Patents

Literature

136results about How to "Reduce the likelihood of exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

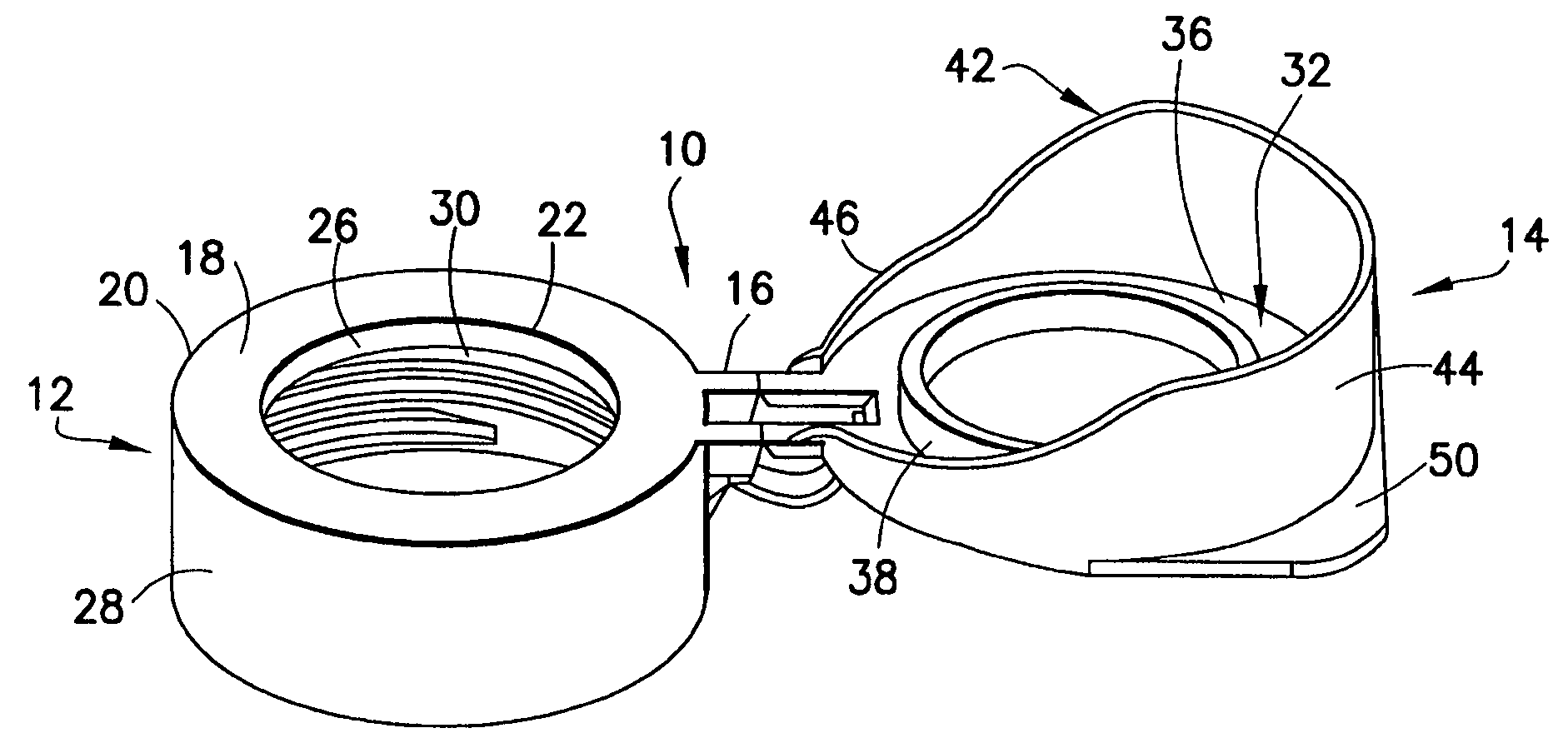

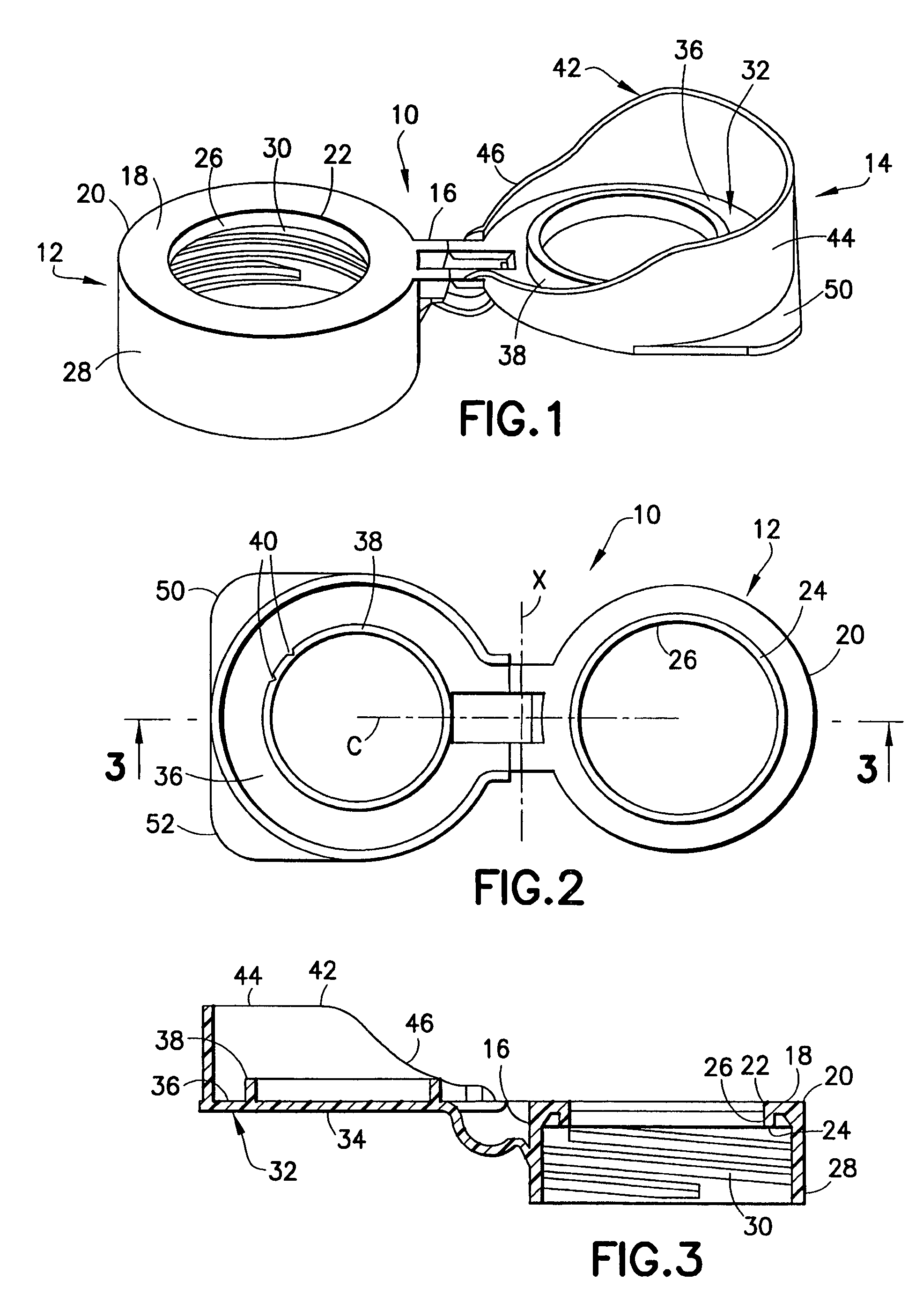

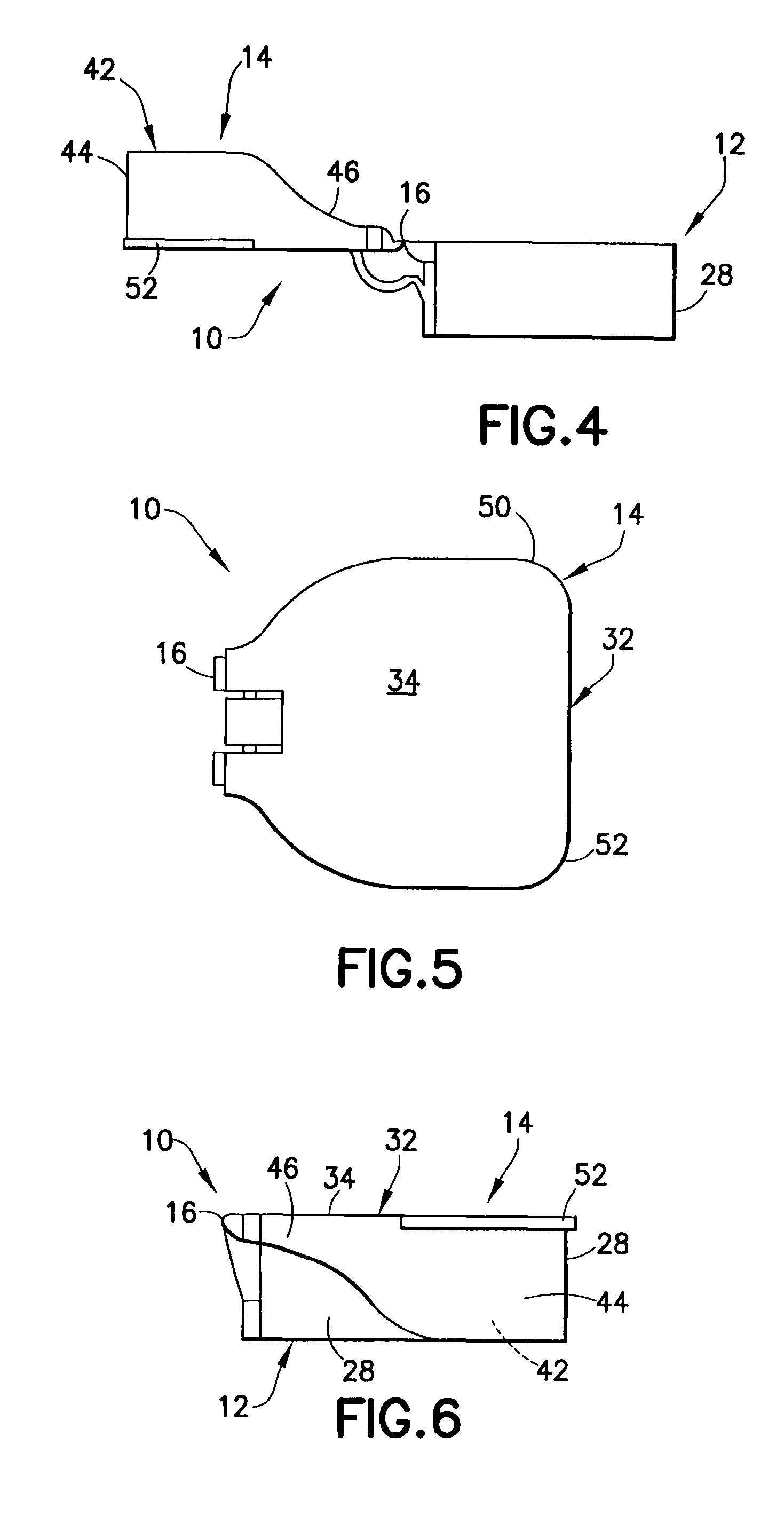

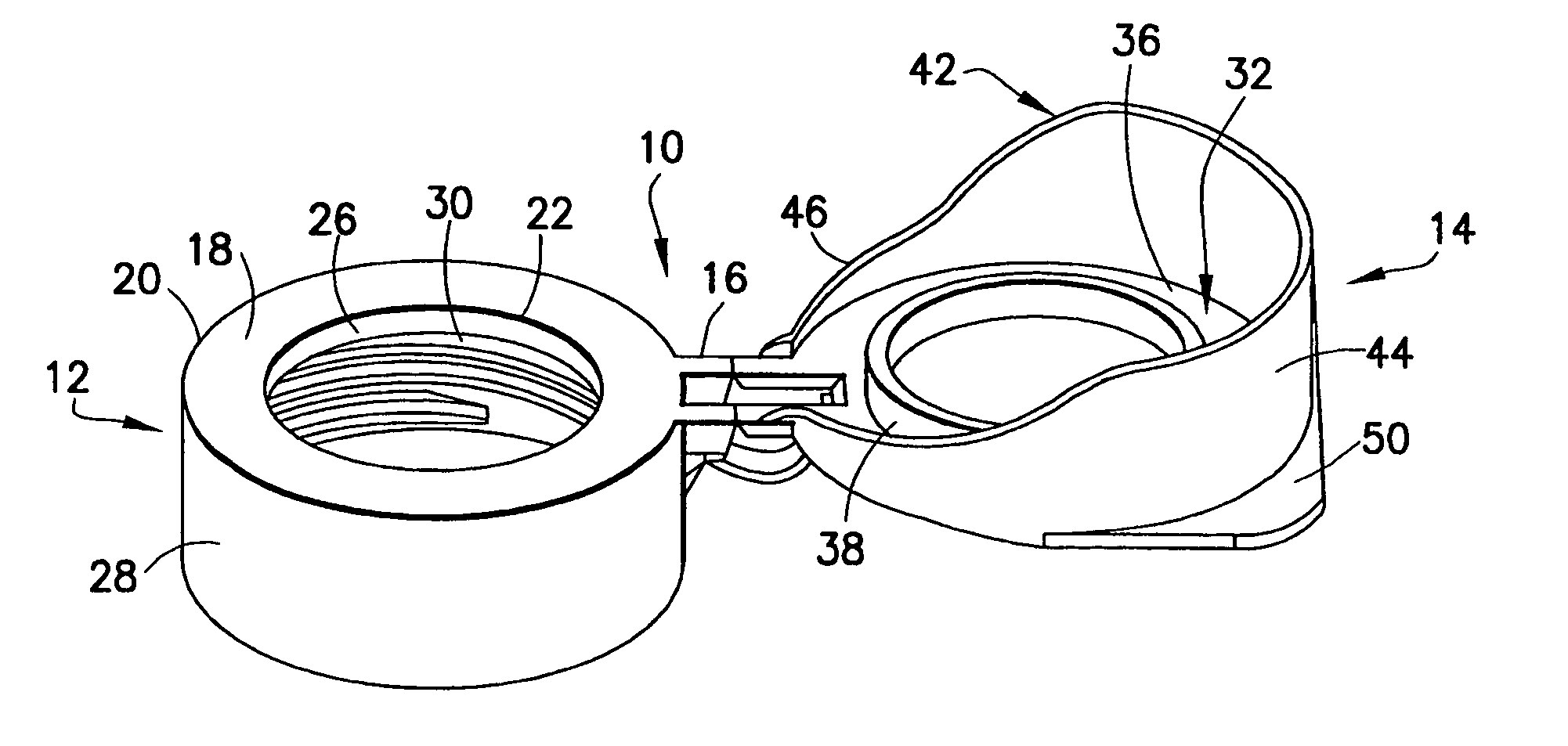

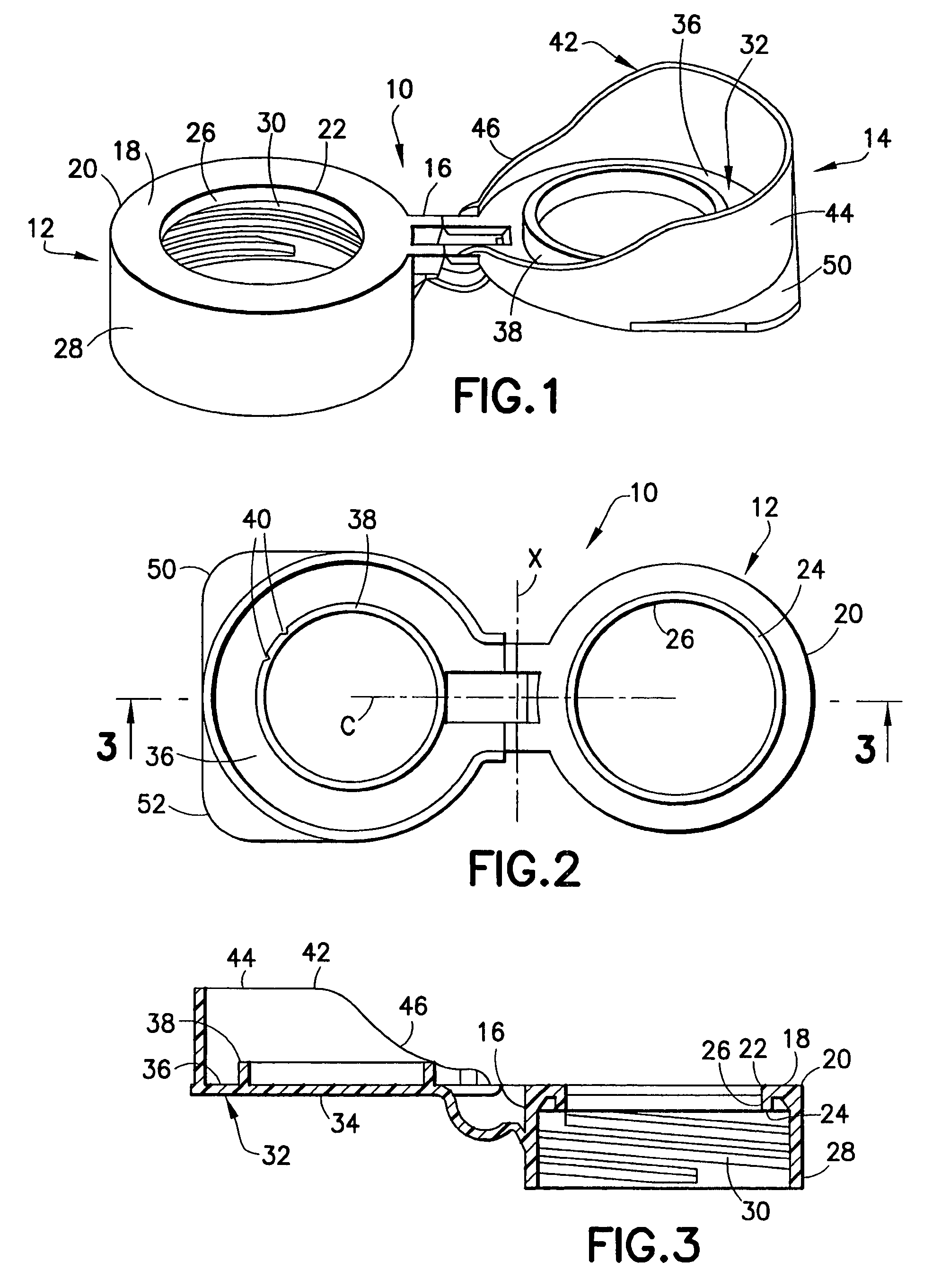

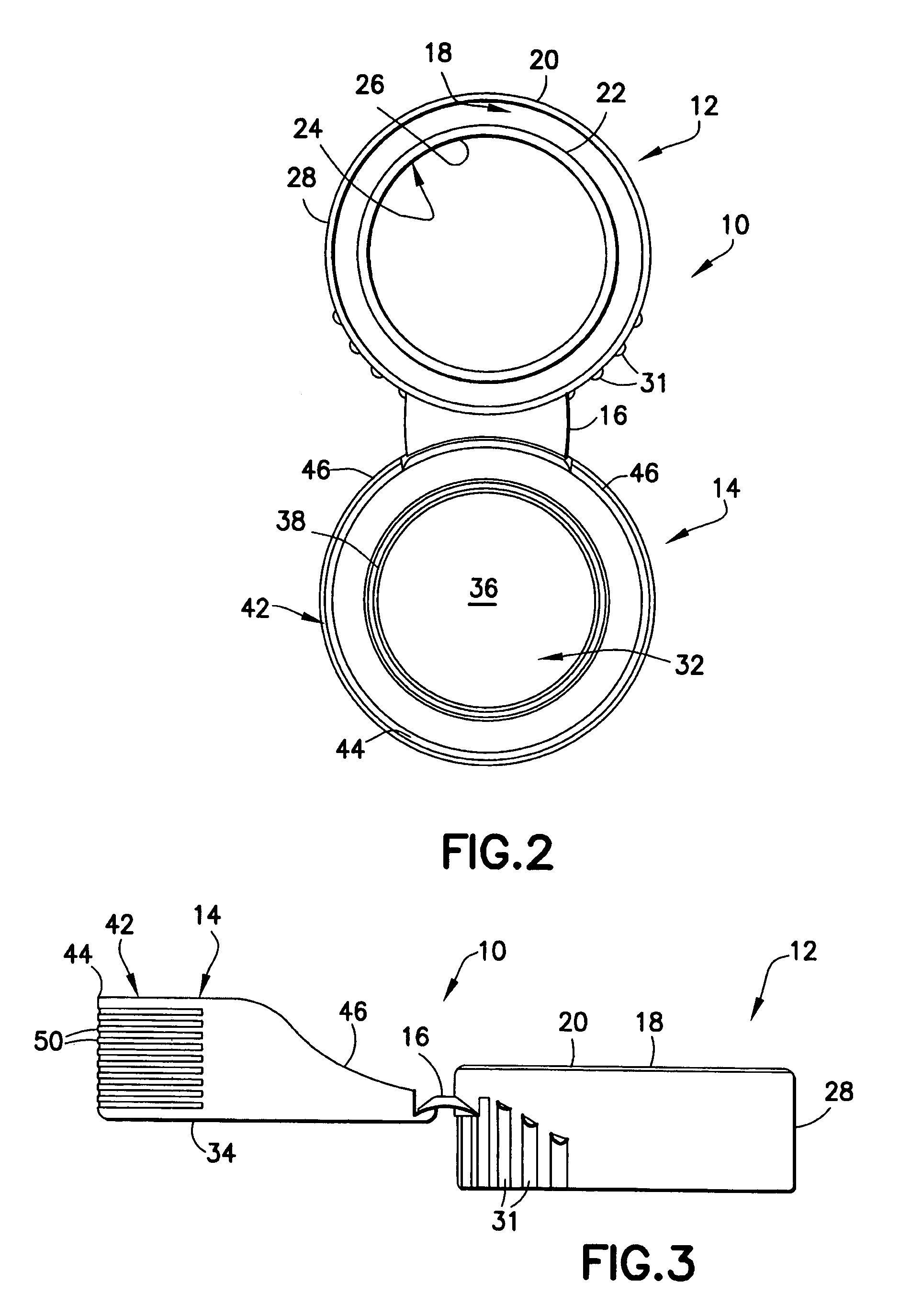

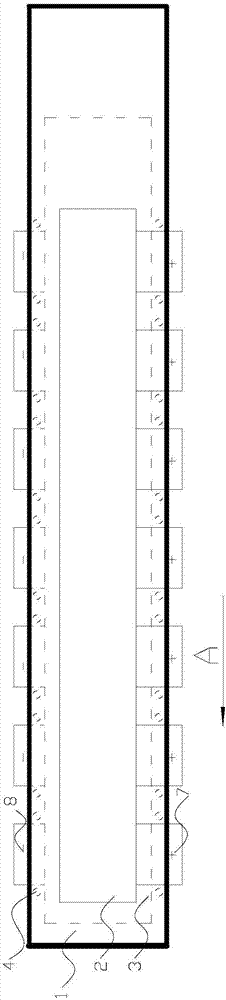

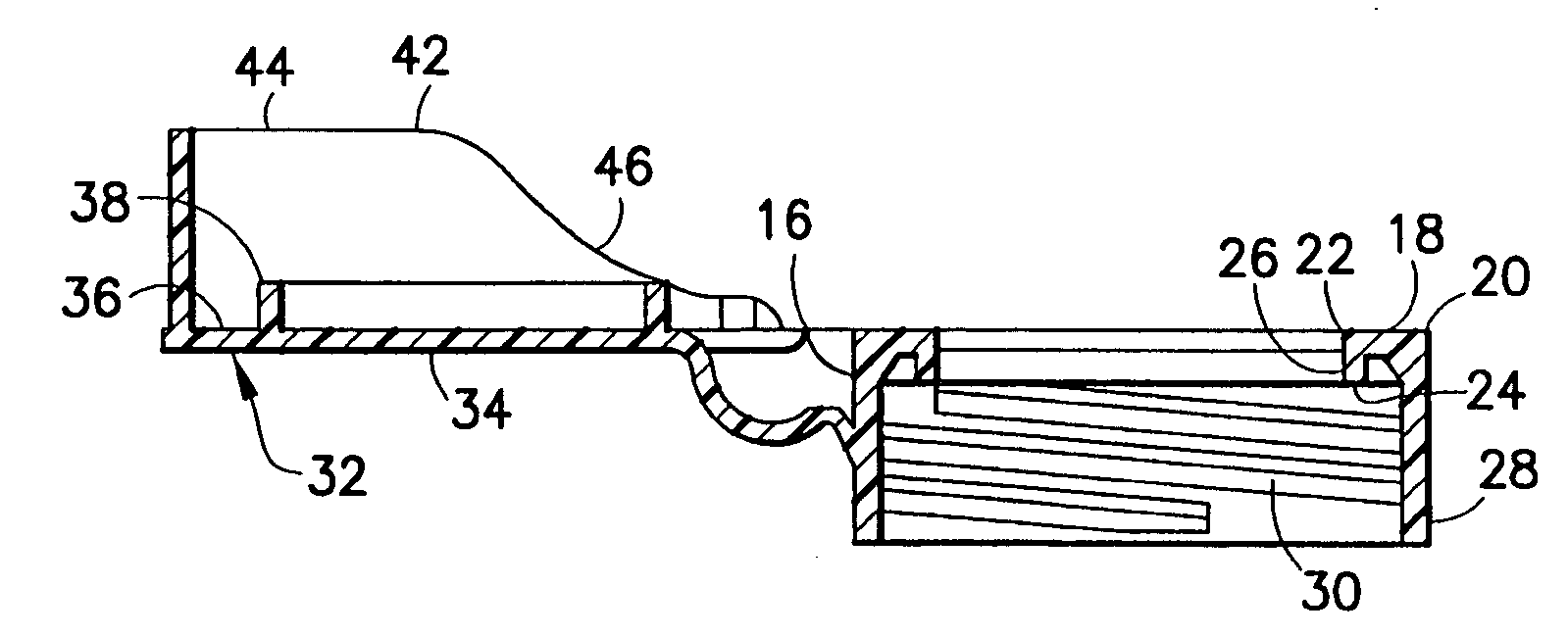

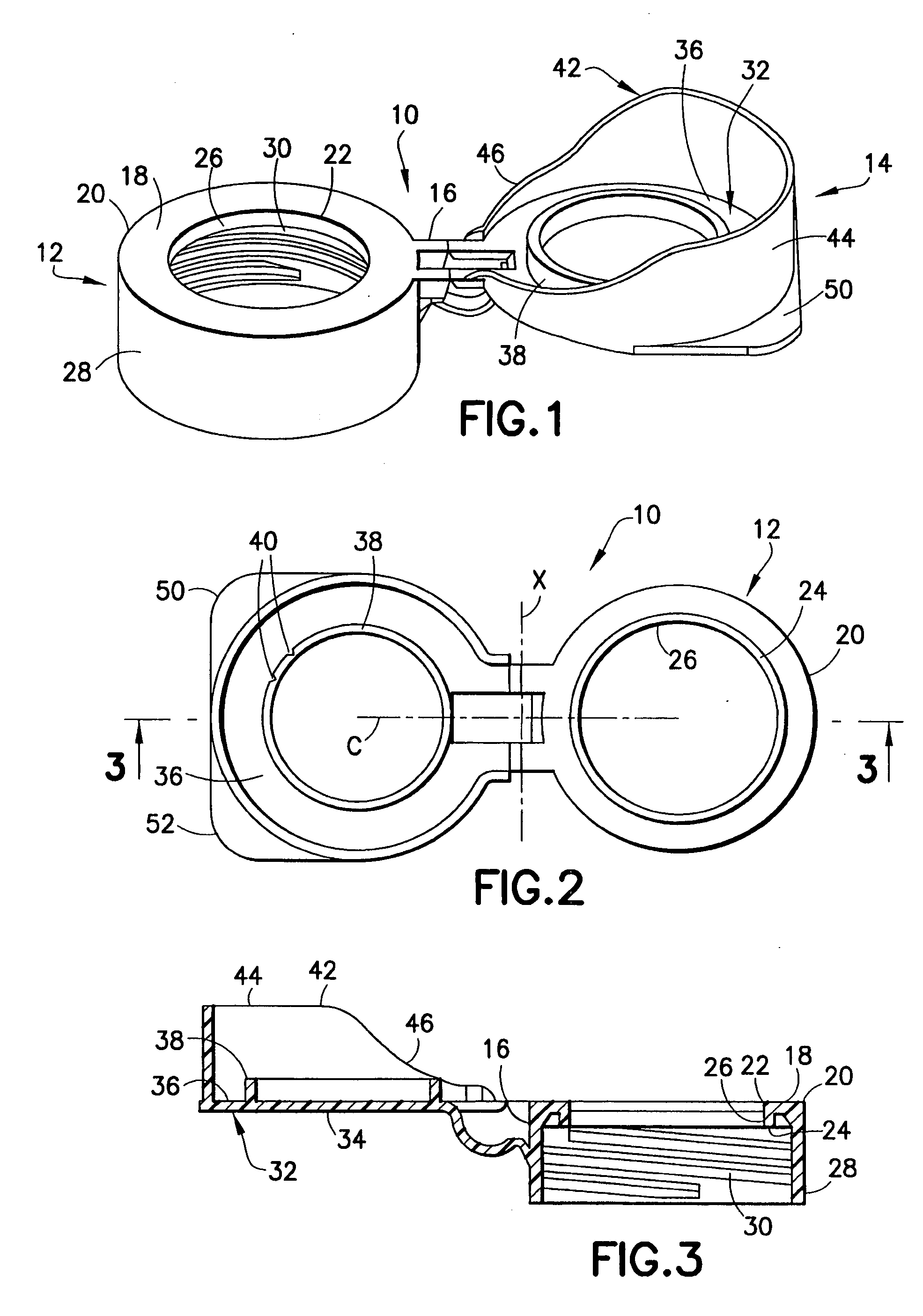

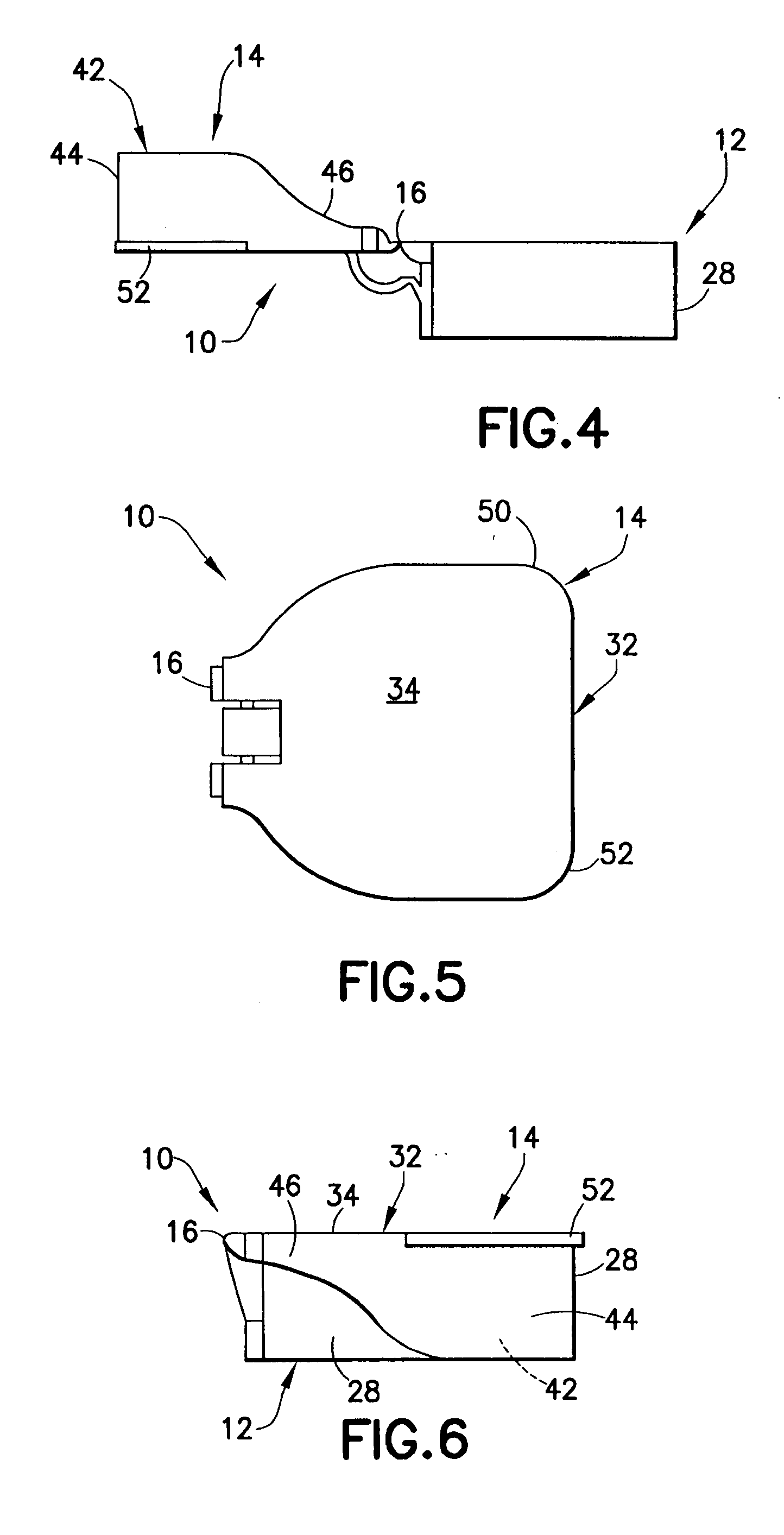

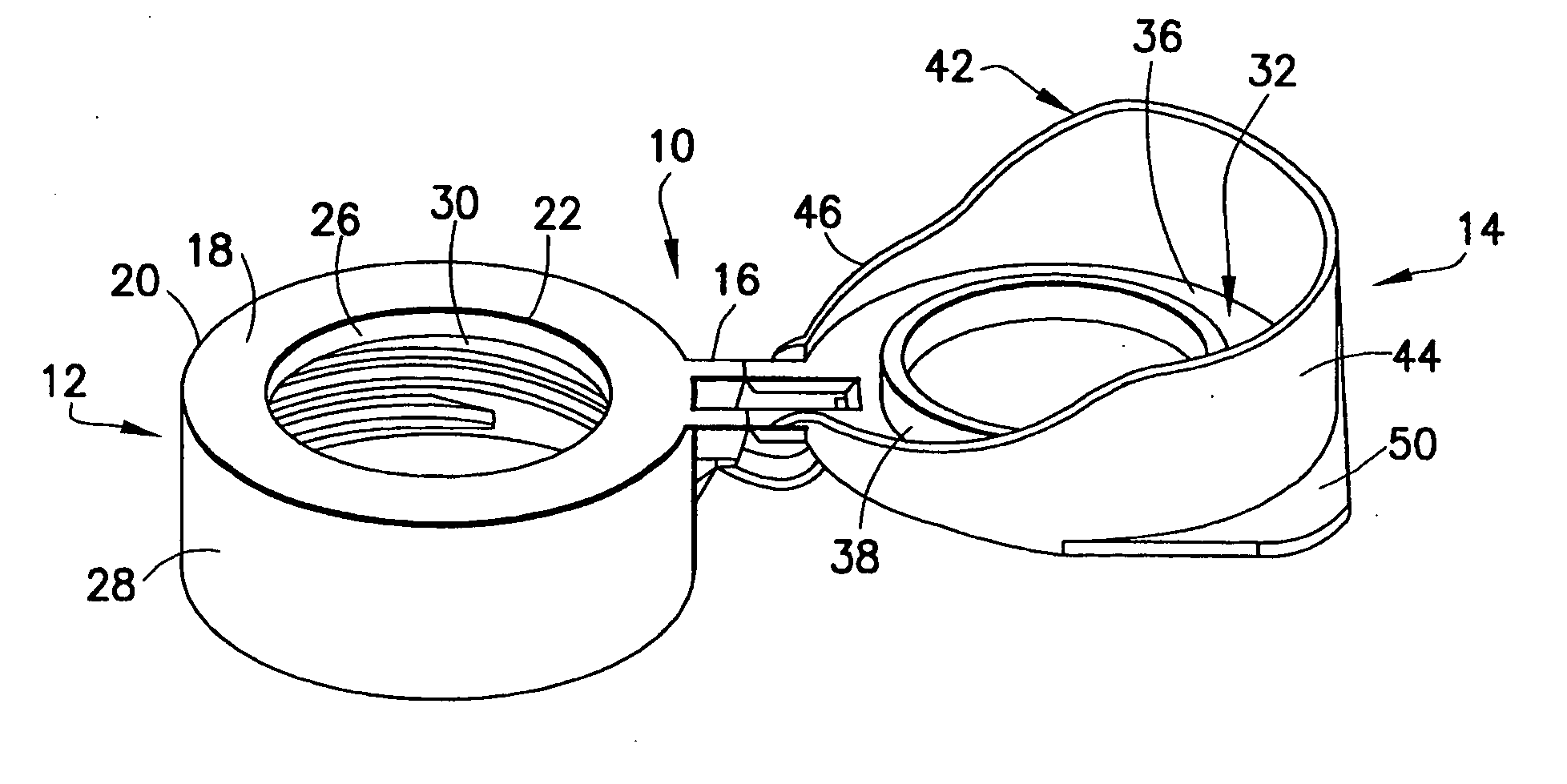

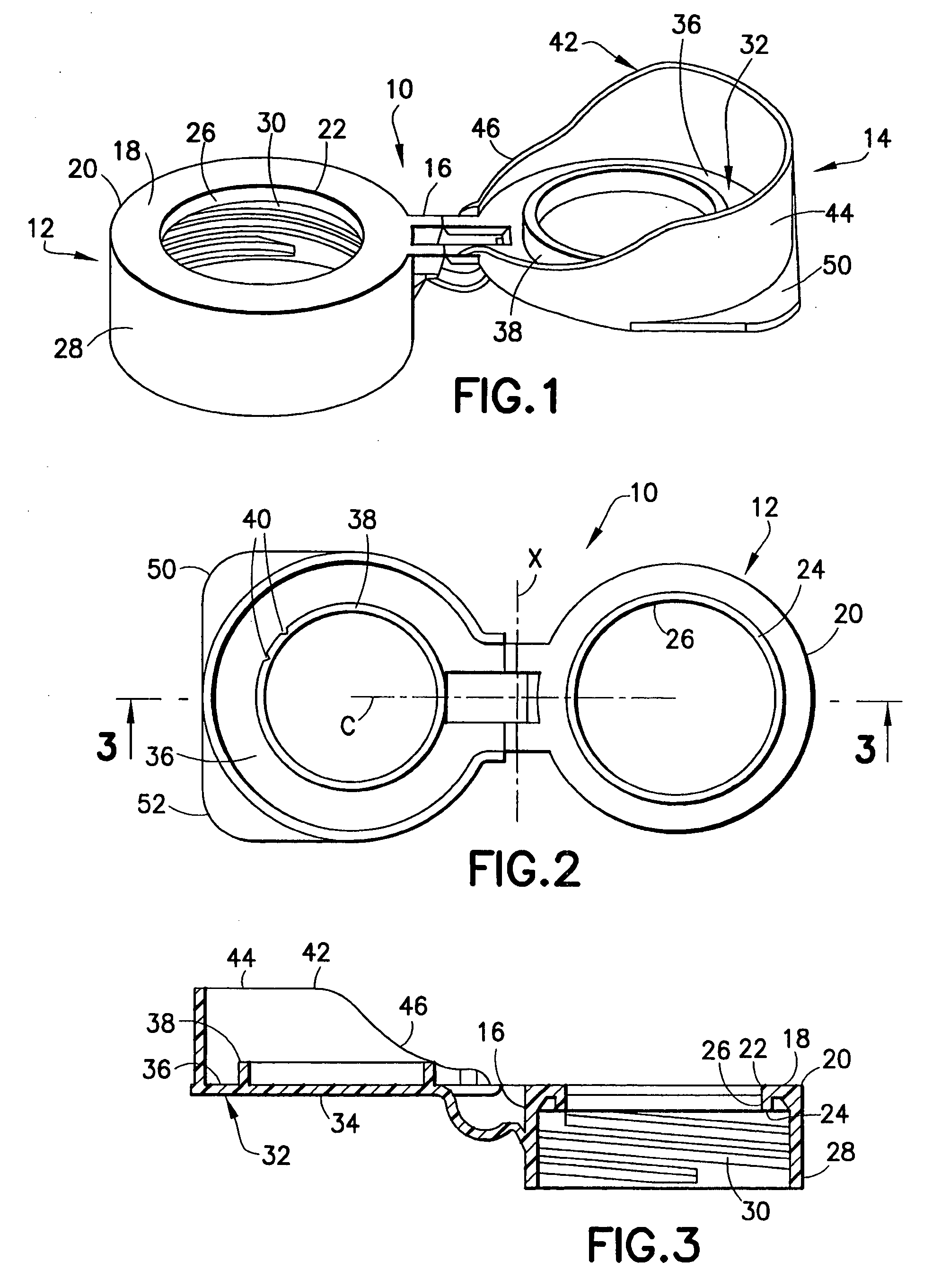

Flip top cap

InactiveUS7717284B2Easy to installReduce the likelihood of exposureCapsClosure capsEngineeringMechanical engineering

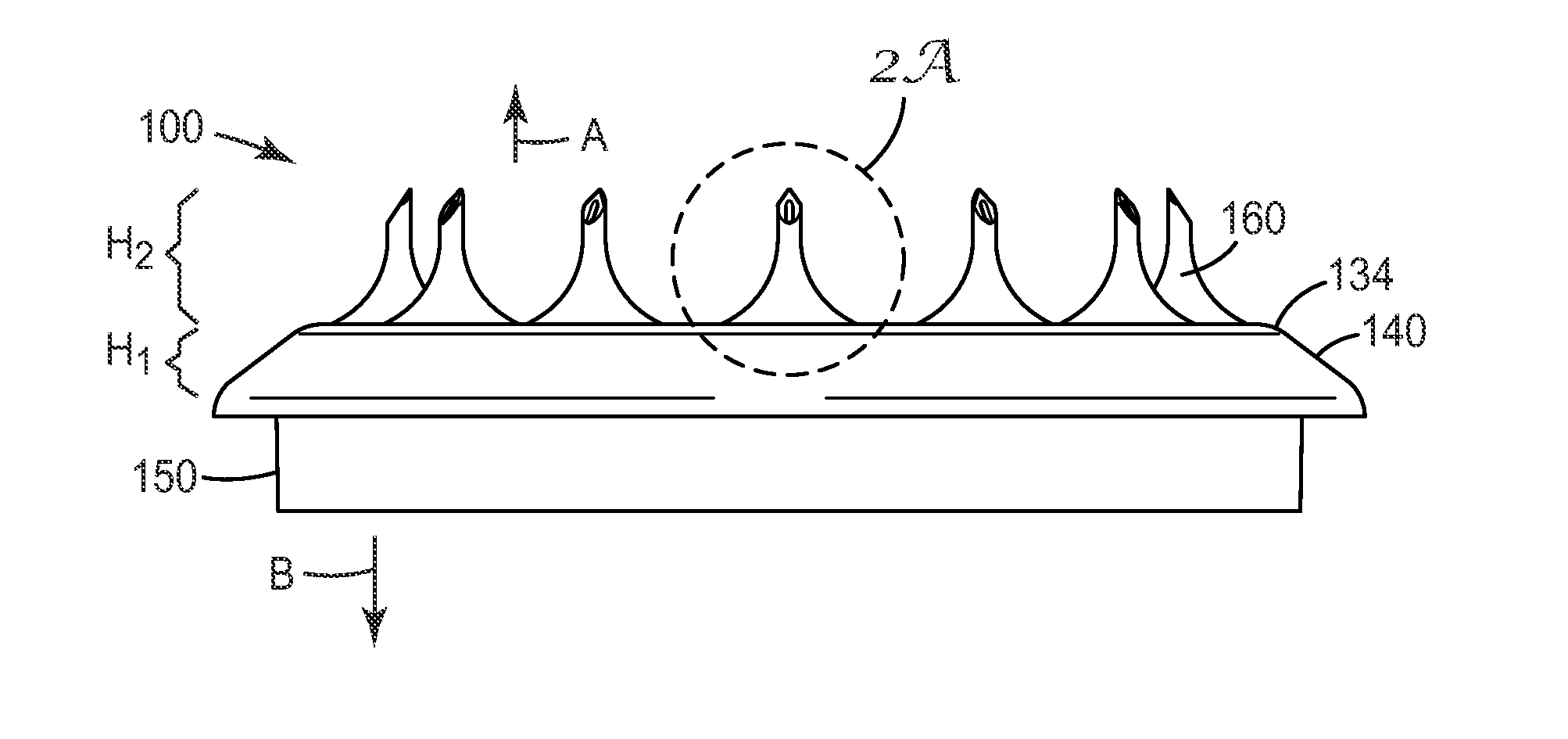

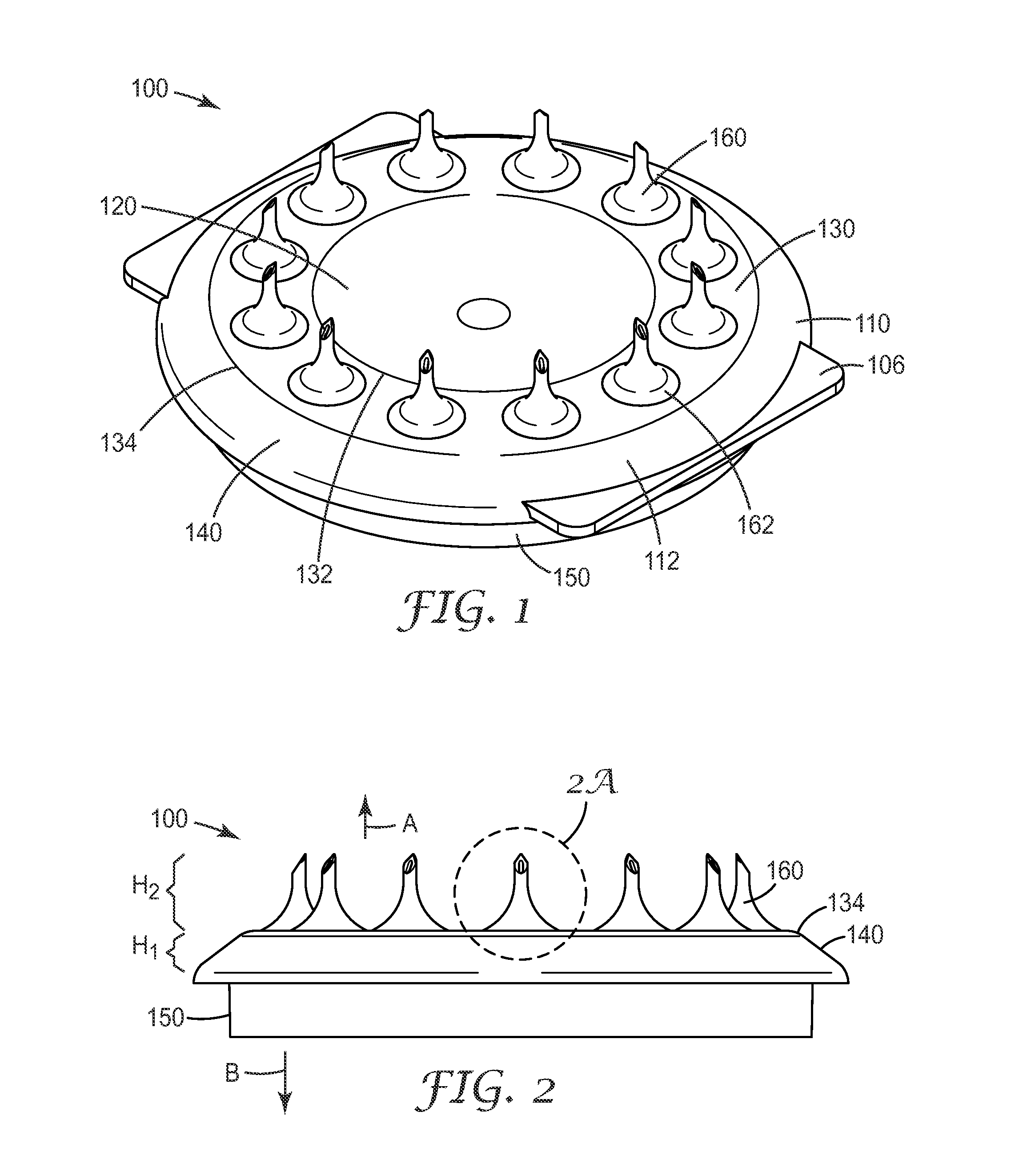

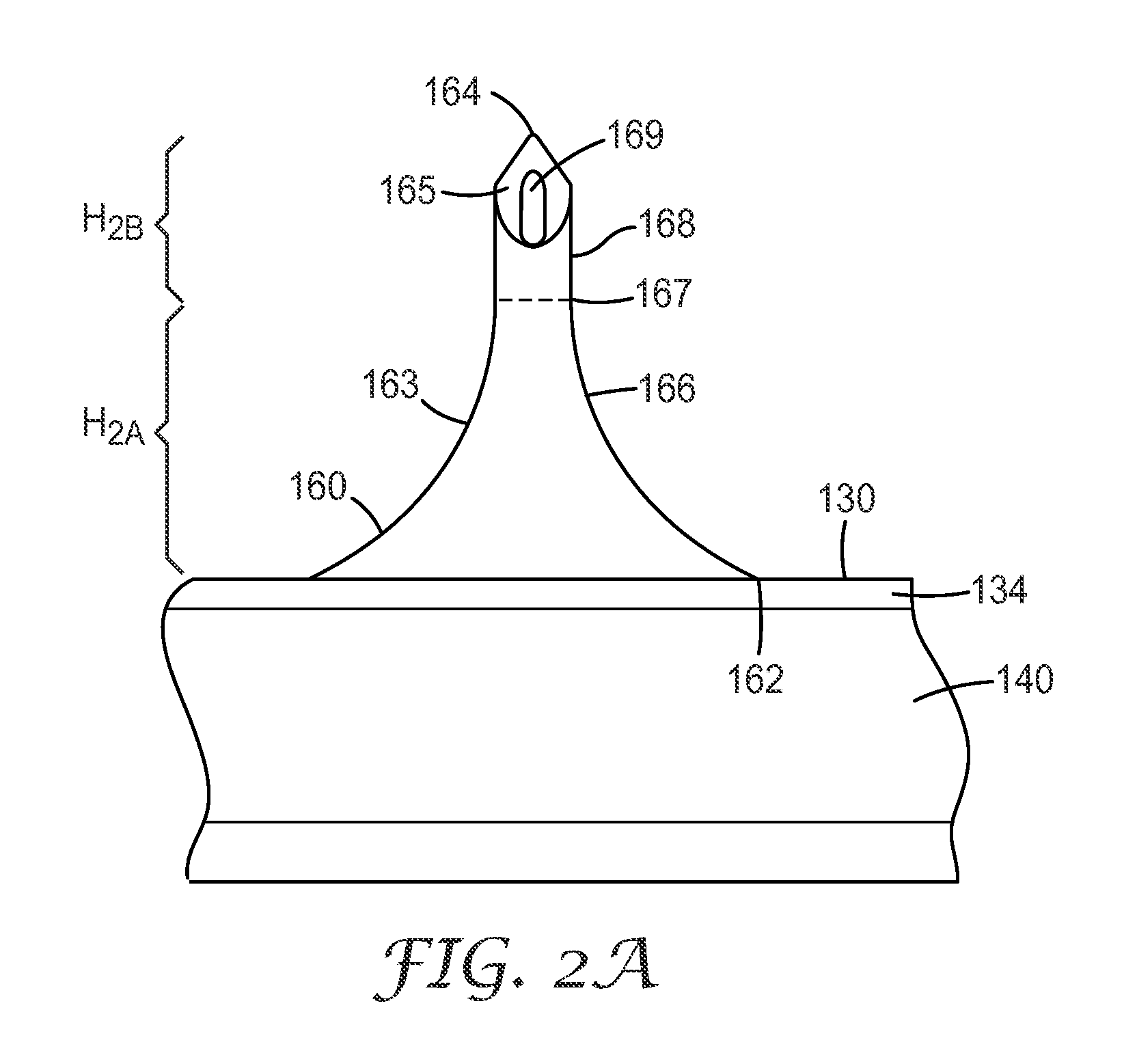

