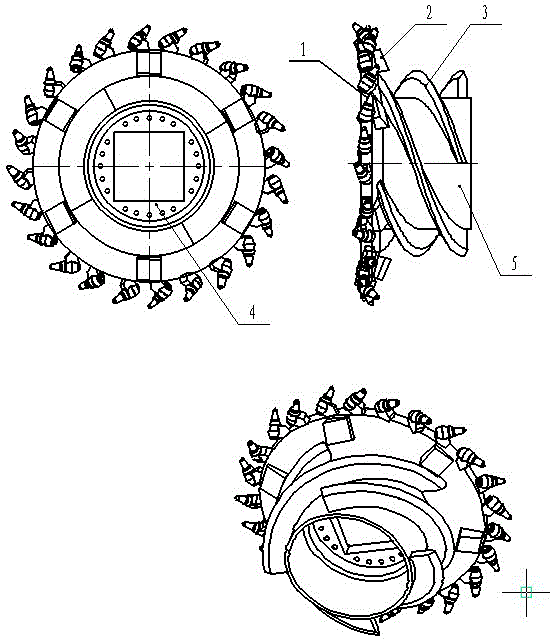

Semi-wedge type roller

A drum and wedge-type technology, applied in the field of wedge-cut drums, can solve the problem of low lump coal rate in the drum, and achieve the effects of dust reduction, cost reduction, and coal production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Referring to the accompanying drawings, the cutting disk 1 is welded together with the spiral blade 3, the coupling disk 4, and the cylinder hub 5, and picks are arranged on the outer edge of the cutting disk 1. In order to ensure that the coal in the opened groove can be discharged smoothly, and the two grooves The groove width should be about 200mm (the specific size should be adjusted according to the diameter of the cutting disc 1) so as not to rub against the tooth seat. The wedge 2 is placed between the outer edge of the cutting disc 1 and the spiral blade 3. The outer surface is a space slope, and the direction of inclination should correspond to the direction of rotation of the drum. During operation, the wedge will wedge into the cutting disc 1 as the shearer travels. The trench that is opened, and rely on the thrust of the shearer to walk and the force of the drum rotation to split the coal wedge on the outside of the trench, so the wedge 2 will be mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com