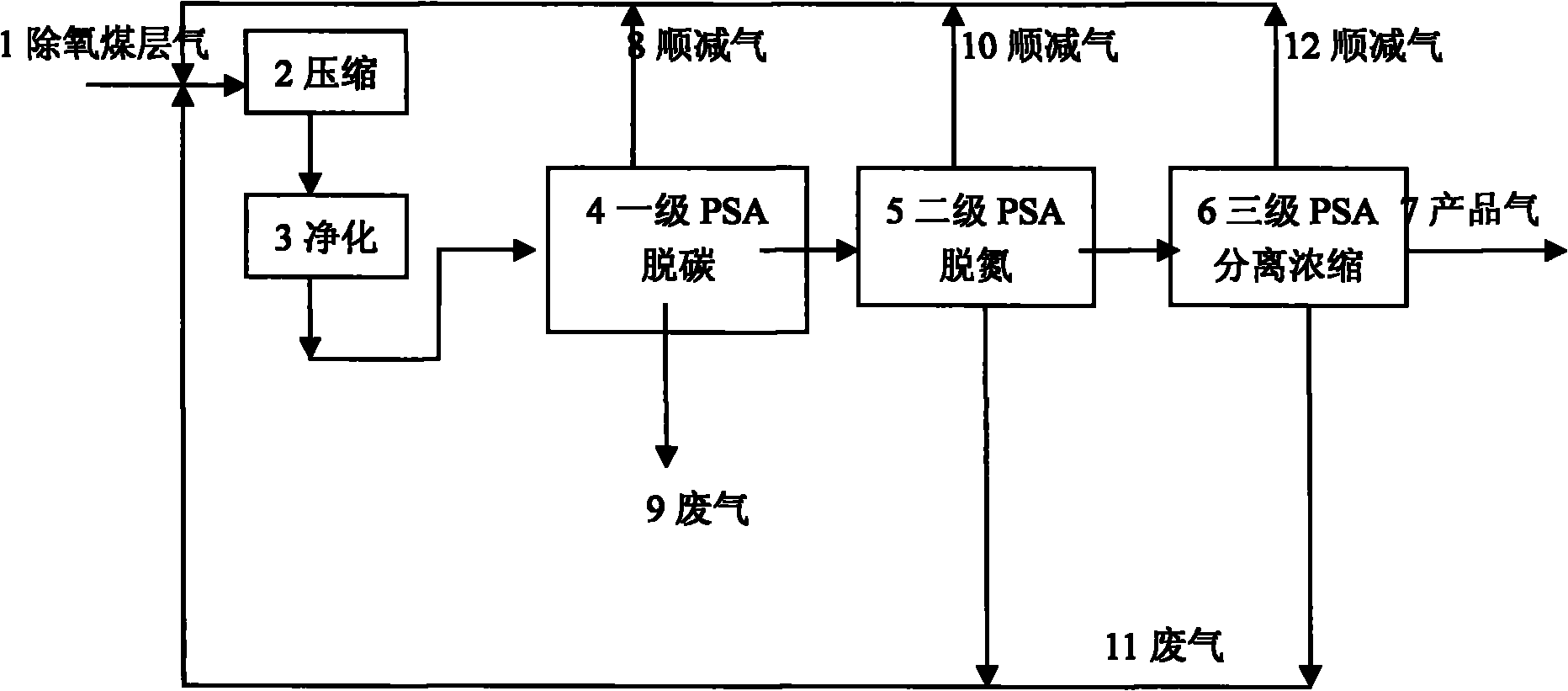

Method for deoxidizing coal bed gas and separating methane by concentration

ActiveCN101921642AReduce consumptionReduce consumption costGaseous fuelsMolecular sieveOxygen content

The invention discloses a method for deoxidizing coal bed gas and separating methane by concentration. By using the method, the coal bed gas having 20 to 50 percent of CH4 can be deoxidized, and the requirement on the oxygen content in raw material gas is low, so that the raw material gas can be deoxidized when the oxygen content is 10.6 to 15 percent, and the times of circulated deoxidization can be obviously reduced compared with that of the conventional method. Therefore, energy consumption and production cost can be lowered, deoxidization time can be shortened, and production efficiency can be further improved. The method is characterized by wide application range, low investment consumption, complete and fast deoxidization, and good application prospect in the field of coal bed gas deoxidization. The concentration of the methane in the coal bed gas can be improved from 20 to 50 percent in the raw material gas to 80 to 90 percent by the method. CH4 concentration, decarbonization and denitrification can be performed by the method with only one carbon molecular sieve, so that the concentration separation efficiency is obviously improved, and the method has great significance andapplication value in the aspect of industrialized popularization of the coal bed gas.

