Electrode for secondary battery with improved safety, manufacturing method thereof, and secondary battery including same electrode

A secondary battery and electrode technology, applied in the direction of electrode manufacturing, battery electrodes, non-aqueous electrolyte storage battery electrodes, etc., can solve problems such as undisclosed structures or methods, prevent or reduce short circuits, improve safety, and reduce contact area small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

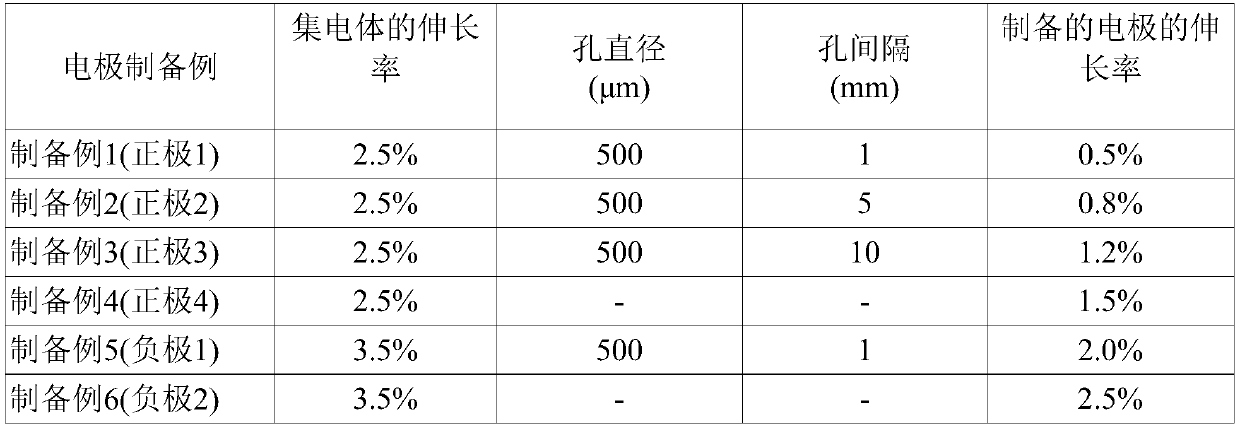

[0049] Preparation example 1 (positive electrode 1)

[0050] An aluminum foil having a thickness of 12 μm and an elongation of 2.5% was prepared as a positive electrode current collector.

[0051] In addition, LiNi as a positive electrode active material 0.6 Mn 0.2 Co 0.2 O 2 (Average particle size: 14μm), PVDF as a binder and Denka black as a conductive material are dissolved in a solvent N-methylpyrrolidone (NMP) in a composition ratio of 93:4:3 to prepare a positive electrode active Material layer of positive electrode slurry.

[0052] The positive electrode slurry was coated on both sides of the aluminum foil, dried and rolled to produce a positive electrode.