A cap is provided for a laboratory vessel. The cap includes a lid that can be rotated relative to the laboratory vessel from a closed position to an open position. The lid includes at least one tab dimensioned and disposed for receiving manual digital pressure for opening and / or closing the lid. The tab is in an offset position to prevent a thumb or forefinger from passing over and in contact with the opening to the vessel. Additionally, the lid includes a shield inwardly from the tab for further preventing contact between a finger and the open top of the vessel.

Owner:CORNING INC

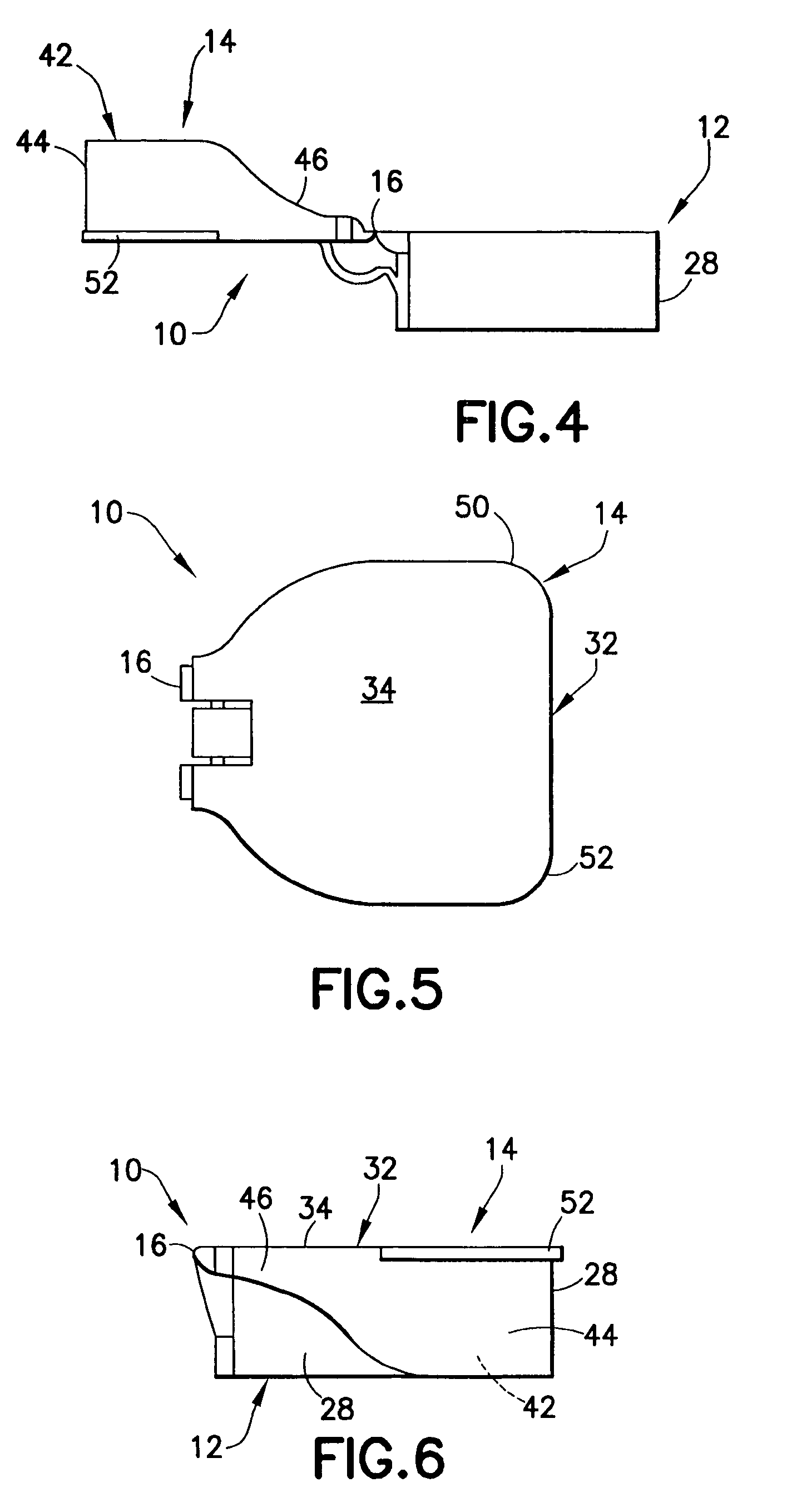

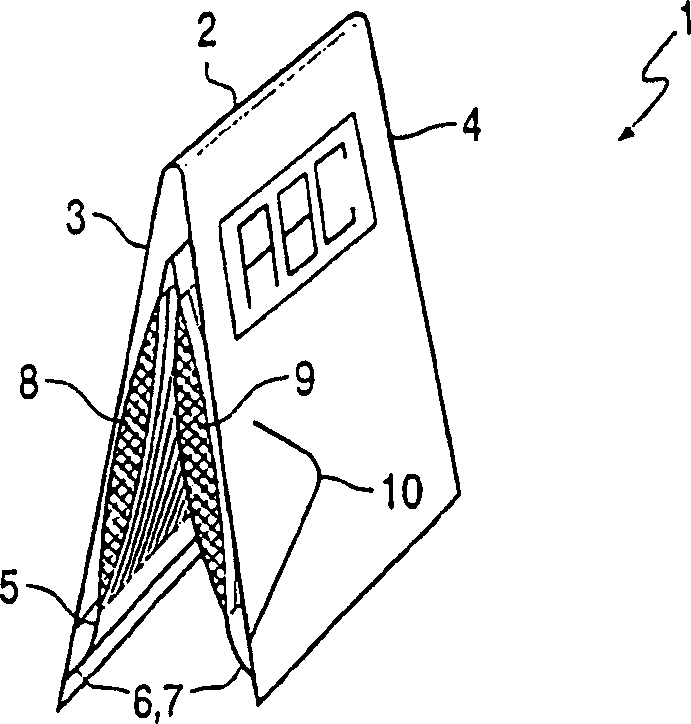

Flip top cap with contamination protection

ActiveUS8172101B2Easy to installReduce the likelihood of exposureCapsLaboratory glasswaresEngineeringMechanical engineering

Owner:CORNING INC

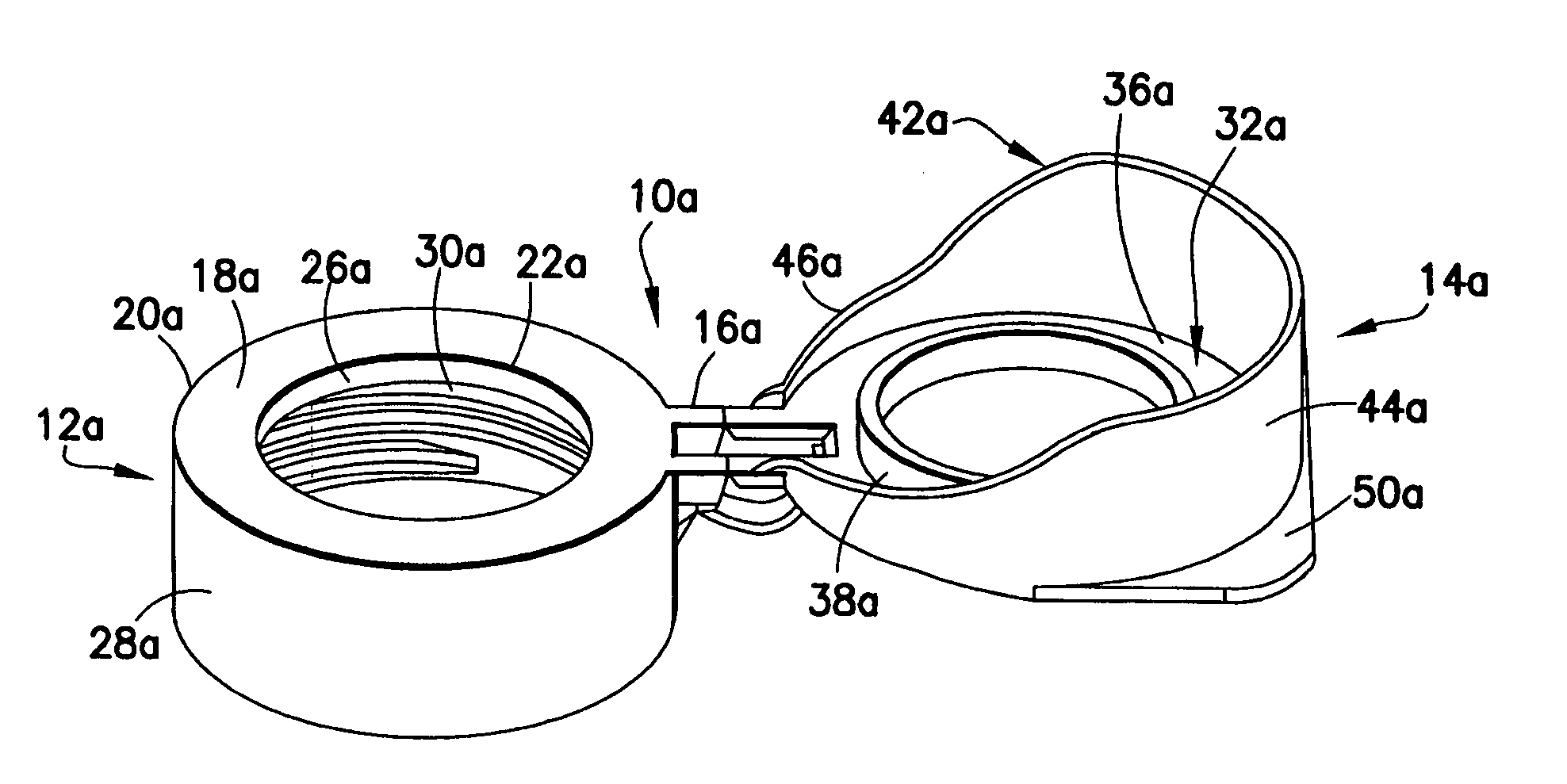

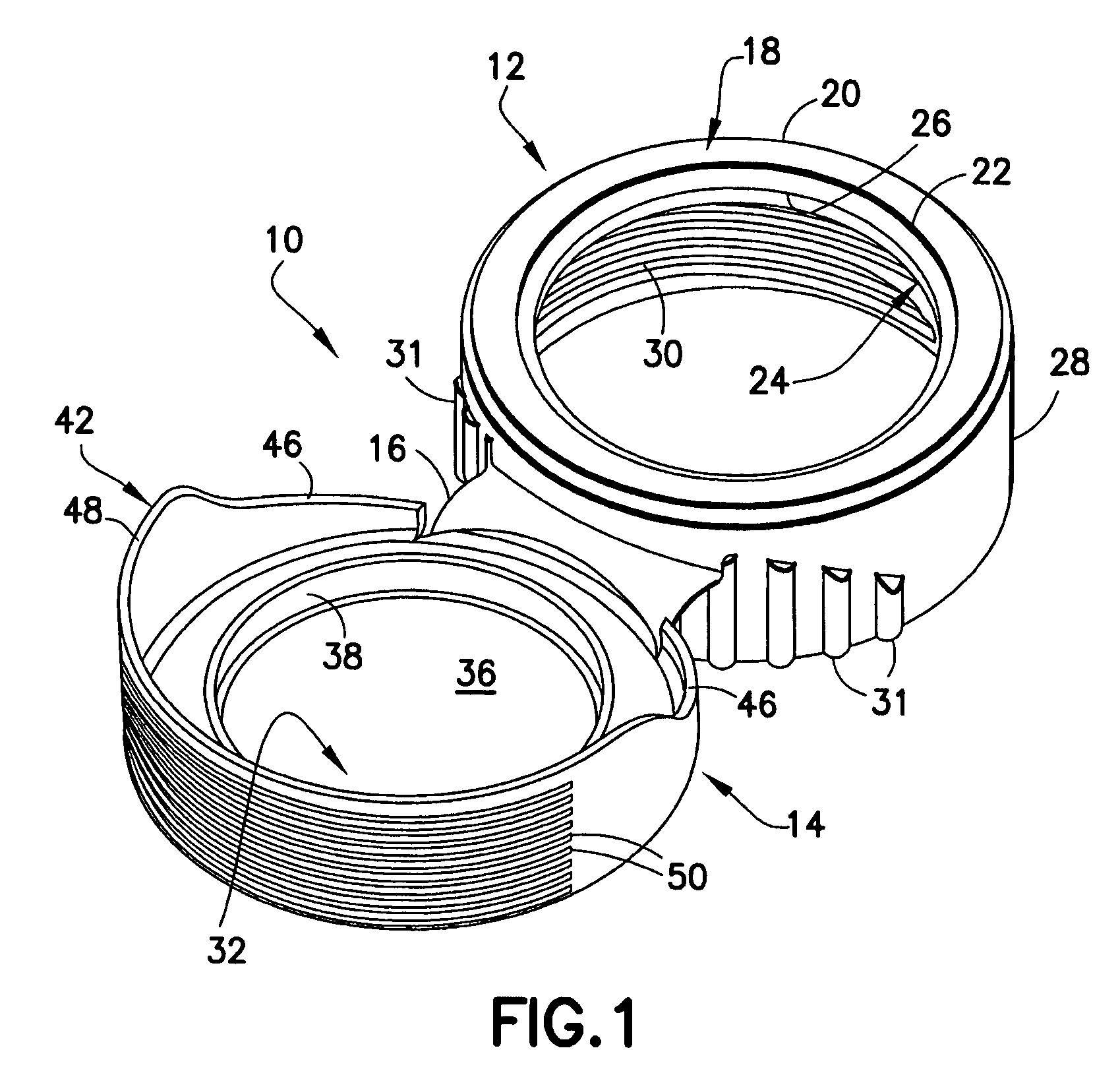

Flip top cap

ActiveUS7546931B2Easy threaded installationFacilitate gripping and rotationCapsClosure capsEngineeringMechanical engineering