Owner:CCTEG CHINA COAL RES INST

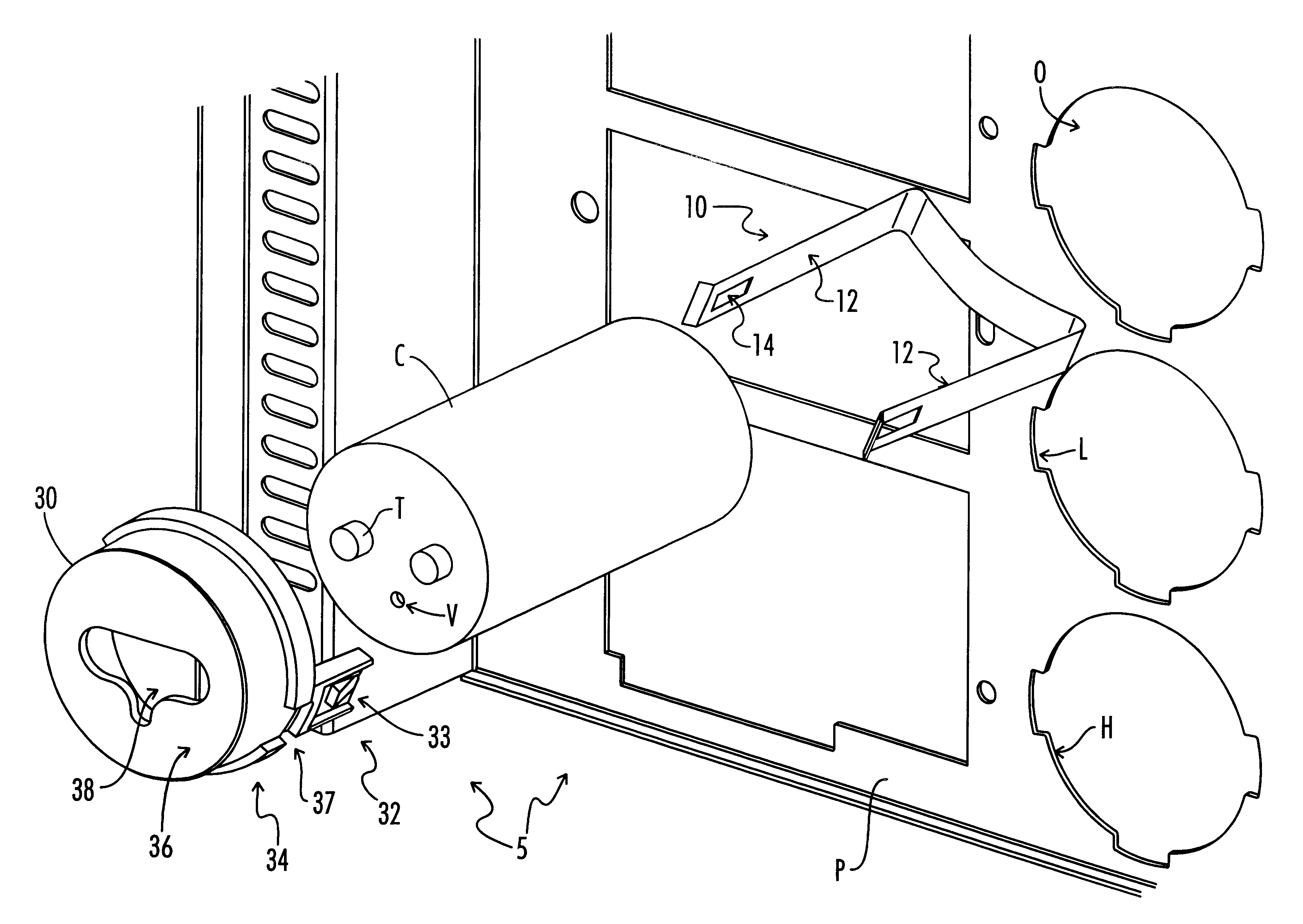

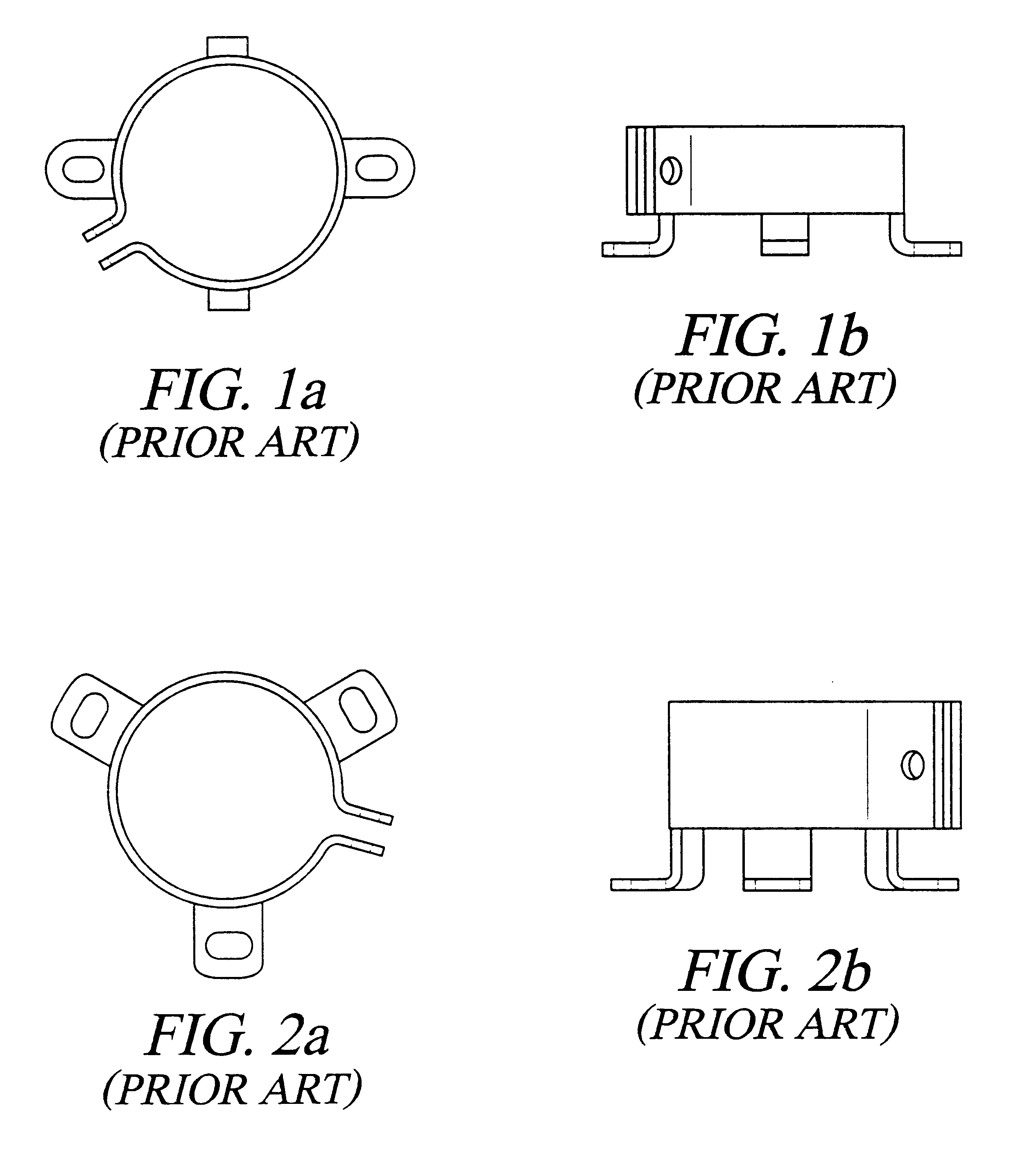

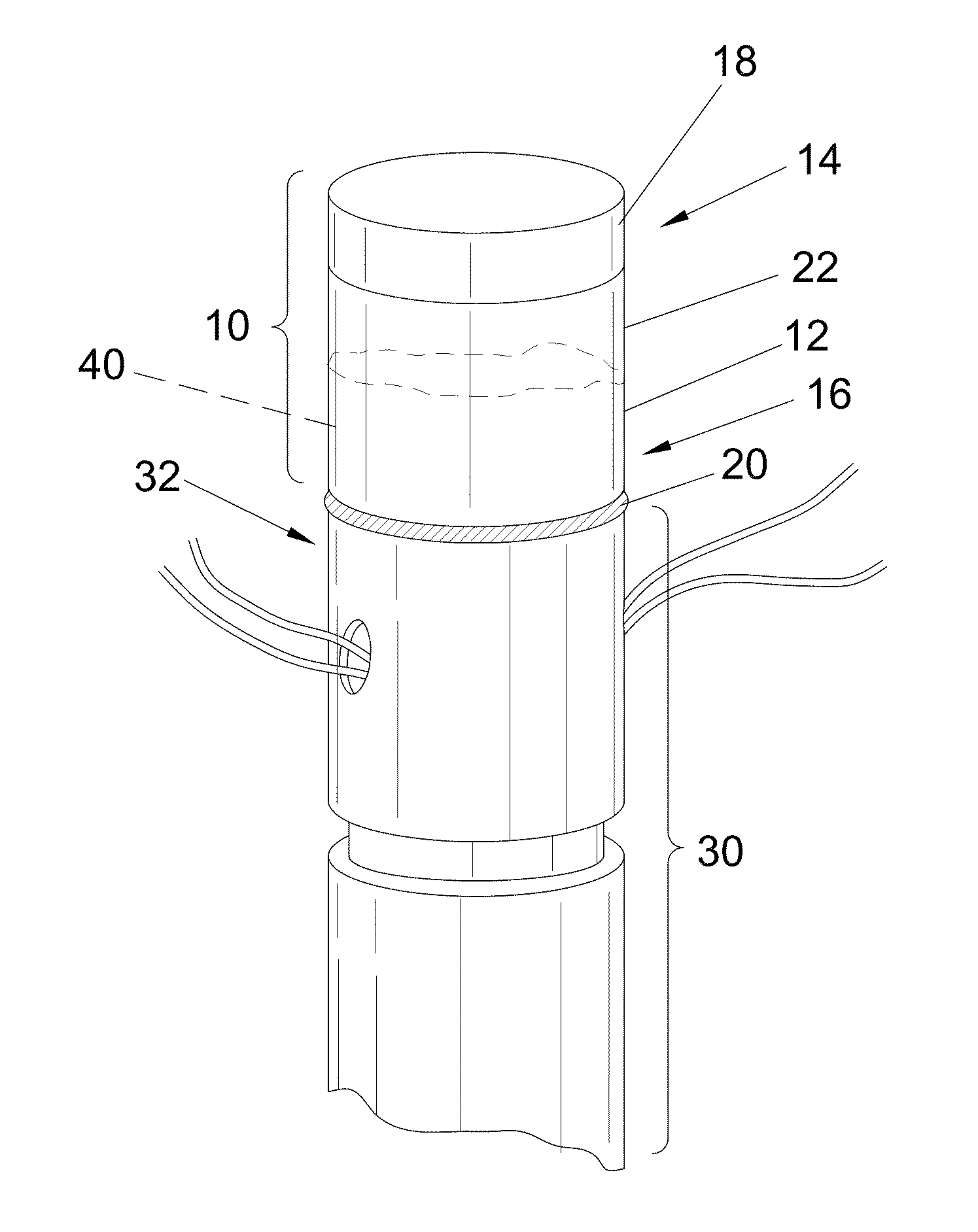

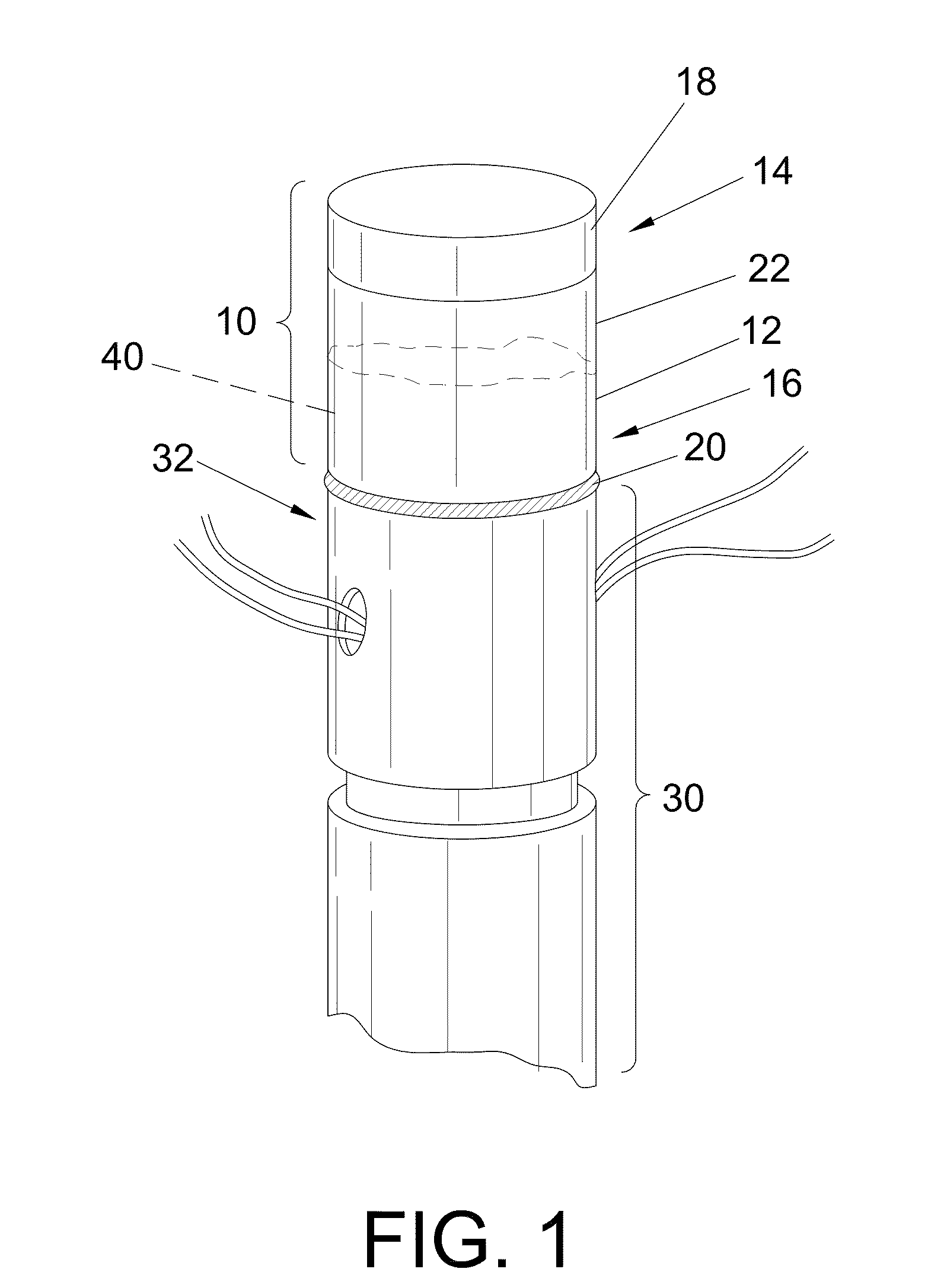

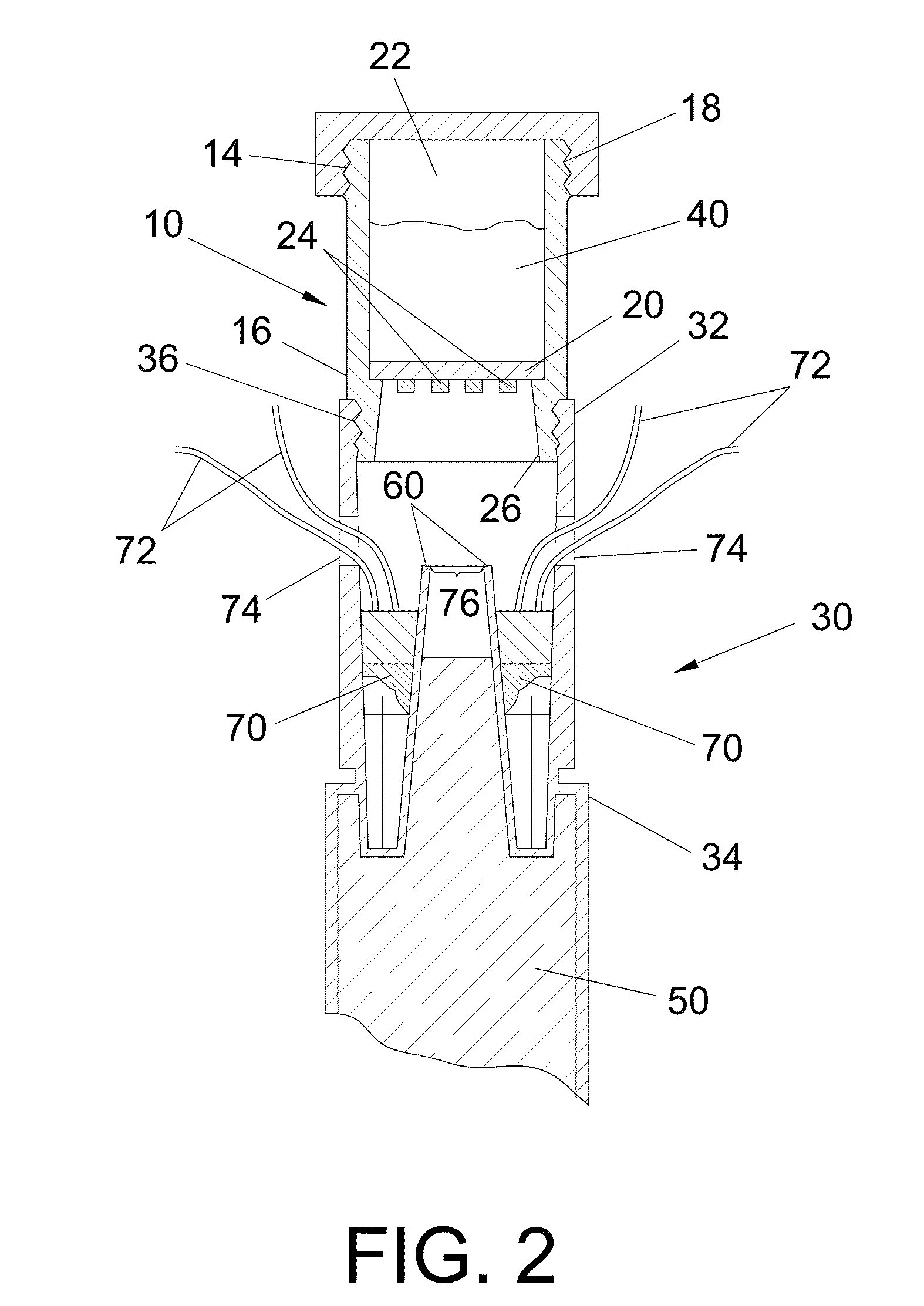

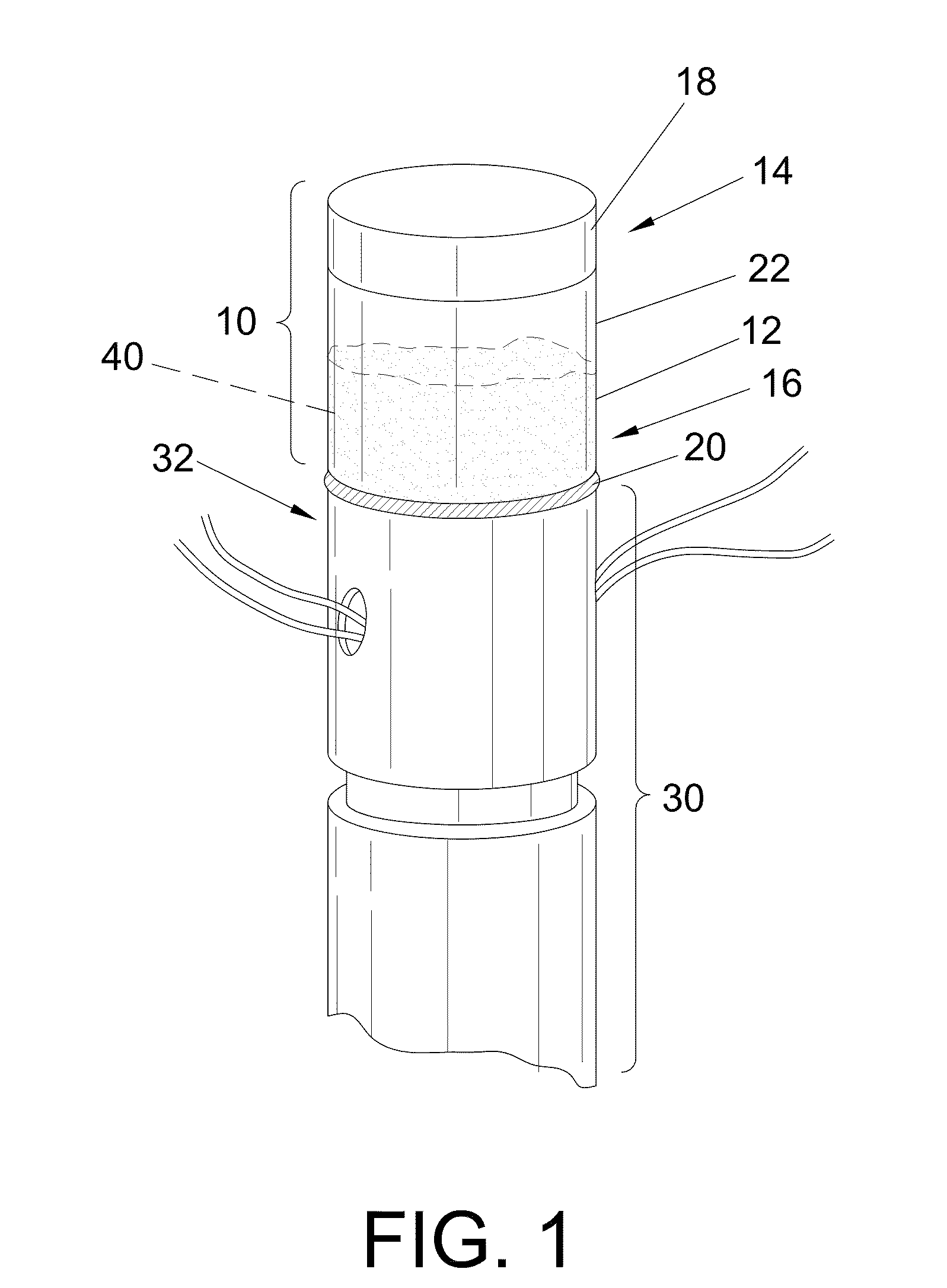

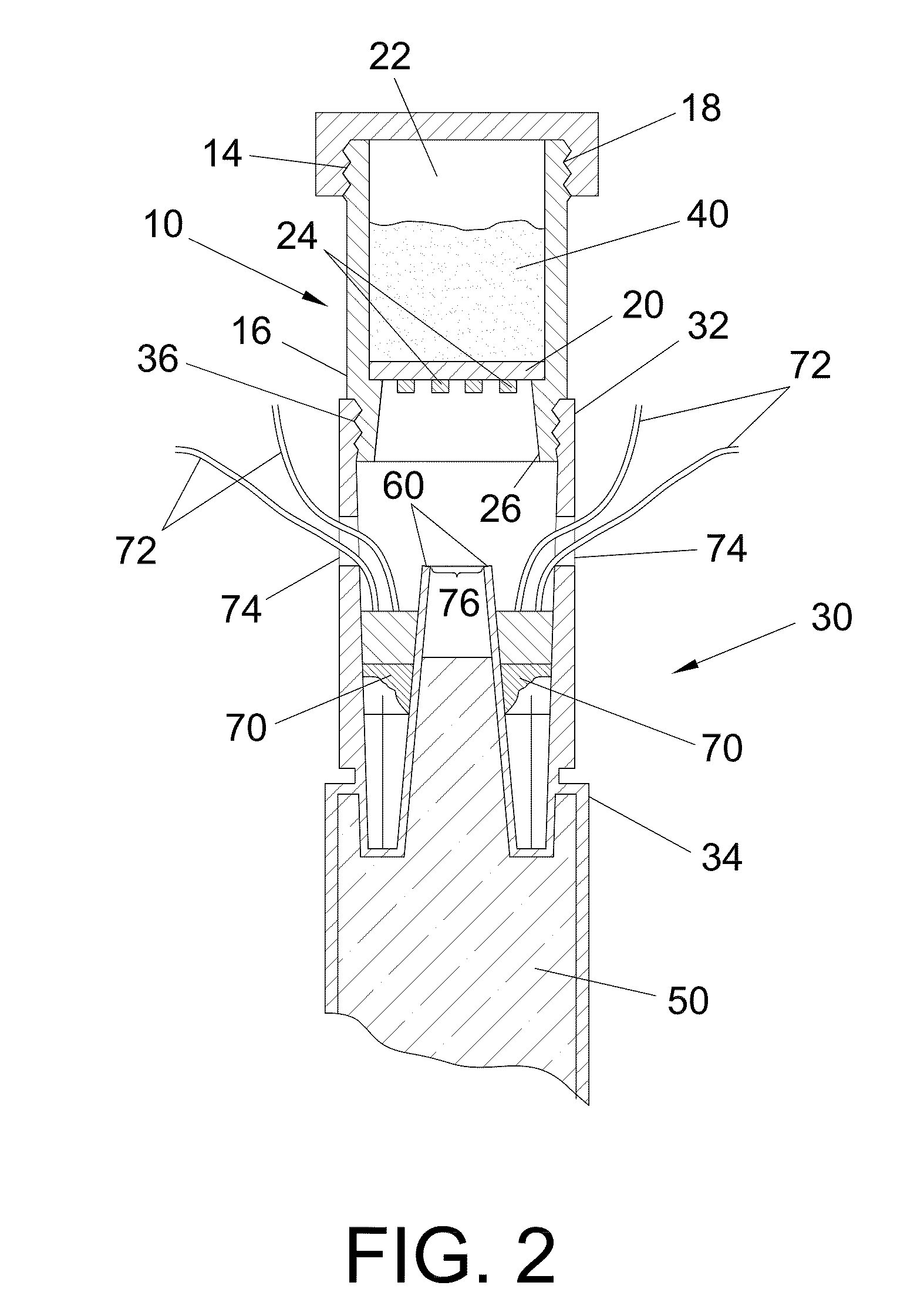

Method and apparatus for holding a capacitor without separable fasteners

InactiveUS6244544B1Shorten the timeReduce manufacturing costInstrument housingCapacitor housing/encapsulationCapacitorElectronics

A capacitor holder for mounting capacitors used in electronics assemblies into a fixture, as well as mounting other types of components in other panels. The capacitor holder includes a support for receiving the capacitor and a cover for covering the capacitor. The cover and the support are attached to each other without the use of separable fasteners. Typically, snap-fit tabs depending from the cover are used to attach the cover to the support with a capacitor there between to form an assembly. The assembly is mounted into a fixture panel without the use of separable fasteners. In another typically embodiment, the mounting members are push-in and twist or push-in and snap-fit members integral with the cover. Thus, the capacitor is mounted within a fixture without separable fasteners. A method of aligning the capacitor within the panel is also disclosed.

Owner:MAGNETEK

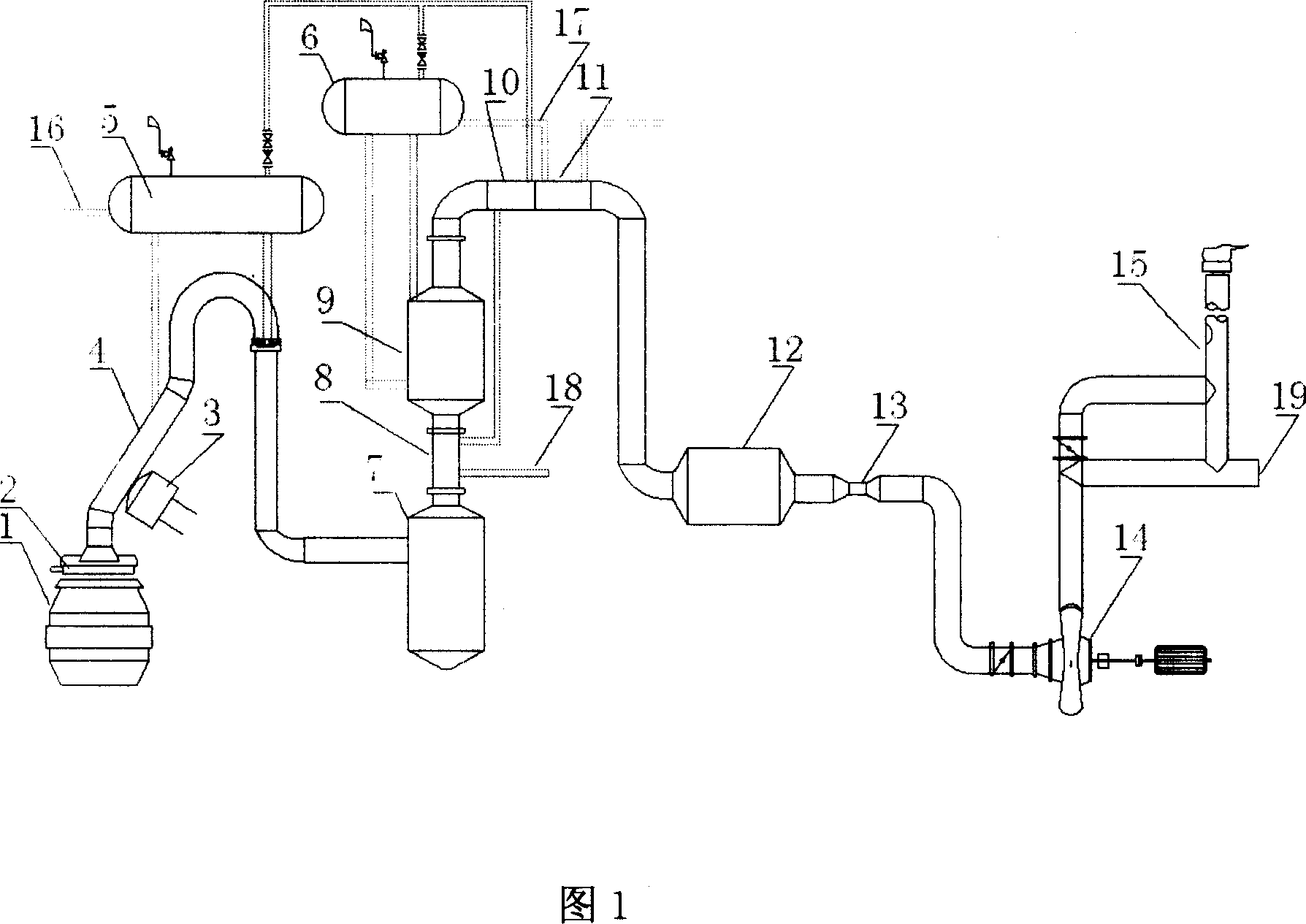

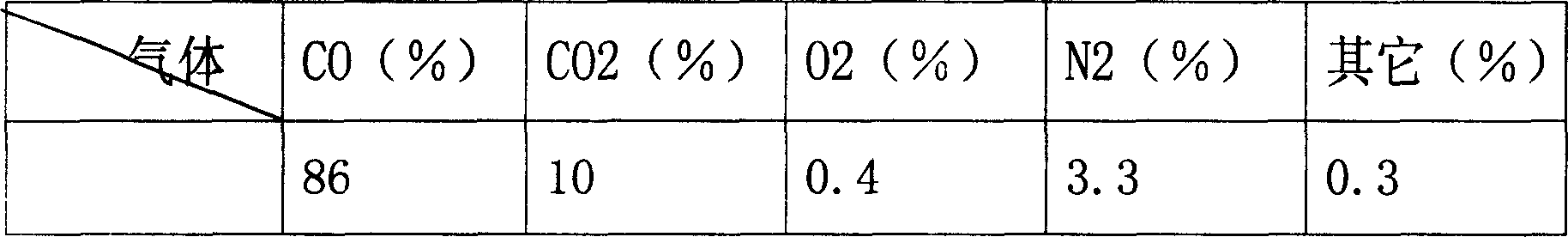

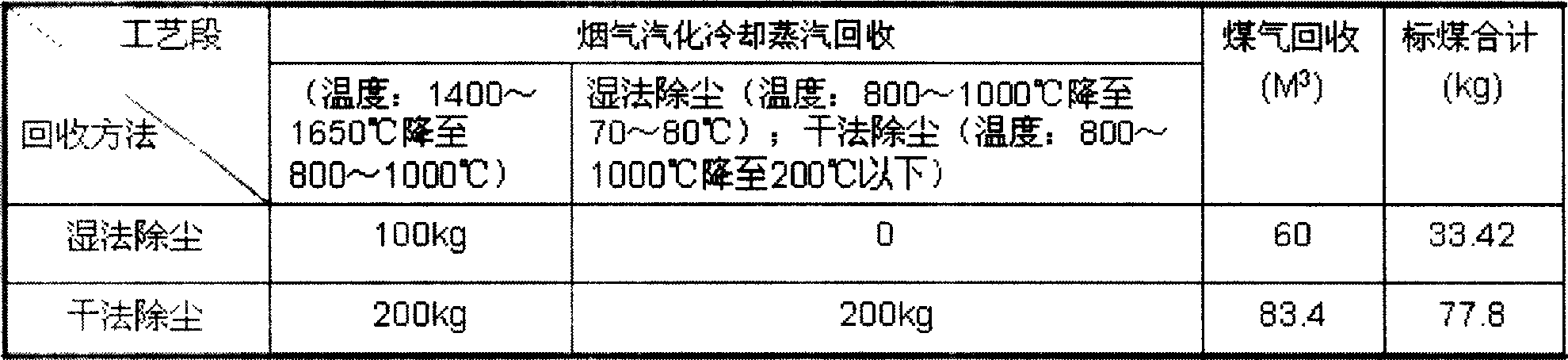

Process for recovery of excess energy of flue gas from converter

InactiveCN1971191ASolve the problem of sudden cold and hotEasy to recycleIncreasing energy efficiencyWaste heat treatmentSteelmakingCombustion chamber

The invention relates to gas residual energy recovery area of steelmaking converter, comprising eliminating dust for high-temperature gas generated in steelmaking converter, decreasing the temperature of recovery steam by heat exchanging, and collecting gas; characterized in that in not-blowing period of steelmaking converter, converter gas collected is returned to combustor between hood and vaporizing cooling flue and is mixed with air to burn; high temperature gas with more than 1500DEG C generated in vaporizing cooling flue can ensure steam recovery enough and continuously and control oxygen content in gas equal to or less than 1% after burning. The merit is that oxygen content of gas in flue is used in the process that burning decreases the gap of converter effectively, meanwhile residual energy recovery is continued, the safety and recovery efficiency of residual energy are improved greatly and the service life of equipment is prolonged. It is the effective method for decreasing steelmaking energy consumption.

Owner:昆明幸福阳光新能源有限公司

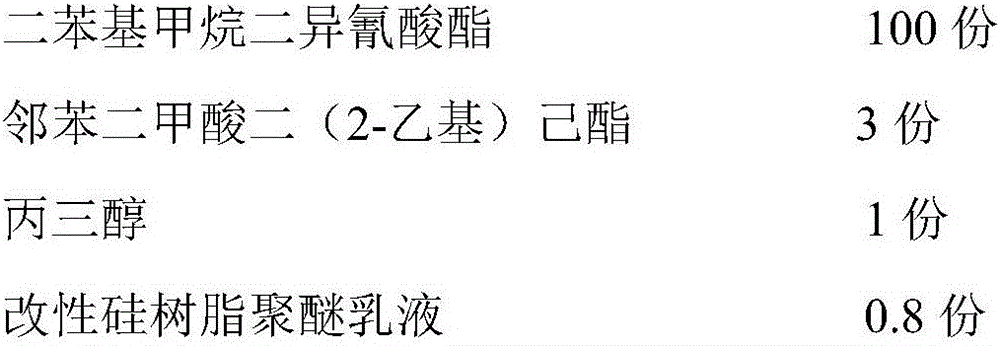

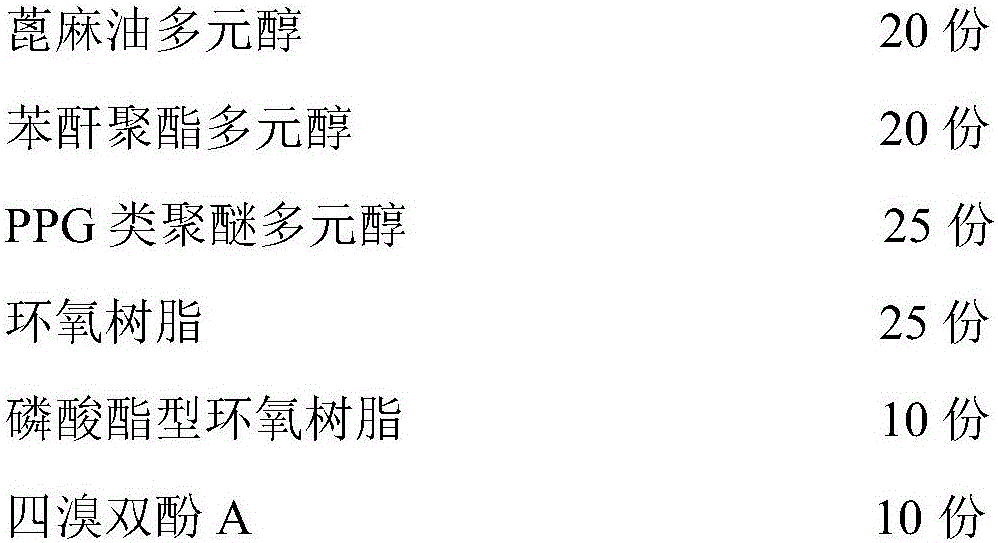

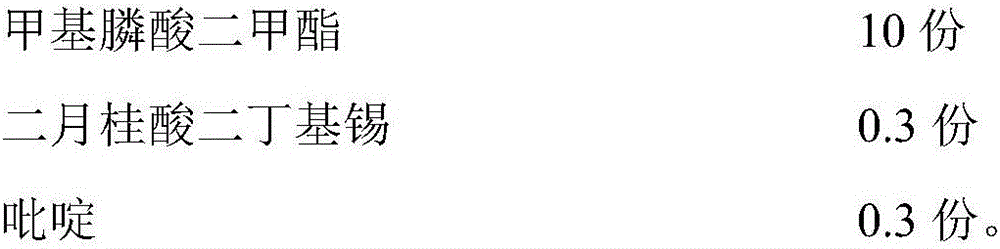

High polymer grouting reinforcement material

The invention discloses a high polymer grouting reinforcement material which comprises a component A and a component B. The component A comprises 100-120 parts of isocyanate, 3-5 parts of plasticizers, 0.5-1.5 parts of glycerol and 0.4-1.0 part of foam stabilizers. The component B comprises 60-70 parts of polymer polyol, 25-45 parts of inert diluents, 20-30 parts of flame retardants and 0.5-1.0 part of catalysts. The high polymer grouting reinforcement material is high in curing reaction speed, adjustable in curing time and low in curing reaction heat release, the possibility of smoldering and explosion of cured coal and rock masses can be greatly reduced when the high polymer grouting reinforcement material is applied to coal mine grouting reinforcement, foaming rate is low, foam is uniformly distributed, solids can reach 45-60MPa, engineering construction requirements are completely met, and engineering safety is guaranteed. Preparation steps are simple, operation is facilitated, and practicability is high.

