Reinforced dedusting device for coal min safety

A technology for dust removal device and coal mine safety, applied in safety devices, mining devices, dust prevention and other directions, can solve the problems of general filtration effect, decreased air permeability of filter material, short service life of filter material, etc., to improve coal mine safety factor, reduce Possibility of small explosions, effect of increasing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

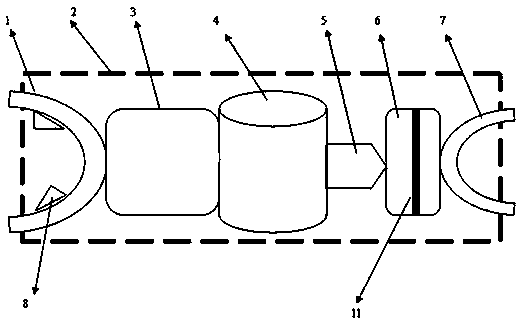

[0033] like figure 1 Shown is the strengthened dedusting device for coal mine safety of the present invention in the daily working state, and the dedusting device includes a fan, a housing, an adsorption filter component, a water vapor dedusting component, a bag dedusting component and a dust inlet;

[0034] After the dust inlet, the water vapor dust removal parts, bag dust removal parts, fan and adsorption filter parts are arranged in sequence, and the housing is located outside the entire dust removal device;

[0035] The water vapor dedusting part is used to perform preliminary water vapor dedusting of the dust collected from the dust inlet into the dust removal device; the electrode dedusting part is in a closed state;

[0036] The fan is used to suck the dusty gas in the environment into the dust removal device, and the fan is a Roots fan;

[0037] The adsorption filter part performs deep dust removal on the remaining dust particles with smaller particle diameters in the ...

Embodiment 2

[0043] The enhanced dust removal device for coal mine safety of the present invention in the drilling state, the dust removal device includes a fan, a housing, an adsorption filter part, a water vapor dust removal part, a bag dust removal part and a dust inlet;

[0044] After the dust inlet, the water vapor dust removal parts, bag dust removal parts, fan and adsorption filter parts are arranged in sequence, and the housing is located outside the entire dust removal device;

[0045] The water vapor dedusting part is used for performing water vapor dedusting and dedusting on the dust collected from the dust inlet into the dedusting device;

[0046] The fan is used to suck the dusty gas in the environment into the dust removal device, and the fan is an enhanced version of the fan;

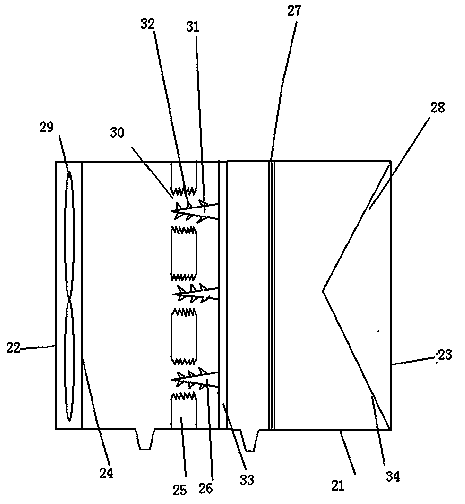

[0047] The water vapor dust removal part is opened, including a water vapor dust removal shell, a water vapor air inlet, a water vapor outlet, a water vapor inlet frame, a perforated plate, a composit...

Embodiment 3

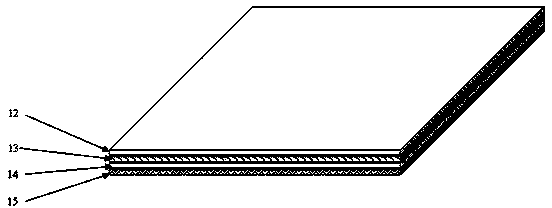

[0053] like figure 2 The filter membrane of the shown adsorption filter part is a layered structure, which is composed of an outer layer, an inner layer and an intermediate layer respectively, and the intermediate layer includes a filter layer; the filter layer includes the first honeycomb photocatalyst filter screen layer, the first solid-carried nano-titanium dioxide filter layer positioned at one side of the honeycomb photocatalyst filter layer, the second honeycomb photocatalyst filter layer positioned at the other side of the first solid-carried nano-titanium dioxide filter layer, and the The second solid-loaded nano-titanium dioxide filter layer on the other side of the second honeycomb photocatalyst filter layer, the aperture of the first honeycomb photocatalyst filter layer is 0.98mm, and the thickness is 0.88mm; the second honeycomb photocatalyst The aperture of the filter screen layer is 0.79mm, and the thickness is 0.89mm; the volume content of activated carbon in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com