Method for producing ammonium nitrate

A production method, ammonium nitrate technology, applied in the direction of ammonium nitrate, etc., can solve the problems of neutralization reaction exceeding the critical temperature, explosion accidents, etc., to reduce the possibility of explosion and achieve the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

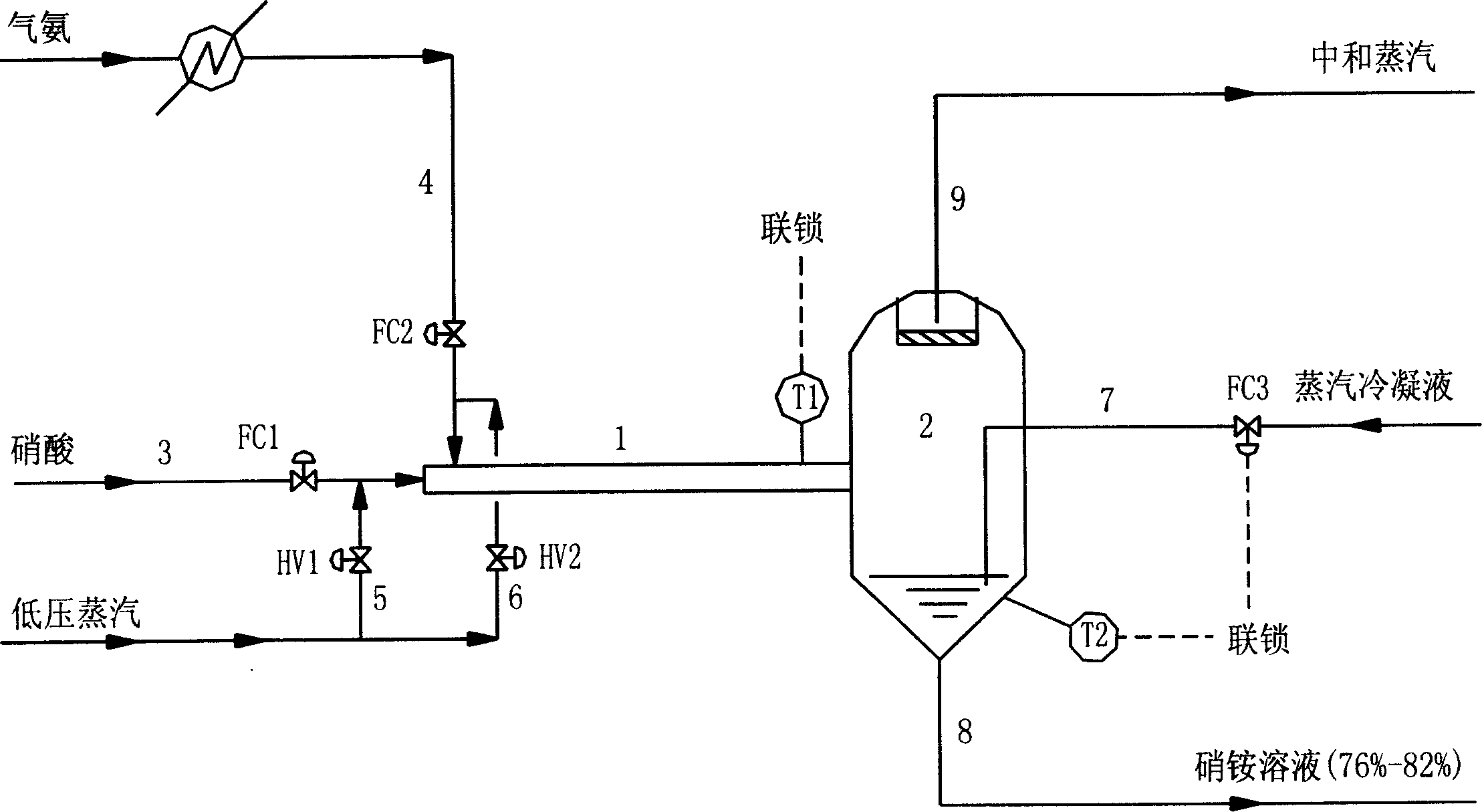

[0027] One end of the tubular reactor 1 is installed with a nitric acid feed pipe 3 and a gas ammonia feed pipe 4, and material control valves FC1 and FC2 are arranged on the feed pipes. The nitric acid feeding pipe 3 and the gas ammonia feeding pipe 4 are respectively connected with steam pipes 5 and 6 behind the material control valves, and steam control valves HV1 and HV2 are set. A temperature measuring device T1 is installed on the tubular reactor 1, and FC1, FC2, HV1, HV2 are interlocked with T1. The back end of the tubular reactor 1 is connected to the flash tank 2, the bottom of the flash tank is connected to the ammonium nitrate delivery pipe 8, and the neutralization steam output pipe 9 is installed above it. The temperature measuring device T2 is installed at the lower part of the flash tank 2, and a steam condensate pipe 7 is passed into the flash tank 2, and T2 is interlocked with the control valve FC3 on the steam condensate pipe 7.

[0028] During normal produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com