Owner:SHANDONG UNIV

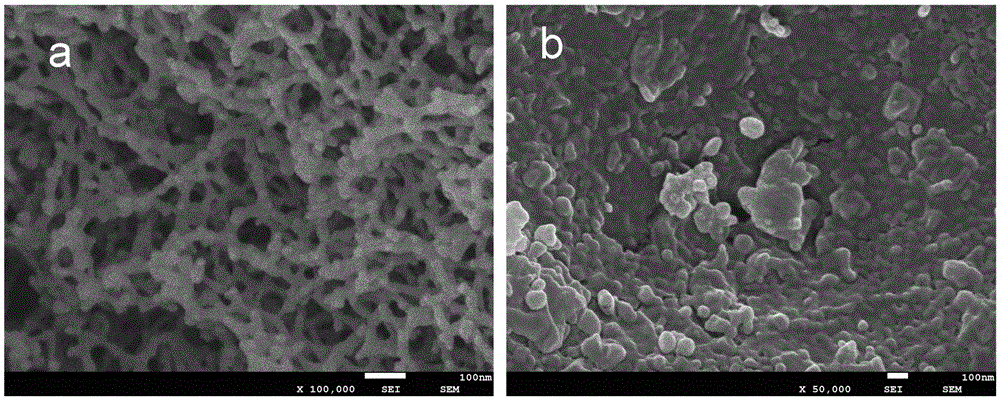

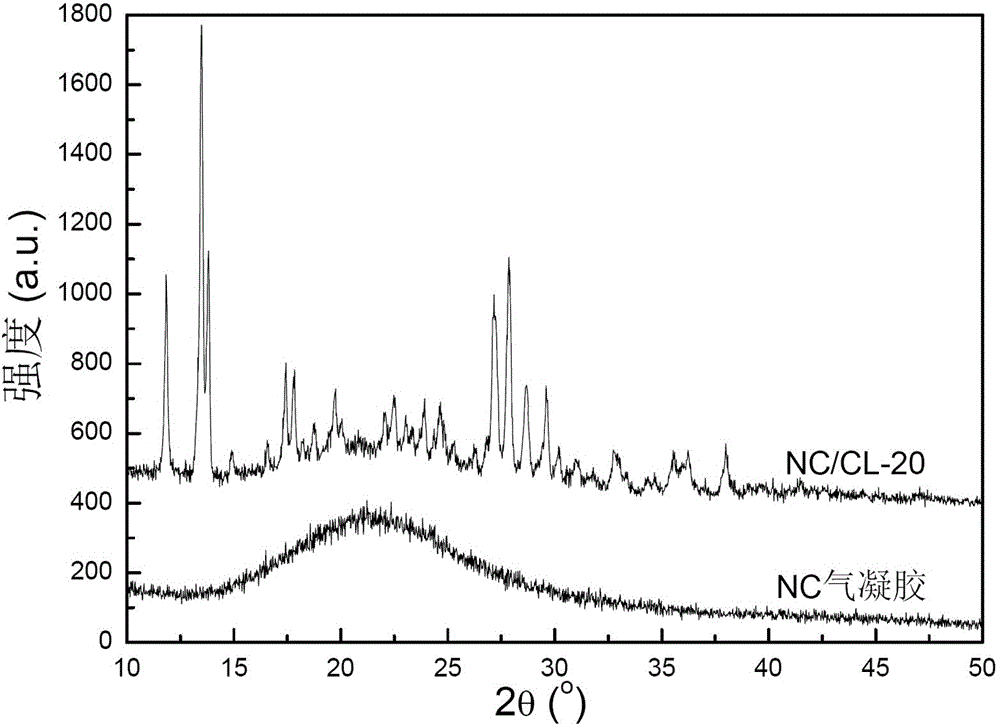

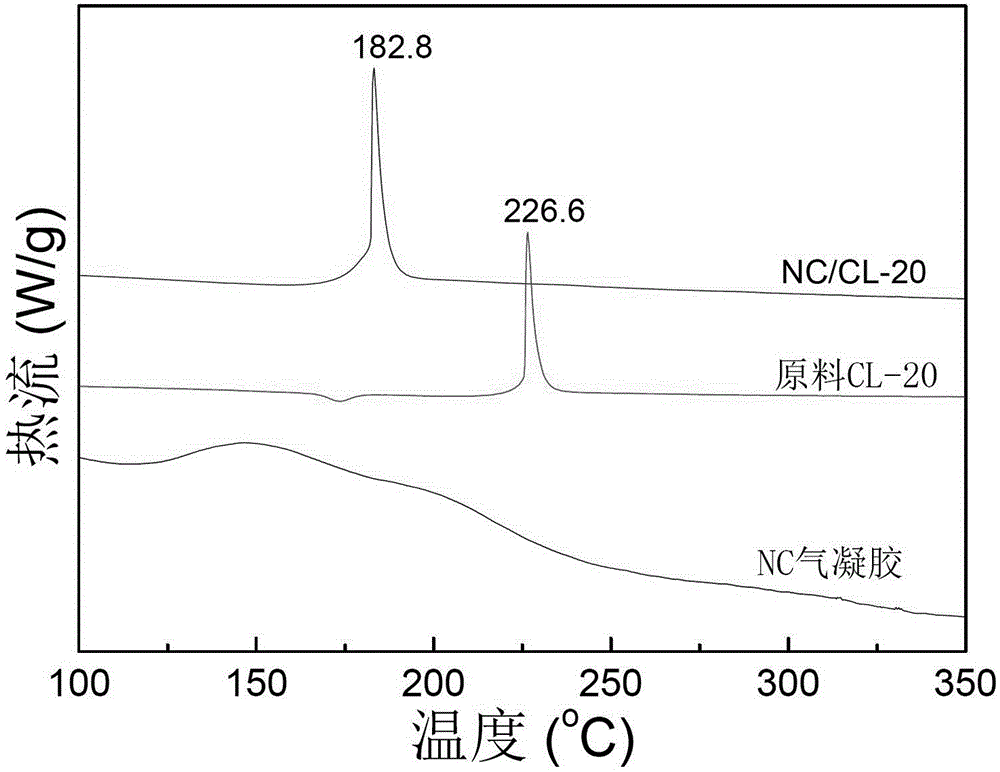

Nano-composite energetic material and preparation method thereof

InactiveCN105481617AHigh energyHigh activityExplosive working-up apparatusNitroparaffin explosive compositionsSupercritical dryingNano structuring

The invention discloses a nano-composite energetic material. The nano-composite energetic material is prepared through the steps that CL-20 and NC are taken as raw materials and then dissolved in weak-polar solvent according to the mass ratio (0.1-3):1 of the CL-20 to the NC to be prepared into a transparent solution, an isocyanate curing agent and a composite catalyst of T-12 and TEDA are added to form wet gel, the solvent is removed through supercritical drying after the wet gel is aged, and then the aerogel-state nano-composite energetic material is obtained. The prepared composite energetic material has the nano-structure, is higher in energy and activity and lower in sensitivity, has the good prospect on the aspects of improving the security feature and energy releasing efficiency of energetic components and the like and can be applied to the fields of high-energy density materials such as solid propellants, explosives and powders and pyrotechnic compositions.

Owner:ZHONGBEI UNIV

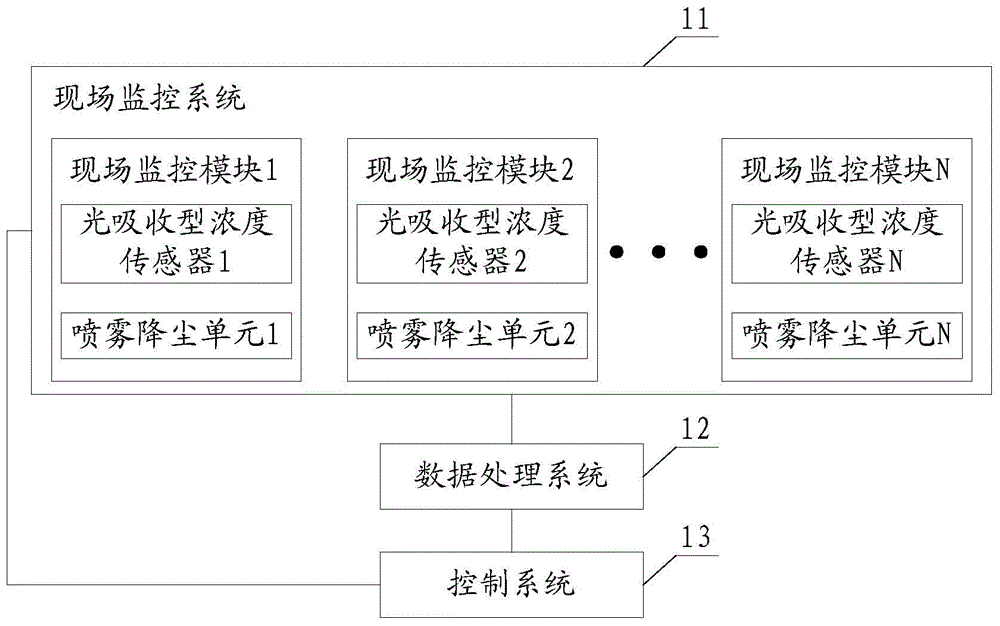

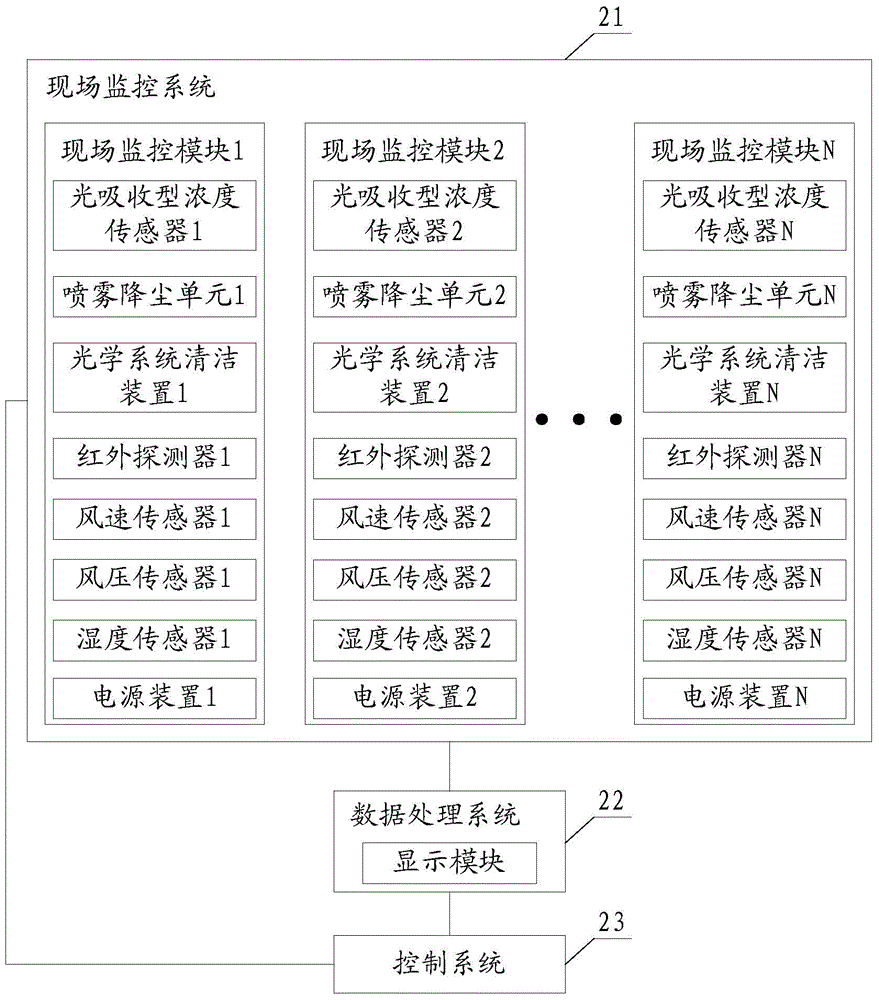

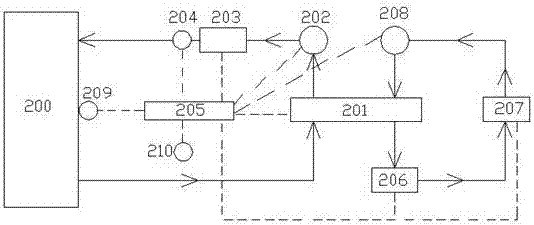

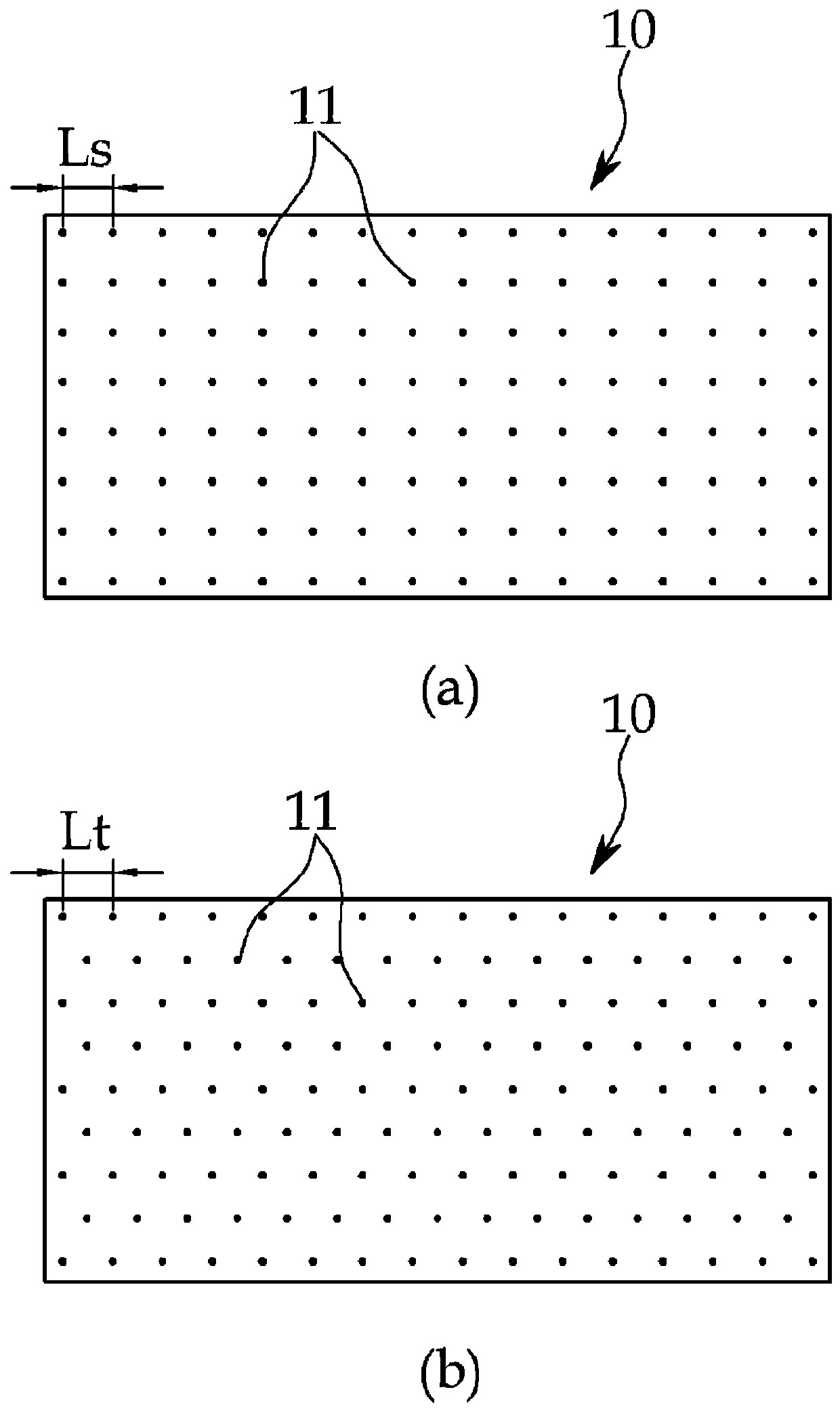

Coal mine dust monitoring system and method

InactiveCN104564156AAvoid explosive situationsReduce the likelihood of an explosionMining devicesDust removalDust explosionNormal values

The invention discloses a coal mine dust monitoring system and method. The system comprises a light absorption type concentration sensor, a data processing system and a control system, wherein the light absorption type concentration sensor is used for collecting real-time dust concentration data, when the real-time dust concentration data is an abnormal value, the data processing system generates warning eliminating signals, when the real-time dust concentration data is changed from an abnormal value to a normal value, the data processing system generates warning elimination signals, and the control system is used for controlling a spraying dust reducing unit to start or stop the spraying processing. In the system disclosed by the embodiment of the invention, the collected dust concentration data is real-time dust concentration data, the condition that the dust explosion can be caused since the real-time performance of the dust concentration data is poor in the prior art is avoided, and the dust explosion possibility is reduced; in addition, the control system can control the spraying dust reducing unit to stop the spraying processing, the condition that the spraying device is in the spraying state for a long time due to the personnel negligence in the prior art is avoided, and the utilization rate of water resources is improved.

Owner:浙江图讯科技股份有限公司

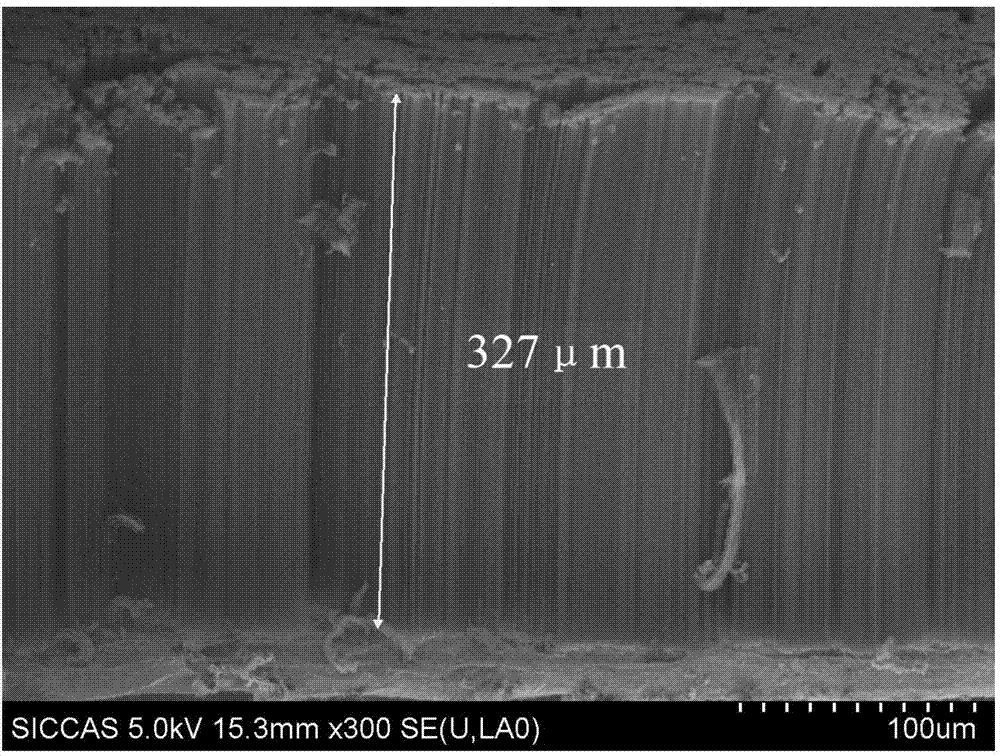

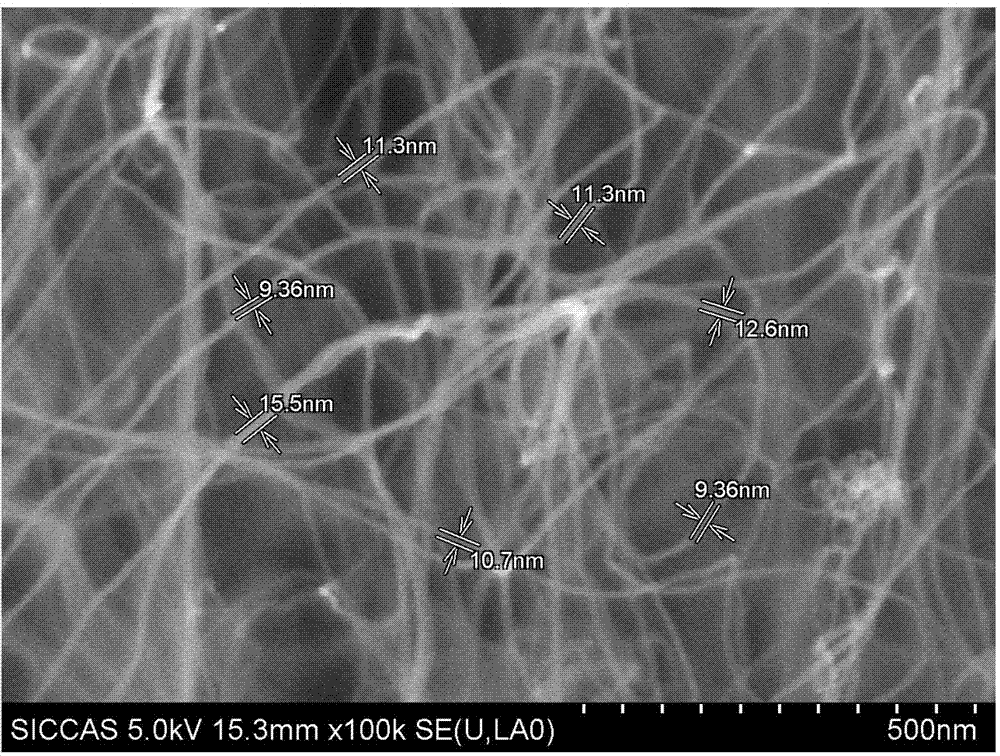

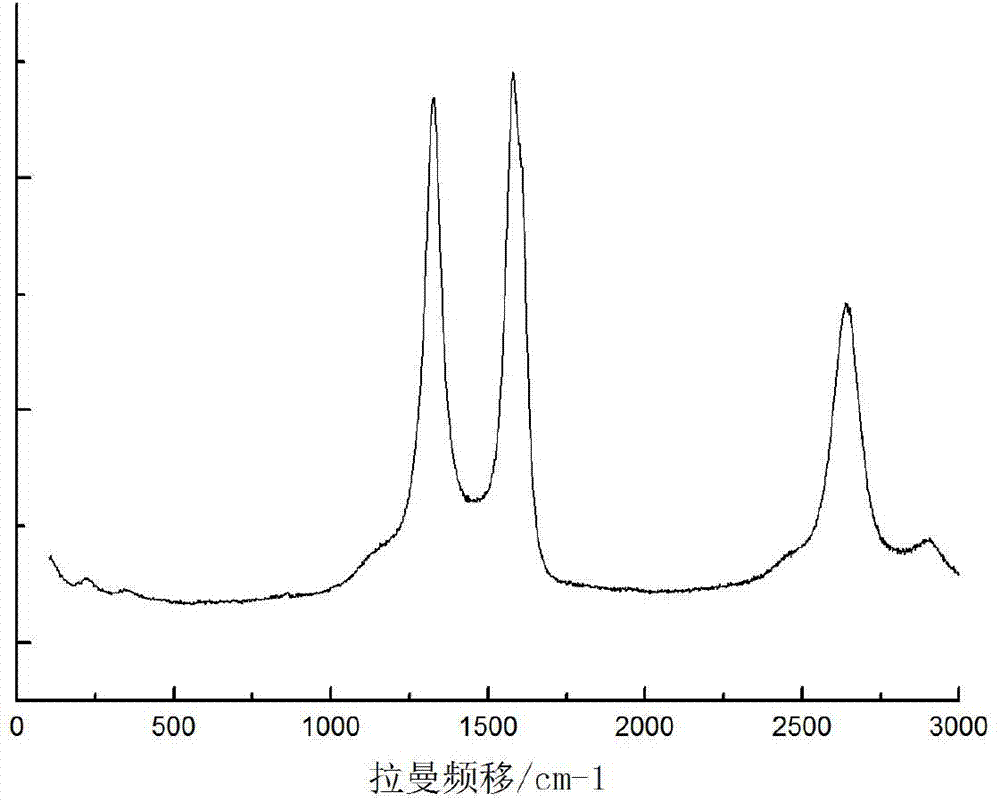

Carbon nano-tube array with uniform tube diameter and growing method thereof

ActiveCN103771389AImprove securityReduce the likelihood of an explosionMaterial nanotechnologyCarbon compoundsCarbon nanotubeComposite substrate

