Continuous casting and rolling system for lead belt production

A continuous casting and rolling, lead strip technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problem of alloy burnout, manual operation with high chance, endangering the personal safety of operators, and affecting the performance of lead-acid batteries, etc. problems, to achieve the effects of reducing labor costs and management costs, reducing equipment occupancy, and facilitating control and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

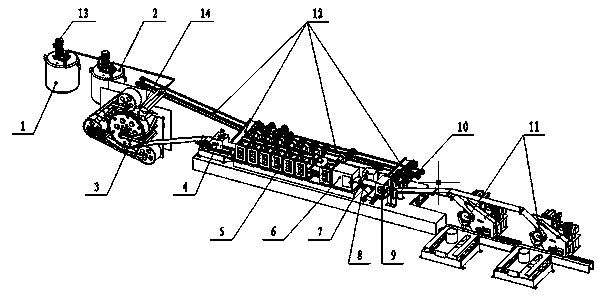

[0018] like figure 1 As shown, the lead strip continuous casting machine 3 is placed behind the smelting furnace 1 and the holding furnace 2, the inlet scissors 4 are arranged between the lead strip continuous casting machine 3 and the lead strip continuous rolling device 5, and the outlet side of the lead strip continuous rolling device 5 Cleaning device 6, slitter 7, exit scissors 9, tape guide 10, and coiling device 11 are installed in sequence; the tape guide 10 can automatically send the lead of each roll of lead tape to the coiler for coiling, and at the same time cooperate with coiling The device 11 establishes the coiling tension to ensure the stable coiling of the lead tape; two sets of coiling devices 11 are used alternately to make the finished lead tape into coils; one side of the inlet scissors 4, the slitter 7 and the outlet scissors 9 is respectively arranged with a conveyor belt 12, Conveyor belt 12 recycles the scraps produced by inlet scissors 4, slitting she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com