Owner:CORNING INC

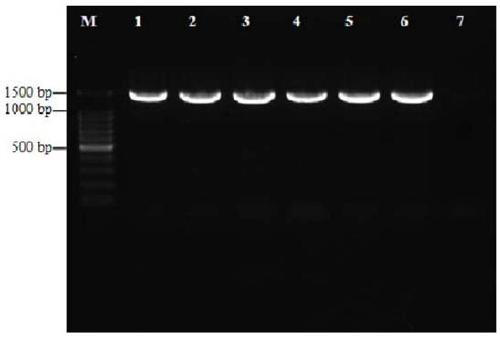

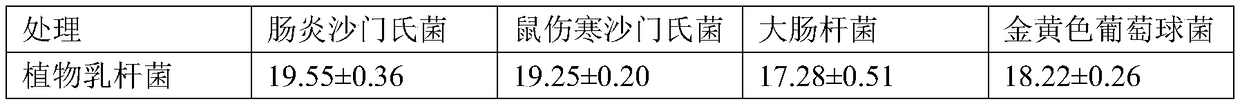

Lactobacillus plantarum and application thereof

ActiveCN109504619AEnsure balanceOf edible plant originAntibacterial agentsBacteriaSide effectGut flora

The invention discloses lactobacillus plantarum and application thereof. A strain of the lactobacillus plantarum is PA01 and the preservation number is CGMCC (China General Microbiological Culture Collection Center) No. 15660. The lactobacillus plantarum has high safety and strong tolerance, can be colonized on intestines and can grow and reproduce on the intestines; the lactobacillus plantarum isused for adjusting the balance of intestinal flora and expressing a probiotic function; the lactobacillus plantarum can be used for preparing foods or feed additives, regulators for regulating intestinal diseases of animals, animal antibiotic substituting agents, immunoregulators and pathogenic bacterium bacterium-inhibition agents, and also can be used for improving the production performance ofbroiler chickens; the lactobacillus plantarum has a good effect, is safe and has no side effect.

Owner:NORTHWEST A & F UNIV

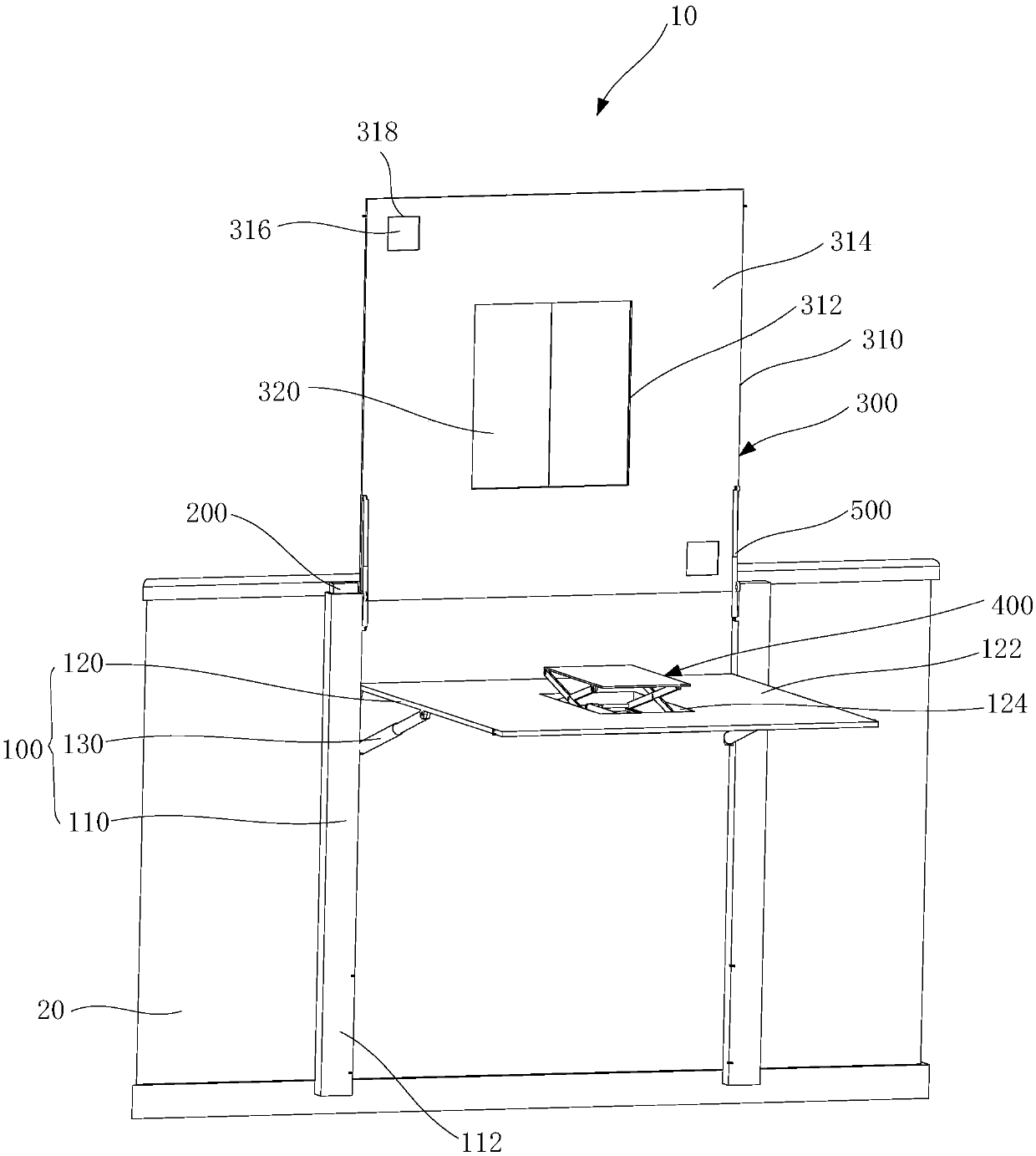

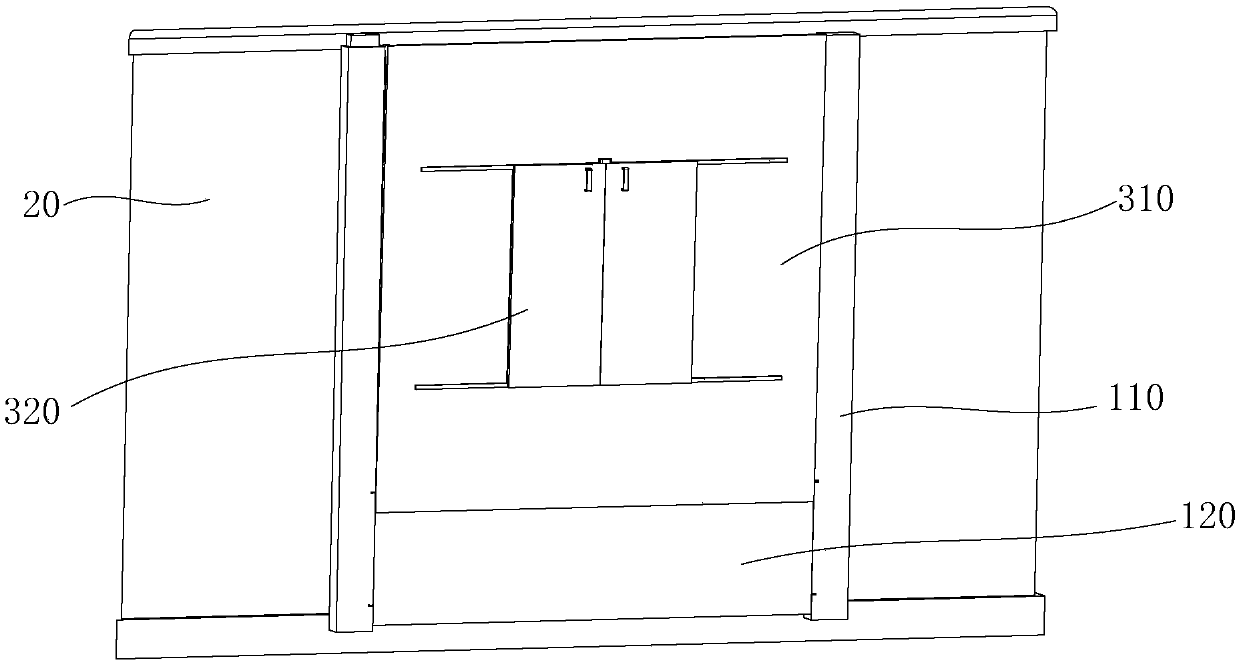

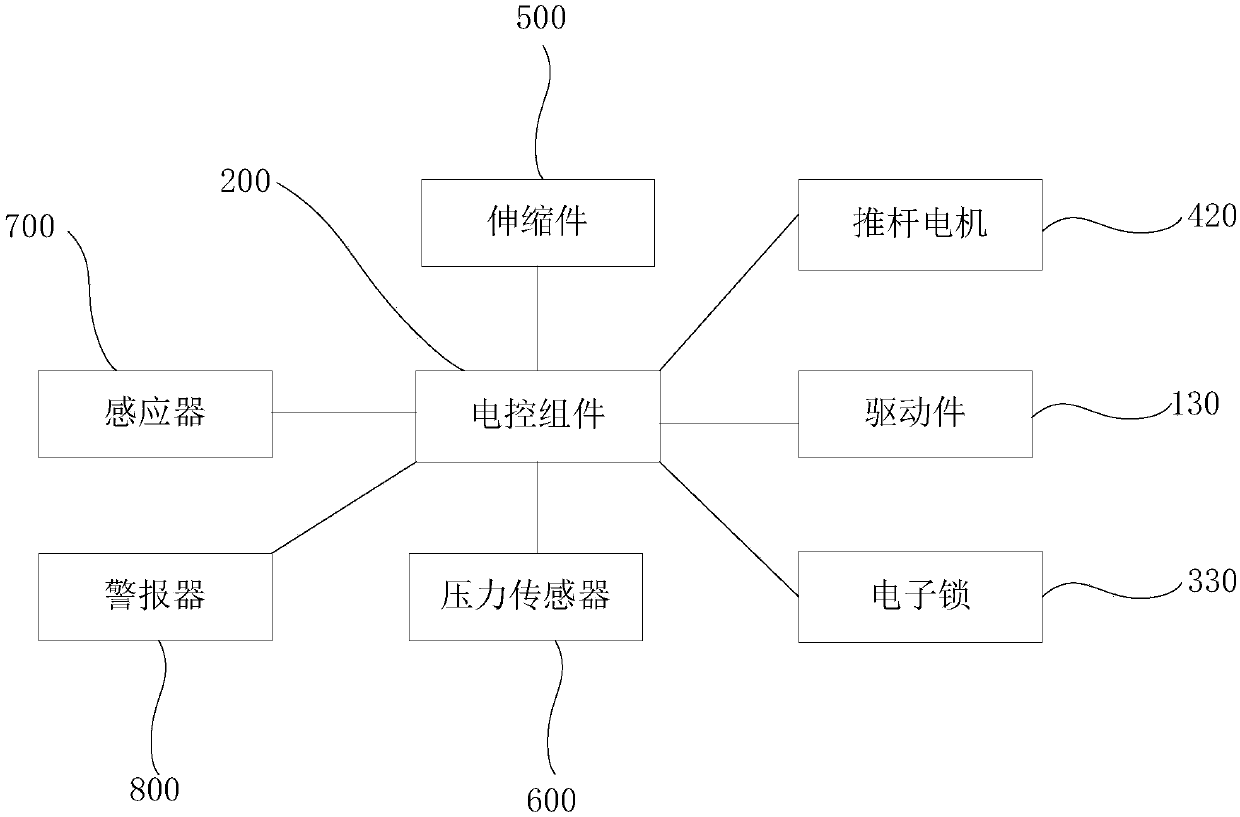

Goods receiving and sending system for unmanned aerial vehicle and method of receiving and sending goods

ActiveCN107697304AReduce the likelihood of exposureHelicopter landing platformLanding aidsEngineering

The invention relates to a goods receiving and sending system for an unmanned aerial vehicle (UAV) and a method of receiving and sending goods. The goods receiving and sending system for the UAV comprises a support assembly and a barrier assembly, wherein the support assembly comprises a take-off and landing platform which can be mounted on a building; the take-off and landing platform is providedwith a working surface; the working surface is provided with a working area for the landing of the UAV and the placement of the goods; the barrier assembly comprises a barrier board and a movable door; the barrier board is provided with a pick-up and placement opening; a user can pick up or place the goods from or on one side of the barrier board by virtue of the pick-up and placement opening; the movable door is movably mounted on the barrier board; the movable door can cover the pick-up and placement opening; and the working area is arranged on the other side of the barrier board to enablethe barrier board to be positioned between the building and the working area so that the barrier board and the movable door can jointly separate the user from the UAV. The goods receiving and sendingsystem for the UAV is more secure.

Owner:周鹏跃

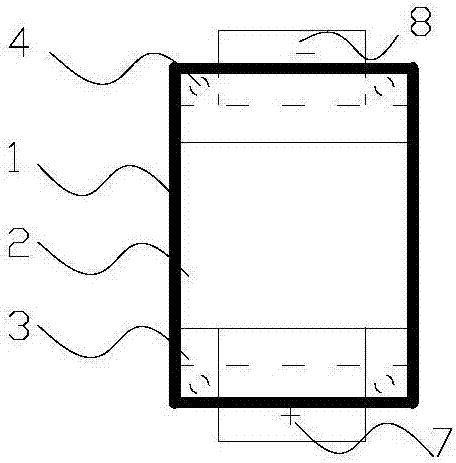

High-temperature safety battery cell

ActiveCN107204415AReduce the likelihood of exposureAvoid short circuitCell seperators/membranes/diaphragms/spacersFinal product manufacturePole pieceEngineering

The invention discloses a high-temperature safety battery cell. The high-temperature safety battery cell comprises diaphragms, a positive pole piece and a negative pole piece, wherein the diaphragms are arranged between the positive pole piece and the negative pole piece at intervals, two adjacent diaphragms are fixed in a bonding manner, and a bonding point is disposed at the outer side of the positive pole piece or the negative pole piece. The high-temperature safety battery cell has the advantages that due to the fixing effect of the bonding point, the heat shrinkage and high temperature resistance of the diaphragms are improved, the contact probability of the positive pole piece and negative pole piece is reduced, and the high-temperature short-circuit risk is decreased; and meanwhile, the diaphragms are fixed in an assisting manner in a stacking structural unit, so that the shifting of the positive pole piece and negative pole piece is avoided, the short circuit caused by the loose folding of the diaphragms can be prevented, the safety potential hazard is avoided, the structure is stable, the safety is high, and the good quality of the battery cell is guaranteed.