The invention discloses a method for growing a carbon nano-tube array with uniform tube diameter. The method mainly comprises the following steps: (A) depositing a buffer layer and a catalyst layer on a foil to form a composite substrate; (B) introducing a reducing gas, and reducing the catalyst on the composite substrate at a low pressure of 3-20kPa; and (C) introducing a gas mixture consisting of an inert gas, a reducing gas and a carbon-source gas, and in-situ growing the carbon nano-tube array on the composite substrate by adopting a chemical vapor phase deposition method at a low pressure of 15-40kPa. In the method, reduction of the catalyst and growth of the carbon nano-tube array are respectively controlled at the low pressure of 3-20kPa and the low pressure of 15-40kPa, so that the process safety can be improved, the grain diameter and appearance of catalyst grains and array growth can be effectively controlled, and the carbon nano-tube array with high quality and uniform tube diameter can be obtained. The height of the carbon nano-tube array is 100-350mu m, the tube diameter is distributed uniformly and between 8 and 20nm, and the standard deviation is less than 3nm.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

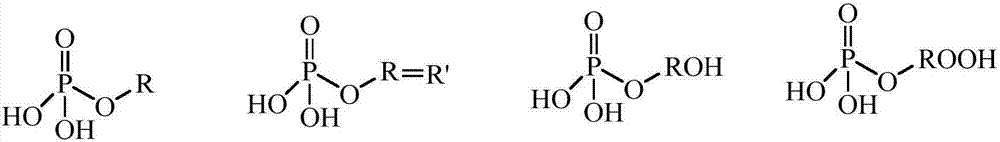

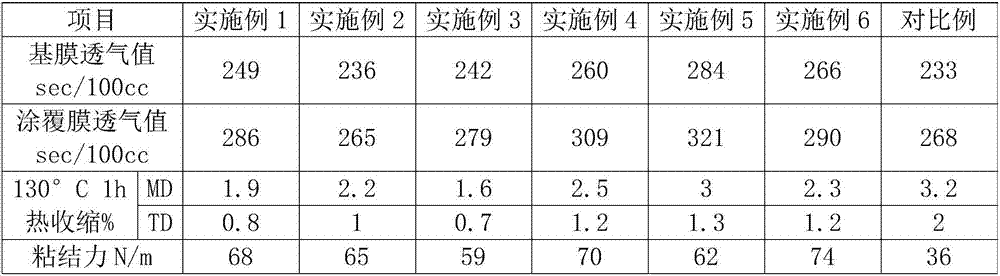

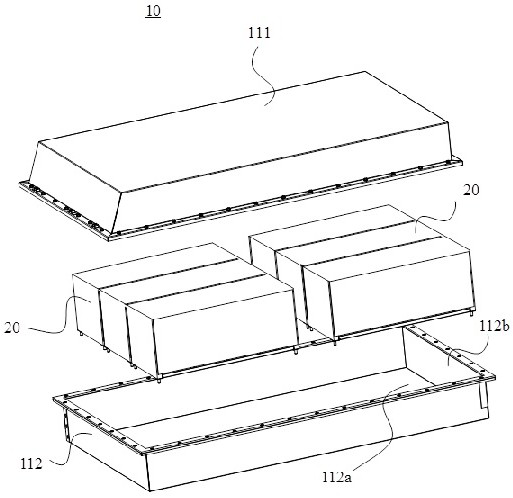

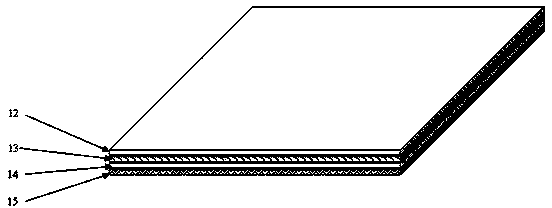

Preparation method of high-safety ceramic coating separator

ActiveCN106953049AGood dispersionImprove wettabilitySecondary cellsCell component detailsPolyolefinCeramic coating

The invention provides a preparation method of a high-safety ceramic coating separator. The preparation method comprises the following steps of 1) preparing modified alkali ceramic powder, in which short-carbon chain phosphoric acid and a solvent are uniformly mixed and stirred, alkali ceramic powder is added and uniformly stirred to obtain a mixed solution, a temperature is raised to 150-200 DEG C, stirring reaction is performed for 5-10 hours, and the modified alkali ceramic powder is obtained after performing rinsing, filtering and vacuum drying; 2) preparing modified ceramic paste, in which the modified alkali ceramic powder obtained by preparation of the step 1), deionized water and a binding agent are mixed and stirred for 0.5-3 hours to obtain the modified ceramic paste; and 3) coating, in which the modified ceramic paste obtained by preparation of the step 2) is coated at one side or two sides of a polyolefin-based film, a modified ceramic coating layer is formed after drying, and the high-safety ceramic coating separator is prepared. By the preparation method, the mechanical property of the separator is improved, the air permeability of the separator is maintained unchanged, the thermal stability of the alkali ceramic coating layer is maintained, and the conductivity and the safety performance of a lithium battery are improved.

Owner:DONGGUAN ADVANCED ELECTRONICS TECH

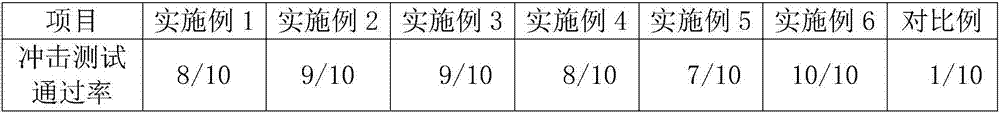

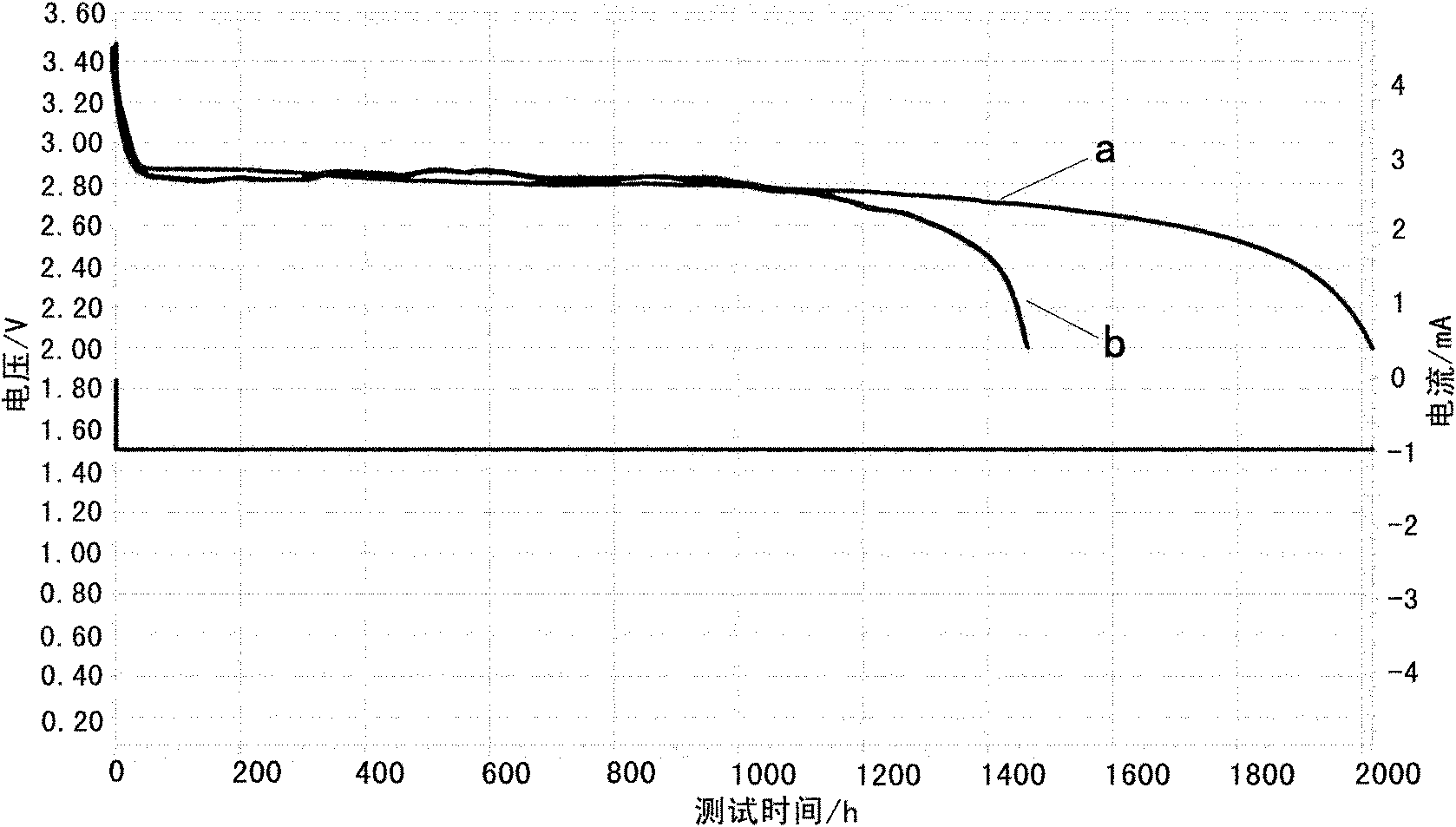

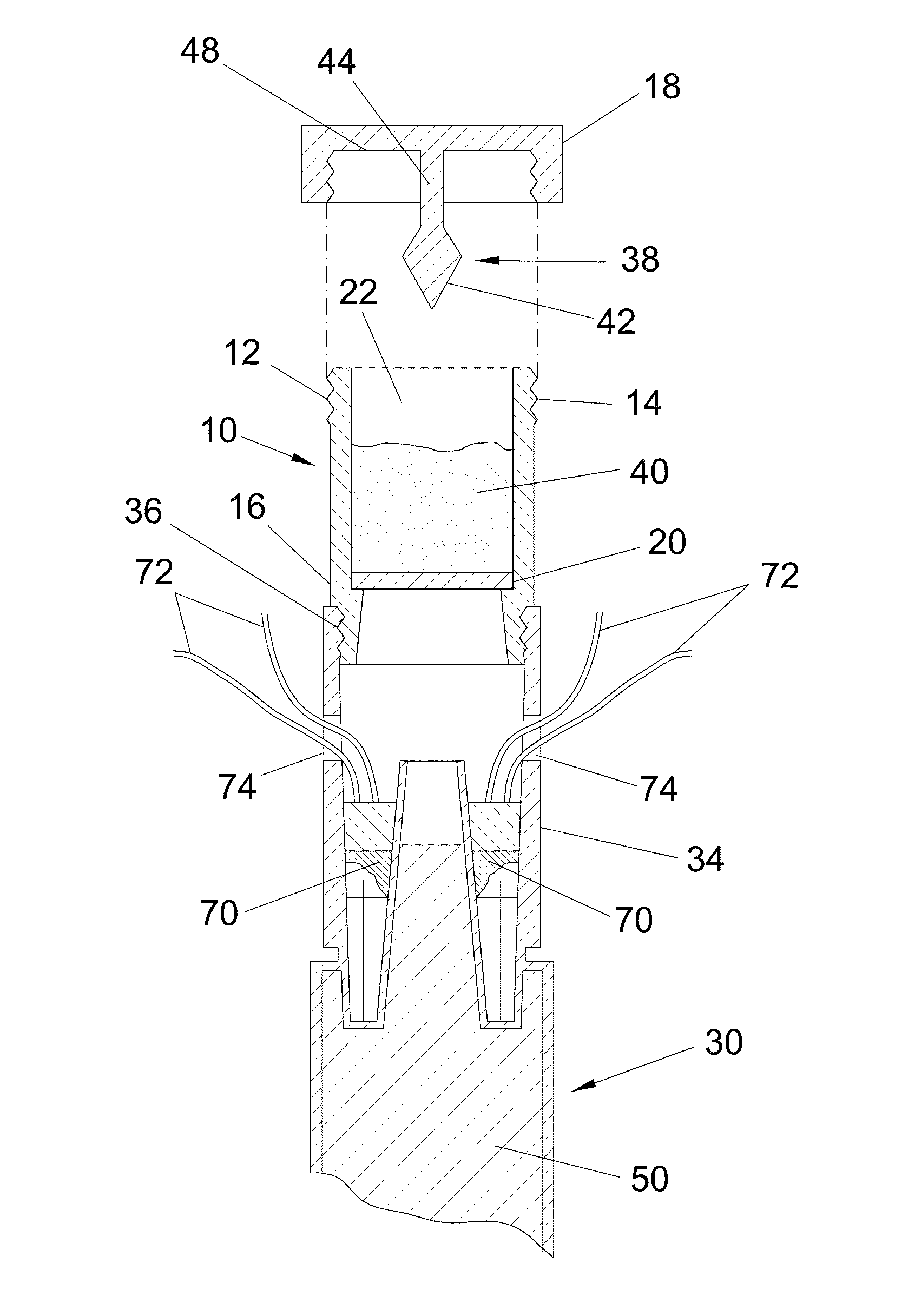

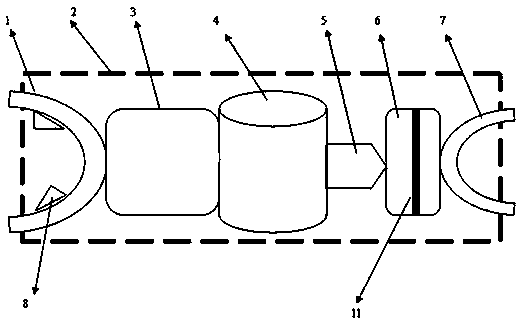

Cylindrical lithium-manganese dioxide battery structure with high capability and preparation method thereof

ActiveCN101916879AReduce contact areaFull use of spaceFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithiumEngineering

The invention relates to a cylindrical lithium-manganese dioxide battery structure with high capability, wherein a ring of diaphragm (4) is wrapped on an outer surface of an anode electrical core (3), a lithium band (5) is arranged between the diaphragm (4) and a steel shell (1), a cover assembly (9) is located on the inner upper end of the steel shell (1), an anode core post (7) is located in the middle of the cover assembly (9), a metal connecting strip (10) is connected with the anode core post (7), the cover assembly (9) is provided with a liquid injection hole (11) and a sealing pin (8) for sealing the liquid injection hole (11), and an insulation sheet (6) for isolating an anode piece (3) from the lithium band (5) is arranged at the inner bottom of the steel shell (1). By adopting the cylindrical lithium-manganese dioxide battery structure, the capability of the battery is increased by 25.0%-36.4%, and the cost of materials is reduced. The invention further discloses a method for assembling the cylindrical lithium-manganese dioxide battery structure with high capability.

