Pulverized coal preparation system and pulverized coal preparation method

A pulverized coal preparation and pulverized coal technology, applied in the direction of block/powder fuel preparation, combustion methods, combustion equipment, etc., to achieve the effects of reducing floor space, improving safety, and improving working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

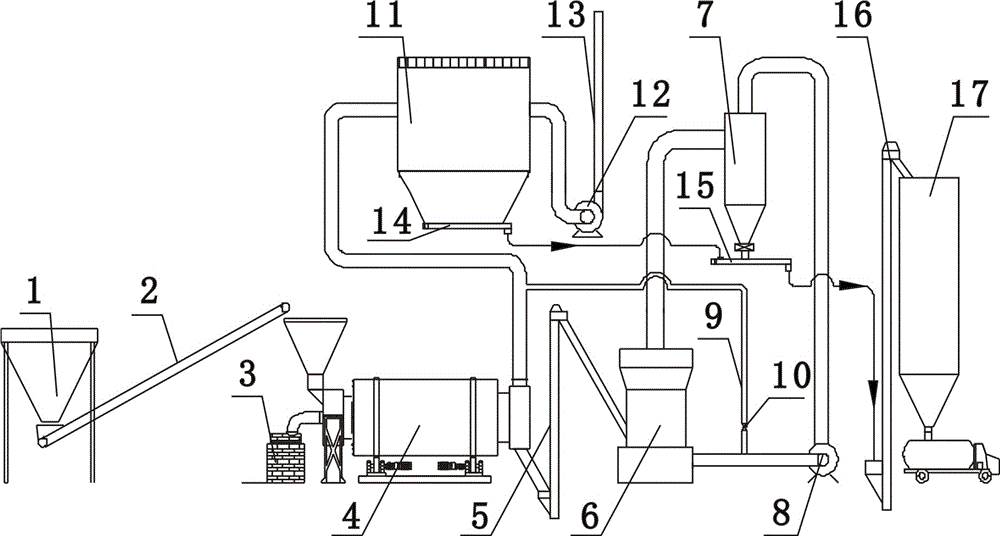

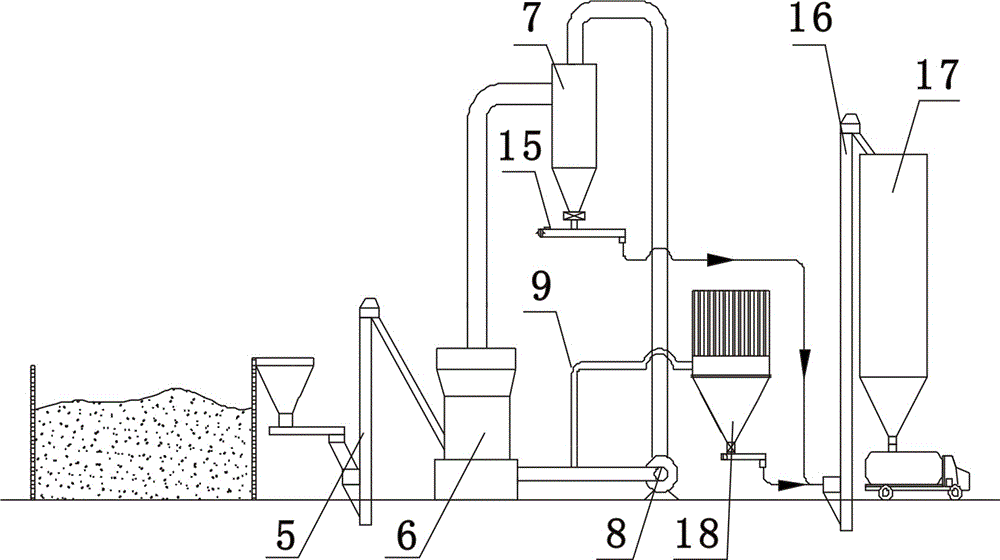

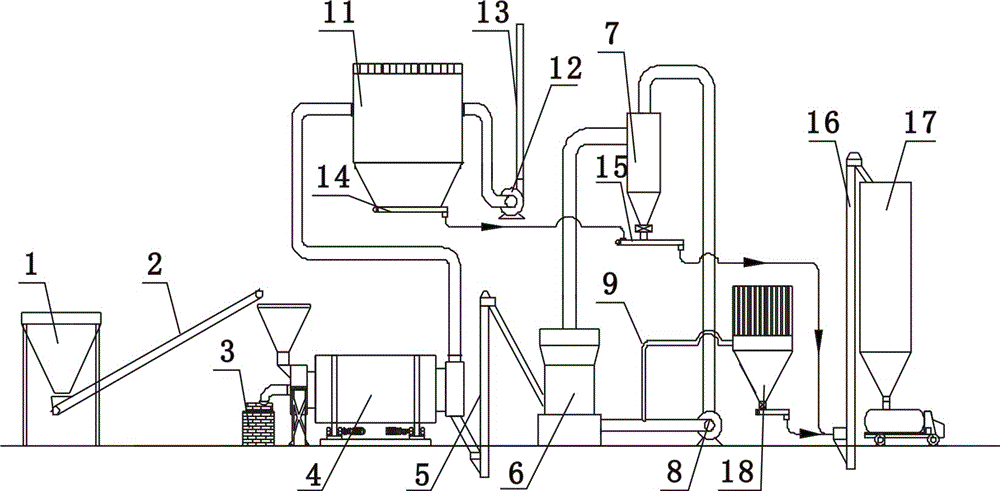

[0039] Attached below figure 1 Specific examples illustrate the present invention in detail. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

[0040]A pulverized coal preparation system, comprising a raw coal screening hopper 1, a raw coal conveying device 2, a heat source device 3, a drying device 4, a hoist 5, a pulverizing device 6, a powder collector 7, a blower 8, a bag filter 11, The induced draft fan 12, the powder conveying device A14, the powder conveying device B15, the powder conveying device C16 and the powder storage bin 17, the raw coal screening hopper 1 sends the coal to the drying device 4 through the raw coal conveying device, the flue gas outlet port of the heat source device 3 It is connected to the inlet end of the flue gas of the drying device 4, the outlet end of the dry raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com