Owner:ETRUST POWER ETP GRP LTD

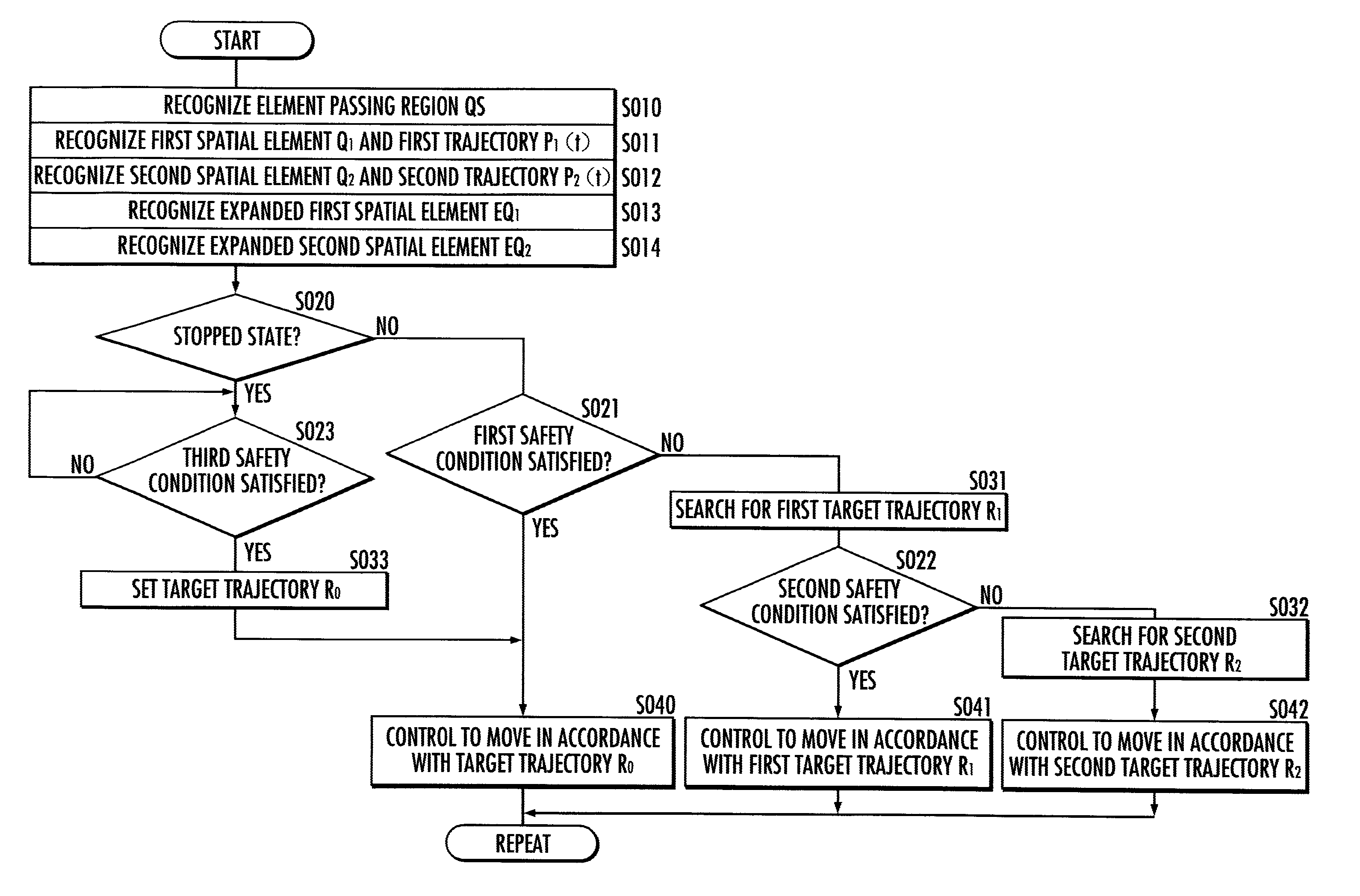

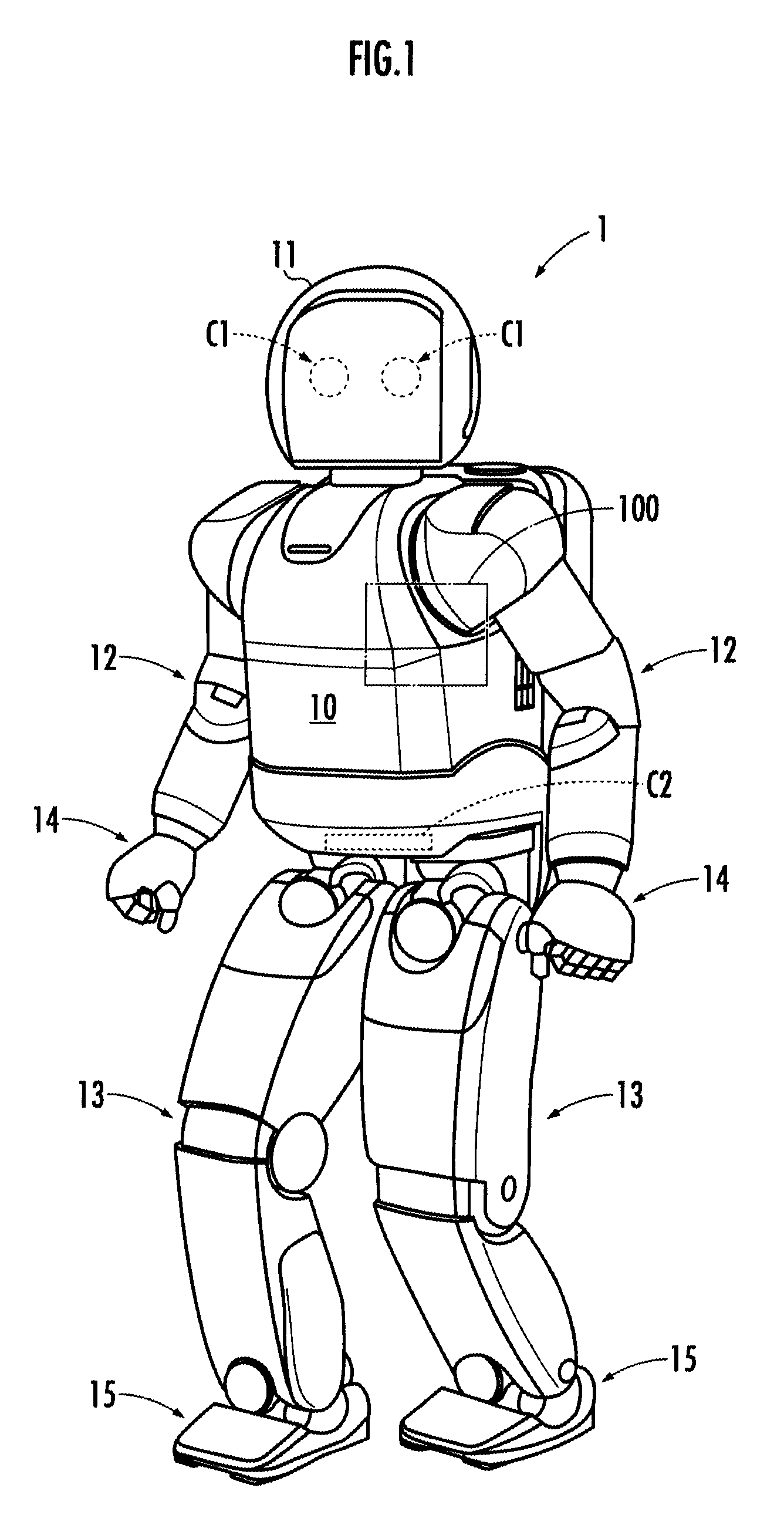

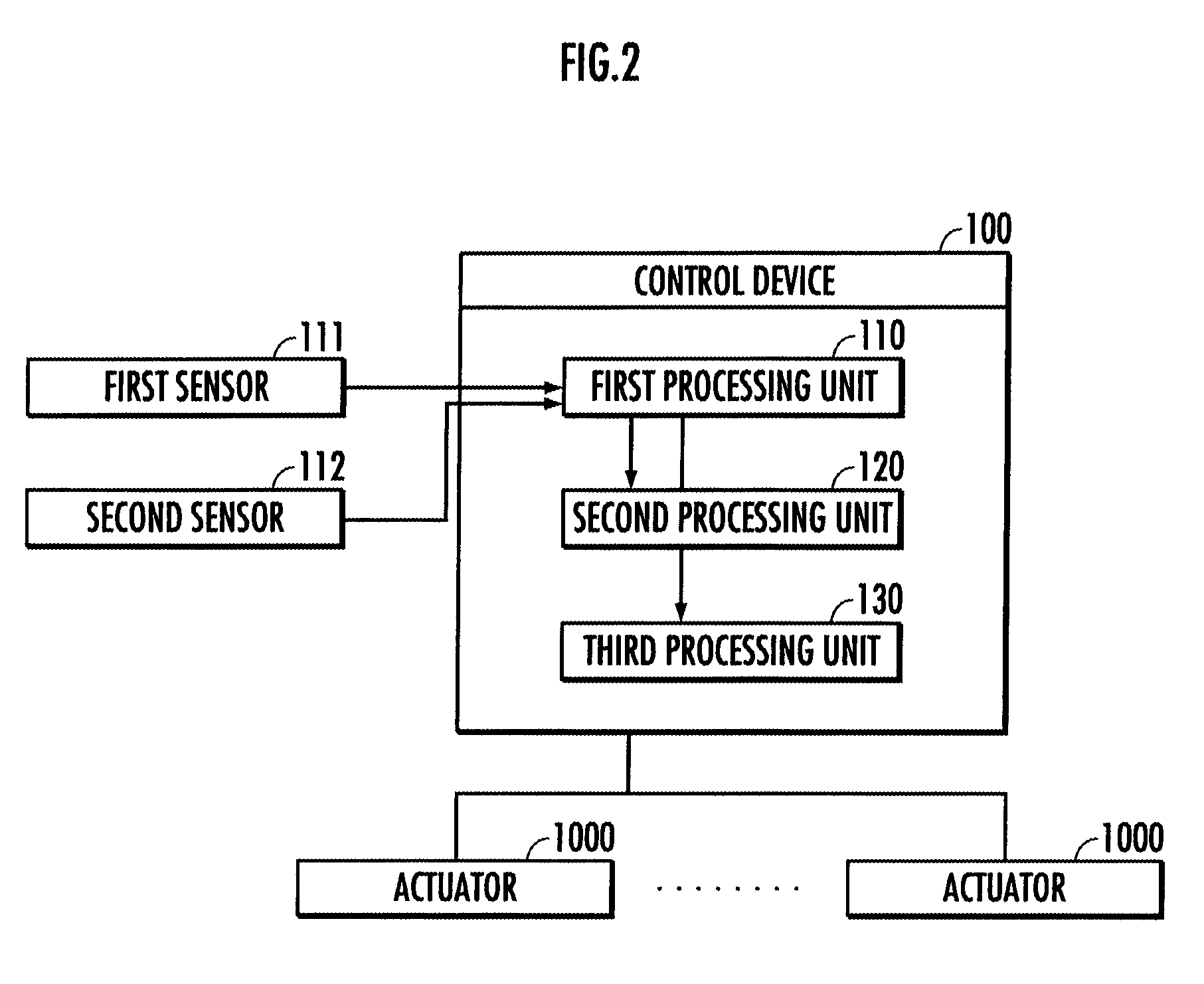

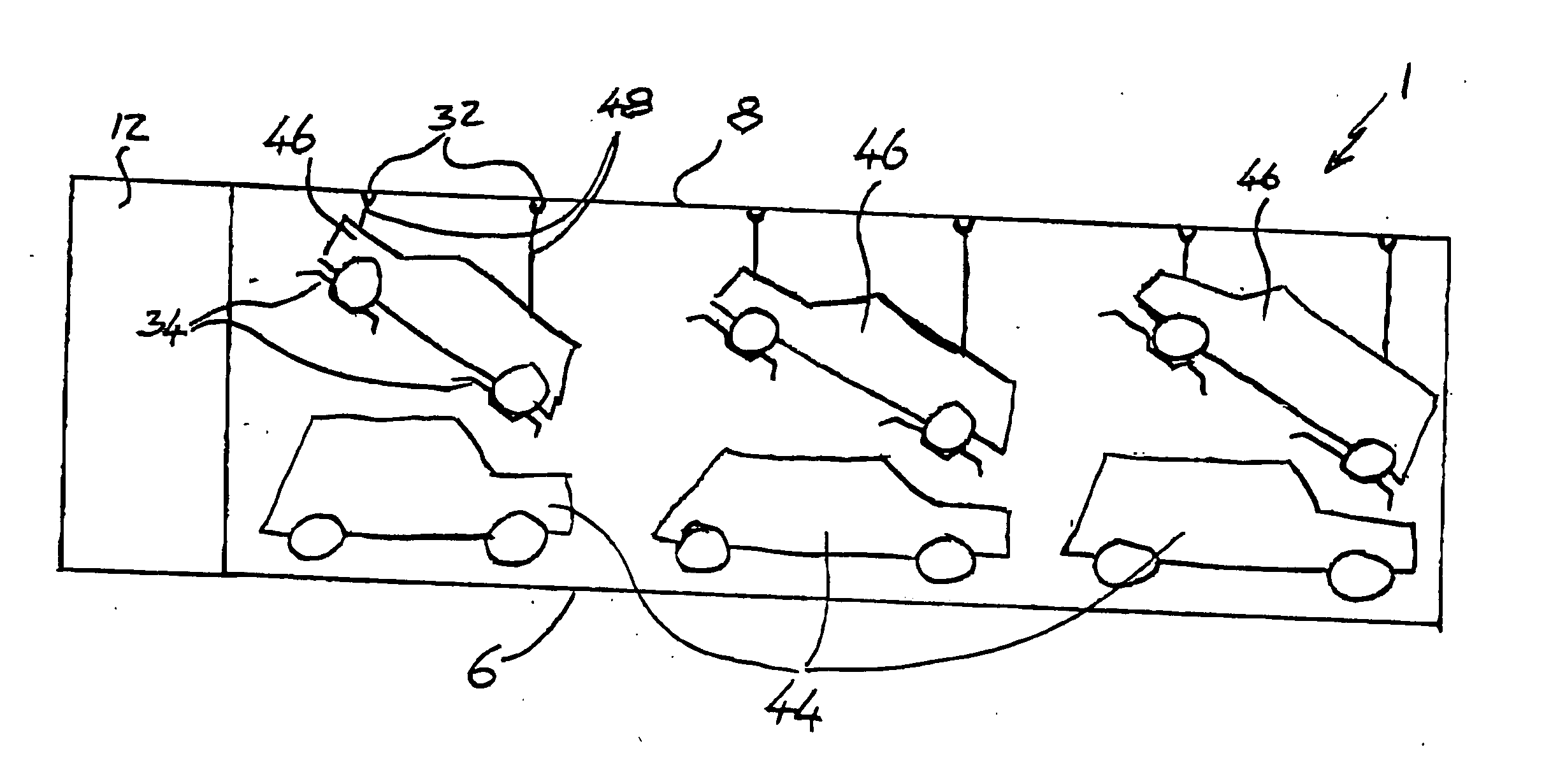

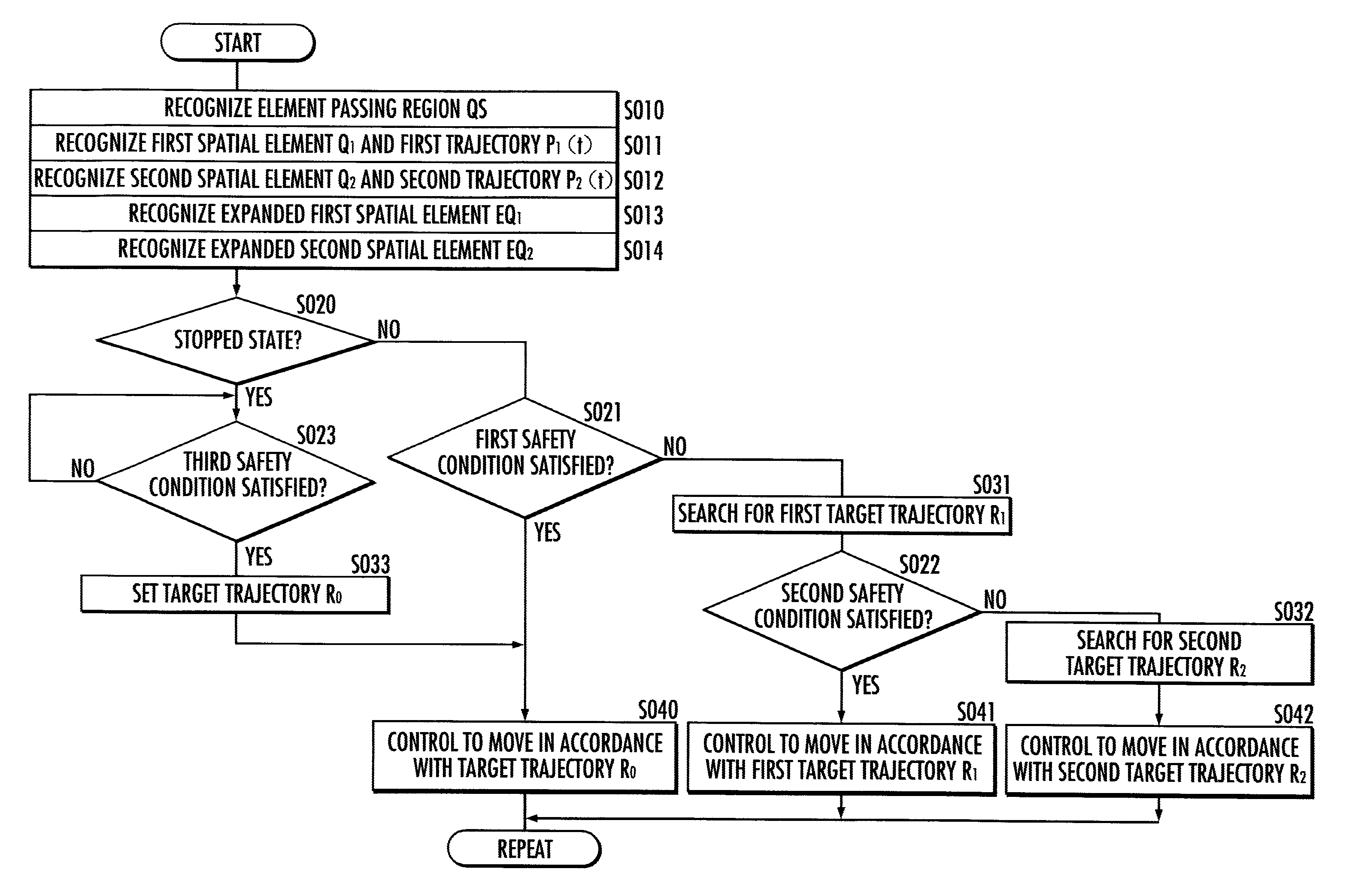

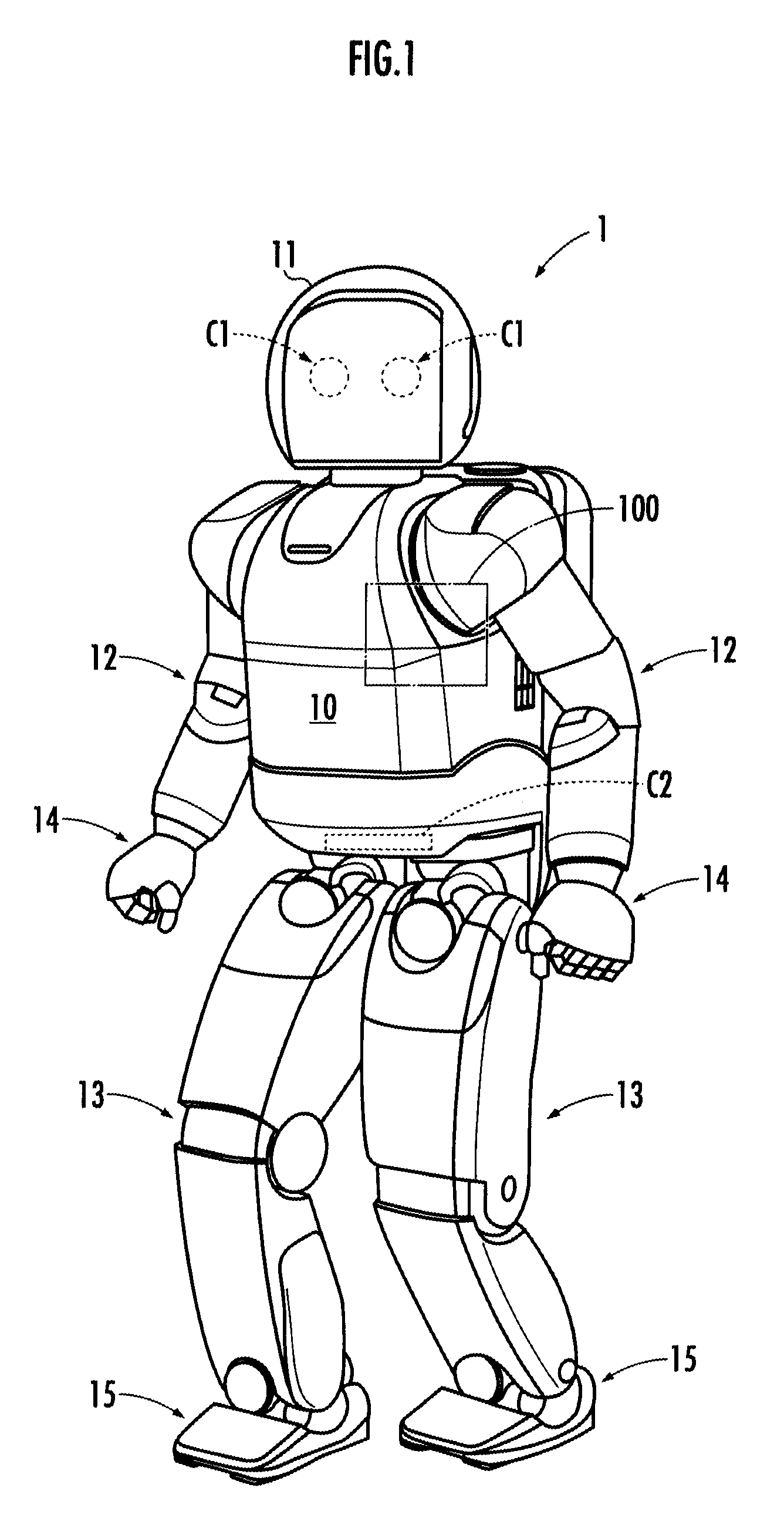

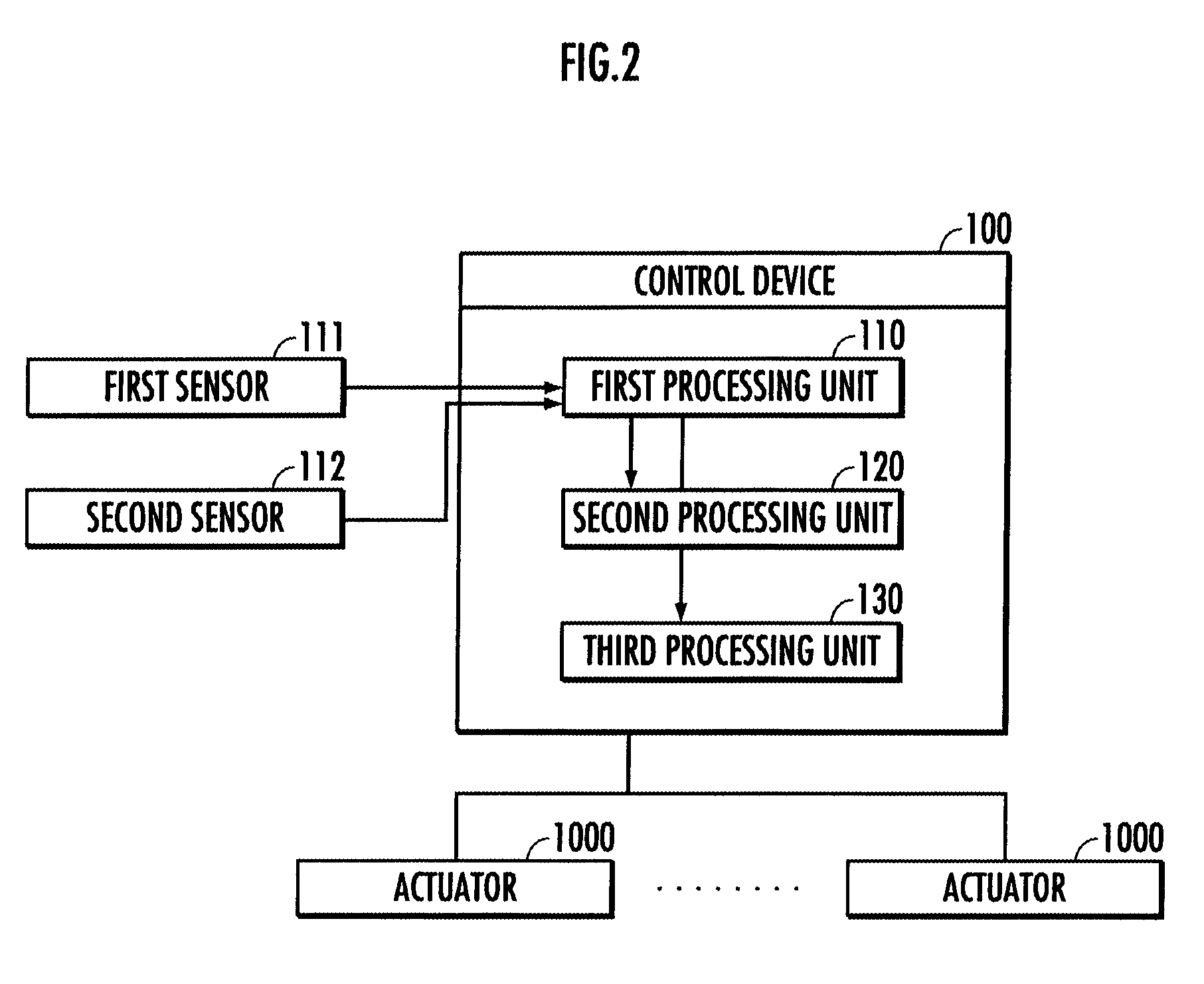

Mobile apparatus and control program therefor

InactiveUS7873438B2Reduce the likelihood of exposureReduce the possibilityAnti-collision systemsKnowledge representationEngineeringMobile device

A mobile apparatus capable of moving or acting autonomously while flexibly avoiding contact with a moving object in accordance with various situations is provided. In a case where a second safety condition is not satisfied because, e.g., a first target trajectory cannot be found, a second target trajectory causing a first spatial element to approach the boundary of an element passing region is searched for and determined. A robot autonomously approaches the boundary of the passable region in accordance with the second target trajectory determined as a provisional target trajectory, and stops at the position corresponding to the end point of the second target trajectory. Such movement of the robot along the second target trajectory increases the space, making it possible to prompt an object to move through the space.

Owner:HONDA MOTOR CO LTD

Flip top cap

A cap is provided for a laboratory vessel. The cap includes a lid that can be rotated relative to the laboratory vessel from a closed position to an open position. The lid includes at least one tab dimensioned and disposed for receiving manual digital pressure for opening and / or closing the lid. The tab is in an offset position to prevent a thumb or forefinger from passing over and in contact with the opening to the vessel. Additionally, the lid includes a shield inwardly from the tab for further preventing contact between a finger and the open top of the vessel.

Owner:CORNING INC

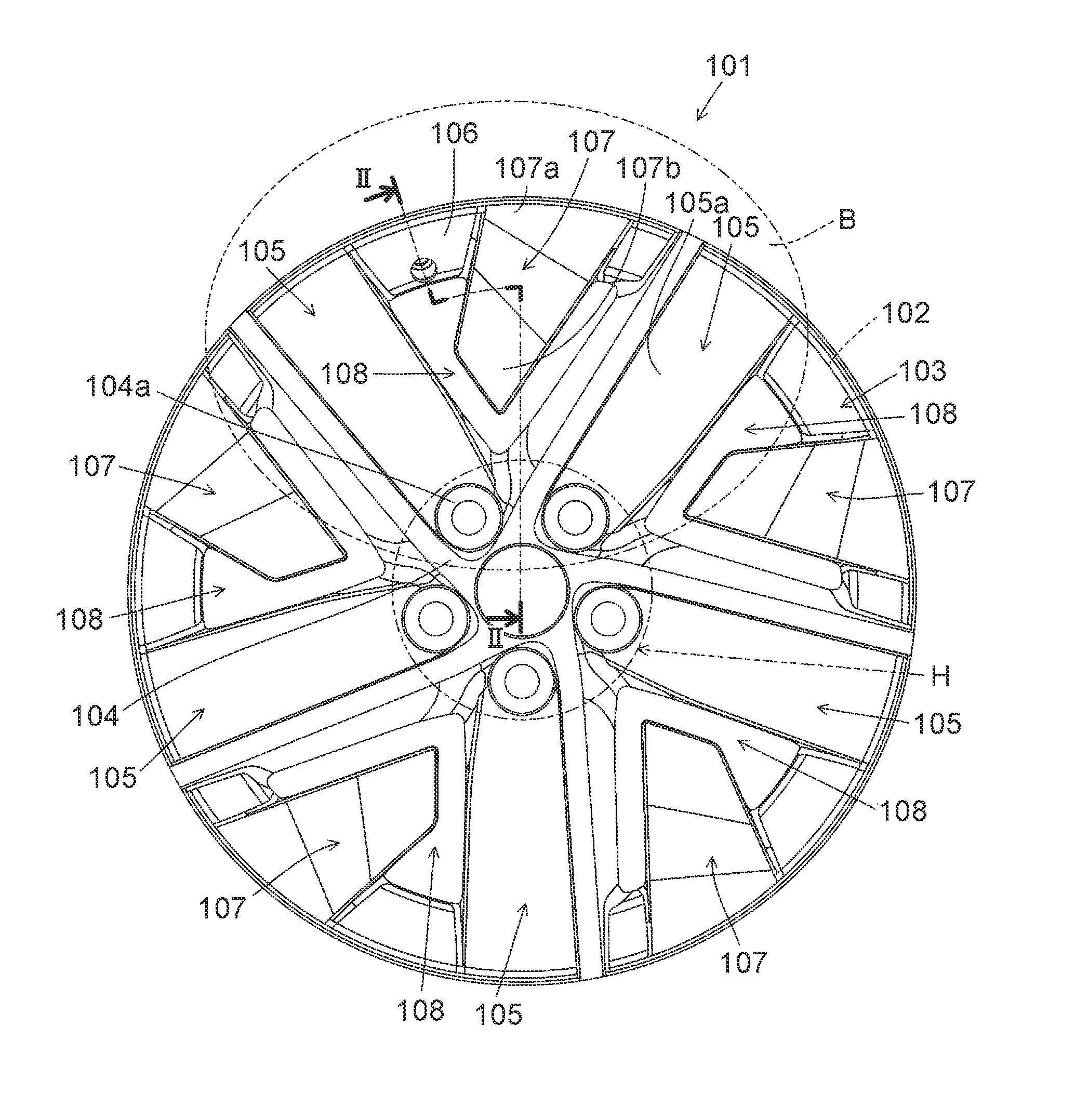

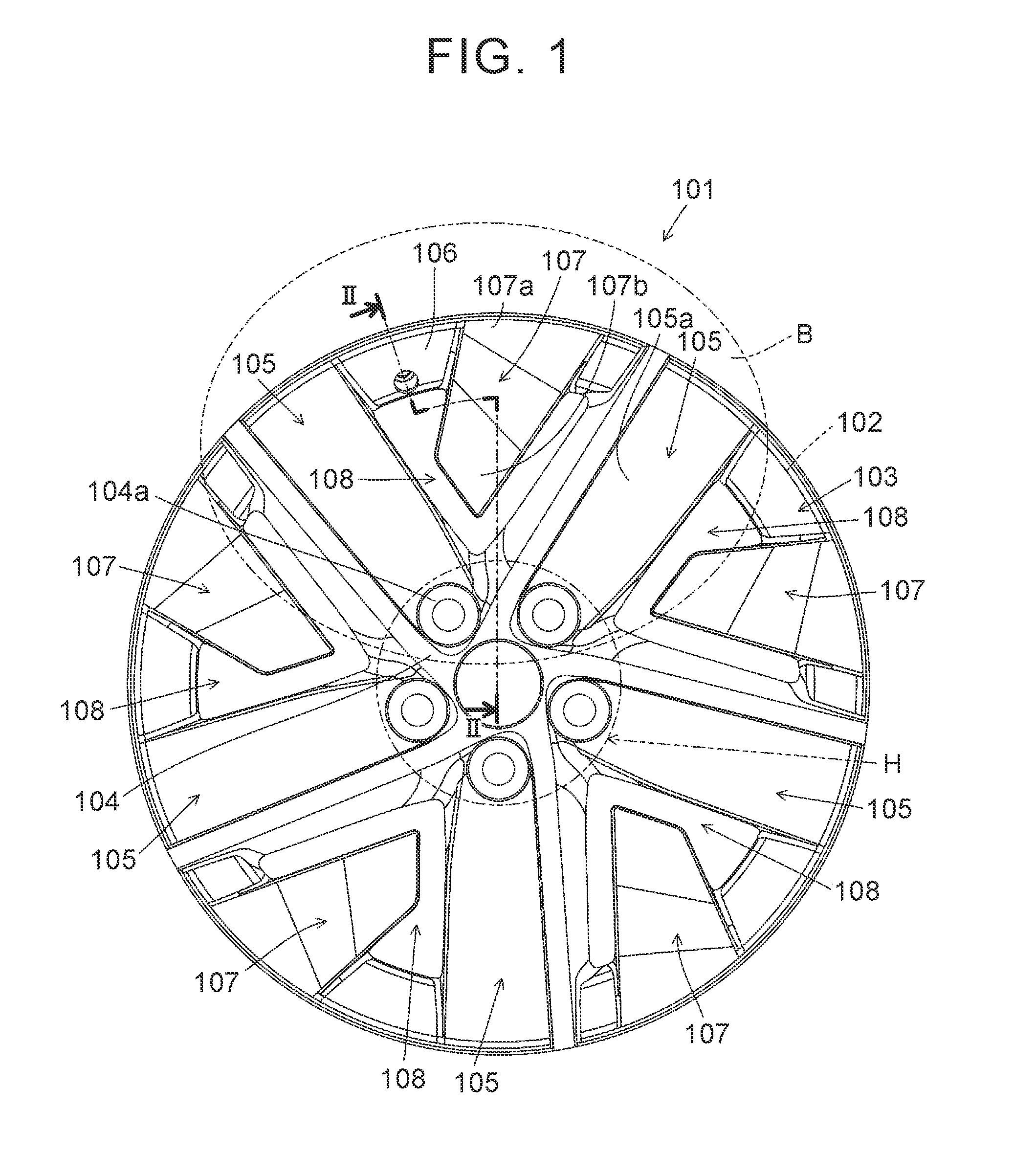

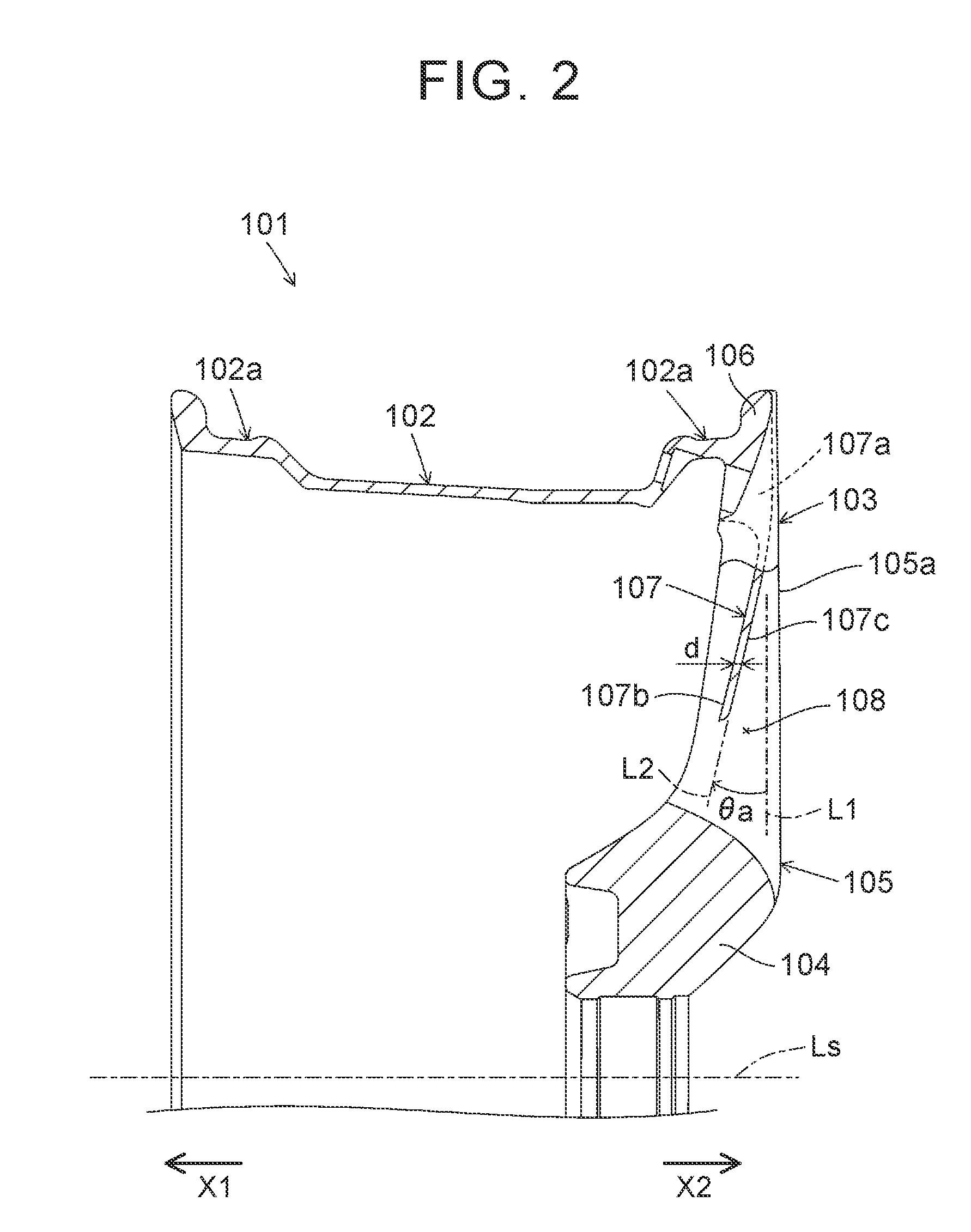

Vehicle wheel

InactiveUS20160361946A1Weight increaseFlow adjustableRimsWheel protectionEngineeringMechanical engineering

A vehicle wheel includes a wheel rim portion; a hub portion; a plurality of spoke portions extending radially from the hub portion to the wheel rim portion and connected to the wheel rim portion; and one or more extending portions each of which is configured to partially cover an opening portion provided between two adjacent spoke portions among the plurality of spoke portions, and to extend from the wheel rim portion toward the hub portion without contacting any of the hub portion and the plurality of spoke portions, the one or more extending portions having a thickness that is smaller than a thickness of each of the plurality of spoke portions in a cylindrical axis direction of the wheel rim portion.