Owner:武汉昊诚锂电科技股份有限公司 +1

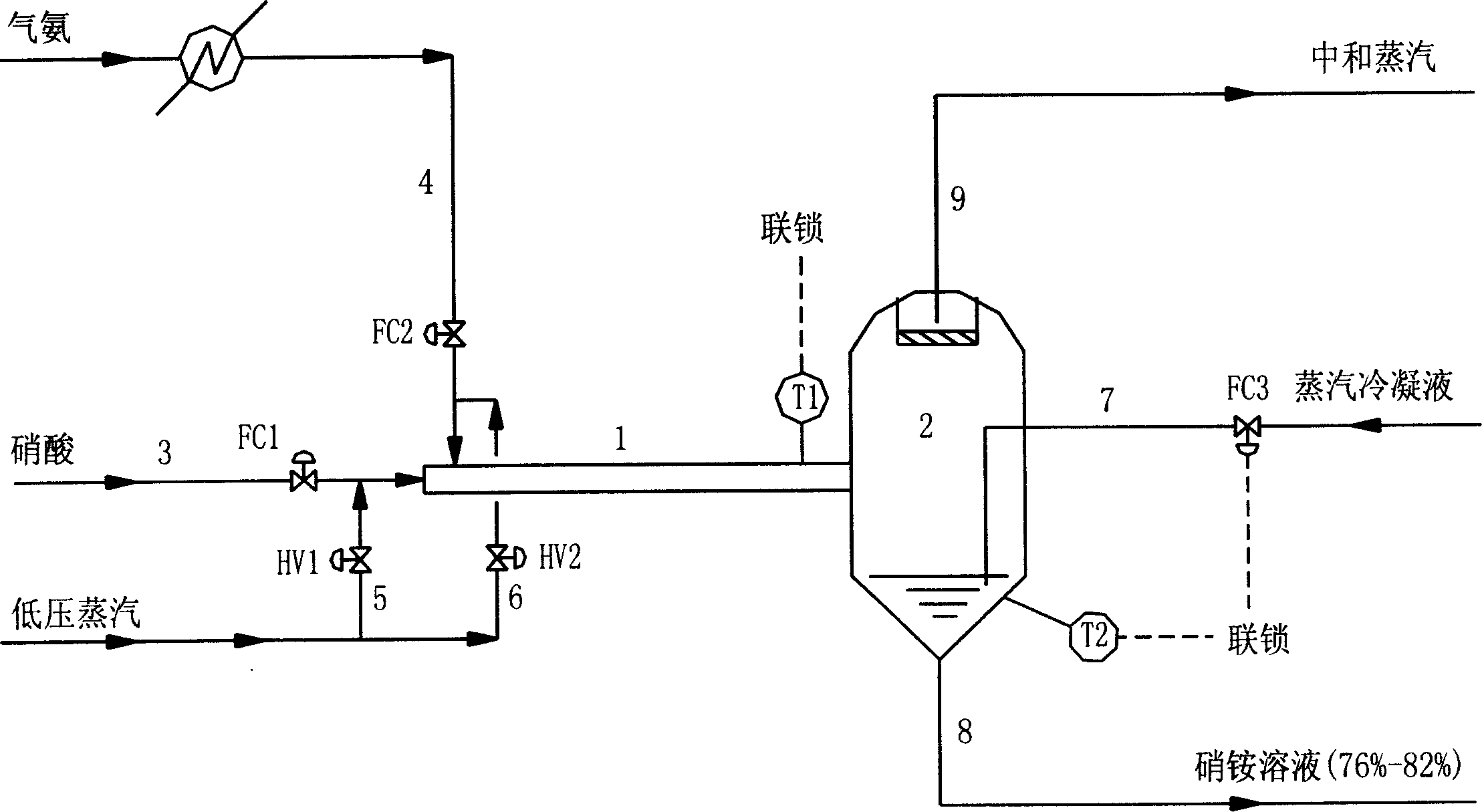

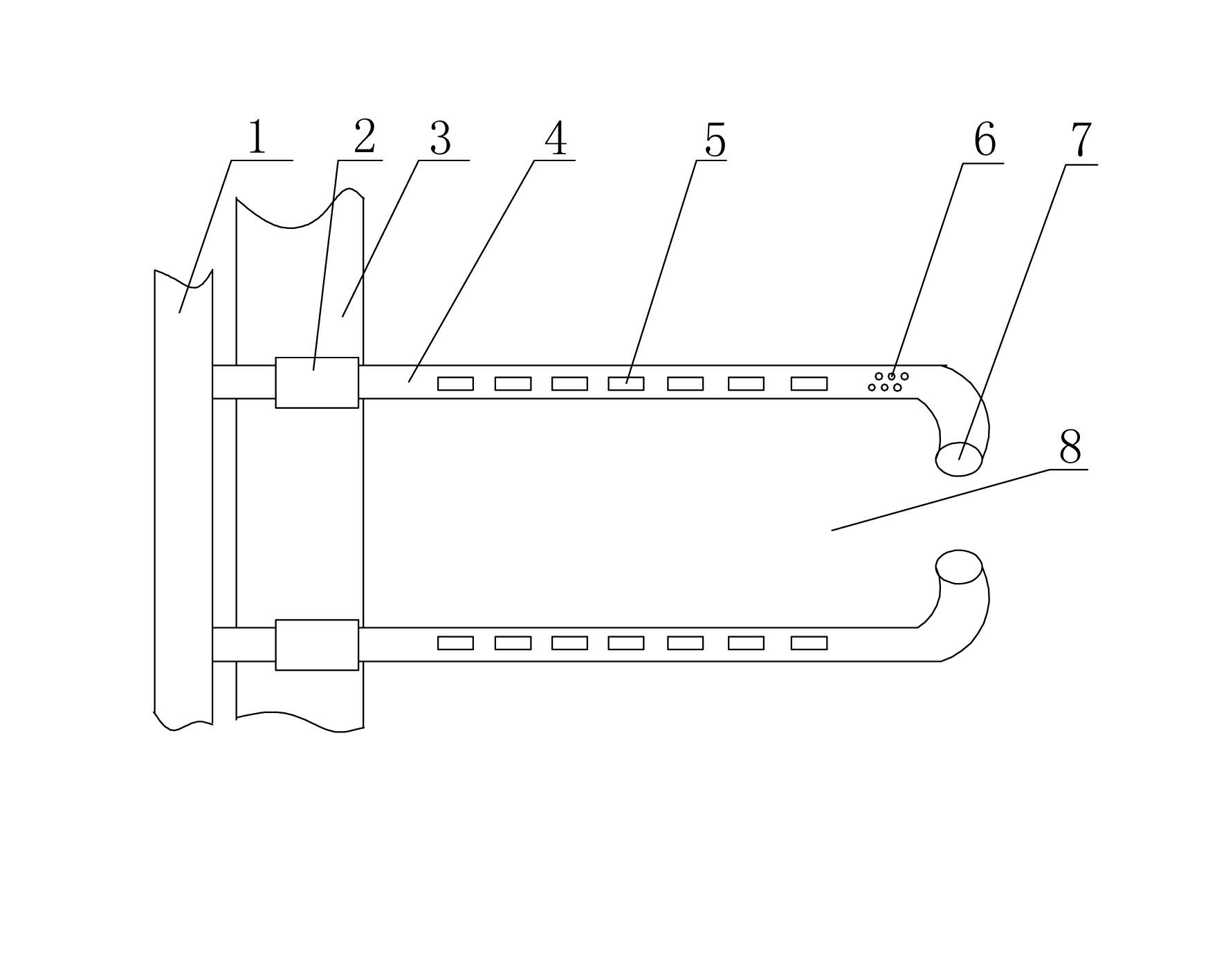

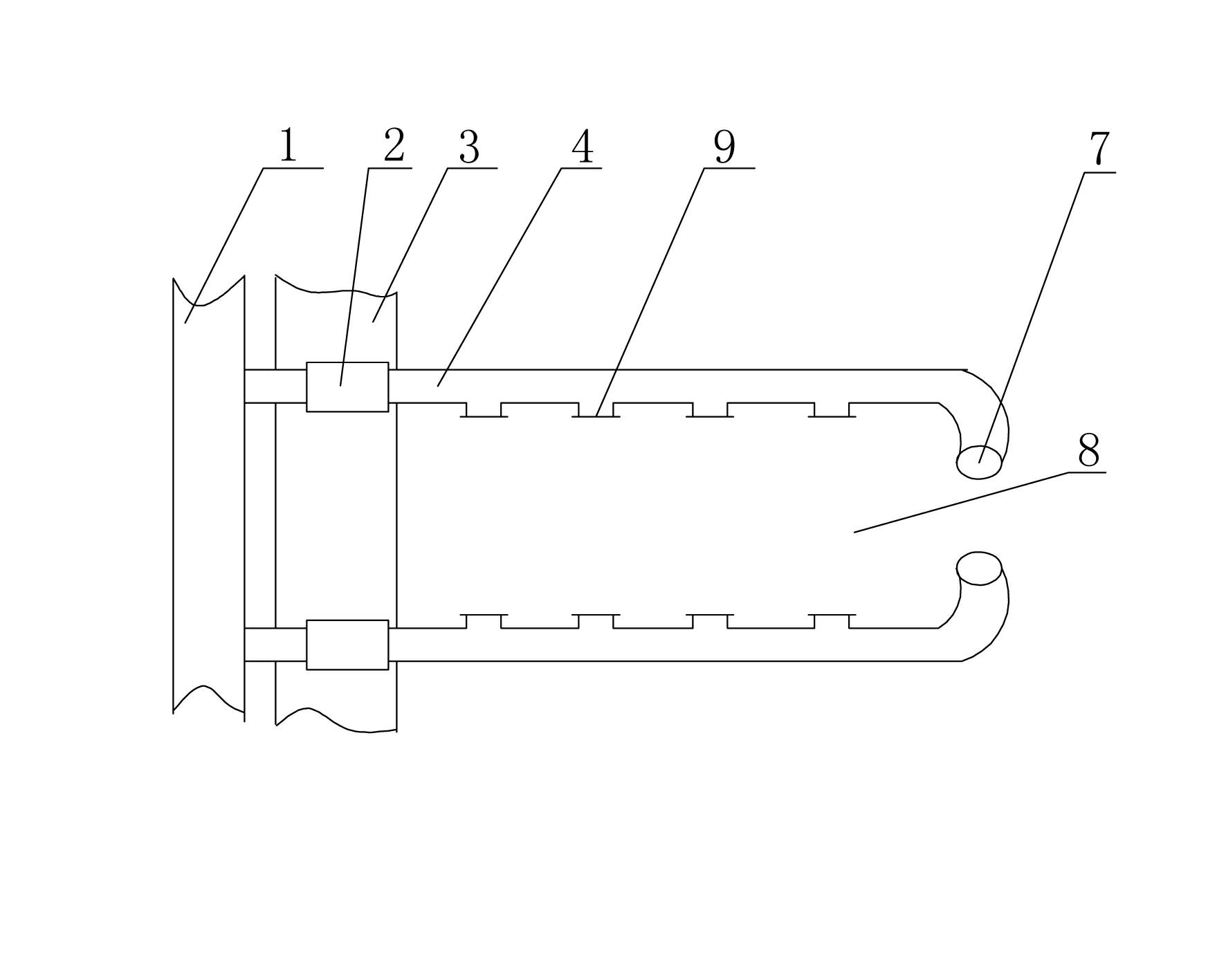

Method for producing ammonium nitrate

ActiveCN1884078AReduce the likelihood of an explosionAchieve productionAmmonium nitratesReaction temperatureProcess engineering

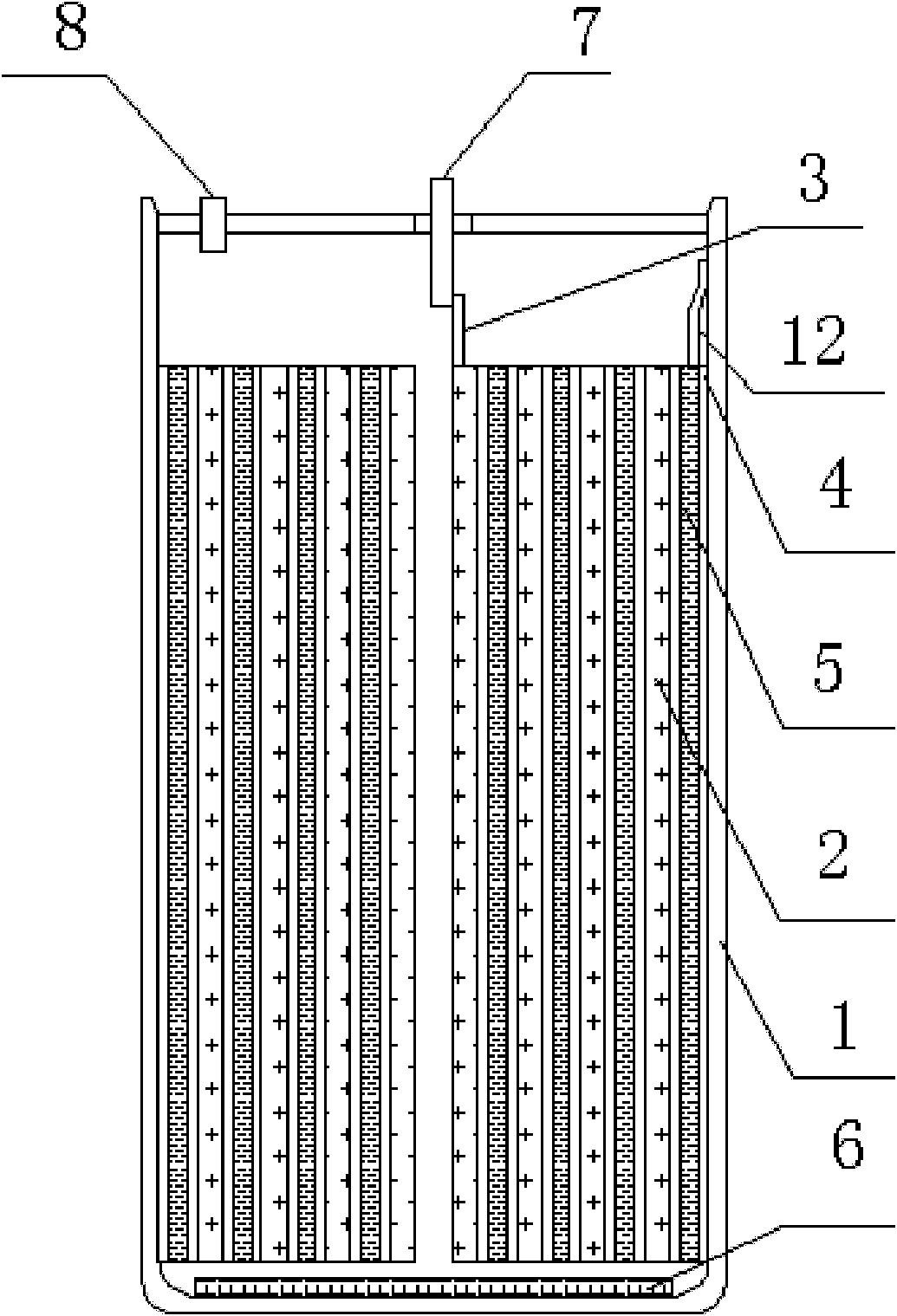

The invention discloses a manufacturing method of ammonium nitrate through neutralizing reaction of nitrate and ammonia gas in the pipe-typed reactor, setting temperature testing device on the pipe-typed reactor; connecting steam pipe on the feeder pipe of nitrate and ammonia gas; assembling steam control valve; interlocking temperature testing device, material controlling valve and steam controlling valve; closing material controlling valve once the reacting temperature reaches the preset control temperature; opening steam controlling valve to guide low-pressure steam to pipe typed reactor; brushing reacting material; avoiding accident to realize safe manufacturing.

Owner:SEDIN ENG

Mine gas, blasting fume and dust separation ventilation system

InactiveCN102661163AAvoid full flowAddress air qualityTunnel/mines ventillationControl of respirationCoal mine methane

The invention relates to the technical field of underground mine ventilation equipment, in particular to a mine gas, blasting fume and dust separation ventilation system. The system comprises fans and a blowdown stack; the top of a mine main roadway is provided with a main air return channel which is connected with the blowdown stack; the tops of branch roadways on two sides of each stope of a mine are provided with branch air return channels which are communicated with the main air return channel of the mine so as to form a double-air inlet double-air return system of the stope; the fans are arranged on the connection parts of the branch air return channels and the main air return channel; one end of each branch air return channel is connected with the fan, and the other end of each branch air return channel is provided with an air inlet; and each branch air return channel is provided with a ventilation control device which consists of exhaust openings formed in the sides of pipe bodies of the branch air return channel and valves matched with the exhaust openings. Different air flow of each section of the roadway and the requirement can be adjusted. The separation ventilation system is also suitable for ventilation of other underground mines.

Owner:耿秀

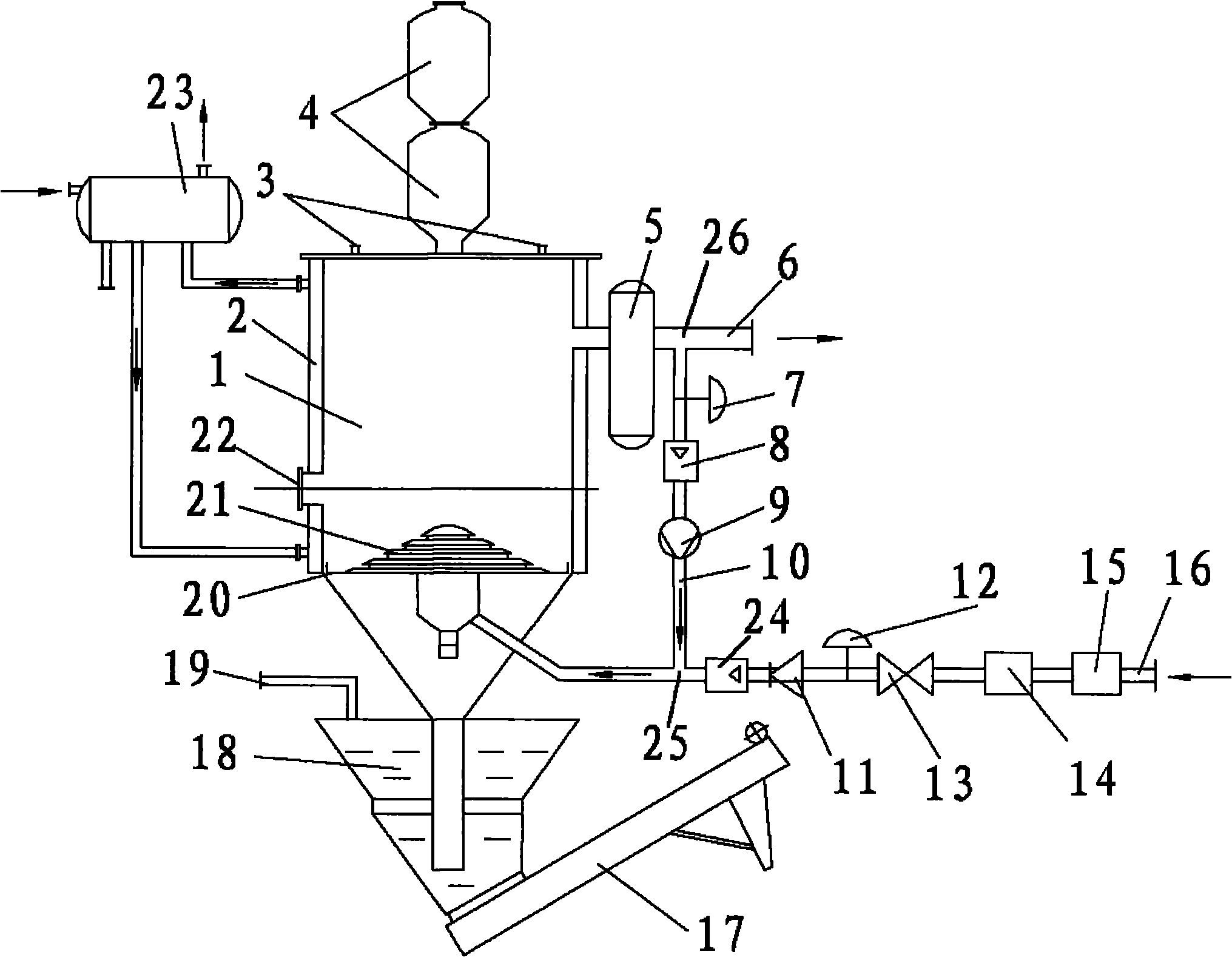

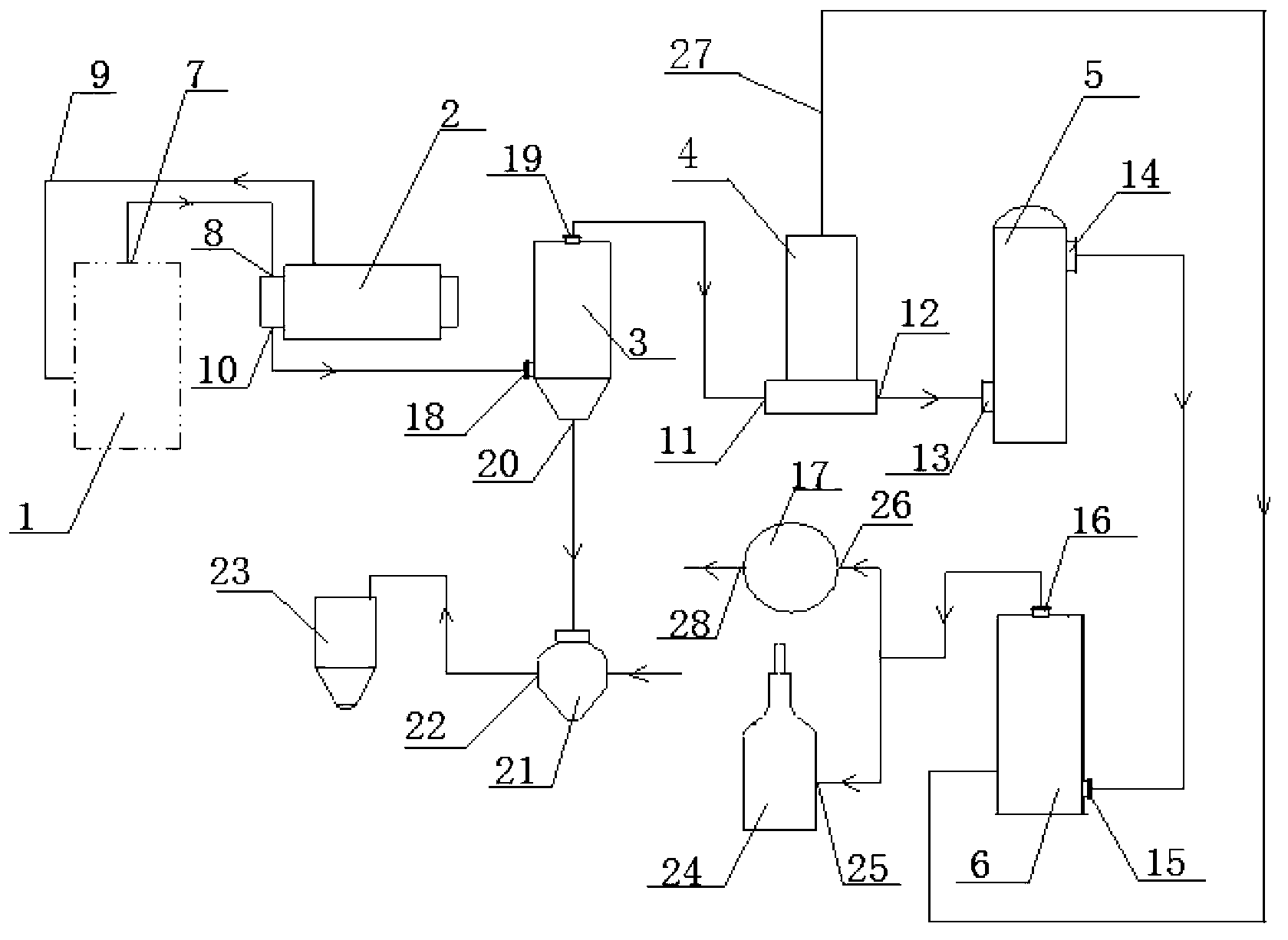

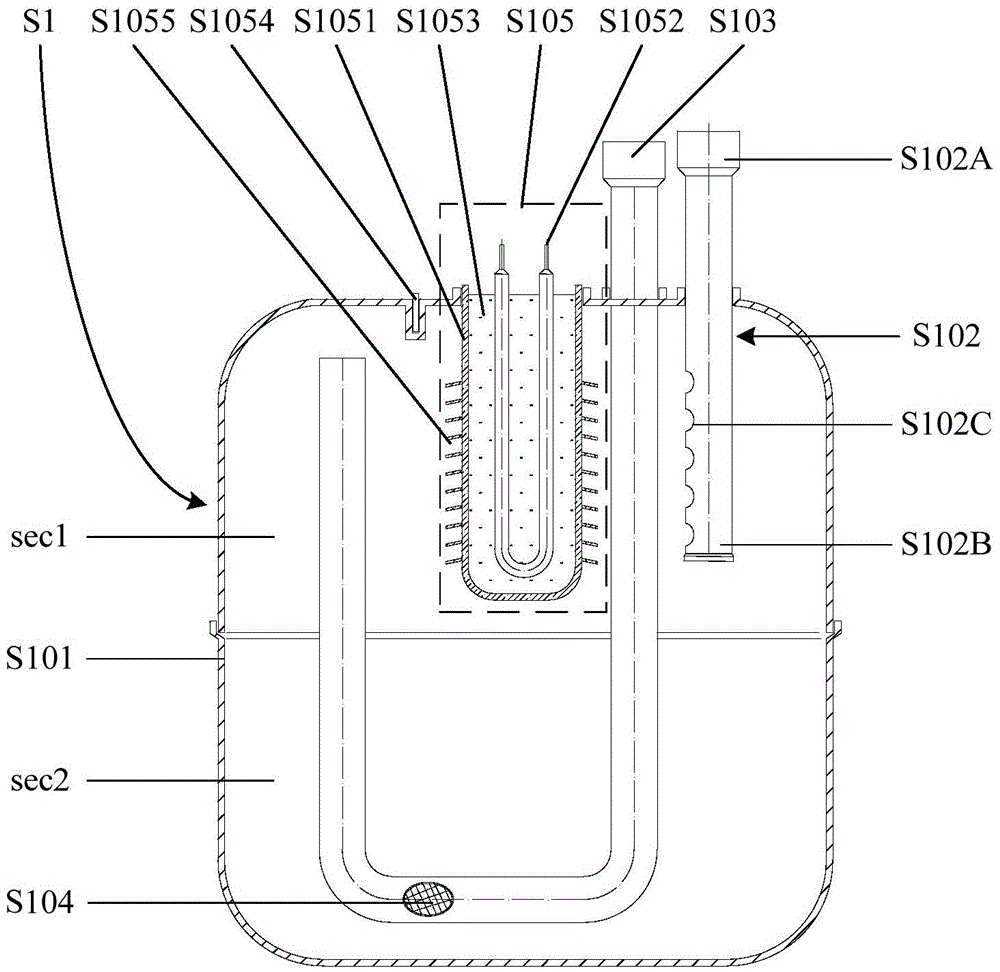

Technology and device for cooling and purifying high-temperature and high-pressure biomass synthesis gas