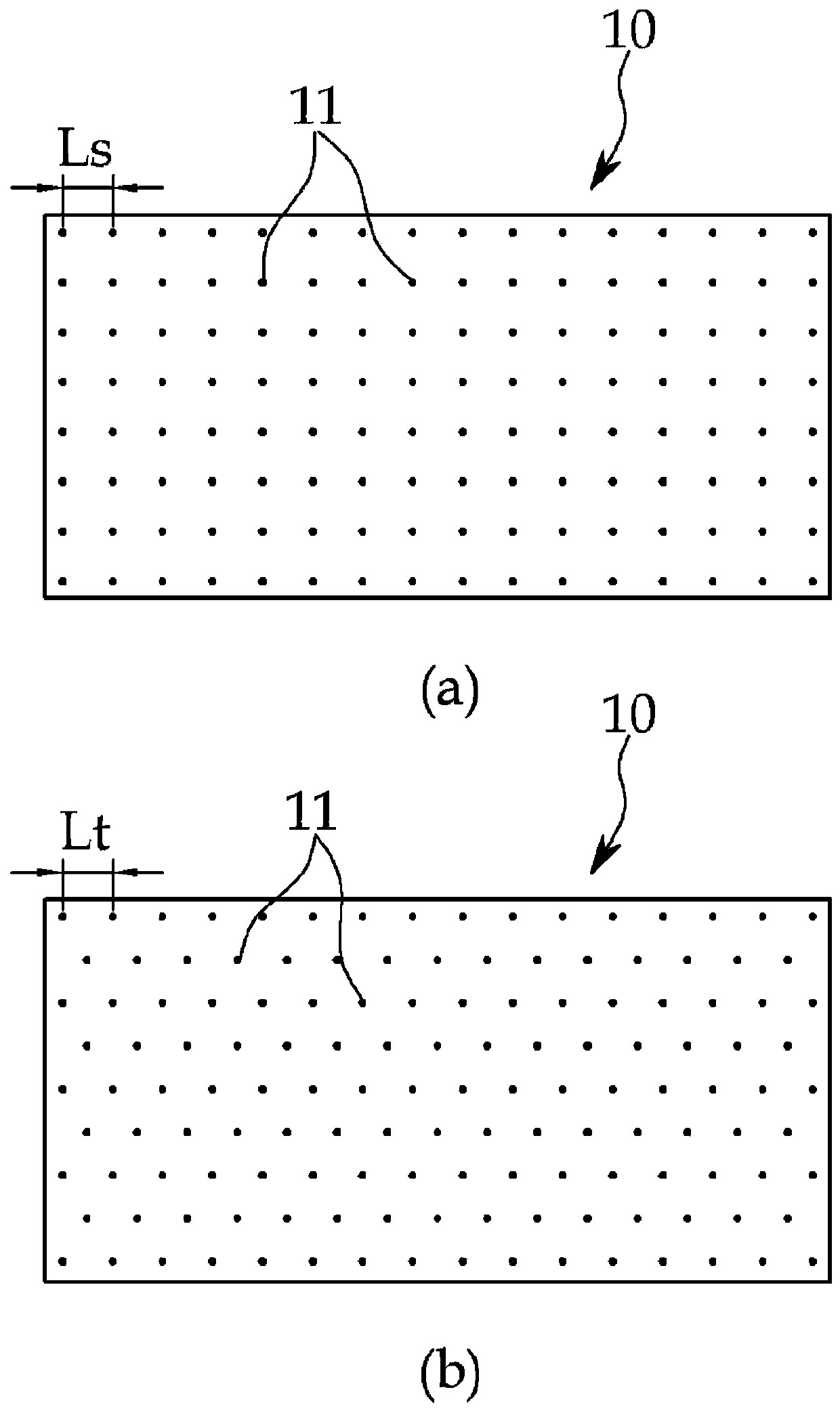

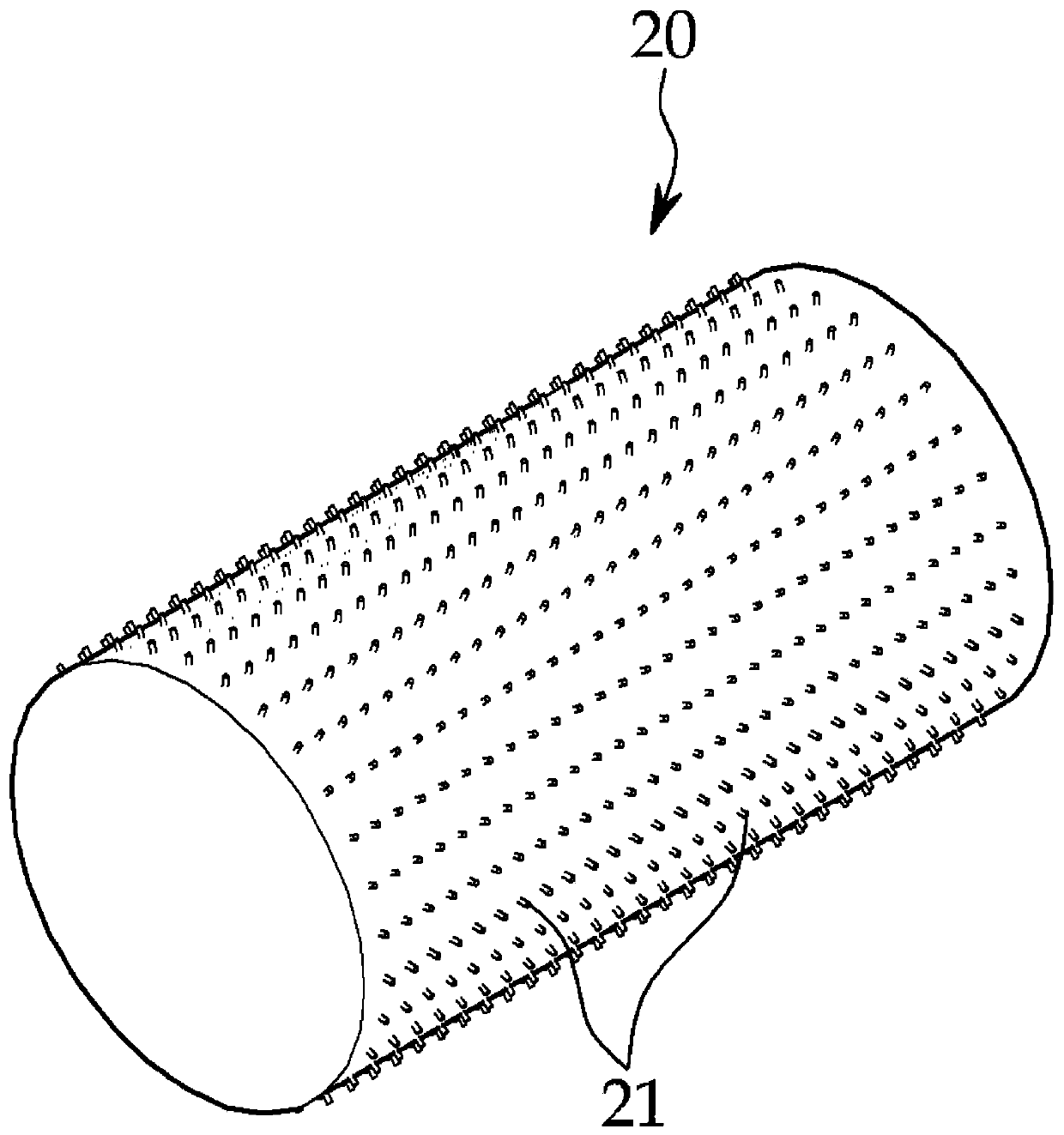

[0053] Used as figure 2 The roll press shown presses the positive electrode to form pores. At this time, the holes have a circular cross section with a diameter of 500 μm, and the arrangement pattern of the holes is figure 1 (a) The square pattern shown, and the hole interval Ls in the length direction of the side is 1 m...

preparation example 2

[0055] Preparation Example 2 (Positive 2)

[0056] A positive electrode was prepared in the same manner as in Example 1, except that the hole interval (Ls) was 5 mm.

preparation example 3

[0057] Preparation example 3 (positive electrode 3)

[0058] A positive electrode was prepared in the same manner as in Example 1, except that the hole interval (Ls) was 10 mm.

[0059] Preparation example 3 (positive electrode 4)

[0060] A positive electrode was prepared in the same manner as in Example 1, except that no holes were formed.

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com