Owner:CENTRAL MOTOR WHEEL CO LTD

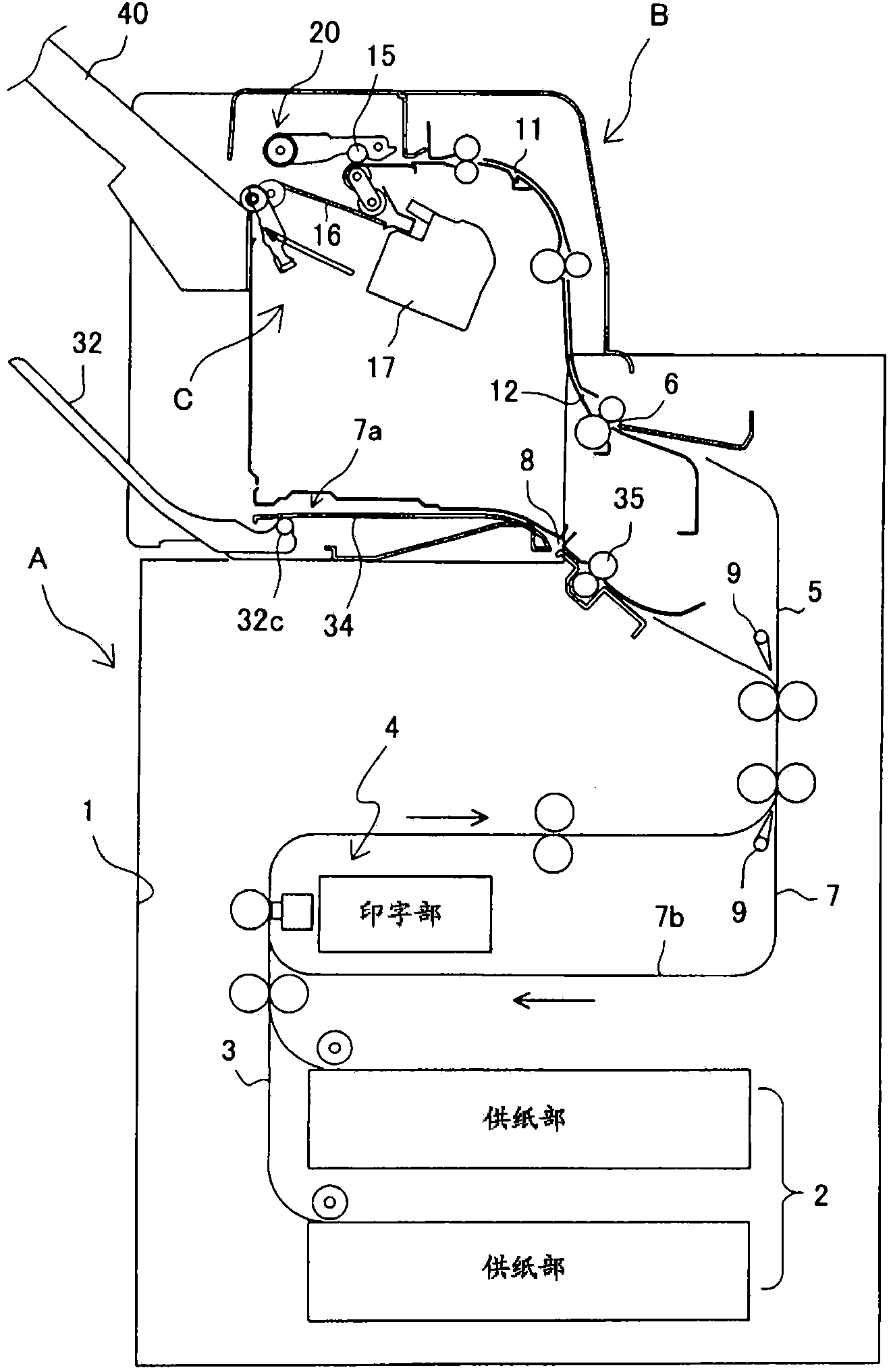

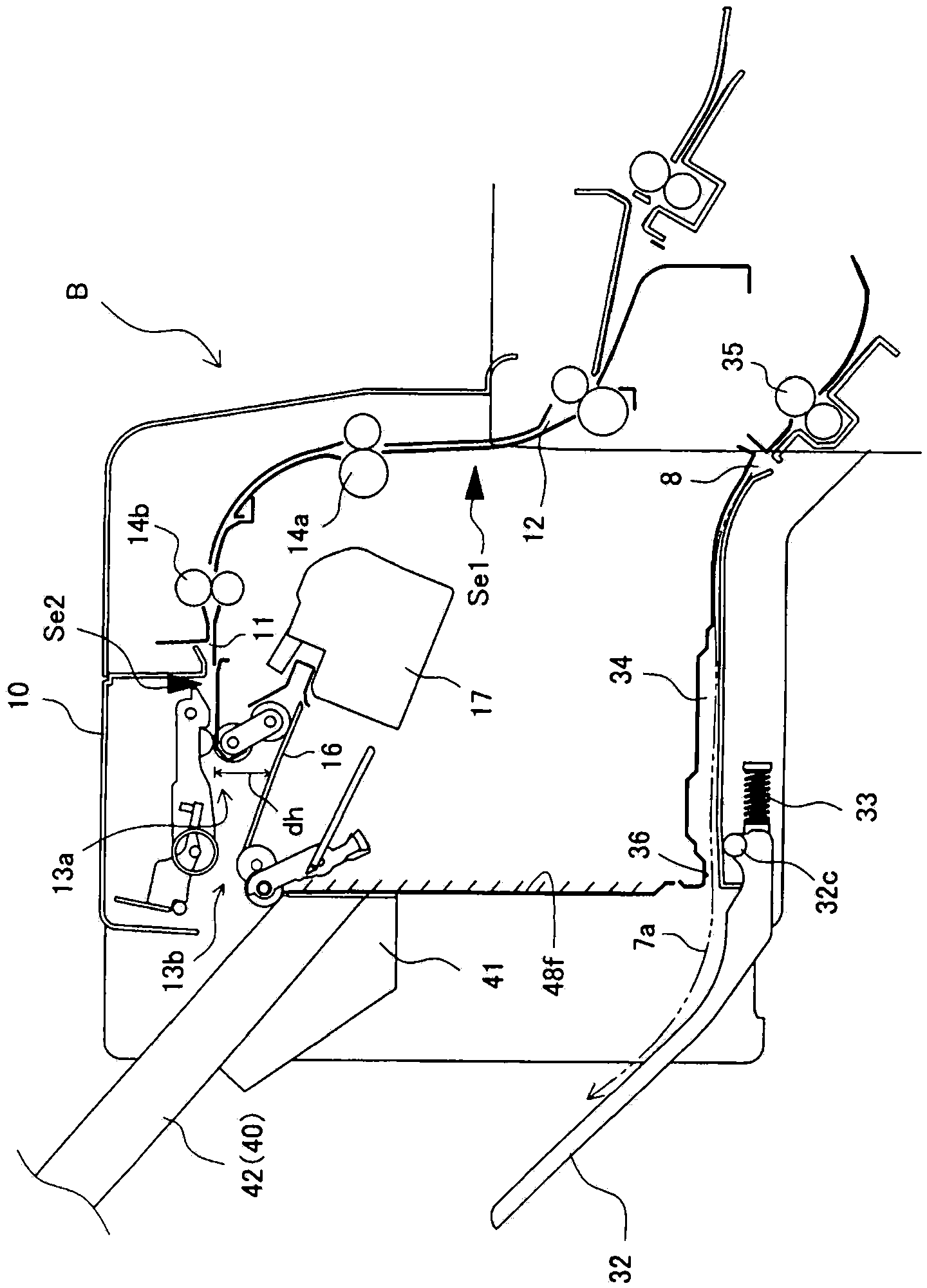

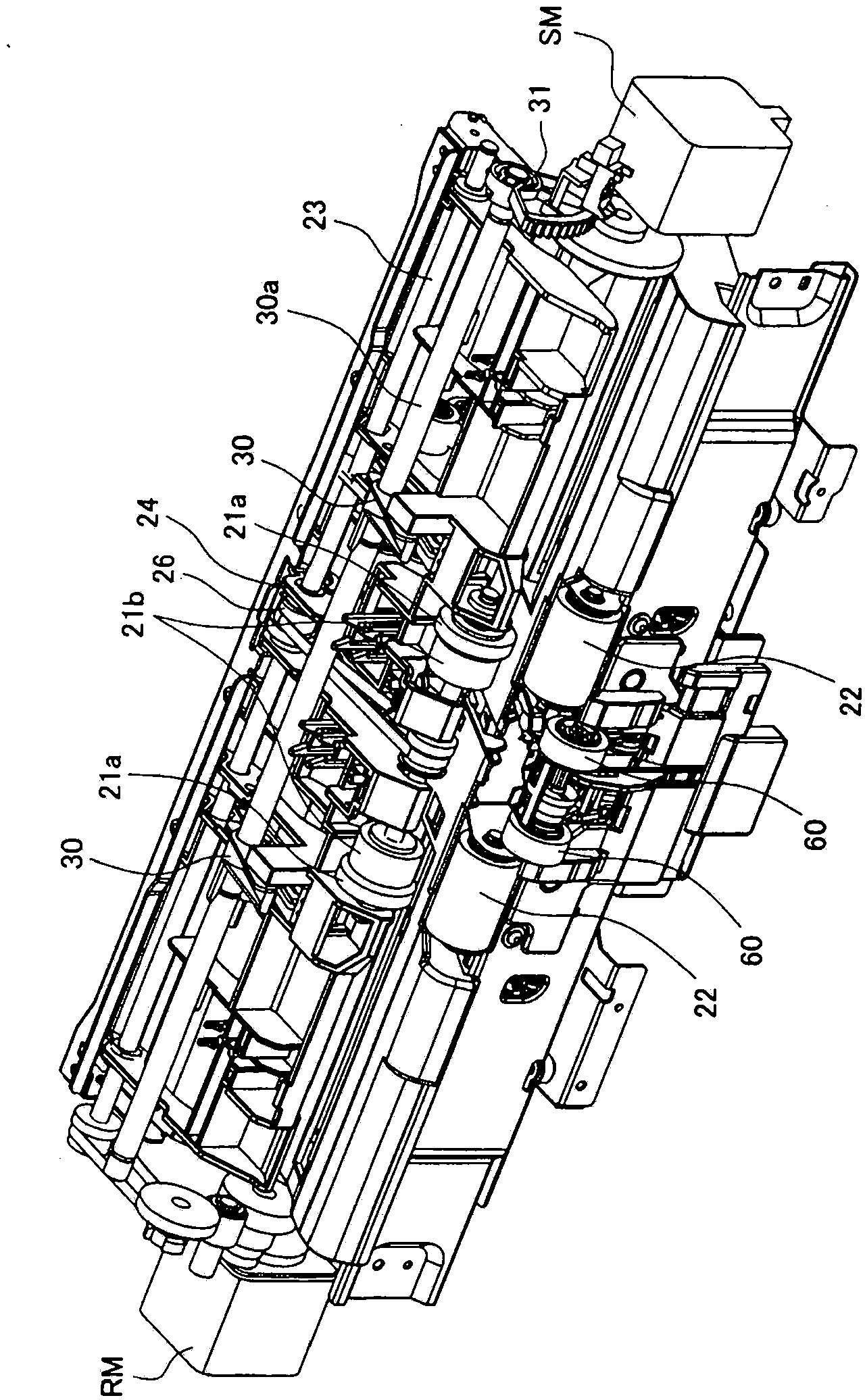

Sheet storing apparatus, post-processing apparatus and image forming system having the same

ActiveCN103662942AWill not prevent moving inReliable detectionFunction indicatorsPile receiversEngineeringBinding process

The invention provides a sheet storing apparatus, a post-processing apparatus and an image forming system having the same. In an apparatus structure having a sheet discharge mode to store sheets at a stack tray from a sheet discharging path and a sheet discharge mode to store binding-processed sheet bundles with collating and stacking, sheet holding means is arranged above a sheet placement face of the stack tray as a sheet pressurization force being variable in two steps, and then, the pressurization force of the sheet holding means is adjusted in two steps in accordance with the sheet discharge mode for storing sheets at the stack tray.

Owner:NISCA KK +1

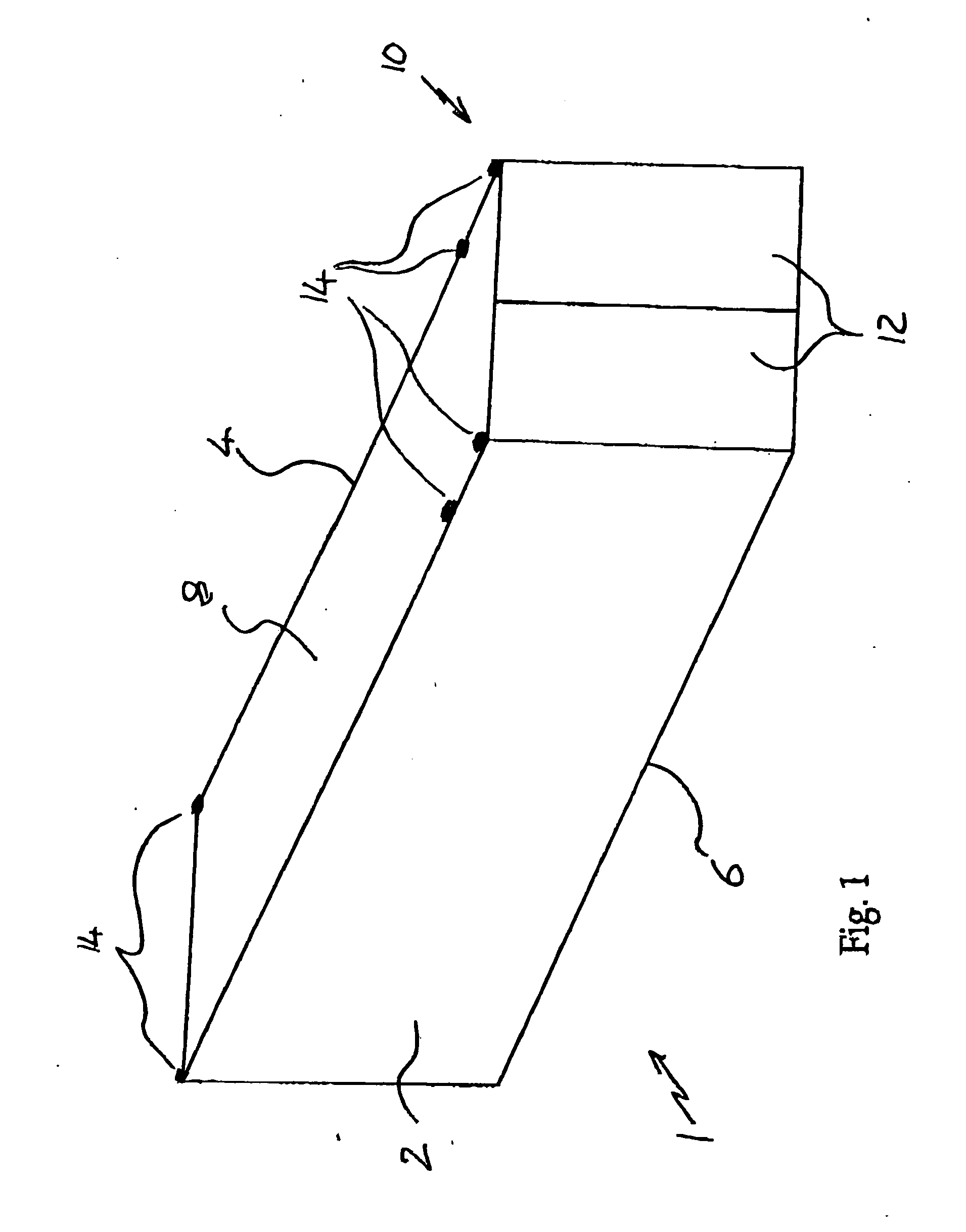

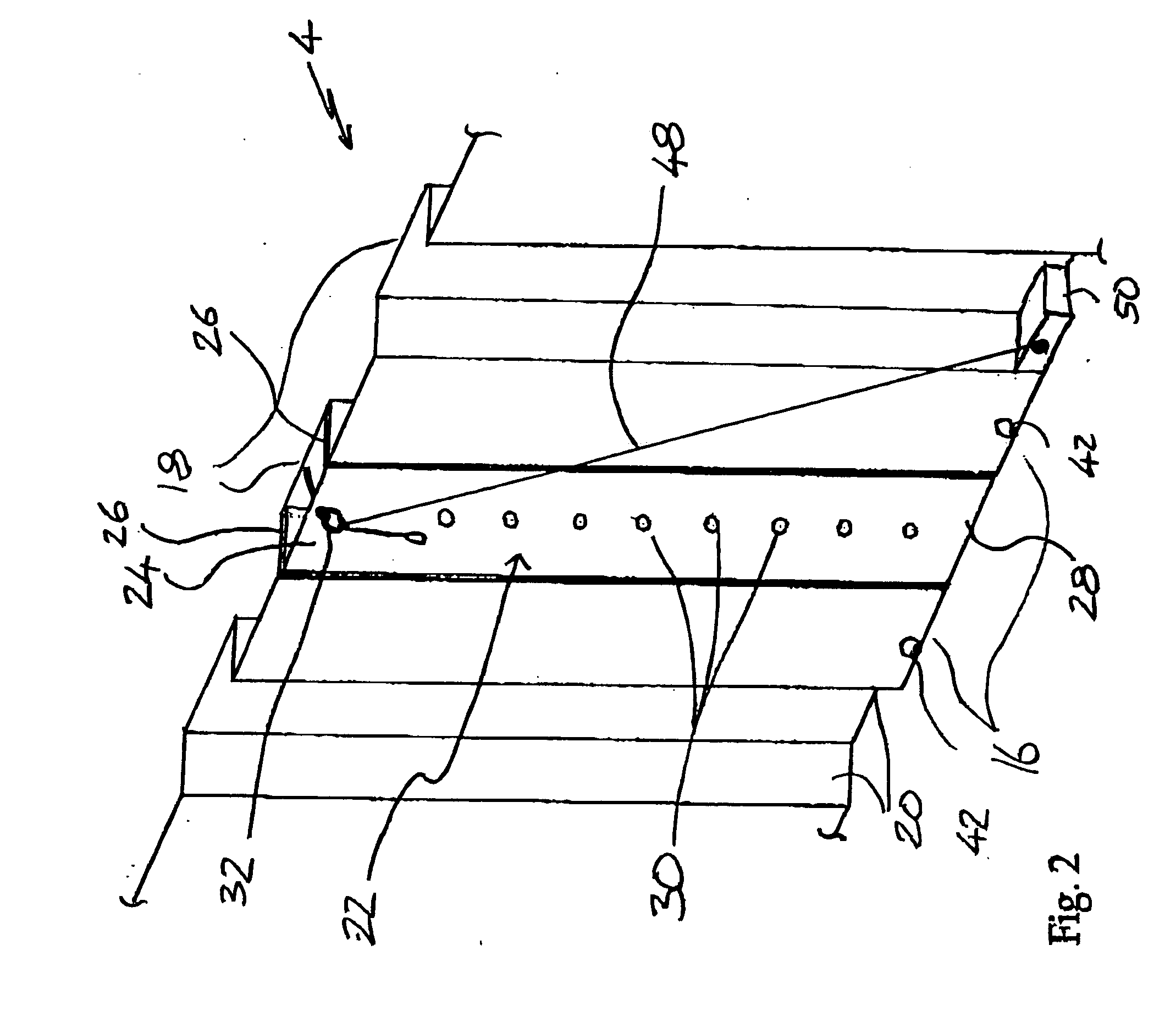

Transport apparatus

InactiveUS20050006261A1Promote sportsEasy loadingPackaging vehiclesContainers for machinesEngineeringMechanical engineering

Owner:ADAPTAINER

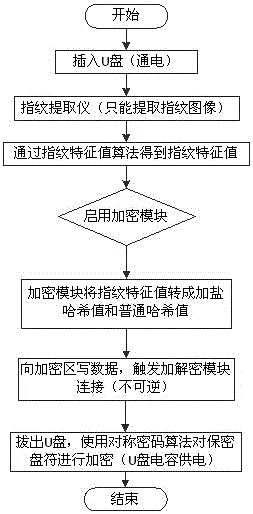

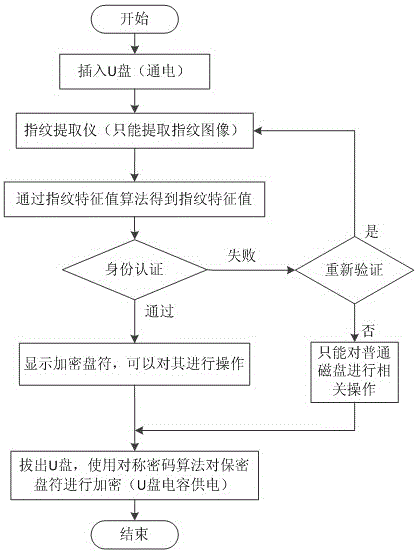

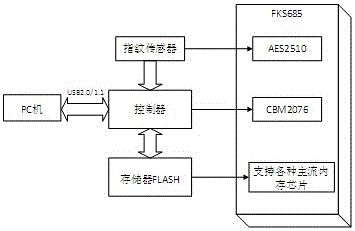

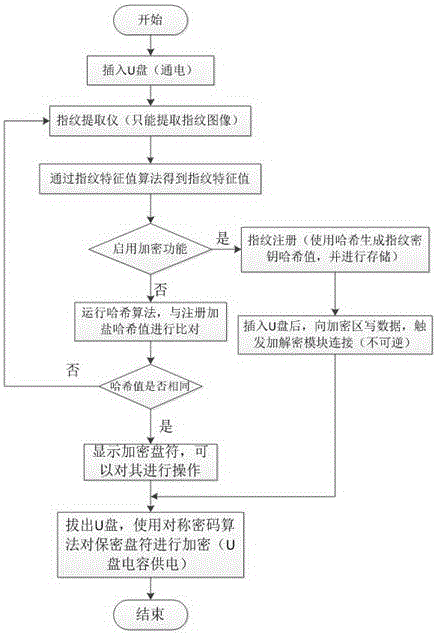

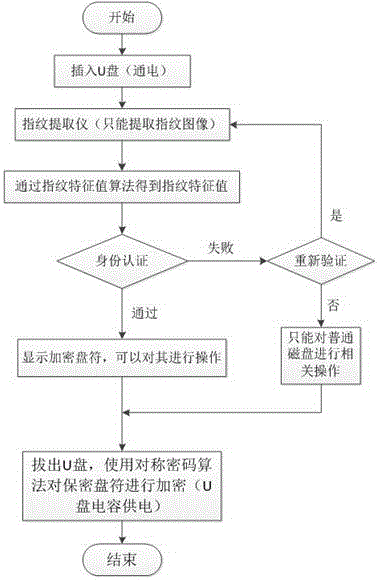

USB flash disk fingerprint authentication encryption method

InactiveCN105809070AReduce occupancyPrevent leakageDigital data protectionInternal/peripheral component protectionInformation quantityUSB

The invention discloses a USB flash disk fingerprint authentication encryption method. According to the method, fingerprint features of a user are extracted; a hash value is converted by adopting a hash algorithm; registering encryption is carried out by adopting a symmetric encryption algorithm; and when a USB flash disk is used next time, conversion is carried by using the extracted fingerprint features, thus realizing the comparison decryption process of the hash value. According to the method, the extracted fingerprint features are used for producing a secret key through adoption of the pseudo-random number generation symmetric encryption algorithm; a file is encrypted and decrypted by using the secrete key; in this way, only a fingerprint feature value needs to be stored; the occupancy of a storage space is recued; an information quantity is reduced; the possibility of exposing the effective information is reduced; the security of a system is improved; and the secrete quantity of the symmetric encryption algorithm reaches 128 bits, therefore, the encryption performance is high, the security is high, and the information is effectively prevented from being leaked.

Owner:GUIZHOU UNIV

Flip top cap with contamination protection

A cap is provided for a laboratory vessel. The cap includes a lid that can be rotated relative to the laboratory vessel from a closed position to an open position. The lid includes at least one tab dimensioned and disposed for receiving manual digital pressure for opening and / or closing the lid. The tab is in an offset position to prevent a thumb or forefinger from passing over and in contact with the opening to the vessel. Additionally, the lid includes a shield inwardly from the tab for further preventing contact between a finger and the open top of the vessel.

Owner:CORNING INC

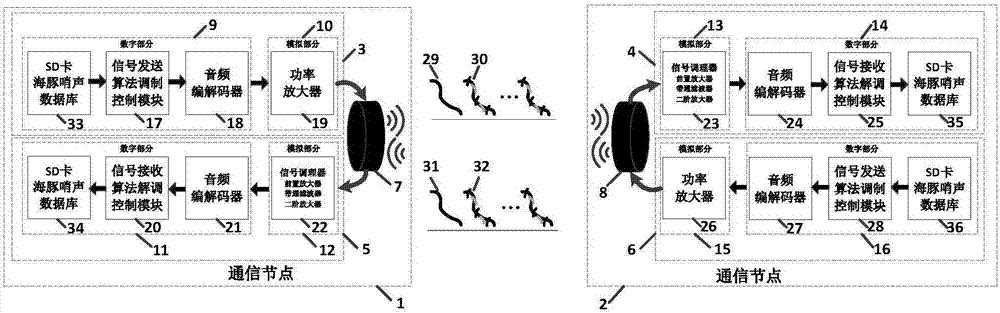

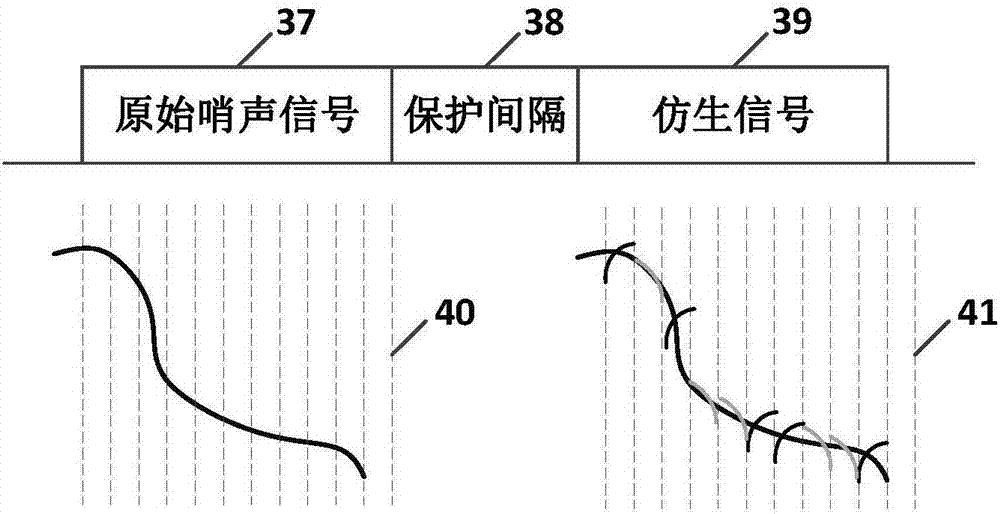

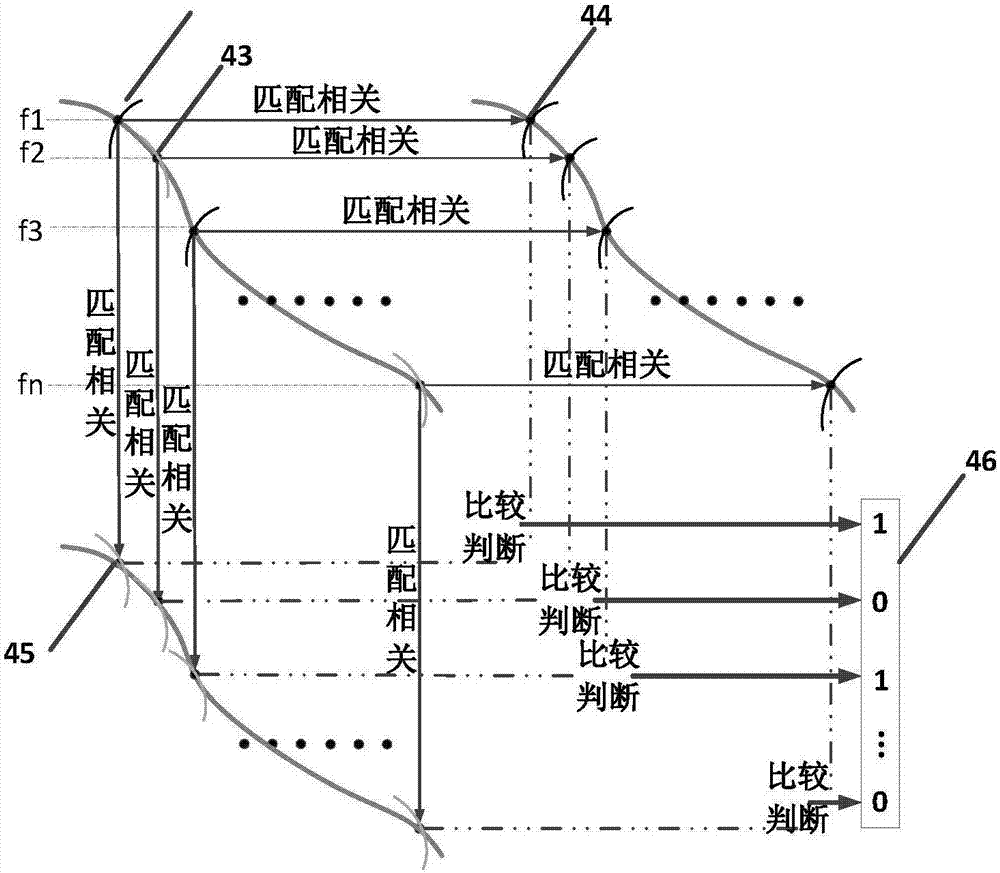

Camouflage hidden underwater communication device for simulating dolphin whistle

ActiveCN106899357AStrong concealmentLong communication distanceSonic/ultrasonic/infrasonic transmissionCamouflageTransducer

The invention provides a camouflage hidden underwater communication device for simulating dolphin whistle. The camouflage hidden underwater communication device comprises at least two communication nodes; each communication node is composed of a signal sending module, a signal receiving module and a receiving and transmitting integrated transducer; and the signal sending module and the signal receiving module are composed of multiple modules, such as SD cards having a dolphin whistle database. The camouflage hidden underwater communication method for simulating dolphin whistle provided by the invention is simple and high in reliability; the camouflage and the security of communication information are ensured; furthermore, requirements of an underwater hidden communication system can be satisfies; simultaneously, the device in the technical scheme of the invention is convenient to realize; compared with the formed underwater communication device, the device provided by the invention has the characteristics of being small in volume and convenient to carry; and the camouflage hidden underwater communication device provided by the invention is mainly applied to underwater acoustic communication.

Owner:HARBIN ENG UNIV

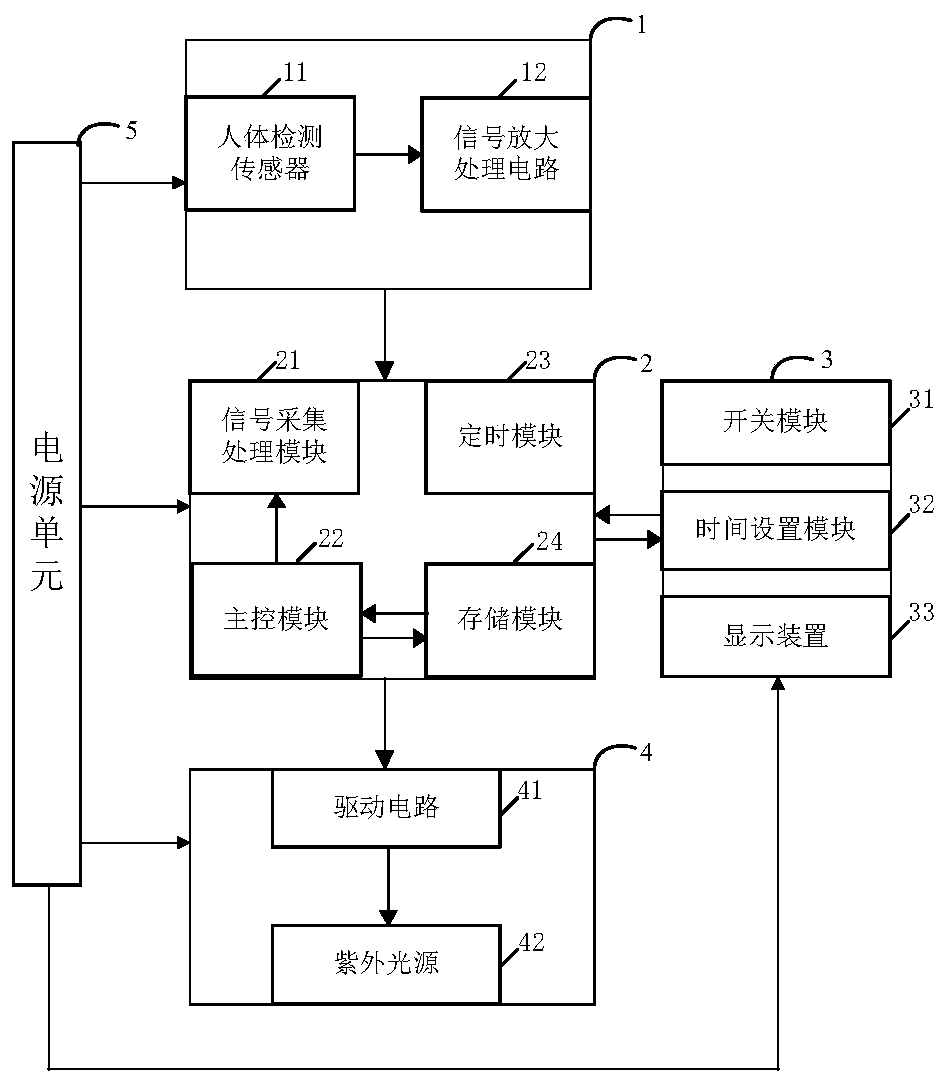

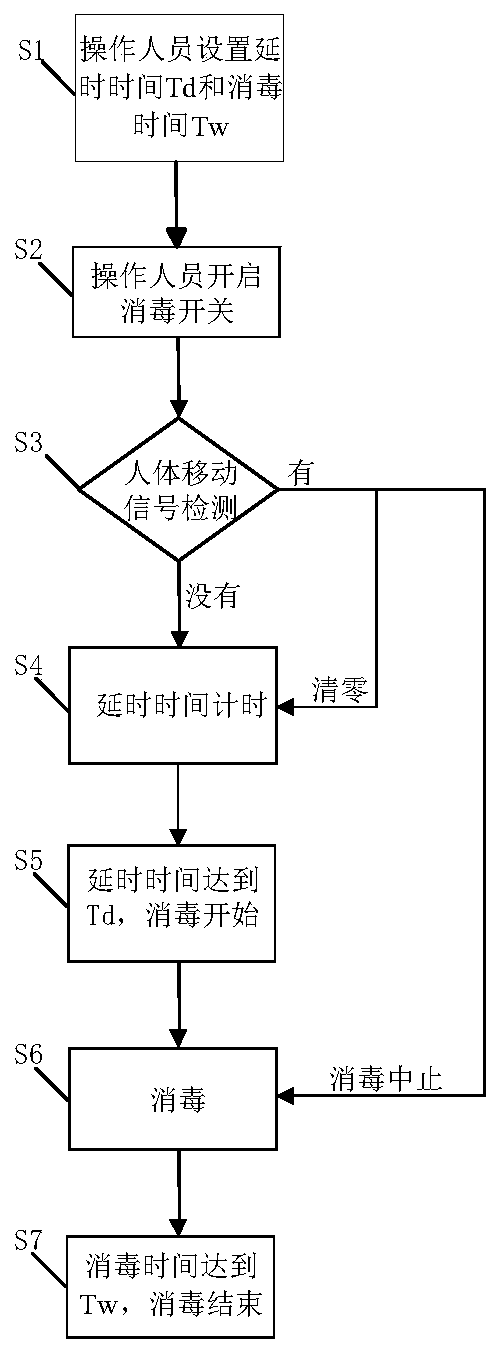

Intelligent ultraviolet ray disinfection lamp and working method thereof

PendingCN111330037AReduce the likelihood of exposureReduce health risksLavatory sanitoryRadiationUltraviolet lightsUv disinfection

The invention discloses an intelligent ultraviolet ray disinfection lamp and a working method thereof. The intelligent ultraviolet ray disinfection lamp comprises a human body detection unit, a control unit, a user interface unit, an ultraviolet light-emitting unit and a power unit. After an operator switches on the ultraviolet ray disinfection lamp, the ultraviolet ray disinfection lamp can be lit after definite time of detection that no personal movement signals exist; during switching on of the ultraviolet ray disinfection lamp, if a person enters by accident, the ultraviolet ray disinfection lamp can be immediately switched off, and disinfection work is stopped. According to the intelligent ultraviolet ray disinfection lamp and the working method thereof disclosed by the invention, thepossibility that a human body is illuminated by the ultraviolet ray disinfection lamp can be eliminated or greatly reduced, and the health rick of the operator and the person entering by accident canbe reduced.