ActiveCN103265979AAvoid resistancePrevent leakageEnergy inputGas purification by non-gaseous materials condensationComing outHigh pressure

The invention discloses a technology and device for cooling and purifying high-temperature and high-pressure biomass synthesis gas. The technology comprises the following steps of: (1) subsection cooling, namely cooling the high-temperature and high-pressure biomass synthesis gas coming out of a biomass gasifier to 350-550 DEG C by process water, recovering waste heat to produce medium-pressure steam, and after that, cooling the biomass synthesis gas to 100-300 DEG C, and recovering waste heat to produce low-pressure steam; (2) collecting and removing tar; (3) washing and purifying; and (4) treating the biomass synthesis gas by a wet type electrostatic precipitator, wherein the pressure of the treated biomass synthesis gas is 0.1-1 MPa. The device mainly comprises a tube shell type waste heat boiler, a dry-type gas filter, a vertical smoke tube waste heat boiler, a packless venturi scrubbing tower and the wet type electrostatic precipitator. The technology and the device can be used for controlling appropriate technological parameters by the optimal design of the technical scheme, thus realizing subsection cooling of the biomass synthesis gas, cascade recycling of the waste heat, gradual dust removal and the purification target of tar removal. The technology and the device are simple in equipment, smooth in technology, low in energy consumption, high in efficiency, high in safety and stability and good in economic benefit.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

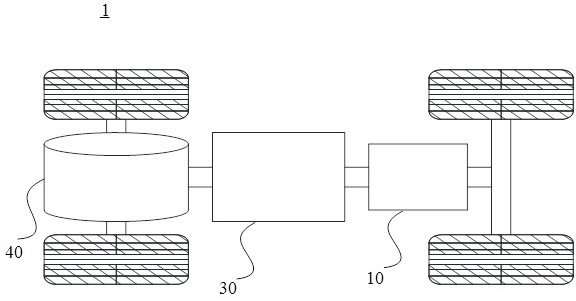

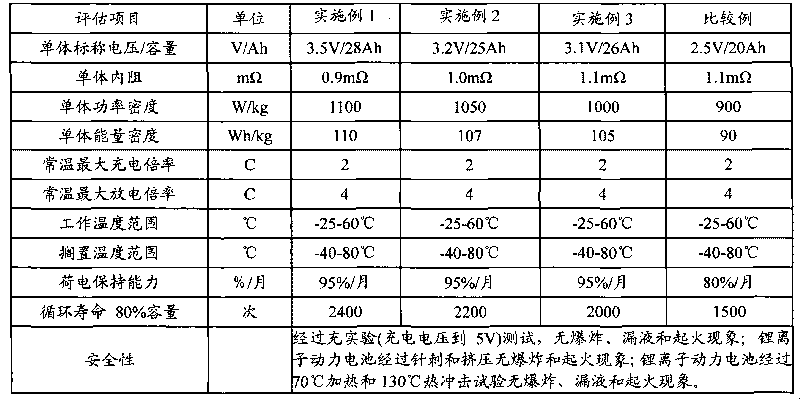

Battery, electric device, and method and equipment for preparing battery

ActiveCN112018302AReduce the likelihood of an explosionImprove securityAssembling battery machinesFinal product manufactureElectrical batteryProcess engineering

The embodiment of the invention provides a battery, an electric device and a method and equipment for preparing the battery. The battery includes a single battery including a pressure relief mechanismfor being actuated to release the internal pressure of the single battery when the internal pressure or temperature of the single battery reaches a threshold value; a fire-fighting pipeline for containing a fire-fighting medium and discharging the fire-fighting medium towards the single battery when the pressure relief mechanism is actuated; and an accommodating part for accommodating the fire-fighting medium discharged from the fire-fighting pipeline so as to cool the single battery. According to the technical scheme of the embodiment of the invention, the safety of the battery can be enhanced.

Owner:JIANGSU CONTEMPORARY AMPEREX TECHNOLOGY LIMITED

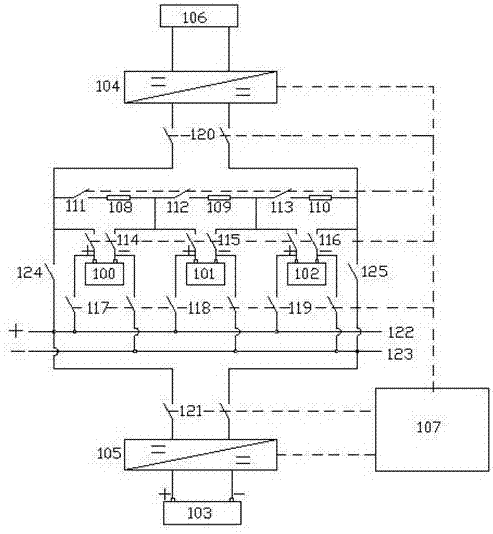

Electric vehicle battery protection system

PendingCN107264305ASave energyReduce the likelihood of an explosionElectric devicesCell temperature controlExothermic reactionAutomotive engineering

The present invention discloses an electric vehicle battery protection system, which comprises a plurality of energy storage devices, a plurality of DC-DC converters, a plurality of switches, a DC bus, a controller, a large-capacity energy storage device, resistors, a collision detection sensor and a refrigeration system. When an accident is detected, energy in batteries can be rapidly decreased, the energy in a battery pack is rapidly decreased by using a rapid cooling system, thus the energy in the batteries can be rapidly transferred to the single large-capacity energy storage device, and the single large-capacity energy storage device is cooled to prevent a fact that heat generated by a damaged battery is transferred to other batteries to make the adjacent batteries to conduct the same exothermic reactions, and the chain of dangerous reactions is caused to spread.

Owner:安徽康力节能电器科技有限公司

Systems and methods for chemical and/or mechanical remediation of nitro compounds and nitrate esters

ActiveUS8585841B2Reduce the likelihood of an explosionReduce the possibilityAmmunition projectilesNon-explosive fillers/gelling/thickening agentsNitro compoundReagent

Owner:MAXAMCORP HLDG SL

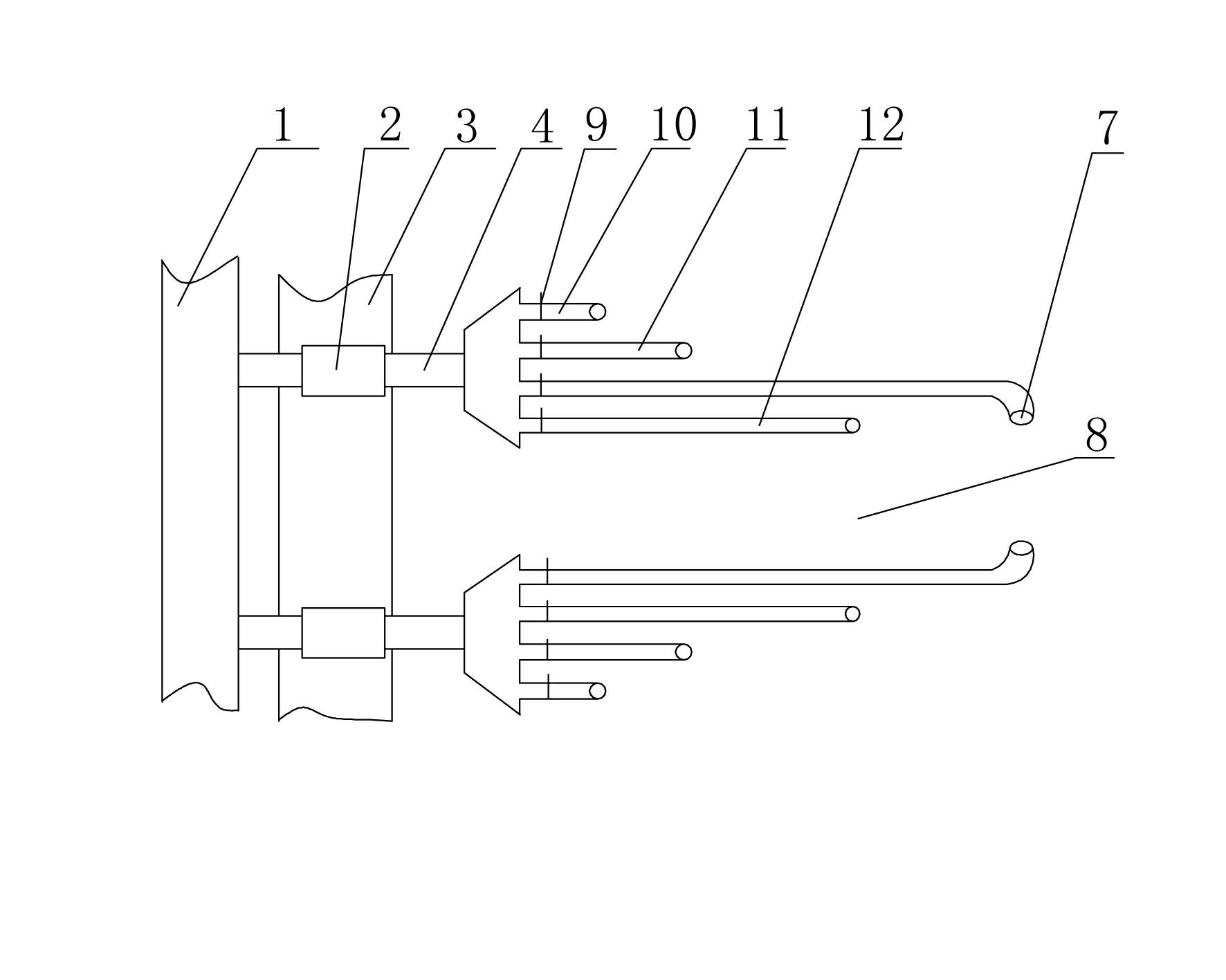

Outdoor terminal of crosslinked electric cable compound insulation sleeve

The present invention relates to a cable accessory and provides a cross-linked cable composite insulation covering outdoor terminal aiming at the defect of the prior technology that the porcelain insulation covering has low safety. The terminal is connected with the tail end of the cross-linked cable and jacketed on the external side of a cross-linked cable core through a core cavity. The outdoor terminal also includes a composite insulation bushing, an insulation medium and a stress petrous pyramid; the composite insulation bushing is jacketed on the external side of the core cavity, including an internal wall and an umbrella skirt tightly combined from inside to outside and these two are respectively made of glass fiber reinforced epoxide resin and silicon rubber materials; the insulation medium is injected into a hollow cavity between the composite insulation bushing and the external layer of the core cavity; the stress petrous pyramid is arranged on one end of the core cavity and immerges in the insulation medium. When the insulation medium is broken down, the composite insulation composed of a silicon rubber and synthetic resin glass fiber cylinder has strong anti-shocking performance, thus reducing the explosion possibility and further greatly improving the safety of the outdoor terminal.

Owner:长园科技集团股份有限公司

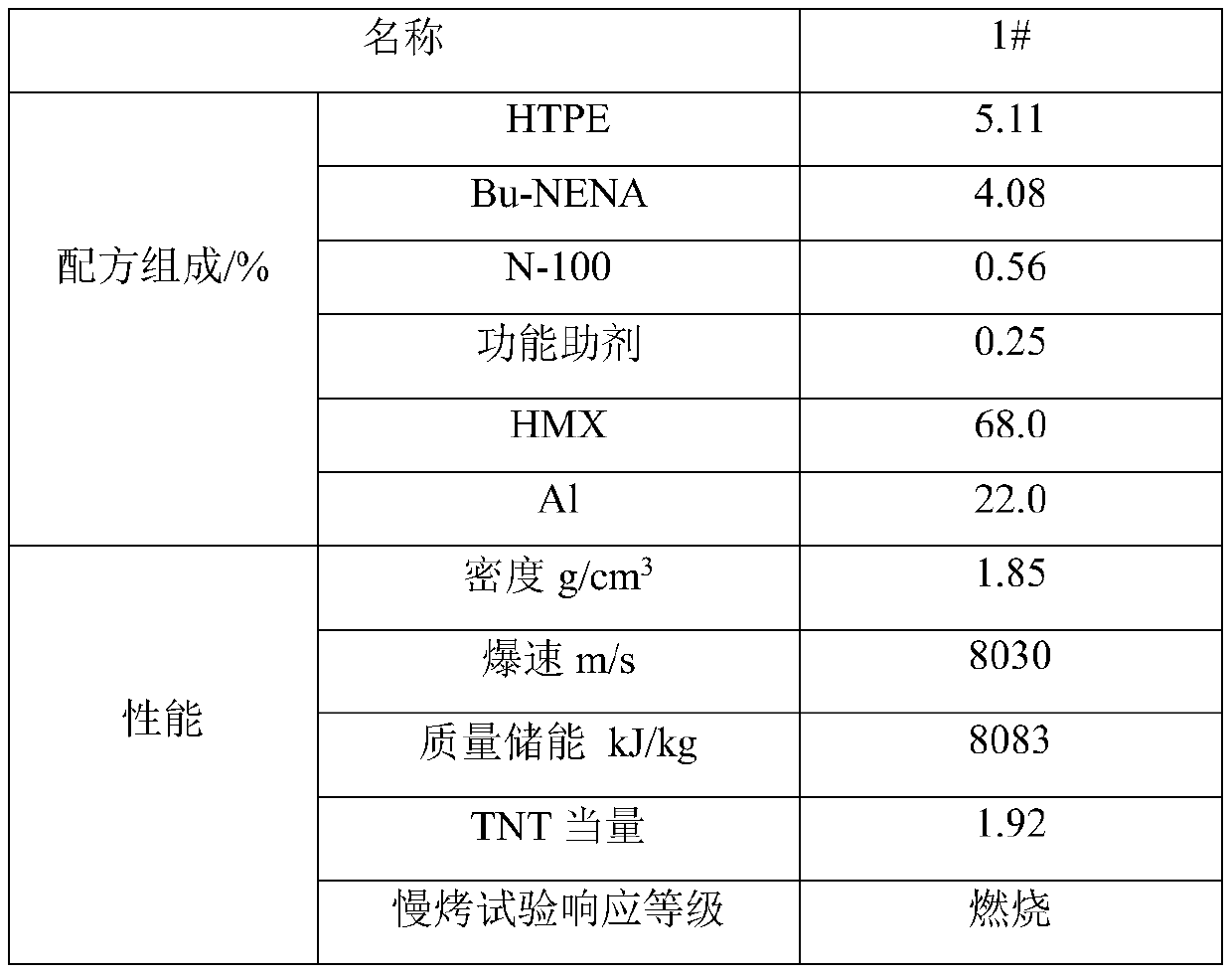

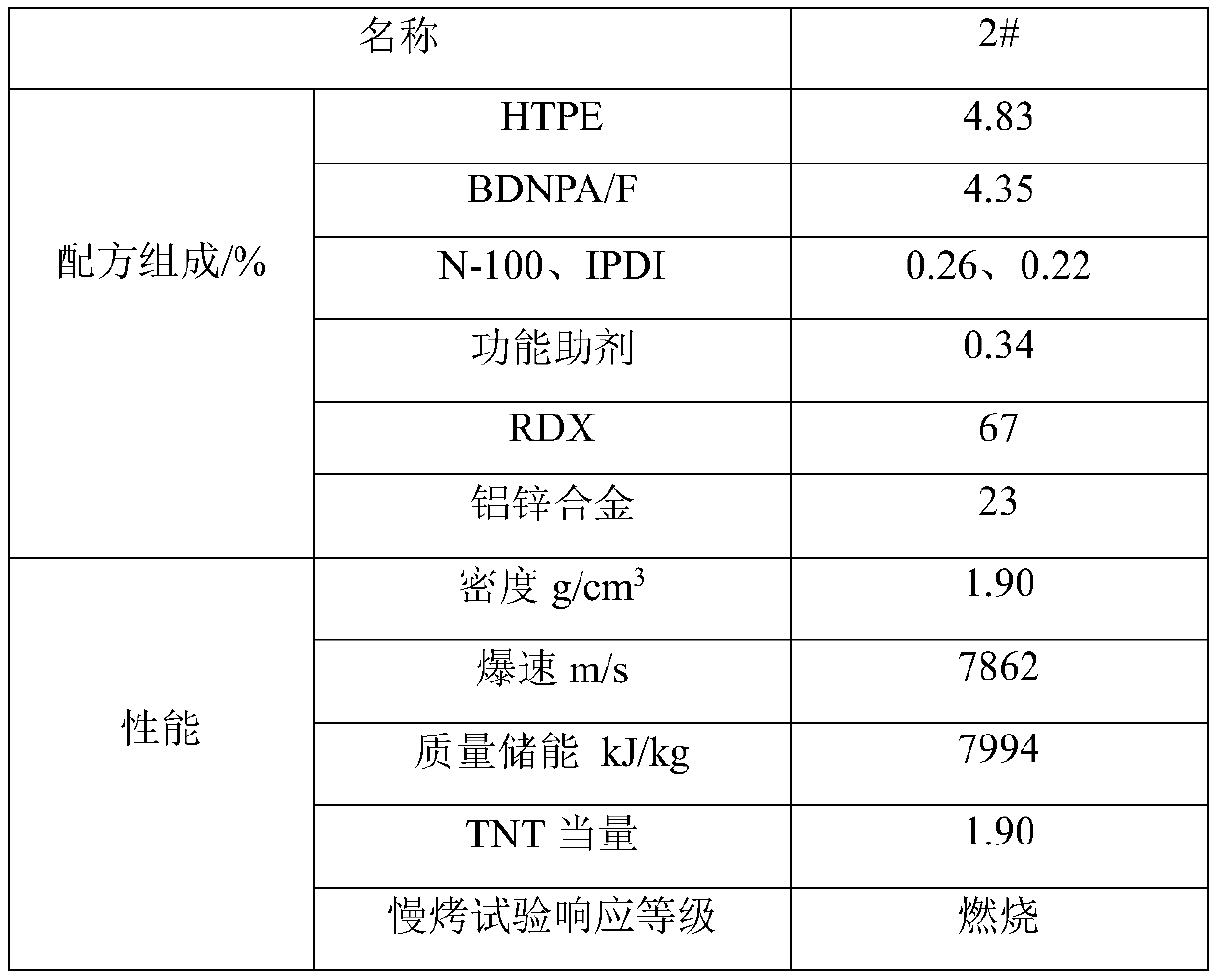

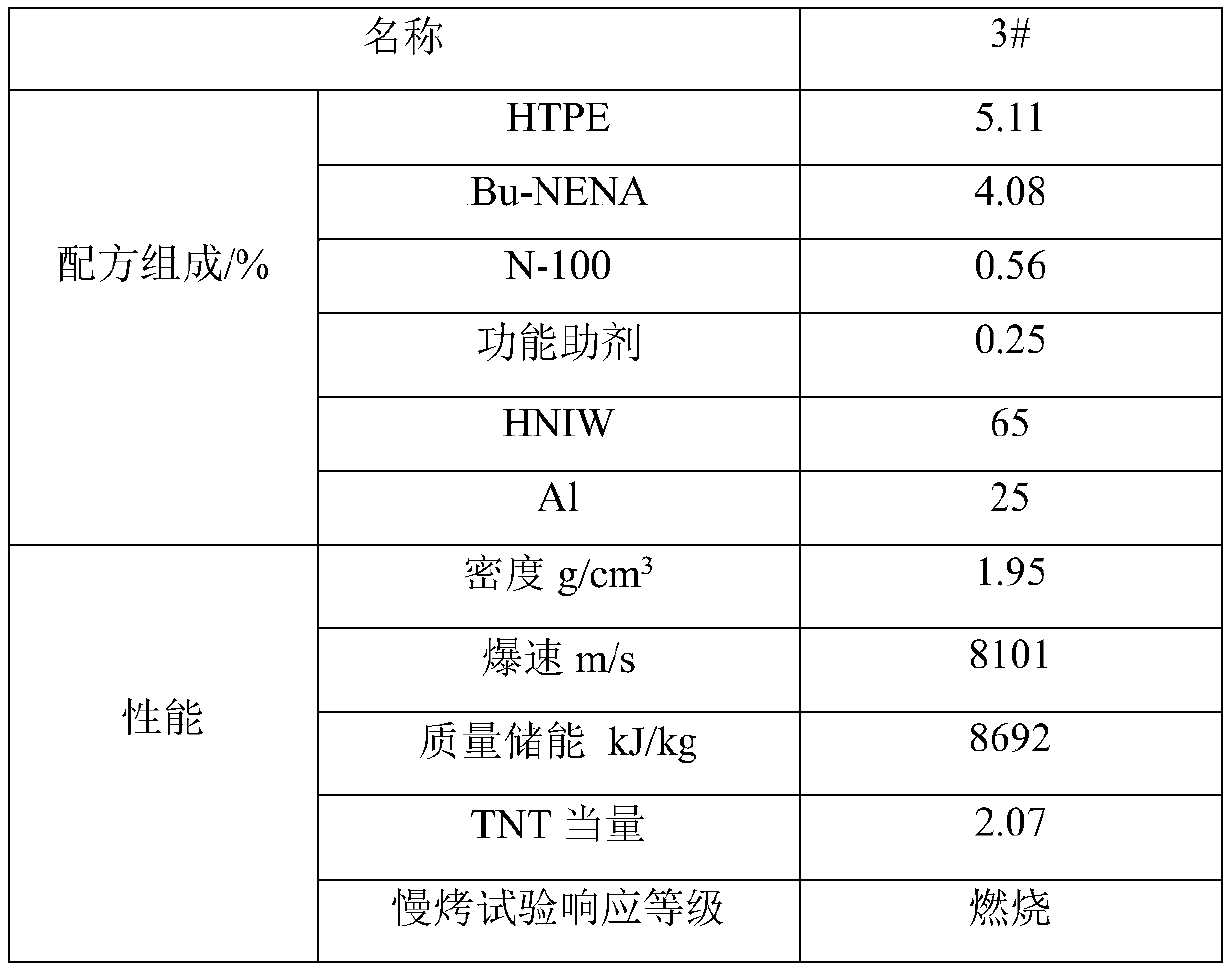

Pouring-type high-energy insensitive explosive and preparation method thereof

ActiveCN110156548AImprove energy characteristicsIncrease energy outputNon-explosive fillers/gelling/thickening agentsAdhesiveHigh energy

The invention relates to a pouring-type high-energy insensitive explosive and a preparation method thereof. In order to solve the problem of a low energy level of traditional butylated hydroxy castingPBX explosives, an energy-containing adhesive and an energy-containing plasticizer are introduced as a binder system, and through addition of high-energy explosives and metal fuel components, the prepared pouring-type PBX explosive has high energy characteristics; the explosive formula has a density greater than 1.85 g / cm<3>, the detonation velocity is greater than 7800 m / s, and the explosive power is that of 1.9 times or above the TNT equivalent; and at the same time, the explosive formula has good low-vulnerability, and especially has mild reactions in slow-speed burning tests, and the reaction level does not exceed a detonation level.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

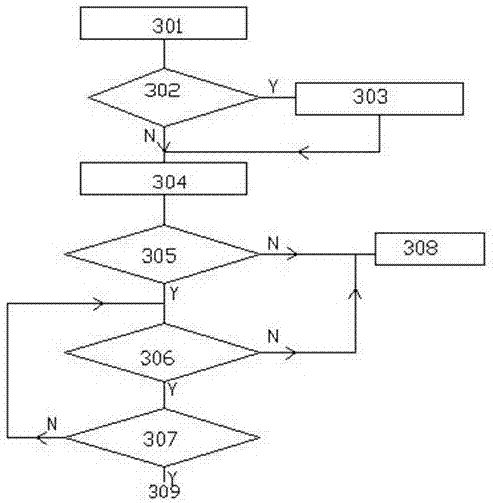

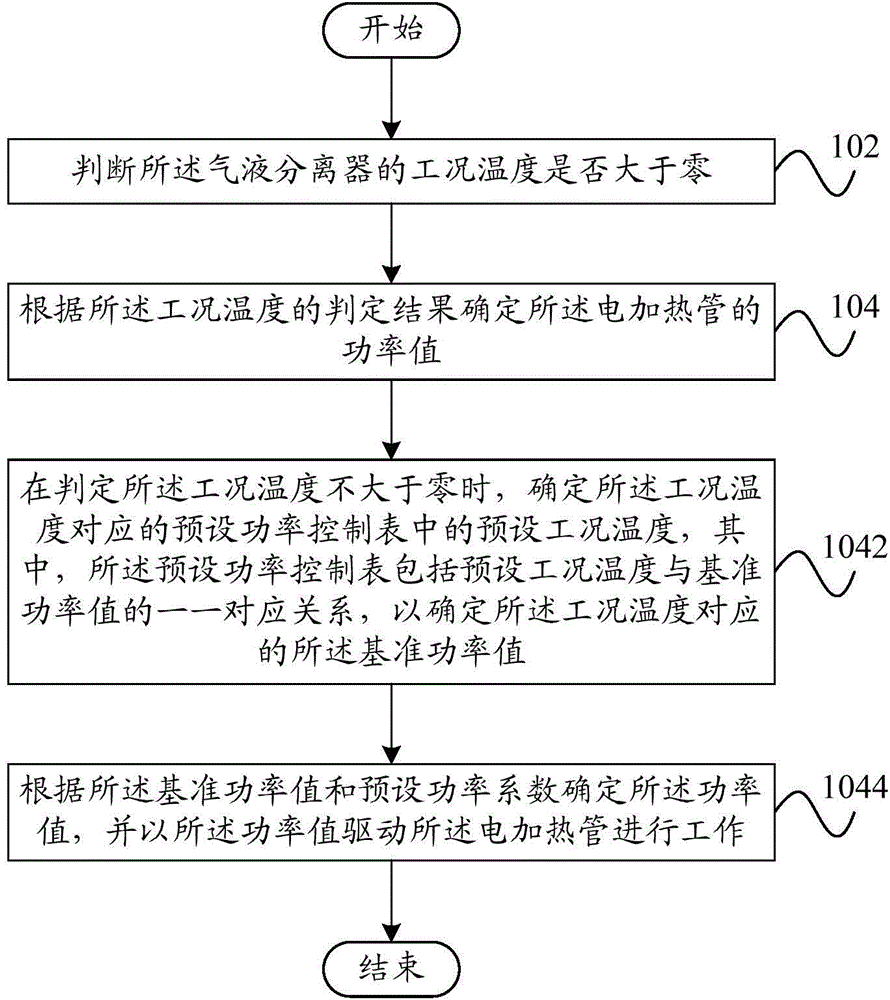

Power control method, power control system, gas-liquid separator and air conditioner

ActiveCN104913557AGuaranteed heating effectReduce power consumptionRefrigeration safety arrangementVapor–liquid separatorPower conditioner

The invention provides a power control method, a power control system, a gas-liquid separator and an air conditioner. The power control method comprises the following steps of judging whether the working condition temperature of the gas-liquid separator is greater than zero DEG C; and determining the power value of an electric heating pipe according to the working condition temperature judgment result. The power control method comprises the following specific steps: if judging that the working condition temperature is not greater than zero DEG C, determining a preset working condition temperature, which corresponds to the working condition temperature, in a preset power control table, so as to determine a reference power value corresponding to the working condition temperature, wherein the preset power control table comprises one-to-one correspondence relation between the preset working condition temperatures and reference power values; determining a power value according to the reference power value and a preset power coefficient, and driving the electric heating pipe to operate at a power value. According to the technical scheme, intelligent optimization control over the power of the electric heating pipe of the gas-liquid separator is realized, and the reliability of the electric heating pipe and the gas-liquid separator can be enhanced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Porous polyolefine isolating film

InactiveCN101702428AReduce internal short circuitReduce short circuit currentSecondary cellsCell component detailsPorosityLithium

The invention discloses a porous polyolefine isolating film. The thickness of the isolating film is 35-80 mu m, the porosity is 30-70 percent, the air permeability is 100-1,000 second / 100ml and the average pore opening diameter is 0.001-1mu m. By using a lithium ion power battery of the porous polyolefine isolating film, the highest temperatures of a drift bolt and a thermal simulation are all not less than 100 DEG C, and the invention has favorable safety performance, circulating performance and charge-discharge performances.

Owner:DONGGUAN AMPEREX TECH

Systems and methods for chemical and/or mechanical remediation of nitro compounds and nitrate esters

ActiveUS20110041718A1Reduce the likelihood of an explosionReduce the possibilityAmmunition projectilesNon-explosive fillers/gelling/thickening agentsNitro compoundCompound (substance)

Systems and methods for chemoremediation or mechanical destruction of undetonated explosive materials. An explosive apparatus contains an explosive material in close proximity to a chemical reagent selected for its chemoremediative properties. A barrier is interposed between the explosive material and the chemical reagent to delay the chemoremediation of the explosive material.Alternatively a water expandable material may be incorporated into the explosive material, whereby upon exposure to moisture the water absorbing material will expand sufficiently to fragment the explosive material into initiation insensitive particles. Initiation insensitivity is achieved by incorporation of water, which acts as a desensitizing agent as well as fragmenting the explosive material into particles sufficiently small that they are below the critical diameter for explosive initiation.The present invention also relates to self-degradable, shaped explosive formulations, comprising an explosive material and a water expandable material.

Owner:MAXAMCORP HLDG SL

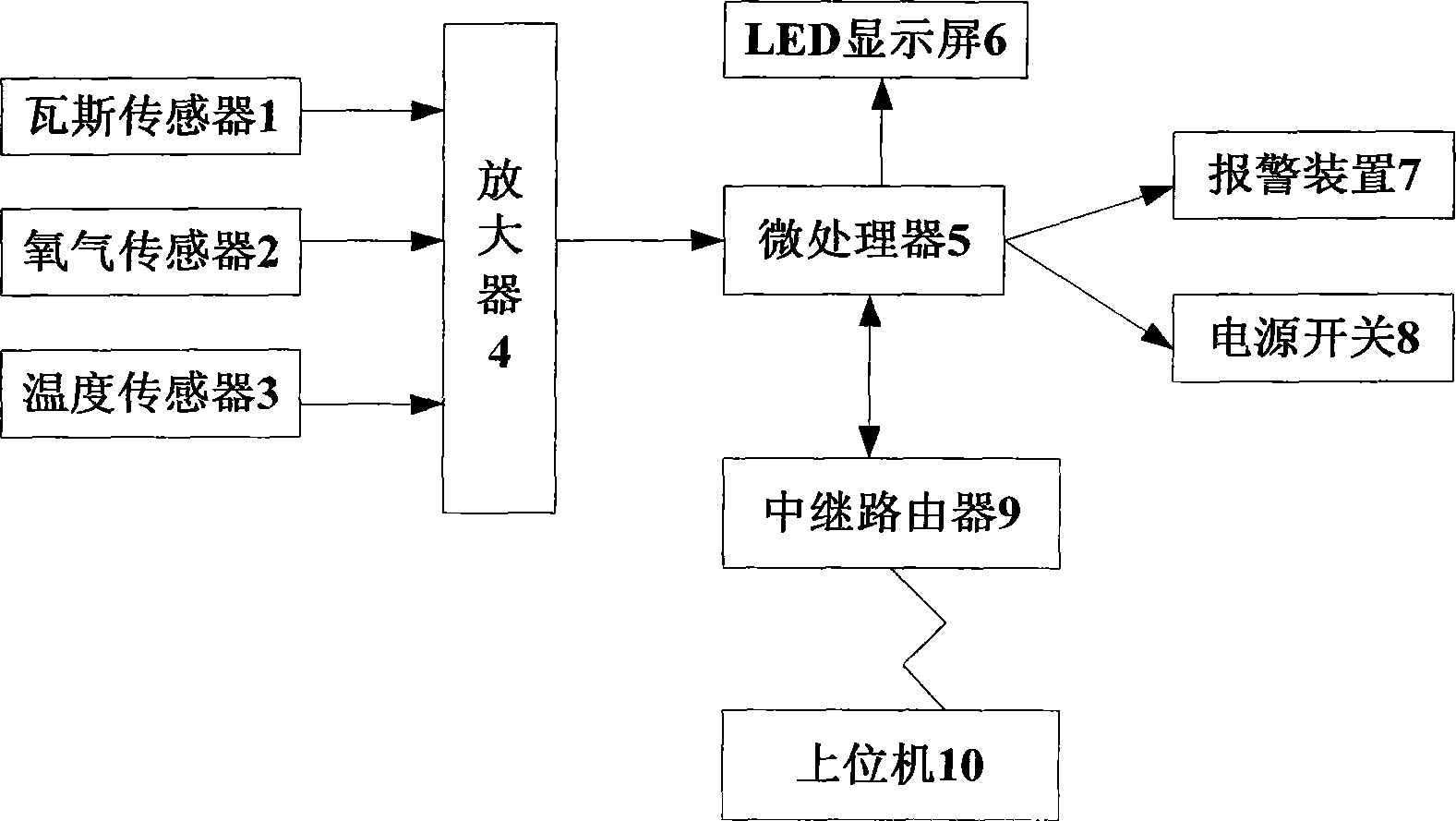

Gas detection alarm device

The invention provides a gas detection alarm device which comprises acquisition devices. The acquisition devices are arranged in an underground environment and are used for acquiring various environmental parameters in real time, and output ends of the acquisition devices are connected with input ends of a microprocessor by wires; output ends of the microprocessor are respectively connected with an alarm device and a power switch used for controlling underground power supply circuits; a relay router is interactively connected with the microprocessor, and underground information is wirelessly transmitted to an upper computer of a ground monitoring center by the relay router. The gas detection alarm device has the advantages that serious accidents of gas combustion and explosion can be fundamentally greatly reduced owing to the audible and visual alarm actions of the alarm device and the power-off action of the power switch; the information is wirelessly transmitted via the relay router, so that an underground condition can be effectively known and controlled via the upper computer of the ground control center.

Owner:安徽省皖北煤电集团有限公司

Explosion-proof structure of medium-voltage power distribution cabinet door plate

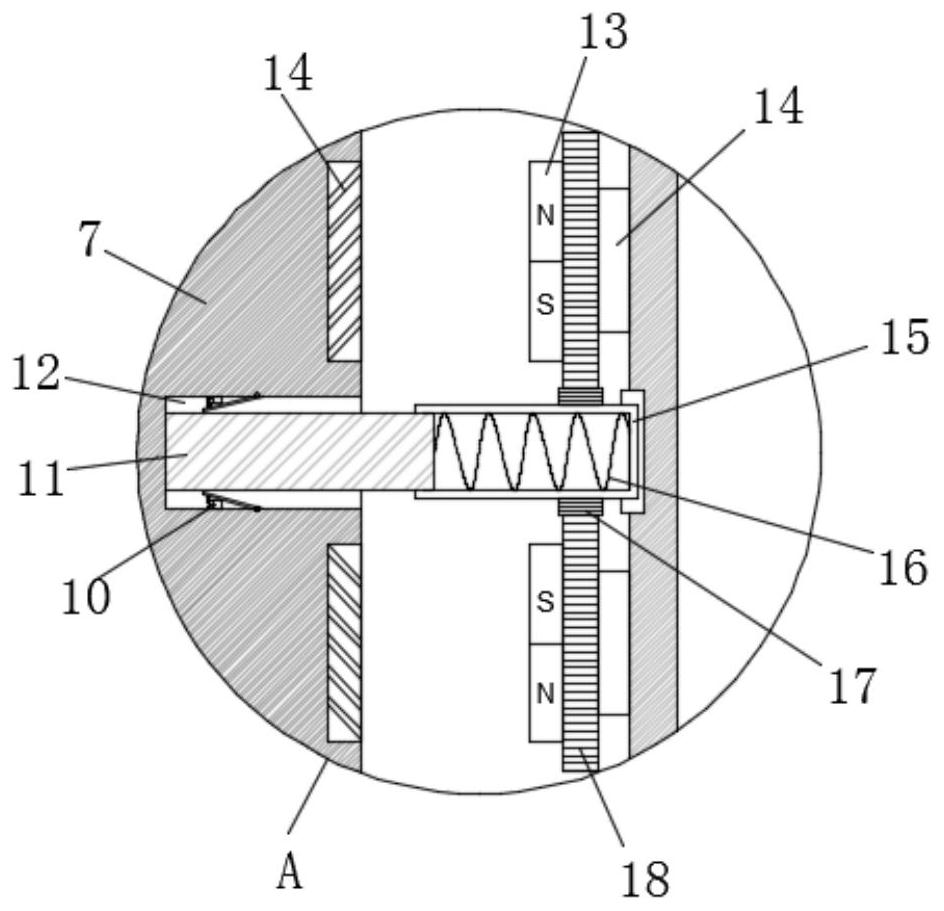

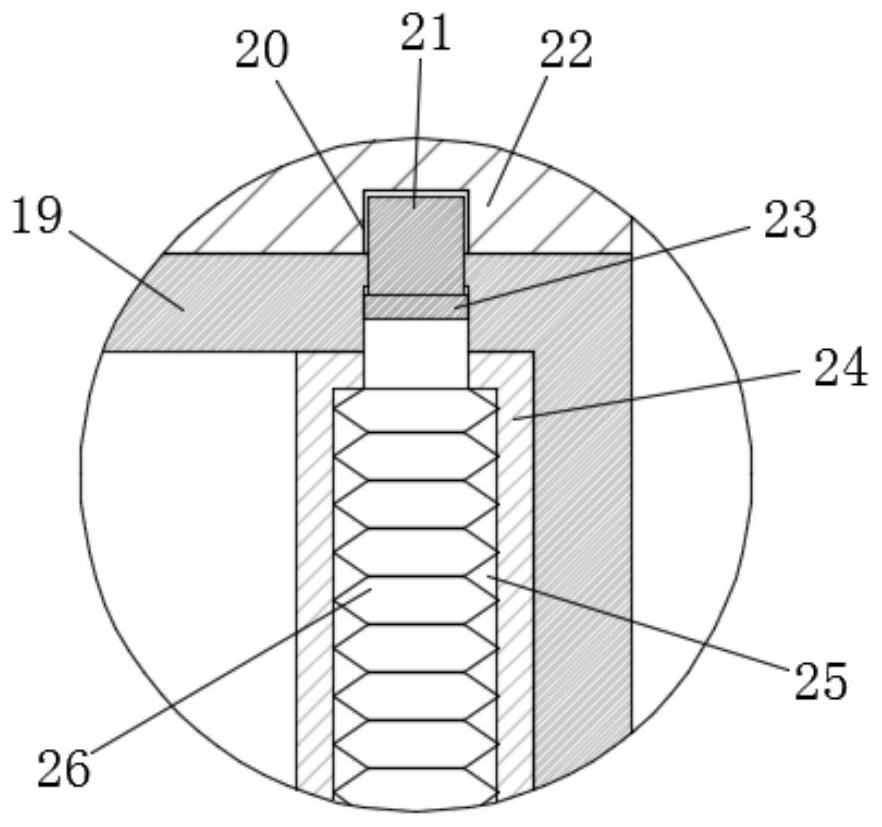

ActiveCN112054397AReduce the likelihood of an explosionOffset the impactSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsStructural engineeringThreaded rod

The invention discloses an explosion-proof structure of a medium-voltage power distribution cabinet door plate. The explosion-proof door plate comprises a cabinet body, a door plate body and an explosion-proof plate, the side wall of the door plate body is connected to the inner wall of the cabinet body through hinges, an explosion-proof cavity is formed in the door plate body, and the explosion-proof plate penetrates through the left side wall of the door plate body and is connected into the side wall of the door plate body in a sliding mode; a mounting groove is formed in the center of the right side wall of the explosion-proof plate, a touch switch is arranged on the side wall of the mounting groove, a threaded rod is fixedly mounted in the center of the mounting groove, the other end of the threaded rod is in threaded connection with a rotating cylinder, and the other end of the rotating cylinder is rotatably connected to the inner wall of the explosion-proof cavity; and a second spring is fixedly installed on the inner wall of the rotating cylinder, and the other end of the second spring abuts against the end, away from the explosion-proof plate, of the threaded rod. Accordingto the invention, impact force generated by explosion is prevented from rushing through the door plate body and hurting pedestrians around the cabinet body.