Owner:HANGZHOU XUANTONG ELECTRONICS CO LTD

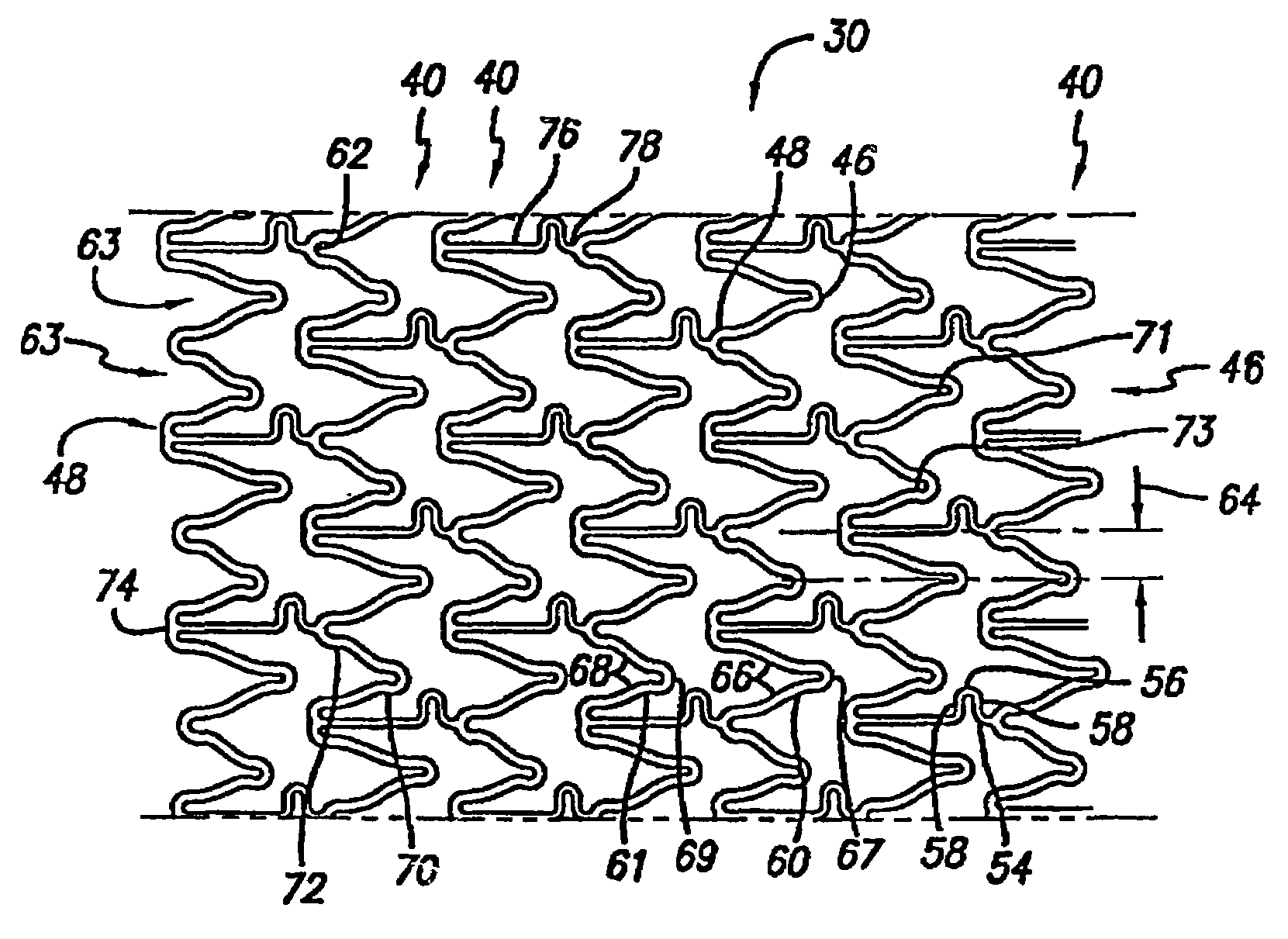

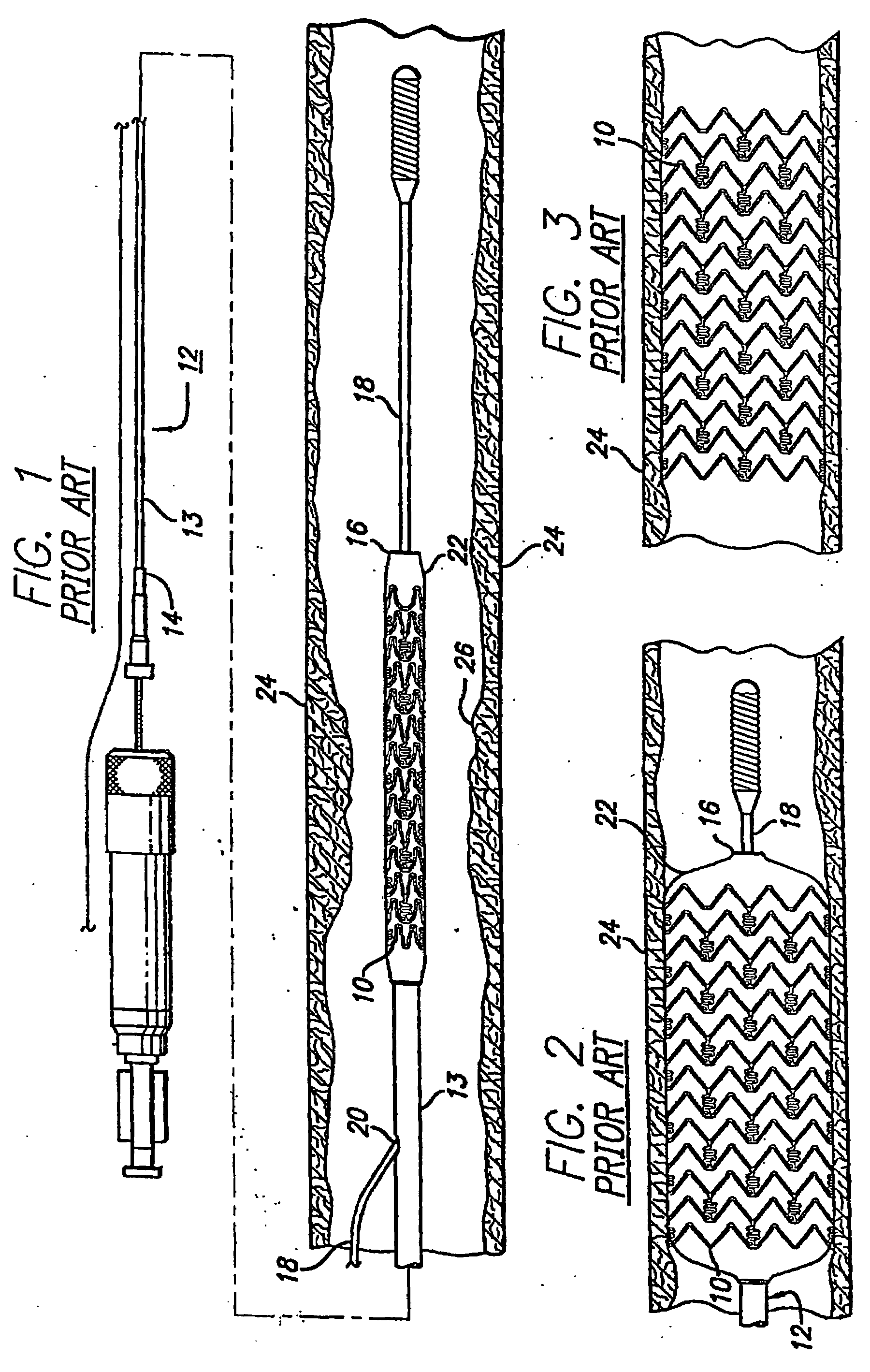

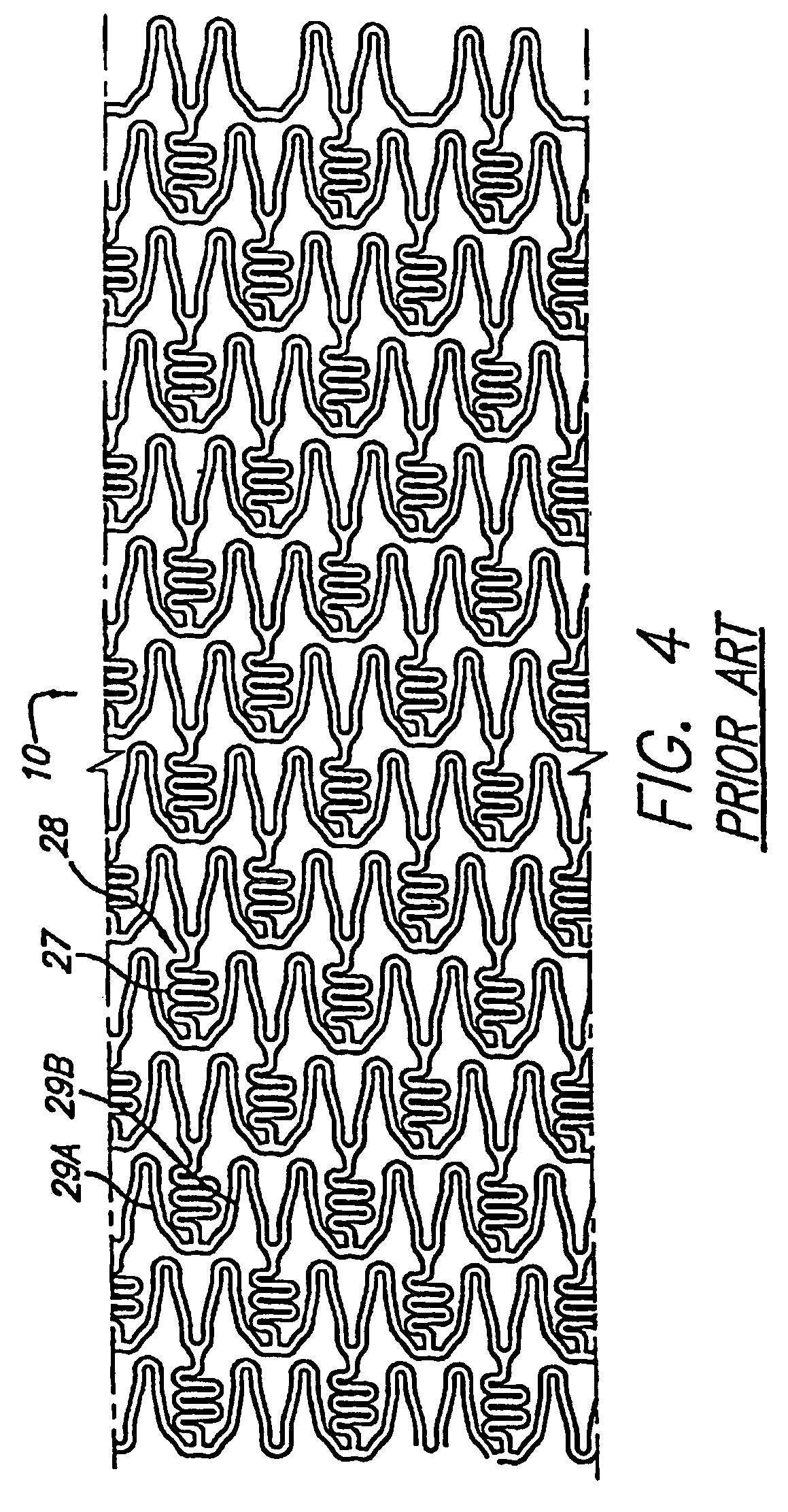

Intravascular stent

InactiveUS20080086194A1Reduce the likelihood of exposureImprove aspectStentsBlood vesselsIntravascular stentDrug coating

A stent design reduces the likelihood of contact among structural members when the stent diameter is reduced before insertion into the body. In one approach, an undulating link has a J-shaped profile or has an angled portion on one side at the peak of the link, in order to reduce contact during crimping. The stent may also include structural features that improve such aspects as flexibility, the coatibility of a drug coating onto the stent, flare reduction, stent retention within the body and / or reduction of the minimum diameter of the stent during crimping.

Owner:ABBOTT CARDIOVASCULAR

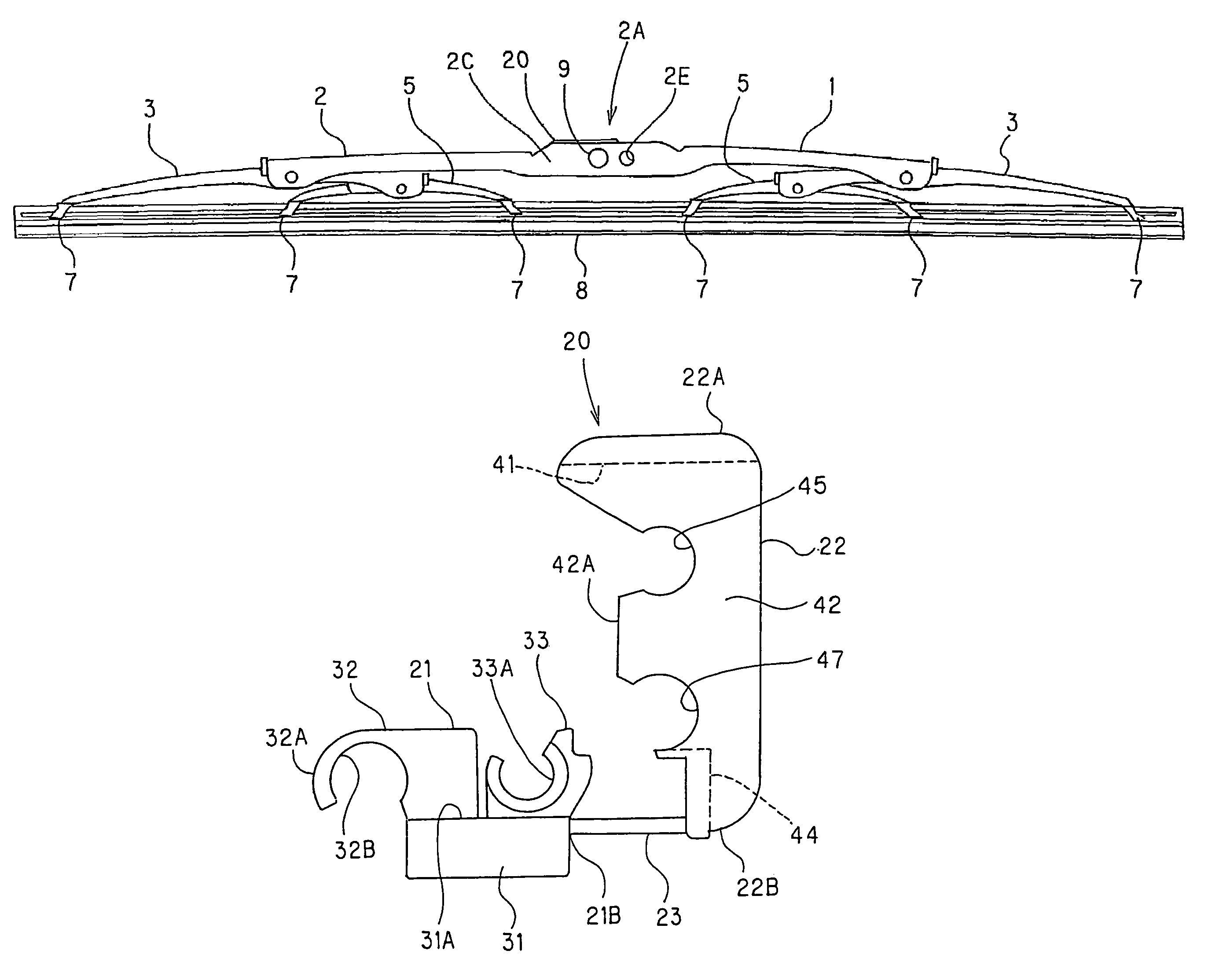

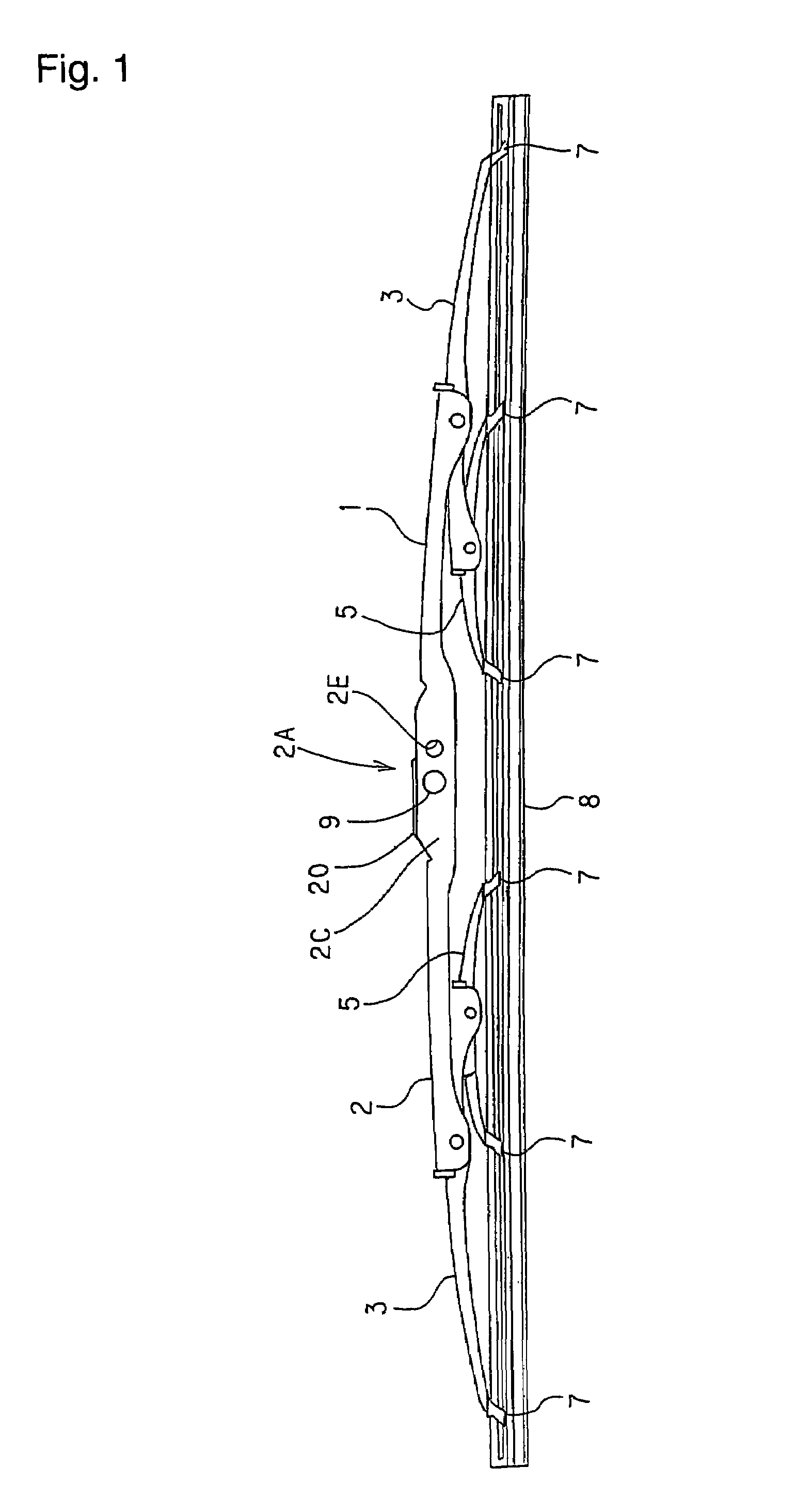

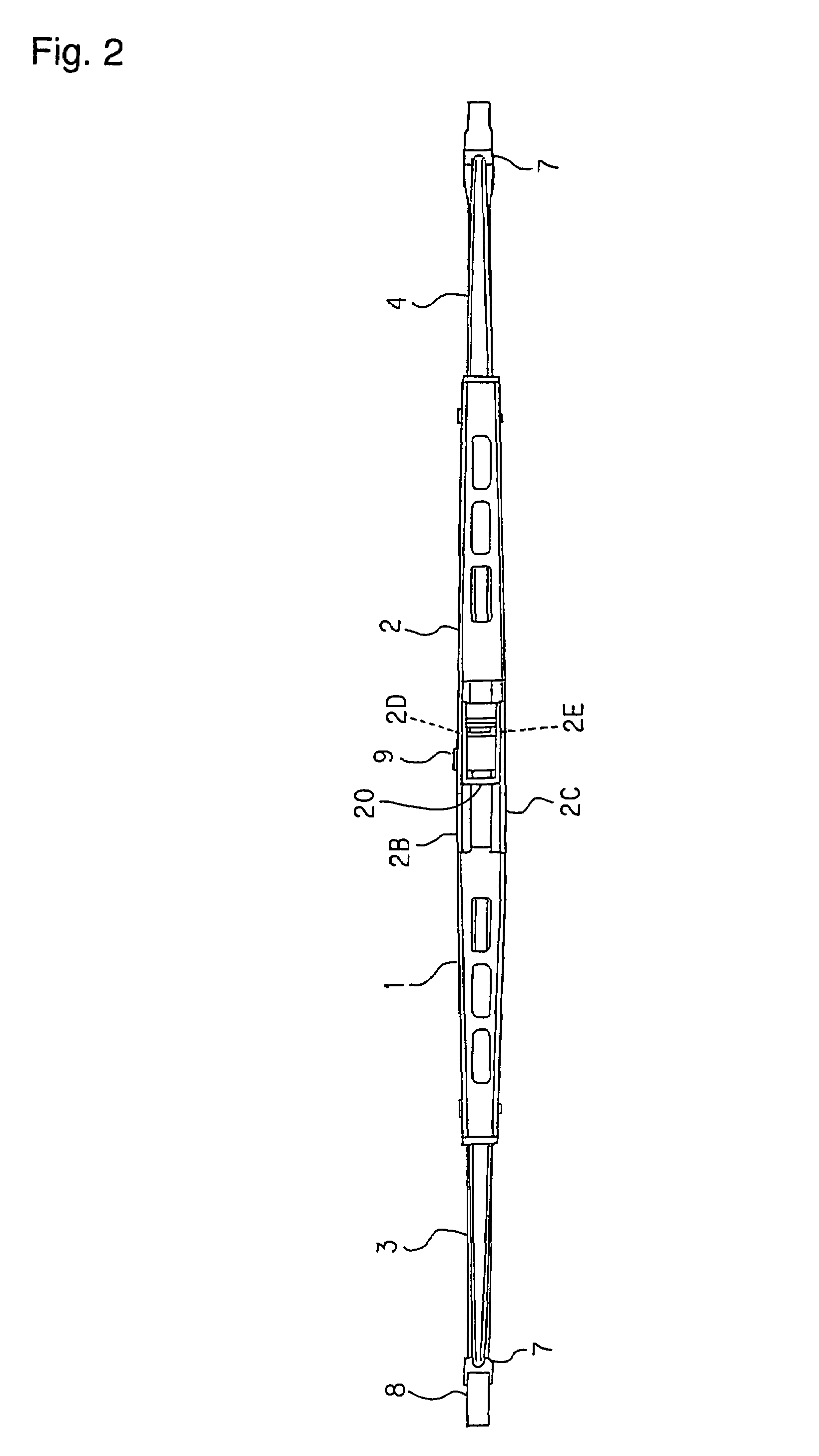

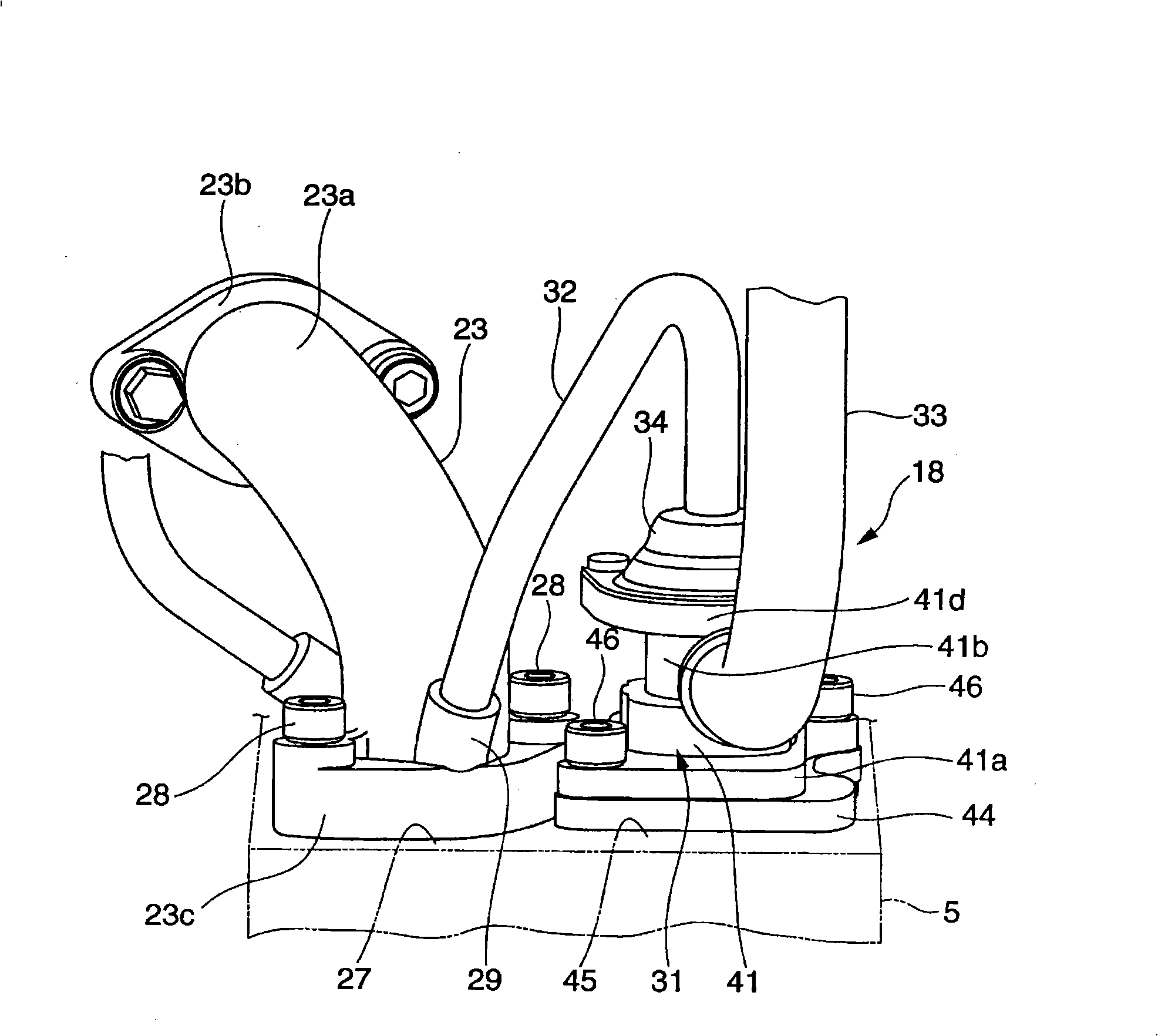

Connector for securing wiper blade to wiper arm and wiper blade assembly

InactiveUS7669277B2Reduce vibrationGood adhesionWindow cleanersVehicle cleaningEngineeringMechanical engineering

A connector (20) for securing a wiper blade to a wiper arm includes a base member (21) including a forward upper portion (32) and a rearward upper portion (33); a locking member (22) for holding either a U-hook portion (12) or a side pin (11) mounted to the base member (21); and a flexible connecting member (23) connecting the locking member (22) to the base member (21). To attach the connector (20) to the side pin (11), the connector is rotated toward the side pin (11) from the opposite side of the side pin (11) so that the side pin (11) fits into a recess (33A) of the rearward upper portion (33). The side pin (11) also fits into the recesses (47 and 48) of the locking member (22) so that the side pin (11) is held between the base member (21) and the locking member (22). The connector enables the firm securing of the wiper blade to the wiper arm so as to restrict vibrations between the wiper blade and the wiper arm.

Owner:DENSO WIPER SYST INC

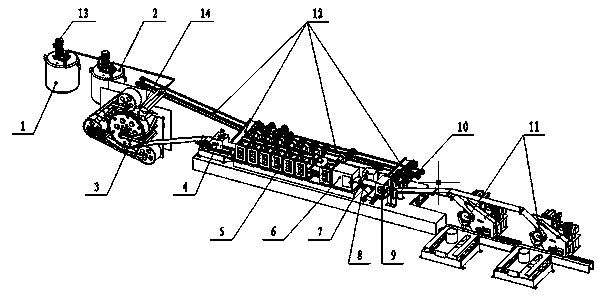

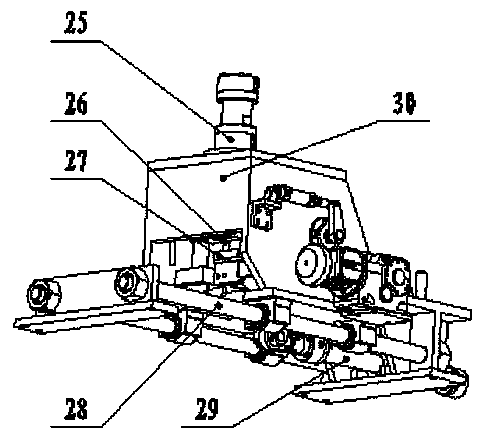

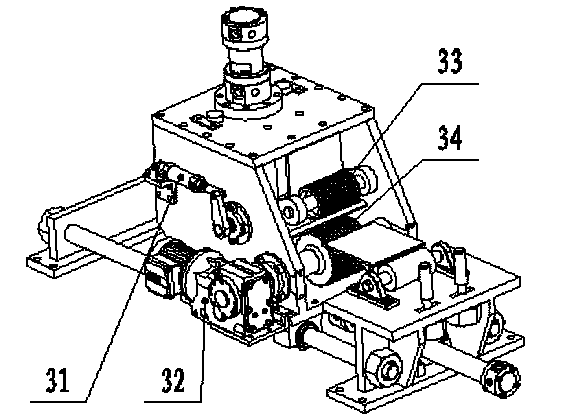

Continuous casting and rolling system for lead belt production

InactiveCN103769418AImprove consistencyImprove performanceMetal rolling arrangementsAlloyContinuous rolling

A continuous casting and rolling system for lead belt production is used for automatically producing a lead belt required by manufacturing a lead-acid storage battery plate gate. The system comprises a smelting furnace, a maintaining furnace, a lead belt continuous casting machine, an inlet shear, a lead belt continuous rolling device, a cleaning device, longitudinal shear, a scrap shear, an outlet shear, a belt guide machine, a coiling device and a conveying belt. The lead belt continuous casting machine is arranged behind the smelting furnace and the maintaining furnace, the inlet shear is arranged between the lead belt continuous casting machine and the lead belt continuous rolling device, the cleaning device, the longitudinal shear, the outlet shear, the belt guide machine and the coiling device are sequentially arranged on the outlet side of the lead belt continuous rolling device, the conveying belt is respectively arranged on one side of the inlet shear, one side of the longitudinal shear and one side of outlet shear, and the scrap shear is arranged below the longitudinal shear. The matching ratio of alloy required by producing different plate gates is adjusted through the smelting furnace, the thickness of a finished lead belt is adjusted through different rolling ratio combinations of the lead belt continuous rolling device, and the width of the finished lead belt is adjusted through combination of different blades of the longitudinal shear and a space bush. The requirements for high efficiency, multispecies, energy saving and environment protection can be met.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

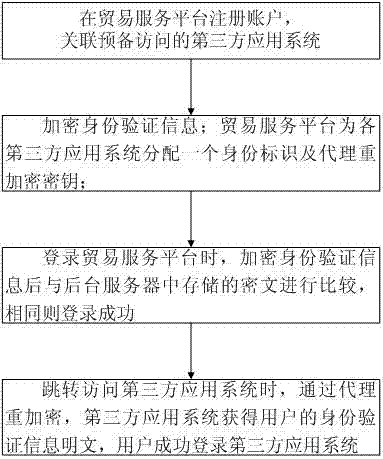

Trade service platform logon method

InactiveCN106878327AEnsure safetyReduce the likelihood of exposureKey distribution for secure communicationUser identity/authority verificationThird partyPlaintext

The invention discloses a trade service platform logon method. The method comprises the following steps: 1) a user registers an account on a trade service platform and associates third-party application systems to be accessed; 2) identity verification information is encrypted, and the trade service platform allocates one identity to each third-party application system and generates a proxy re-encryption secret key; 3) when the user logs on the trade service platform, the encrypted identity identification information is compared with a ciphertext stored in a background server, and when the encrypted identity identification information is same with the ciphertext, logon is successful; and 4) when the user jumps to access the third-party application system, through proxy re-encryption, the third-party application system obtains an identity identification information plaintext of the user, and the user logs in the third-party application system successfully. Based on the proxy re-encryption technology, the plurality of third-party application systems can share identity identification information with the trade service platform, and the user can log onto the plurality of third-party application systems with only one account and passwords being born in mind, thereby realizing an effect of "one login, multiple-party authentication".