Owner:国网河南省电力公司温县供电公司

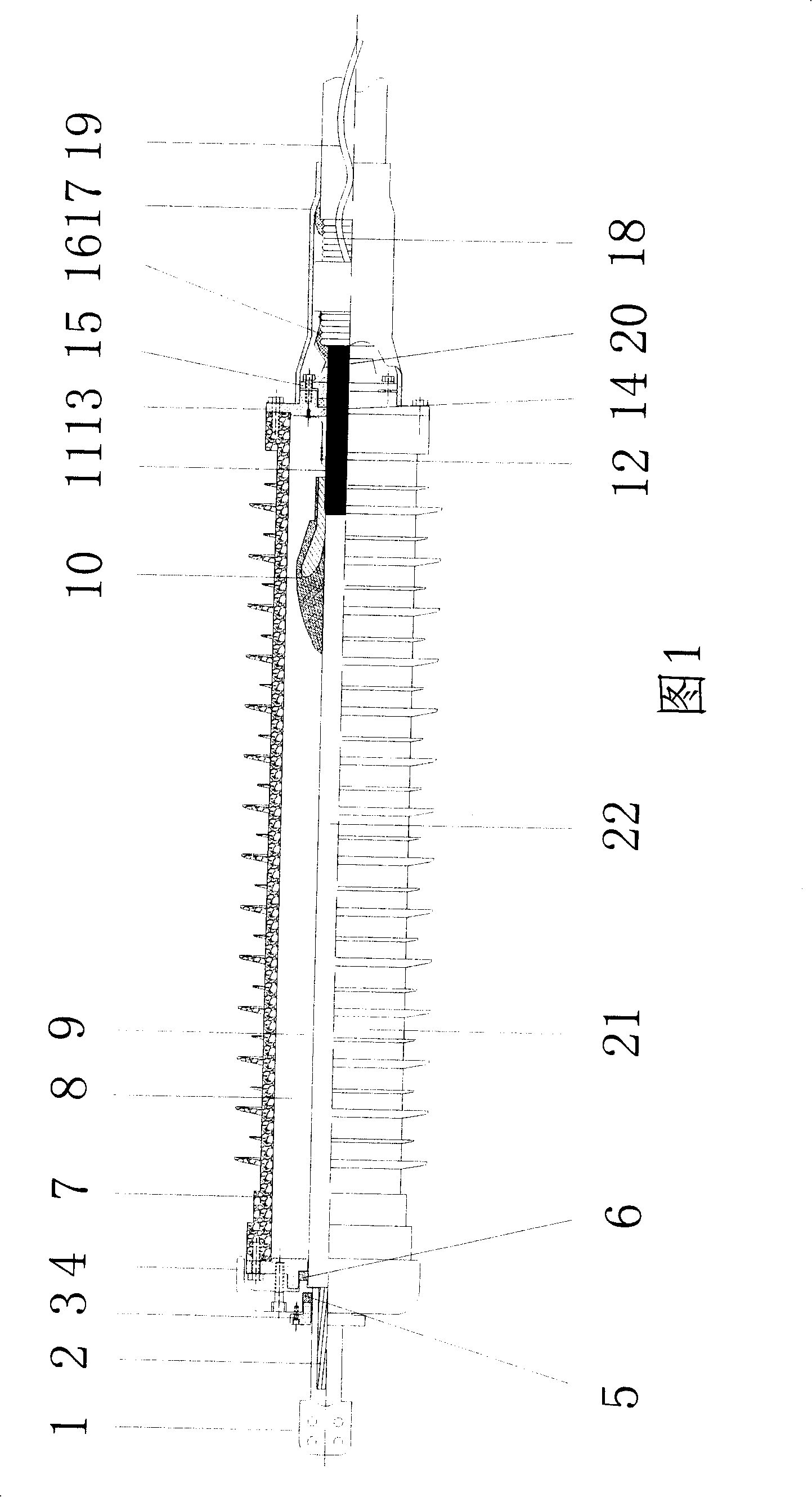

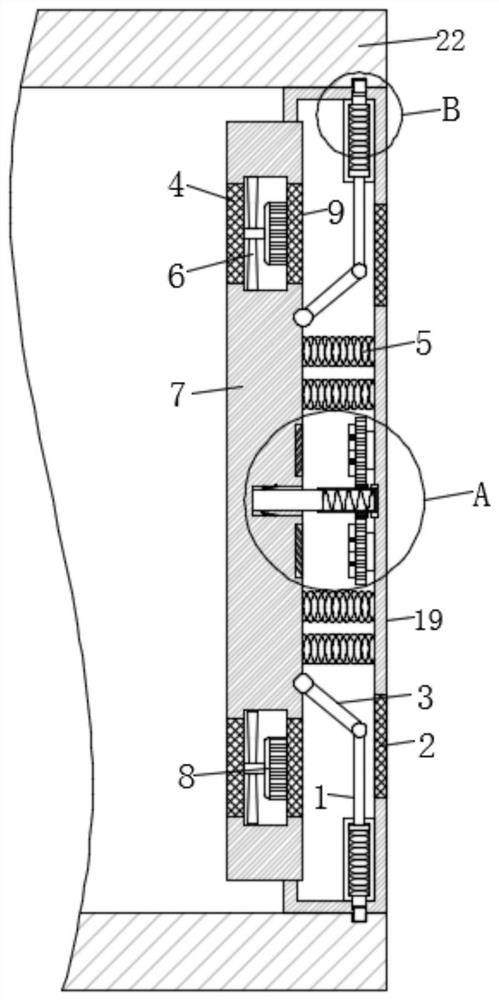

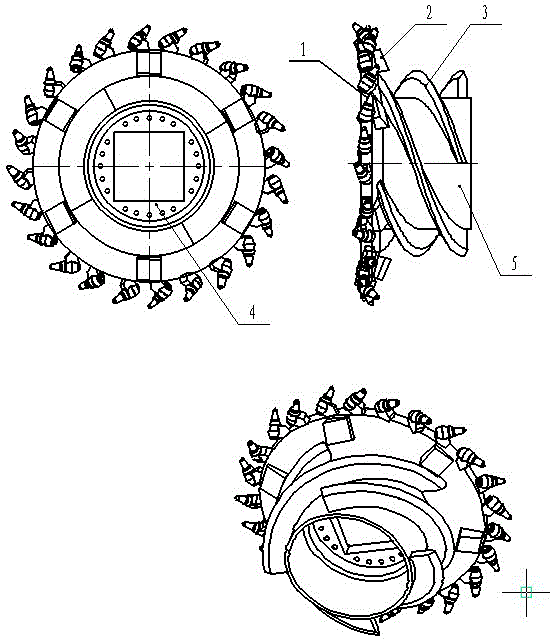

Semi-wedge type roller

The invention relates to a semi-wedge type roller applied in coal cutter of coal mining equipment. In order to improve the block coal rate, a novel coal cutting theory and structure are adopted. The semi-wedge type roller is different from the conventional rollers mainly in three parts: the cutting disc (1), the wedge block (2), and the spiral blade (3). The cutting disc (1) is similar to the end plate in the conventional rollers and is used to dig a groove on the coal wall. The external surface of the wedge block (2) is a spacial inclined plane, the wedge block (2) is inserted into the groove as the coal cutter is moving forward, and the coal on the external side of the groove is cut off through the movement of the coal cutter and the rotation of the roller. The external edge of the spiral blade is in a shape angle shape and is not provided with any cutting pick, the spiral blade (3) is mainly used to store coals, and when the coals are not cut off, the sharp angle of the external edge of the spiral blade (3) will cut off the coals to assist the coal cutting.

Owner:郑涛

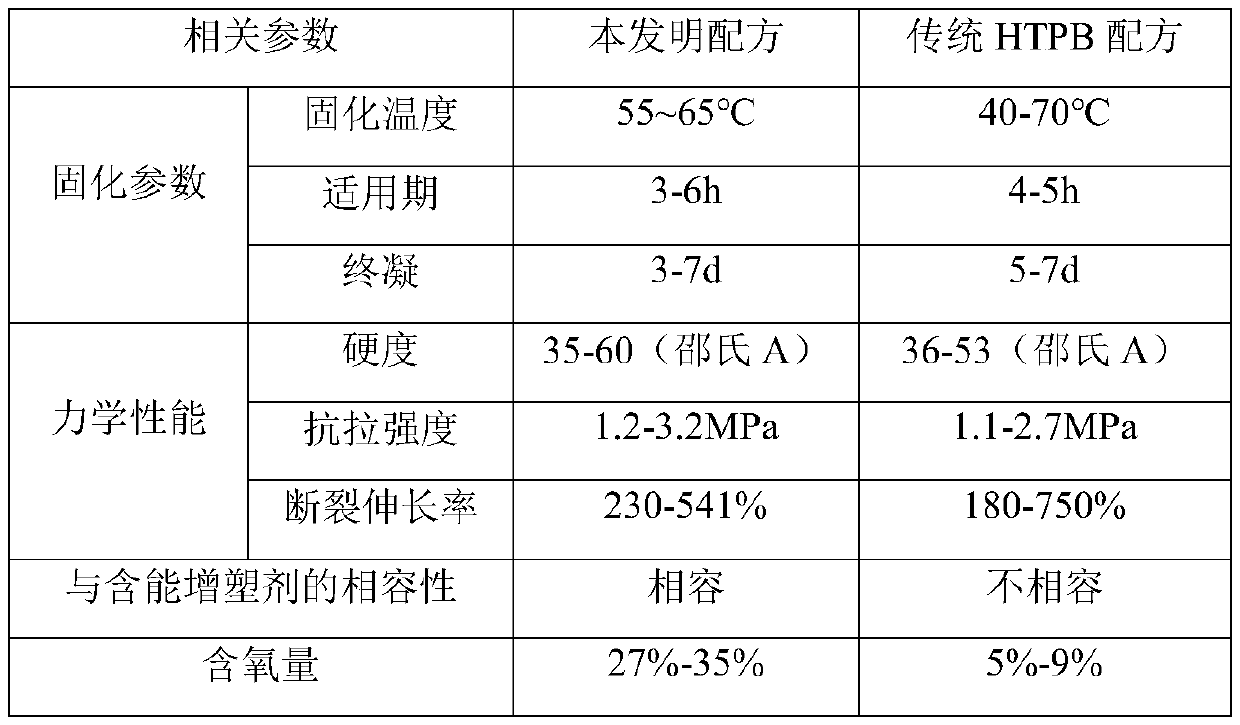

Adhesive system suitable for insensitive munitions and preparation method

InactiveCN110304977AIncrease oxygen contentReduce dosageNon-explosive fillers/gelling/thickening agentsPolyolPlasticizer

The invention provides an adhesive system suitable for insensitive munitions and a preparation method. The adhesive system is prepared by, by weight, 40-50 parts of polyol, 30-60 parts of energetic plasticizer, 5-10 parts of polyisocyanate, 0.0002-0.001 part of catalyst. During preparation, raw material preprocessing including the rotary evaporation dewatering of the polyol and the energetic plasticizer and raw material preheating is performed during preparation, the polyol and the energetic plasticizer are then premixed, and a curing agent is added finally and sufficient and uniform mixing isperformed to perform curing at 55-65 DEG C for 4-7 days. Compared with a traditional hydroxyl-terminated polybutadiene-based (HTPB-based) adhesive system, the adhesive system is high in oxygen content, good in compatibility with the energetic plasticizer, and capable of evidently increasing the energy output of an explosive system; the adhesive system is mild in reaction under a heat stimulationcondition and melts and expand when being heated to break through a munition shell, explosion possibility under the heat stimulation condition is lowered, and munition insensitivity is increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Reinforced dedusting device for coal min safety

InactiveCN103410554AAvoid cloggingEnsure safetyMining devicesDust removalMining engineeringWater vapor

The invention discloses a reinforced dedusting device for coal mine safety. The reinforced dedusting device comprises a fan, a shell, an adsorption filtering part, a water vapor dedusting part, a bag-type dedusting part and a dust inlet, wherein the water vapor dedusting part, the bag-type dedusting part, the fan and the adsorption filtering part are sequentially arranged behind the dust inlet, the shell is located on the outer side of the whole dedusting device, dust particles of various particle sizes are eliminated in sequence, coal mine safety is guaranteed, and the working gas environment of coal mine workers is optimized.

Owner:王业常

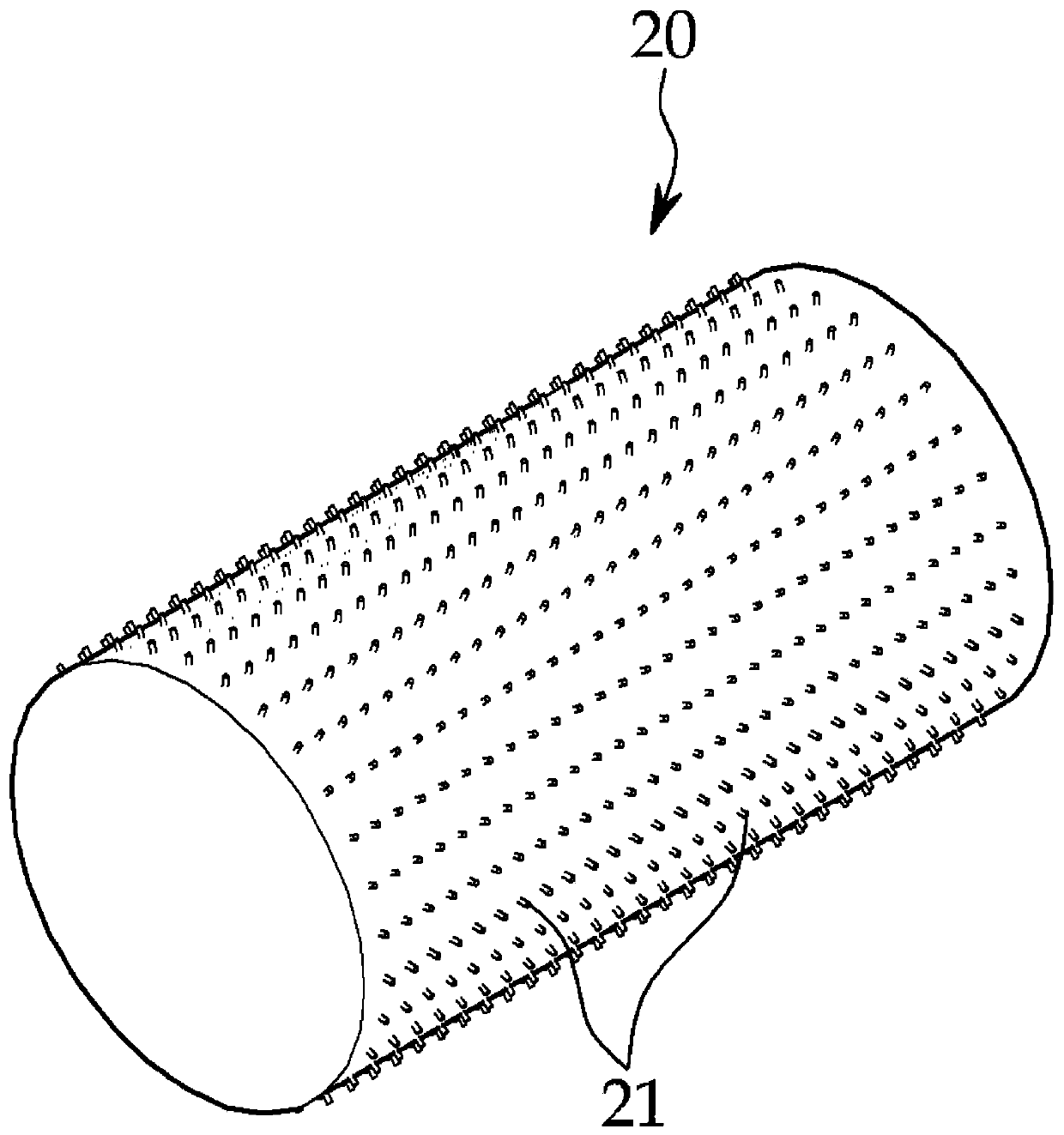

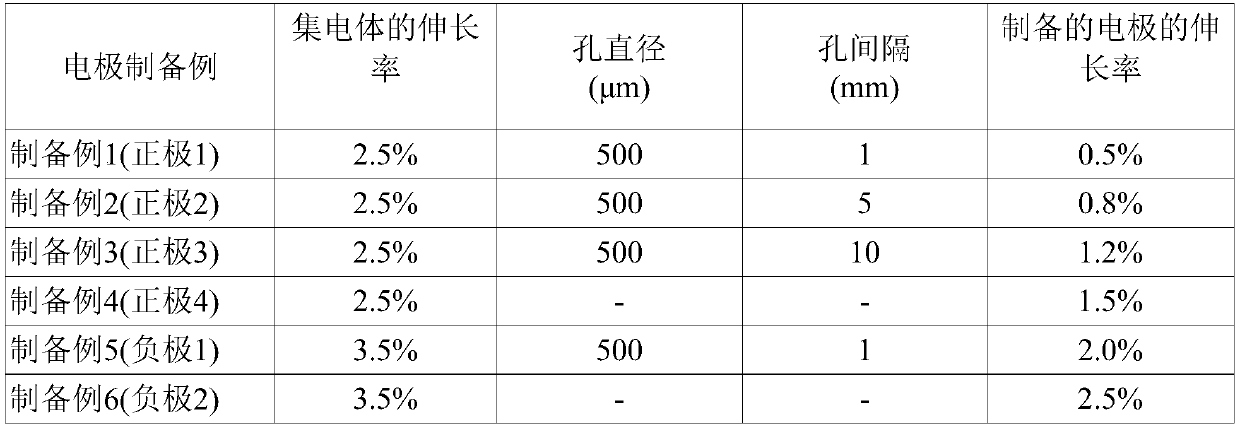

Electrode for secondary battery with improved safety, manufacturing method thereof, and secondary battery including same electrode

ActiveCN110392948ALow elongationLower fireElectrode rolling/calenderingElectrode carriers/collectorsBattery cellMaterials science

The present invention relates to an electrode for a secondary battery with improved safety, a manufacturing method thereof, and a secondary battery including the electrode. The electrode for a secondary battery according to the present invention is characterized by having a plurality of holes formed to penetrate a current collector and an electrode active material layer in the thickness direction.Such an electrode can prevent or minimize the occurrence of ignition or explosion of the battery even when a needle-shaped body such as a nail infiltrates or penetrates into a battery, thereby improving the safety of the battery.

Owner:LG ENERGY SOLUTION LTD

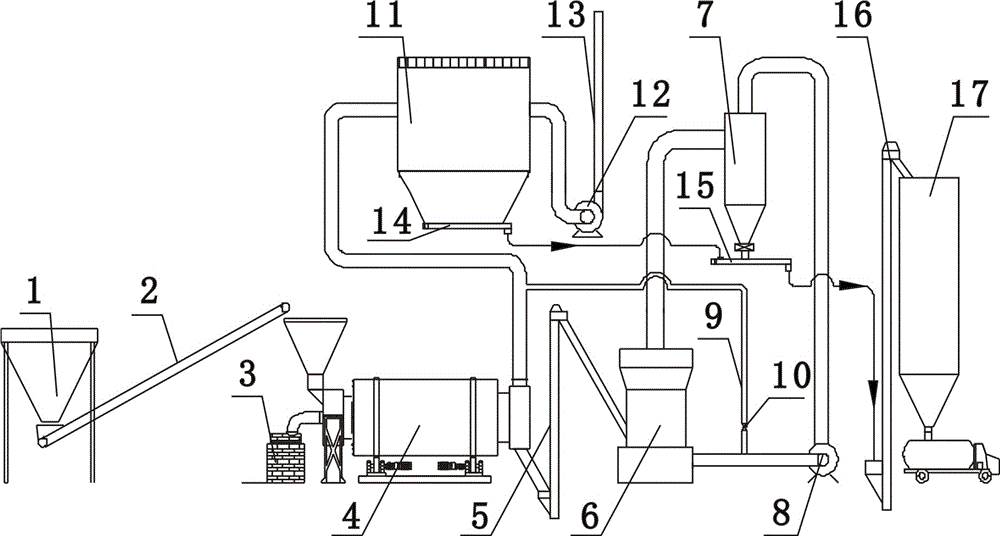

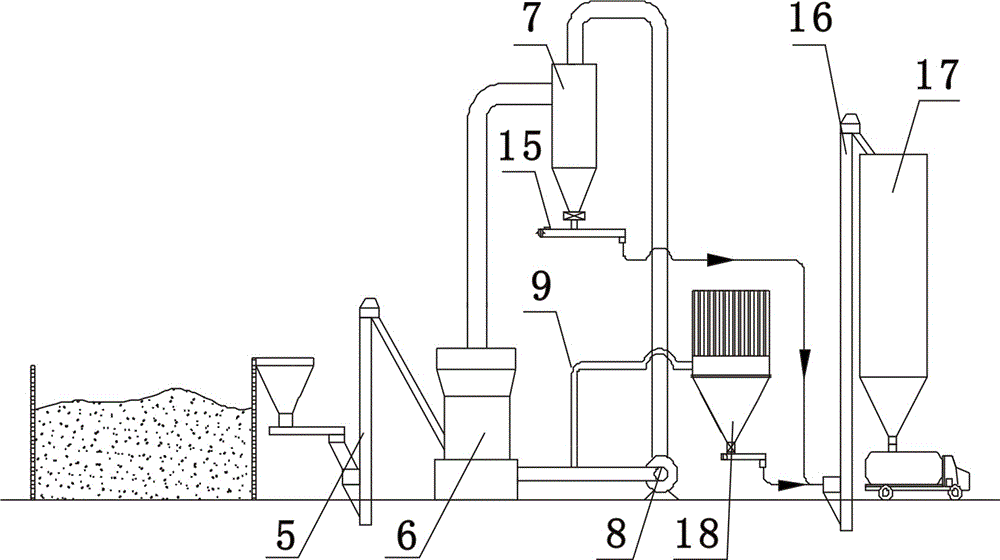

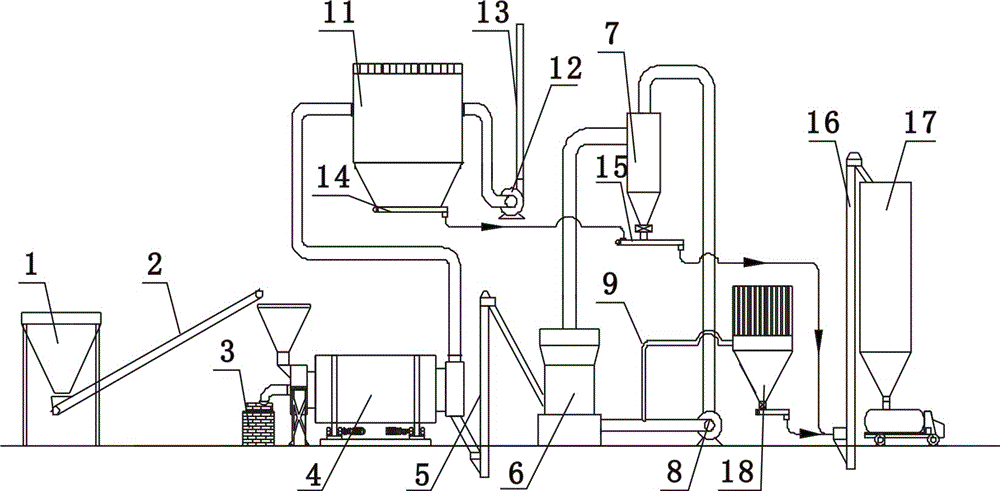

Pulverized coal preparation system and pulverized coal preparation method

InactiveCN105627345AEliminate pollutionUniform moisture contentLump/pulverulent fuel preparationSpontaneous combustionBaghouse

The invention discloses a pulverized coal preparation system and a pulverized coal preparation method. The pulverized coal preparation system comprises a heat source device, a drying device, a pulverizing device, a powder colleting implement, an air blower, a bag-type dust collector and an induced draft fan. The smoke outlet end of the drying device is connected with the smoke inlet end of the bag-type dust collector. The smoke outlet end of the bag-type dust collector is connected with the induced draft fan. Dry raw materials of the drying device are fed into the pulverizing device. a closed grinding circulatory system is formed among the pulverizing device, the powder colleting implement and the air blower. The pulverized coal preparation system further comprises a balance air pipe. The outlet end of the air blower is then connected with the smoke inlet end of the bag-type dust collector through the balance air pipe. According to the pulverized coal preparation system and the pulverized coal preparation method, full negative pressure running of a system air leak position is achieved, and accordingly the purpose of clean production is achieved. The temperature of powder collected by the bag-type dust collector is lowered, and the possibility of powder spontaneous combustion and explosion is reduced, so that the safety performance of the pulverized coal preparation system is significantly improved. Compared with the traditional process, the number of equipment and sites are reduced, and the cost is reduced.

Owner:GUANGDONG OCEAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com