Owner:江苏金易达供应链管理有限公司

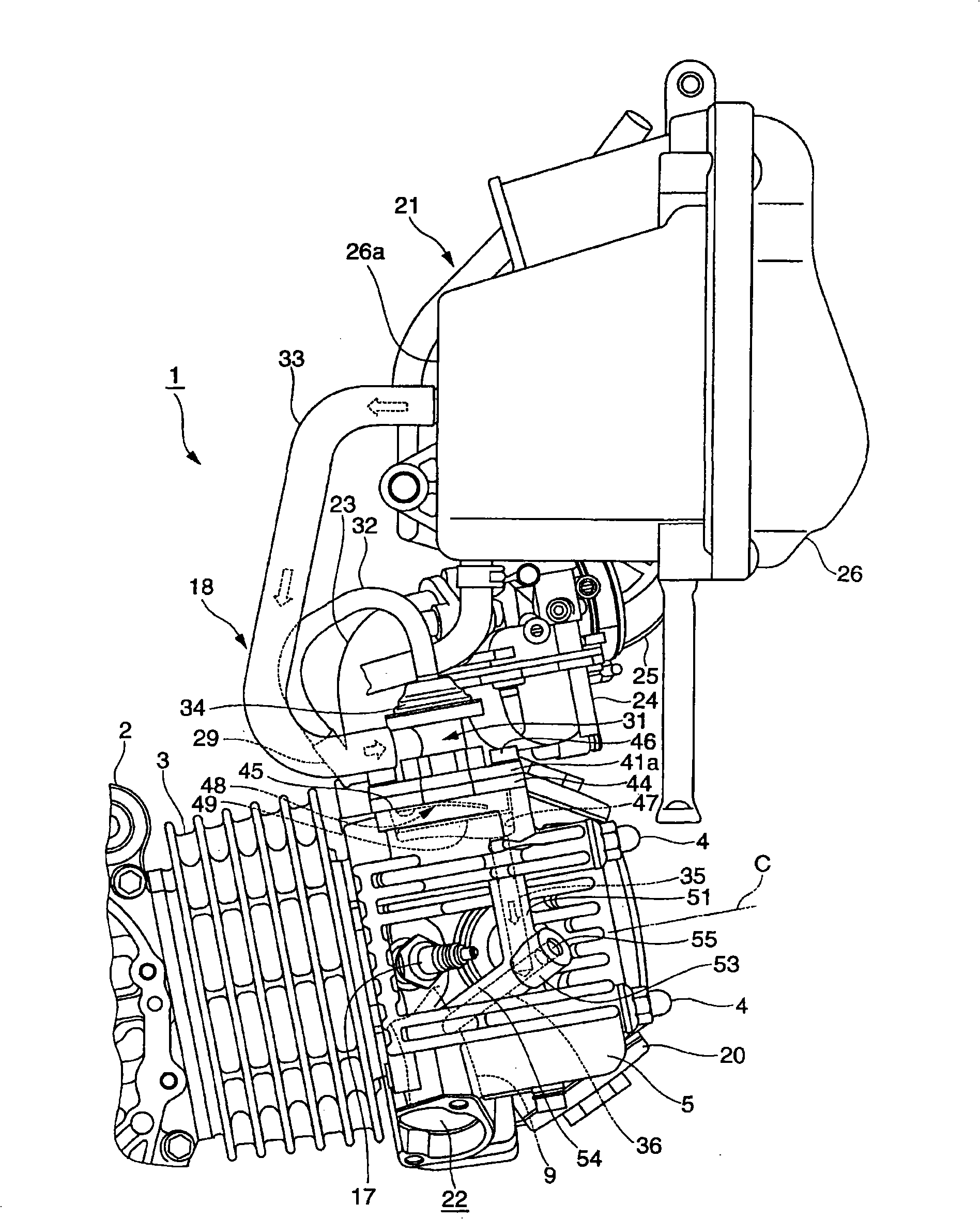

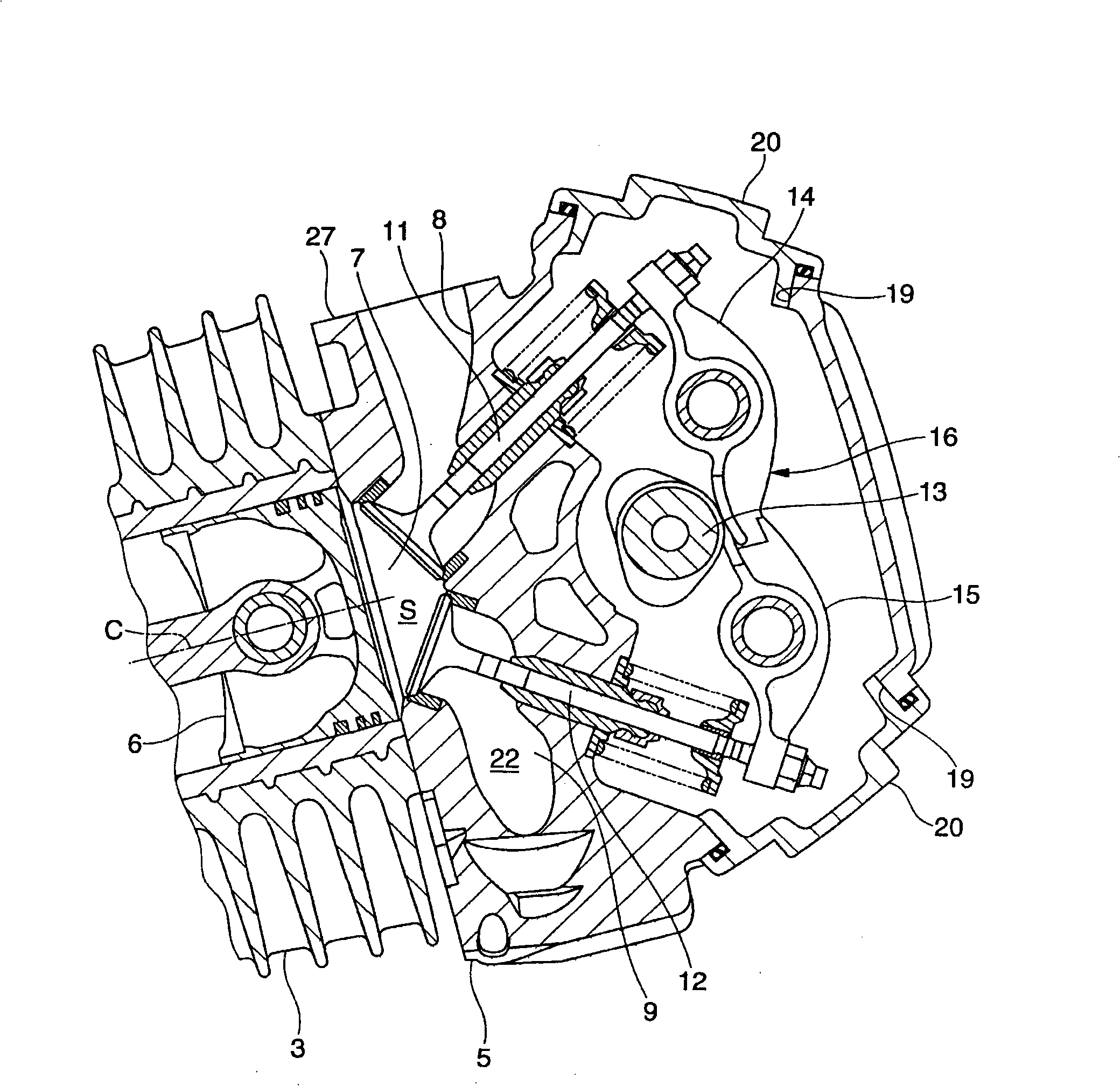

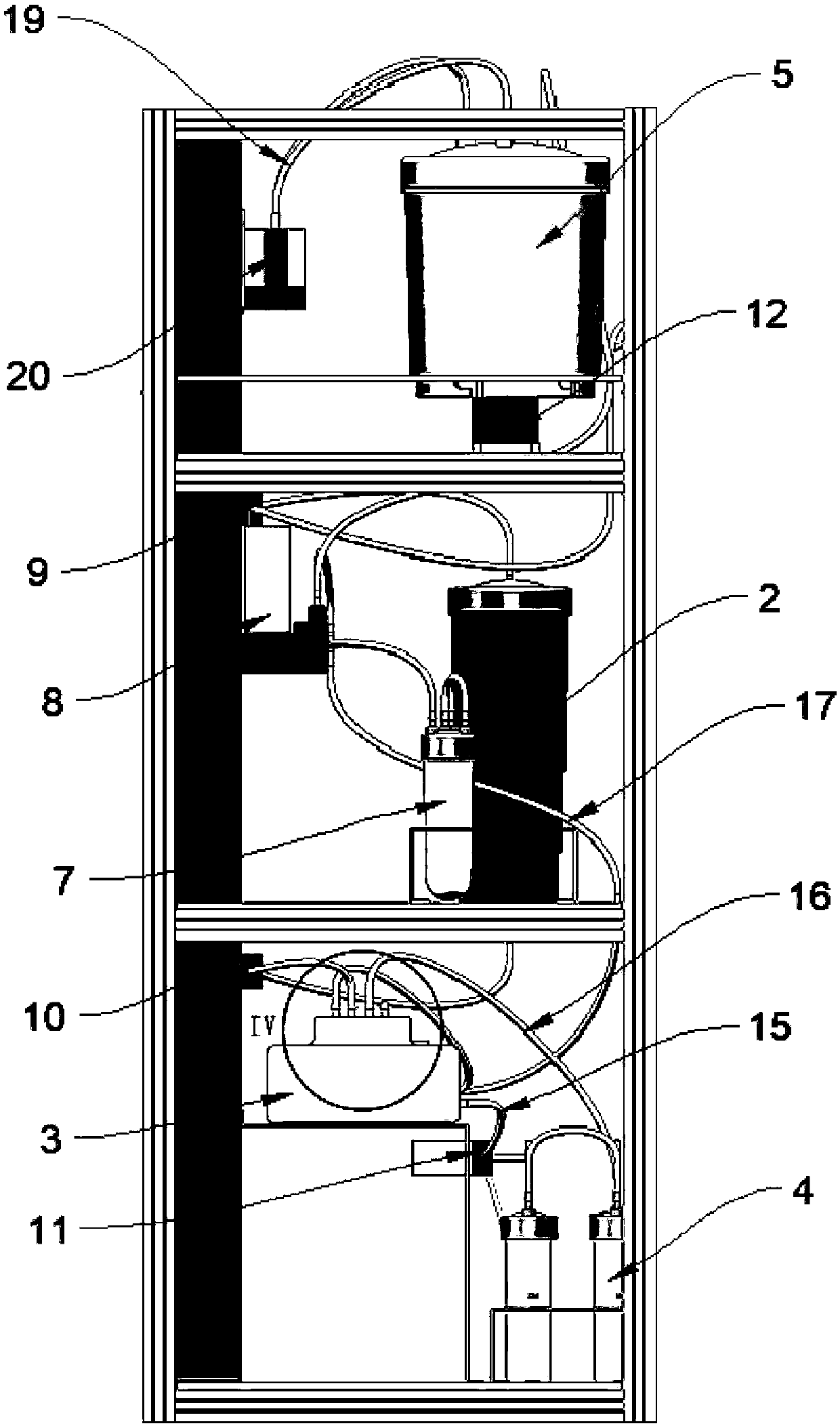

Engine and motorcycle engine

ActiveCN101353976AReduce in quantityReduce manufacturing costInternal combustion piston enginesExhaust apparatusManufacturing cost reductionAir volume

This invention provides an engine and a motorbike engine, wherein the number of pipe for secondary air supply device is reduced to reduce the manufacturing cost. The engine comprises a cylinder body (3), a cylinder cover (5), and a secondary air passage connected to an exhaust passage (22). An air volume control valve (31) and a spring valve (48) are provided in the secondary air passage. The air volume control valve (31) and a one-way valve (48) are provided on the cylinder cover (5). A section of the secondary air passage on the downstream side of the air volume control valve (31) and the one-way valve (48) is formed by passage holes (35, 36) drilled in the cylinder cover (5).

Owner:YAMAHA MOTOR CO LTD

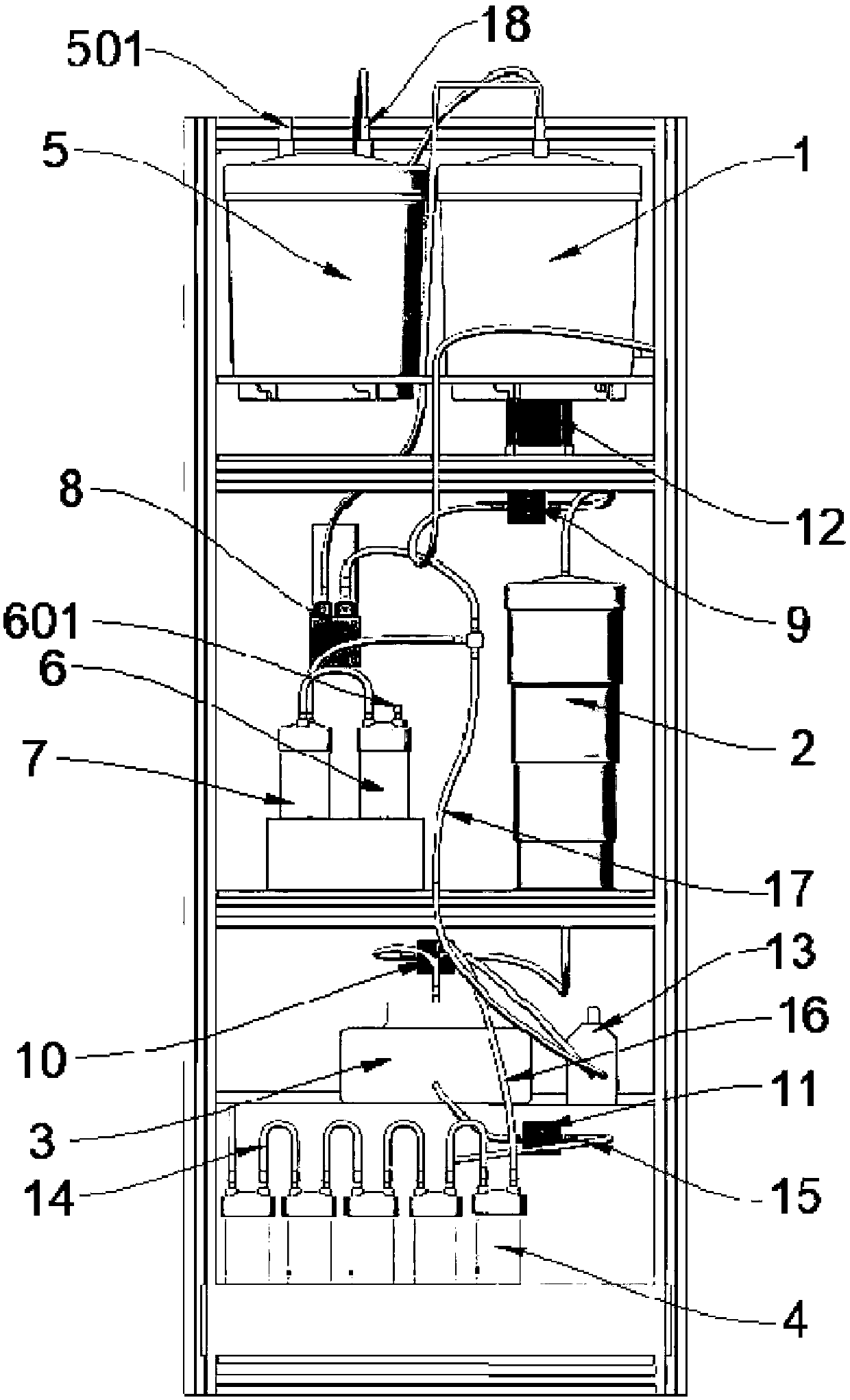

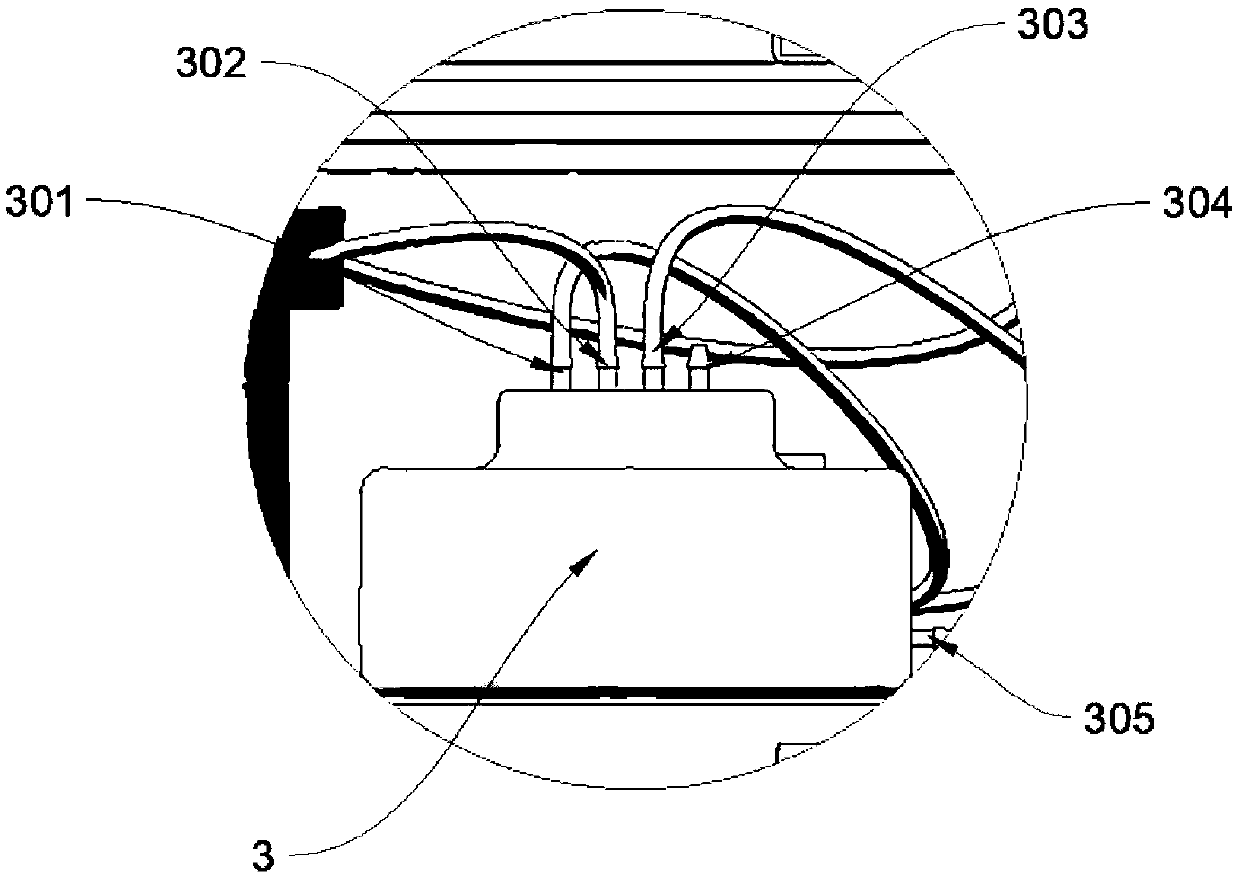

Intestinal microorganism separating device and separating method

PendingCN109517727AImprove working environmentMitigate adverse effects on physical and mental healthBioreactor/fermenter combinationsBiological substance pretreatmentsIntestinal microorganismsLiquid storage tank

The invention provides an intestinal microorganism separating device and separating method. The separating device comprises a feeding unit, a filtering unit and a split charging unit which are sequentially connected from top to bottom; the feeding unit comprises a raw material tank, and a stirring device is fixed to the bottom of the raw material tank; the split charging unit comprises a bacterialliquid storage tank; the separating device comprises a vacuumizing device which is connected with a negative pressure connector of the bacterial liquid storage tank; the separating device further comprises a deodorization unit, and the deodorization unit is connected with a bad smell outlet of the raw material tank and the vacuumizing tank. The feeding unit, the multi-stage filtering unit and thesplit charging unit in the separating device are vertically distributed, and by additionally arranging a vacuum pump, an excrement raw material can flow to the next stage under action of gravity andnegative pressure, so that the phenomenon of blocking in a filtering process is greatly reduced.

Owner:SHANGHAI BIOTECAN PHARMA +1

Article comprising a microneedle

ActiveUS20160151616A1Effectively and consistently insertSimpler and robustMicroneedlesMedical devicesMicro-needleMechanical engineering

Owner:KINDEVA DRUG DELIVERY LP

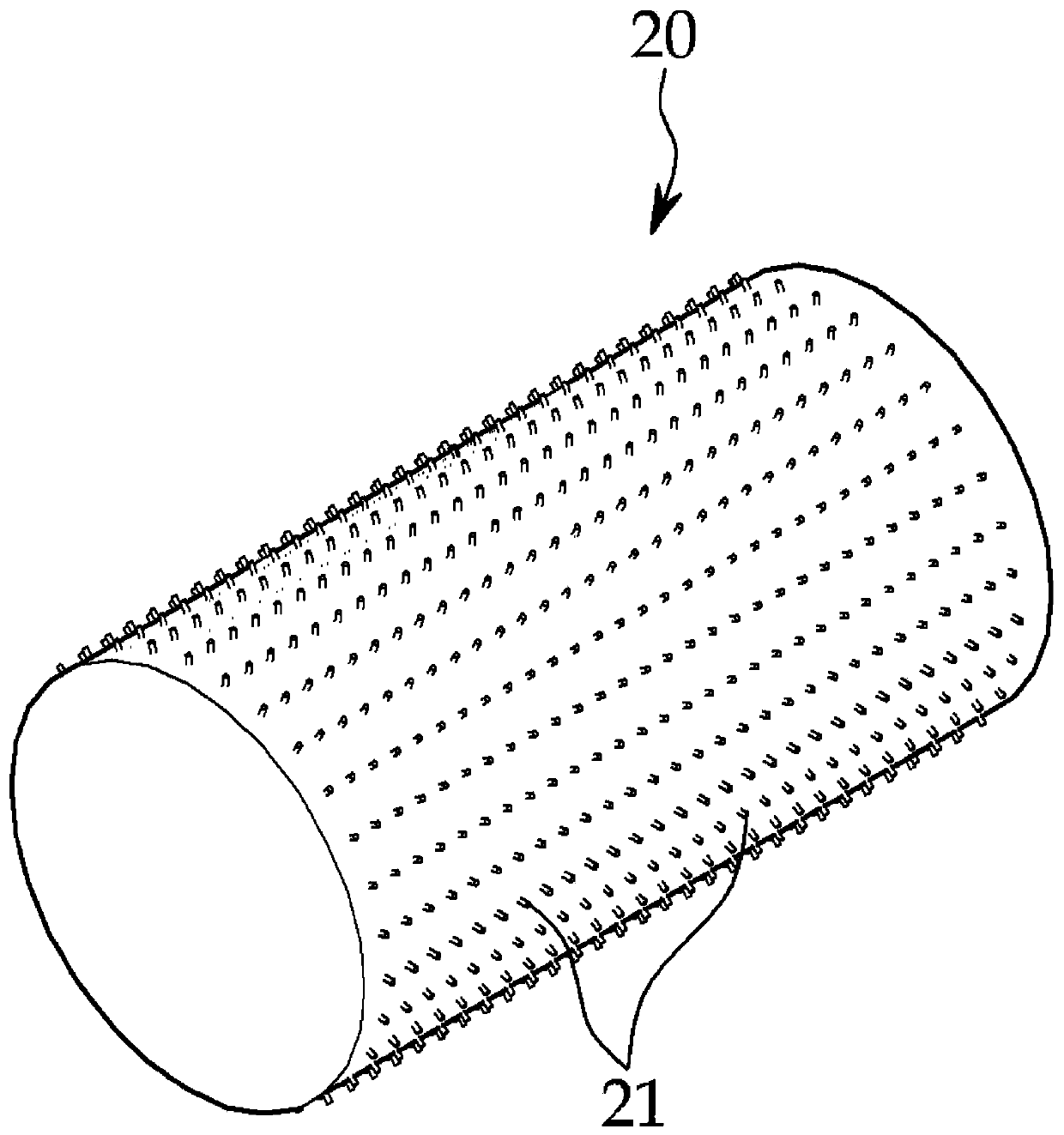

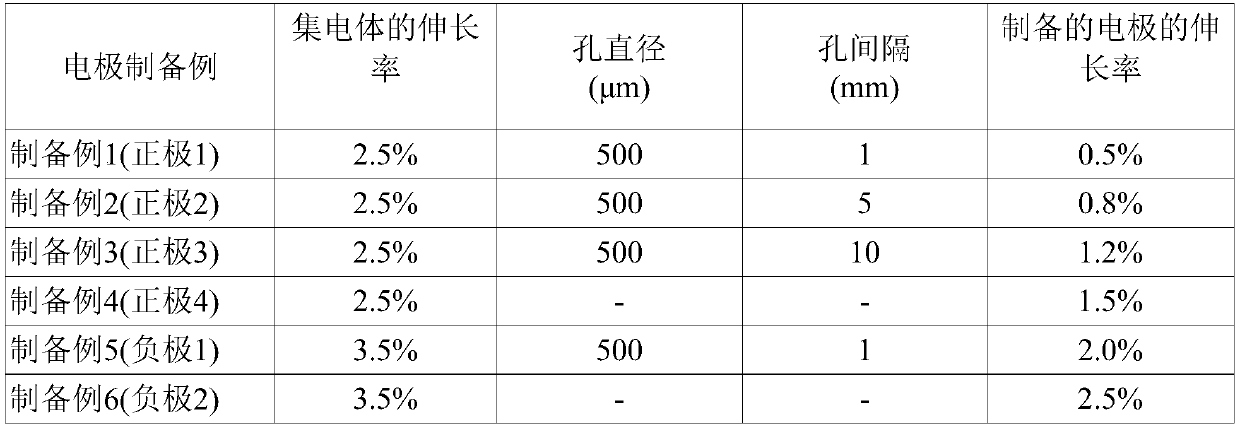

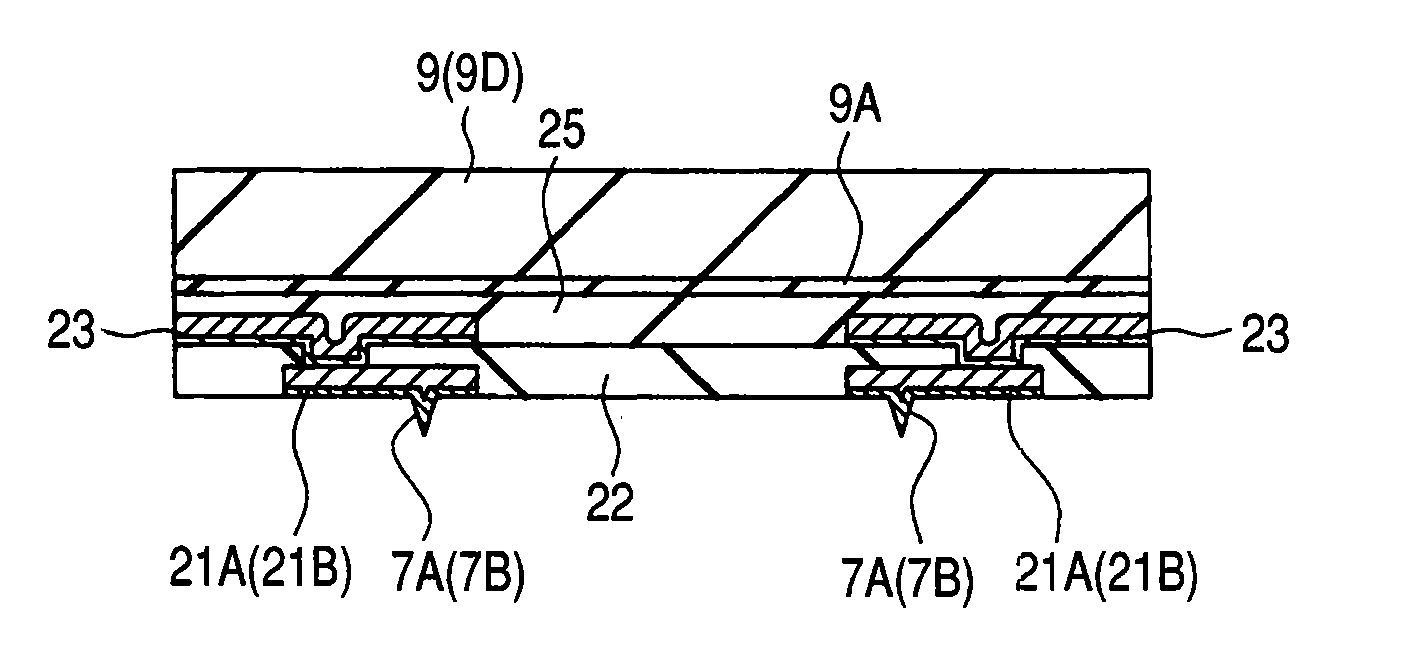

Electrode for secondary battery with improved safety, manufacturing method thereof, and secondary battery including same electrode

ActiveCN110392948ALow elongationLower fireElectrode rolling/calenderingElectrode carriers/collectorsBattery cellMaterials science

The present invention relates to an electrode for a secondary battery with improved safety, a manufacturing method thereof, and a secondary battery including the electrode. The electrode for a secondary battery according to the present invention is characterized by having a plurality of holes formed to penetrate a current collector and an electrode active material layer in the thickness direction.Such an electrode can prevent or minimize the occurrence of ignition or explosion of the battery even when a needle-shaped body such as a nail infiltrates or penetrates into a battery, thereby improving the safety of the battery.

Owner:LG ENERGY SOLUTION LTD

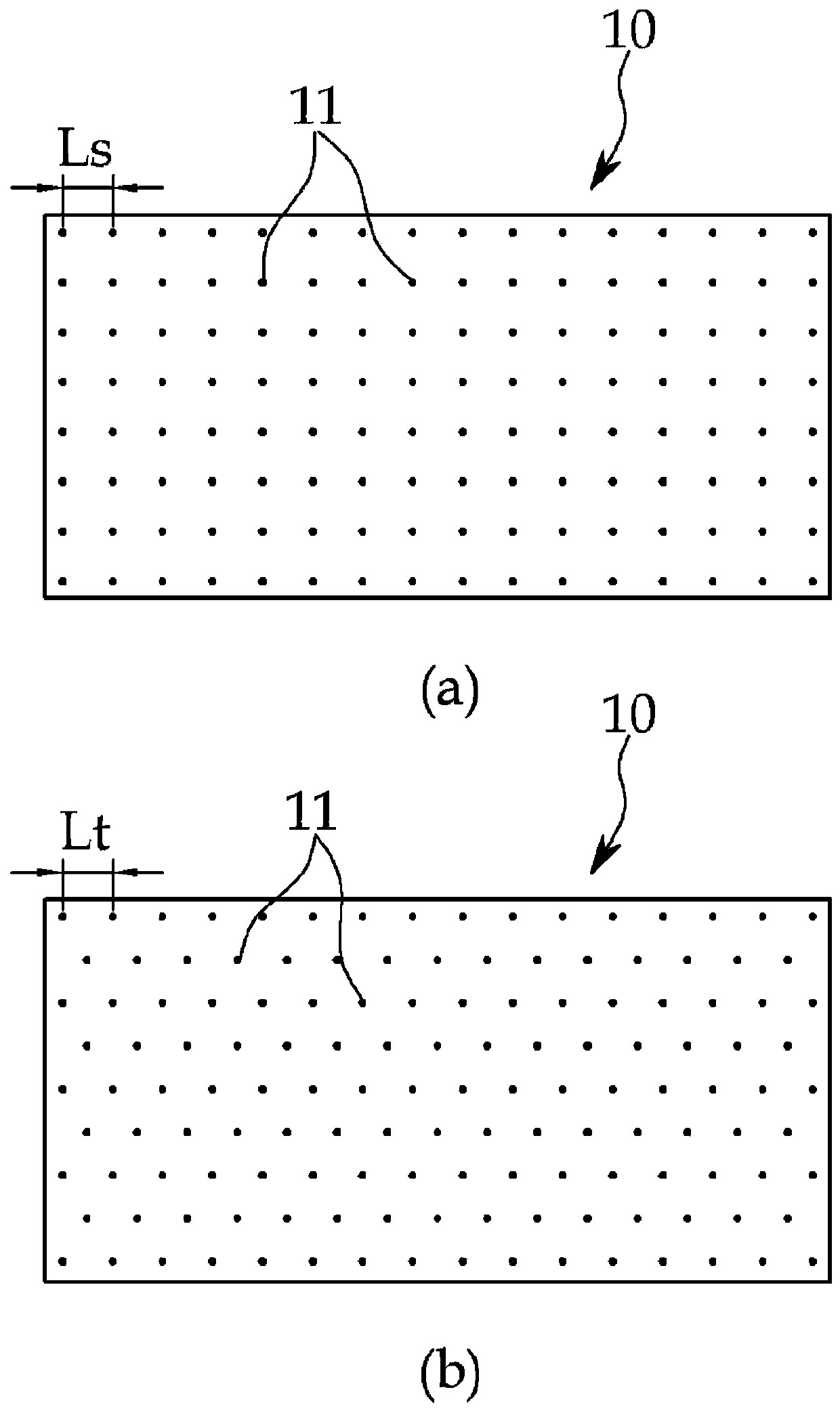

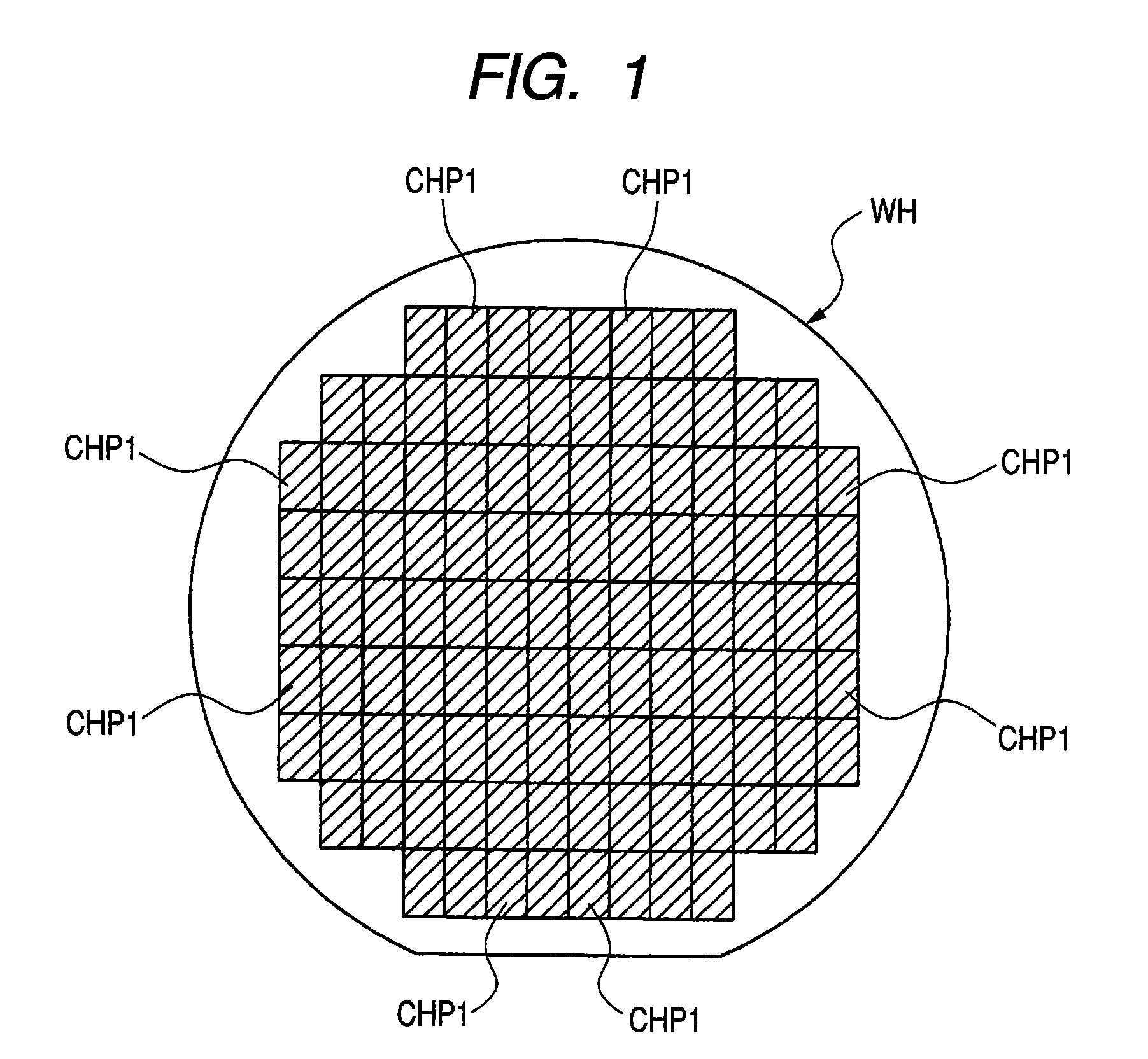

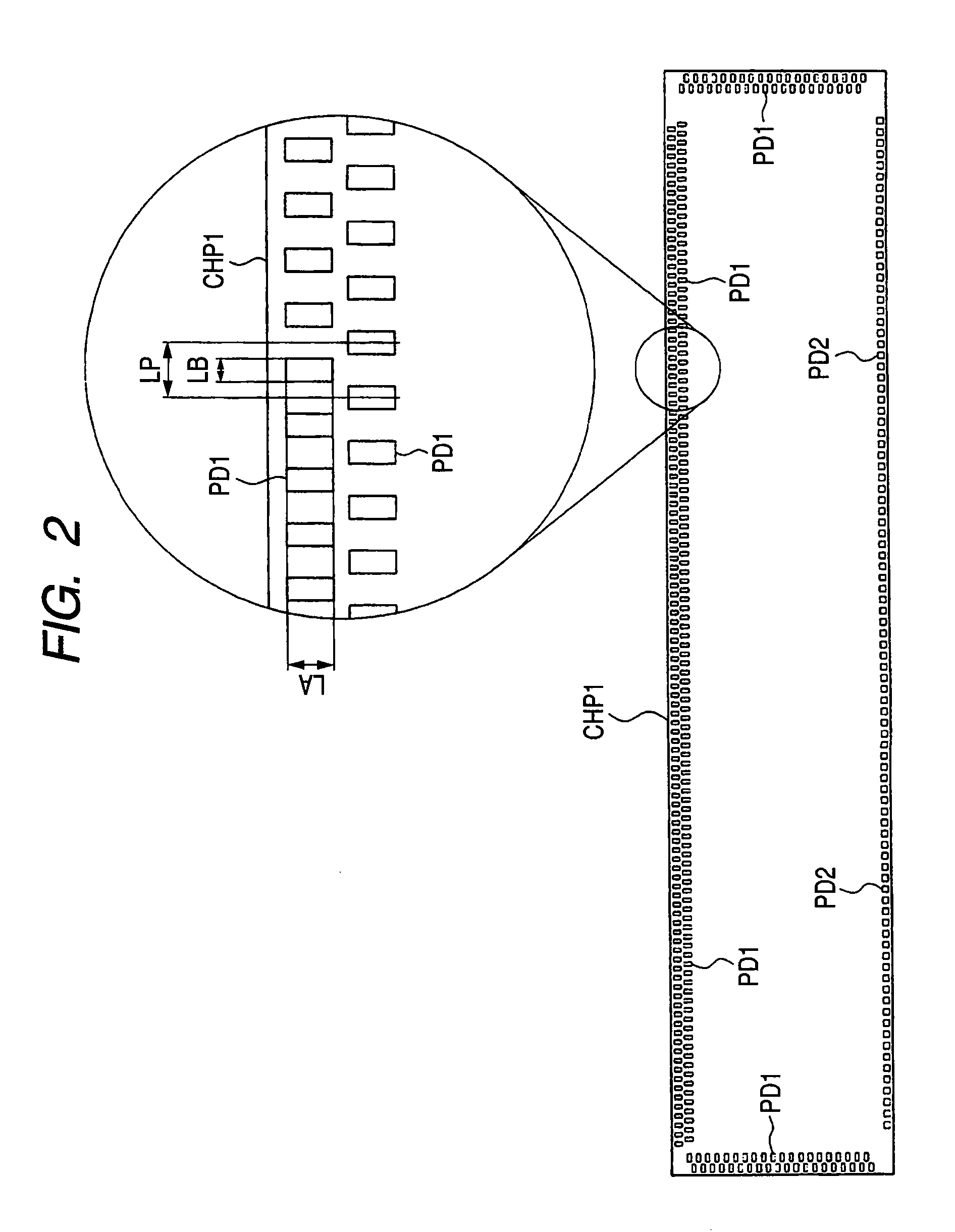

Method of manufacturing a semiconductor integrated circuit device

ActiveUS20080096295A1Reduce the possibilityIncrease productionSemiconductor/solid-state device testing/measurementSolid-state devicesForeign matterManufacturing technology

A technique of manufacturing a semiconductor integrated circuit device is provided for reducing the possibility of attachment of foreign matter to a membrane probe when performing probe inspection using the membrane probe formed by the manufacturing technique. A pressing member for pressing a membrane sheet includes a pressing pin receiving portion relatively disposed above for receiving the tip of a pressing pin of the plunger in a recess, and a membrane sheet pressing portion relatively disposed below. The membrane sheet pressing portion in contact with the membrane sheet has the minimum plane size to enable pressing of the entire surface of one chip of interest to be subjected to the probe inspection.

Owner:RENESAS ELECTRONICS CORP

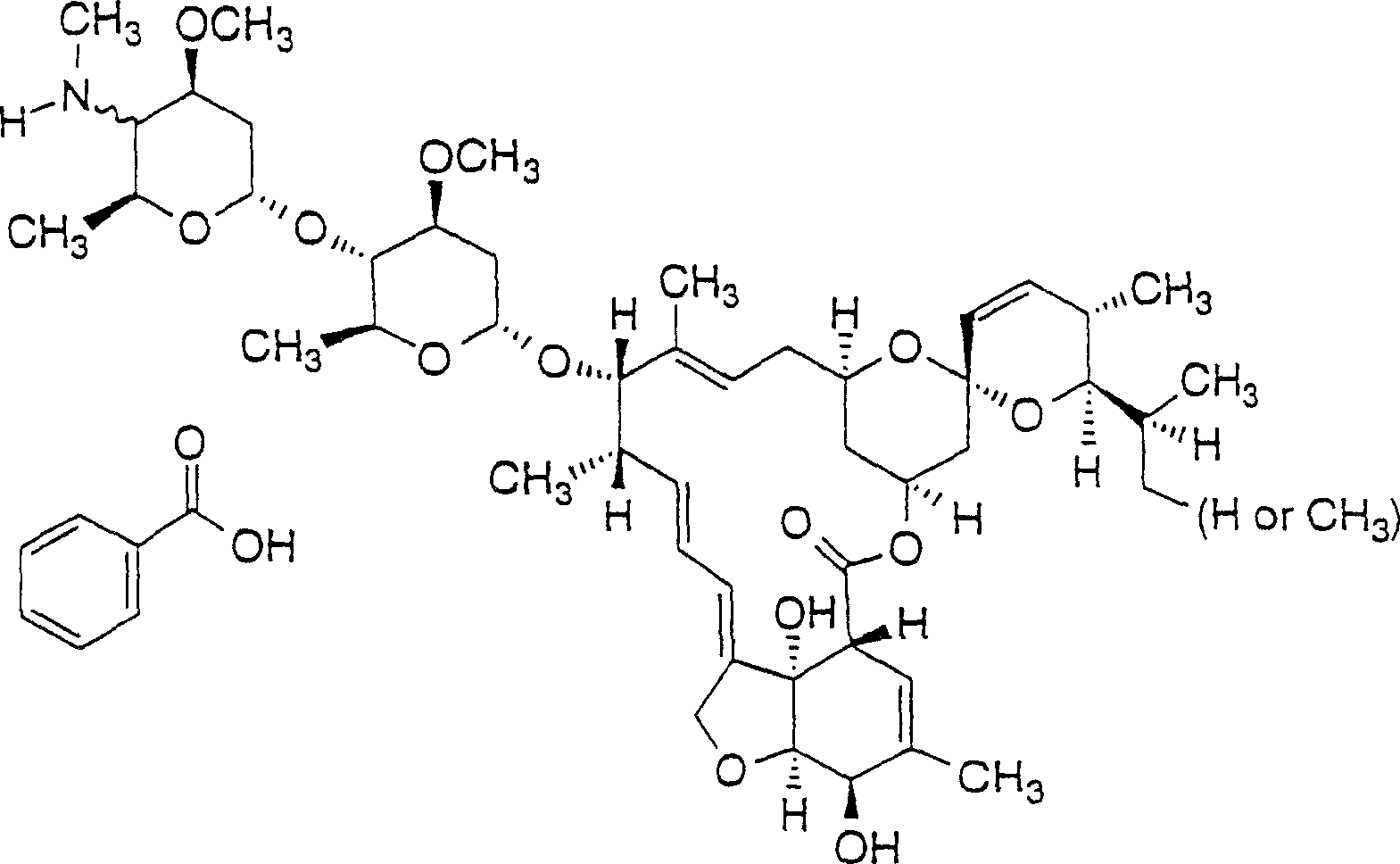

Pesticidal formulation

InactiveCN1915016AReduce riskReduced risk of exposureBiocideDead animal preservationChemical compositionWater soluble

The present invention is directed to a pesticidal composition of a water-soluble pesticide and processes for its manufacture. More specifically, the invention relates to a soluble granule (SG) pesticidal formulation comprising a water-soluble pesticide and a water-soluble filler. The present invention provides a pesticidal formulation with efficacy equal to the corresponding liquid formulation, yet with improved handler safety, such as lower eye irritation.

Owner:SCHERING AG

Mobile apparatus and control program therefor

InactiveUS20090143932A1Avoid contactReduce the likelihood of exposureAnti-collision systemsVehicle position/course/altitude controlEngineeringMobile device

A mobile apparatus capable of moving or acting autonomously while flexibly avoiding contact with a moving object in accordance with various situations is provided. In a case where a second safety condition is not satisfied because, e.g., a first target trajectory cannot be found, a second target trajectory causing a first spatial element to approach the boundary of an element passing region is searched for and determined. A robot autonomously approaches the boundary of the passable region in accordance with the second target trajectory determined as a provisional target trajectory, and stops at the position corresponding to the end point of the second target trajectory. Such movement of the robot along the second target trajectory increases the space, making it possible to prompt an object to move through the space.

Owner:HONDA MOTOR CO LTD

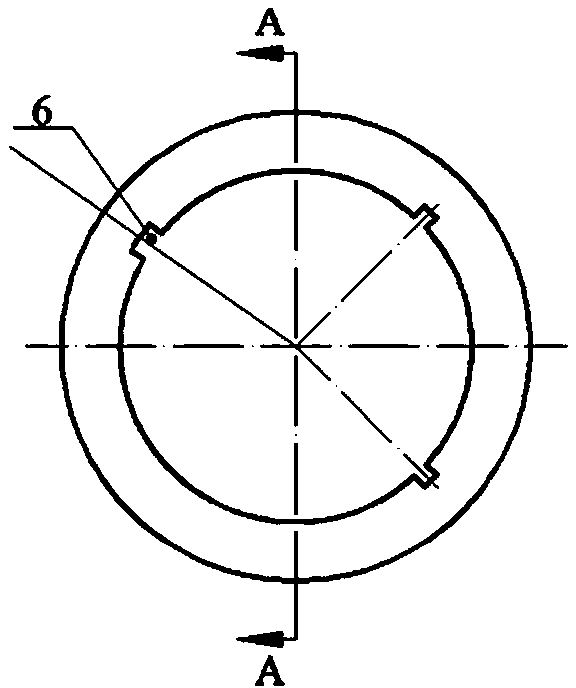

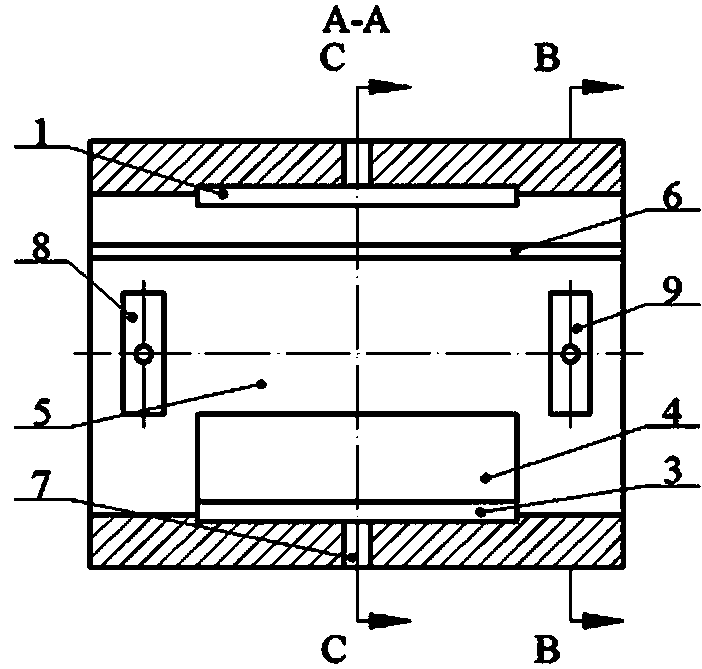

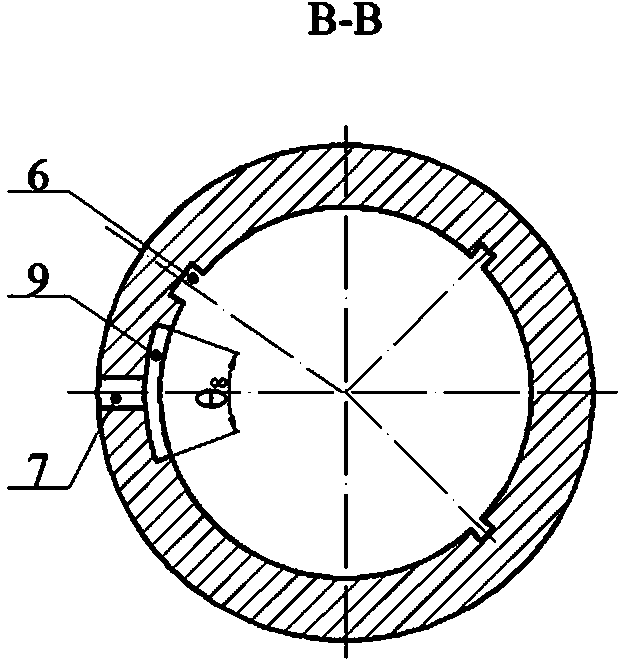

Capillary tube throttling dynamic pressure and static pressure mixed bearing used for heavy roll grinder grinding spindle

InactiveCN103962948AHigh rotation accuracyImprove carrying capacityGrinding machine componentsEngineeringLevel line

A capillary tube throttling dynamic pressure and static pressure mixed bearing used for a heavy roll grinder grinding spindle comprises five static pressure cavities, an arc-shaped shallow cavity and three axial oil return tanks. The upper static cavity and the lower static cavity form a pair of oil containing cavities and are located on the perpendicular line of the bearing. The center of the front static pressure is located on the right of the horizontal line of the bearing and is close to a ground workpiece. The front static pressure cavity is arranged opposite to the left rear static pressure cavity and the right rear static pressure cavity. The horizontal center line of the front static pressure cavity, the horizontal center line of the left rear static pressure cavity and the horizontal center line of the right rear static pressure cavity are in the same horizontal plane. The left rear static pressure cavity and the right rear static pressure cavity are distributed in a central symmetry mode in the width direction of the bearing. A dynamic pressure cavity is the portion, except for the left rear static pressure cavity and the right rear static pressure cavity, of a dynamic pressure oil sealing face. The three axial oil return tanks are arranged at the upper end and the lower end of the front static pressure cavity and the left side of the upper static pressure cavity respectively. The five static pressure cavities are communicated with corresponding oil inlets (7) respectively. The arc-shaped shallow cavity is arranged between the lower static pressure cavity and the dynamic pressure cavity. The requirement for selection of the size of a capillary tube throttle exits. It is ensured that the spindle has high bearing capacity and low temperature rise at a high speed. The spindle has the anti-inclination capacity.

Owner:HUNAN UNIV +1

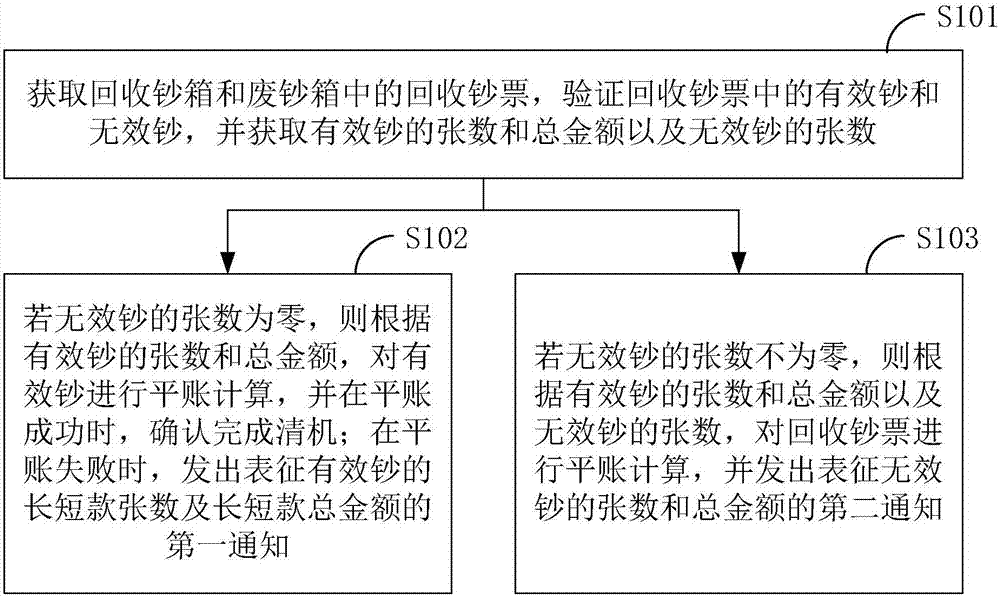

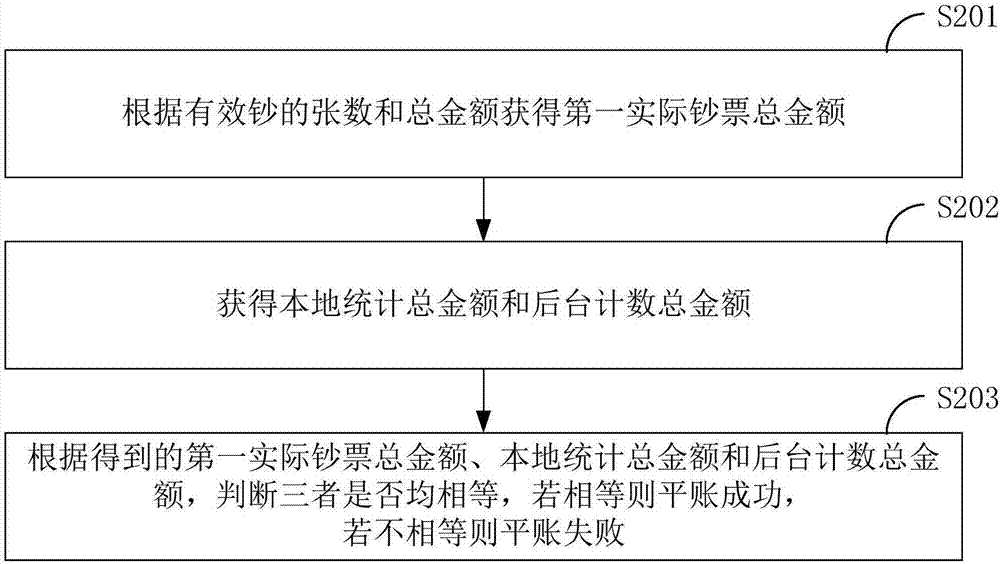

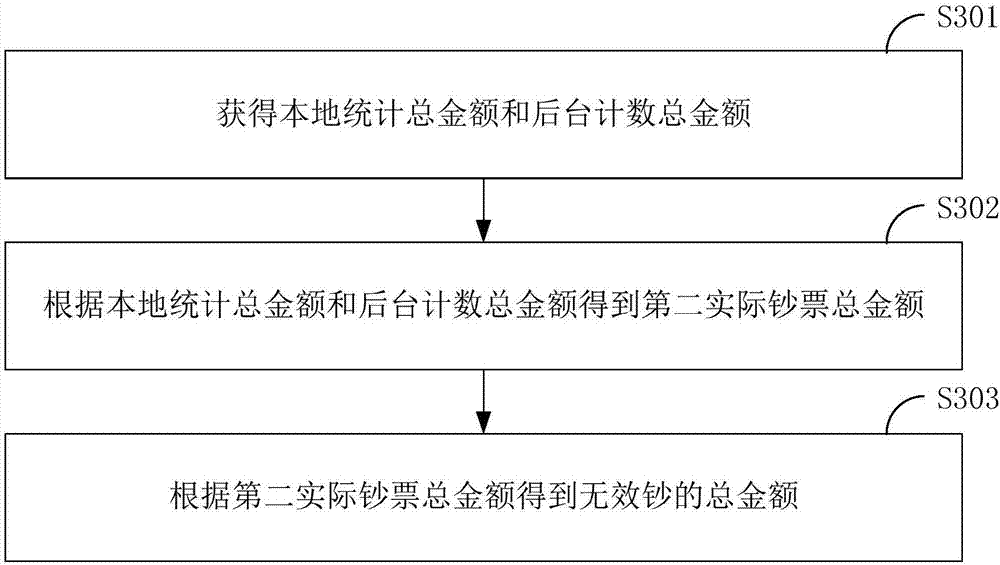

Method and system for clearing financial self-service equipment and terminal equipment and storage media

ActiveCN107358759AReduce the likelihood of exposureImprove cash securityComplete banking machinesAutomatic teller machinesTerminal equipmentPulp and paper industry

The invention discloses a method and system for clearing financial self-service equipment and terminal equipment and storage media. Through obtaining recycled paper money in recycling money boxes and waste money boxes, verifying valid paper money and invalid paper money in the recycled paper money, and obtaining the number and the aggregate amount of valid paper money and the number of invalid paper money; if there is no invalid paper money, then balancing calculation is performed on the valid paper money according to the number and the aggregate amount of valid paper money; if there is invalid paper money, balancing calculation is performed on the recycled paper money and a second notification representing the number and aggregate amount of invalid paper money is sent according to the number and aggregate among of valid paper money and the number of invalid paper money. By means of the invention, automatic clearing is achieved for recycled money boxes and waste money boxes with invalid paper money instead of artificial clearing; the possibility of cash contact during the process of clearing is reduced, the cash safety in financial self-service equipment is further improved and the efficiency of clearing is improved.

Owner:SHENZHEN YIHUA COMP +2

Method for encrypting USB flash disk with fingerprint authentication

InactiveCN105893821AEliminate the trouble of forgetting common passwordsReduce the likelihood of exposureInternal/peripheral component protectionDigital data authenticationInformation quantityInformation security

The invention discloses a method for encrypting a USB flash disk with fingerprint authentication. The USB flash disk is encrypted in a partition mode, namely the USB flash disk is divided into two drives, and a user can select one drive for use according to needs; the current up-to-date symmetric cryptographic algorithm is adopted, is higher in safety level compared with other encrypted USB flash disks and meets the current national conditions; an encryption key is canceled, a secret key is generated from fingerprints, and a file is encrypted or decrypted through the secret key generated from the fingerprints. The secret key is generated from extracted fingerprint characteristic values through a pseudo-random number generation algorithm, in this way, only the fingerprint characteristic values need to be stored, storage space needing to be occupied is reduced, information quantity is reduced, the possibility of effective information disclosure is reduced, fingerprint authentication and the encryption and decryption processes are combined, safety of an overall system is improved, the user can use the USB flash disk conveniently, and the trouble that the user forgets a common command is saved. The file encrypting operation is based on the homemade symmetric cryptographic algorithm, and the independent and controllable requirements for information safety products by China are met.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com