Cylindrical lithium-manganese dioxide battery structure with high capability and preparation method thereof

A lithium-manganese battery and cylindrical technology, which is applied in the field of preparation of high-capacity cylindrical lithium-manganese battery structures, can solve the problems of increasing the probability of internal short circuit, increasing the contact area of positive and negative plates, and occupying the space of the battery core, etc. The effect of reducing the probability of internal short circuit, reducing battery short circuit current, and improving battery safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

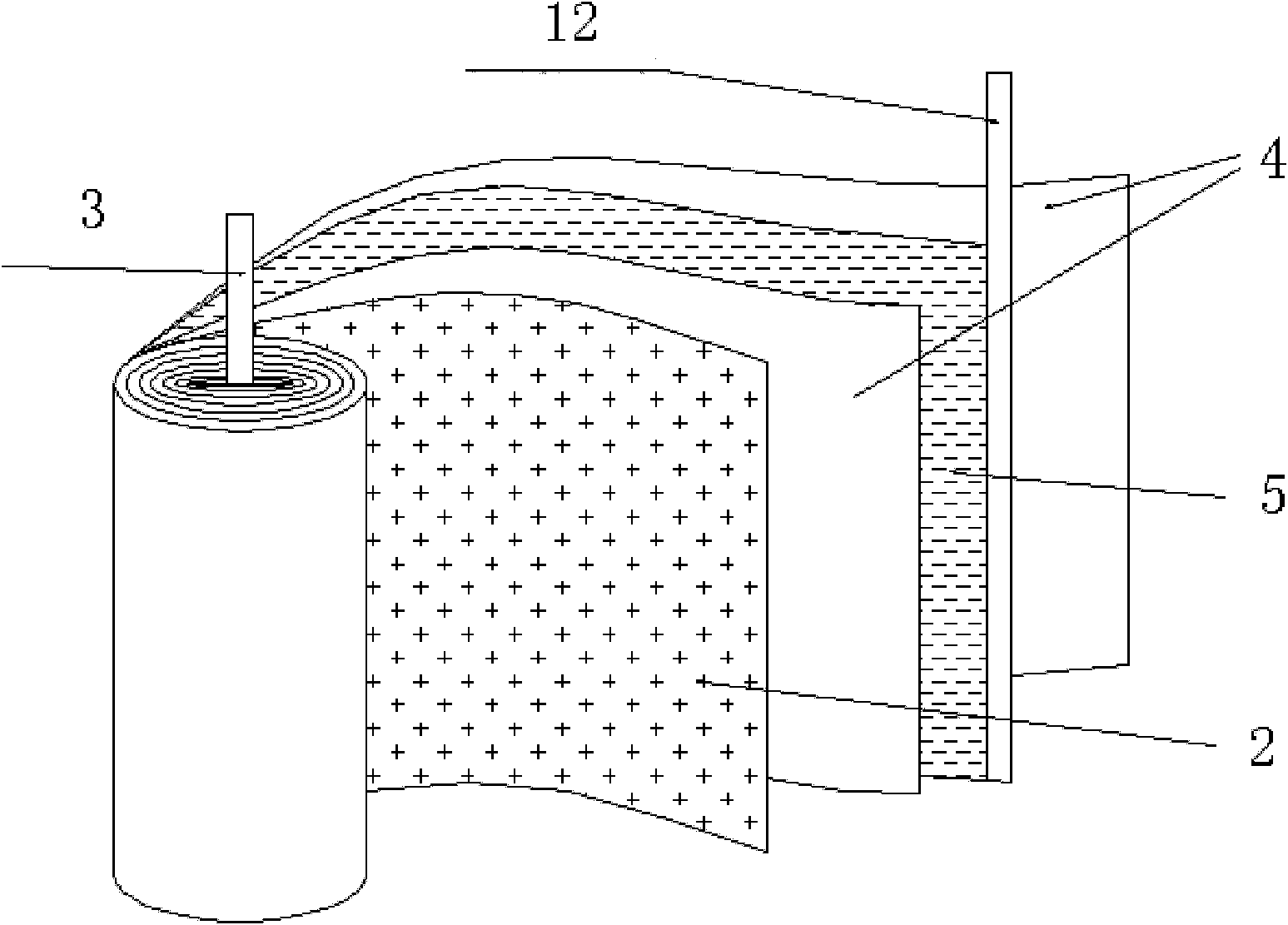

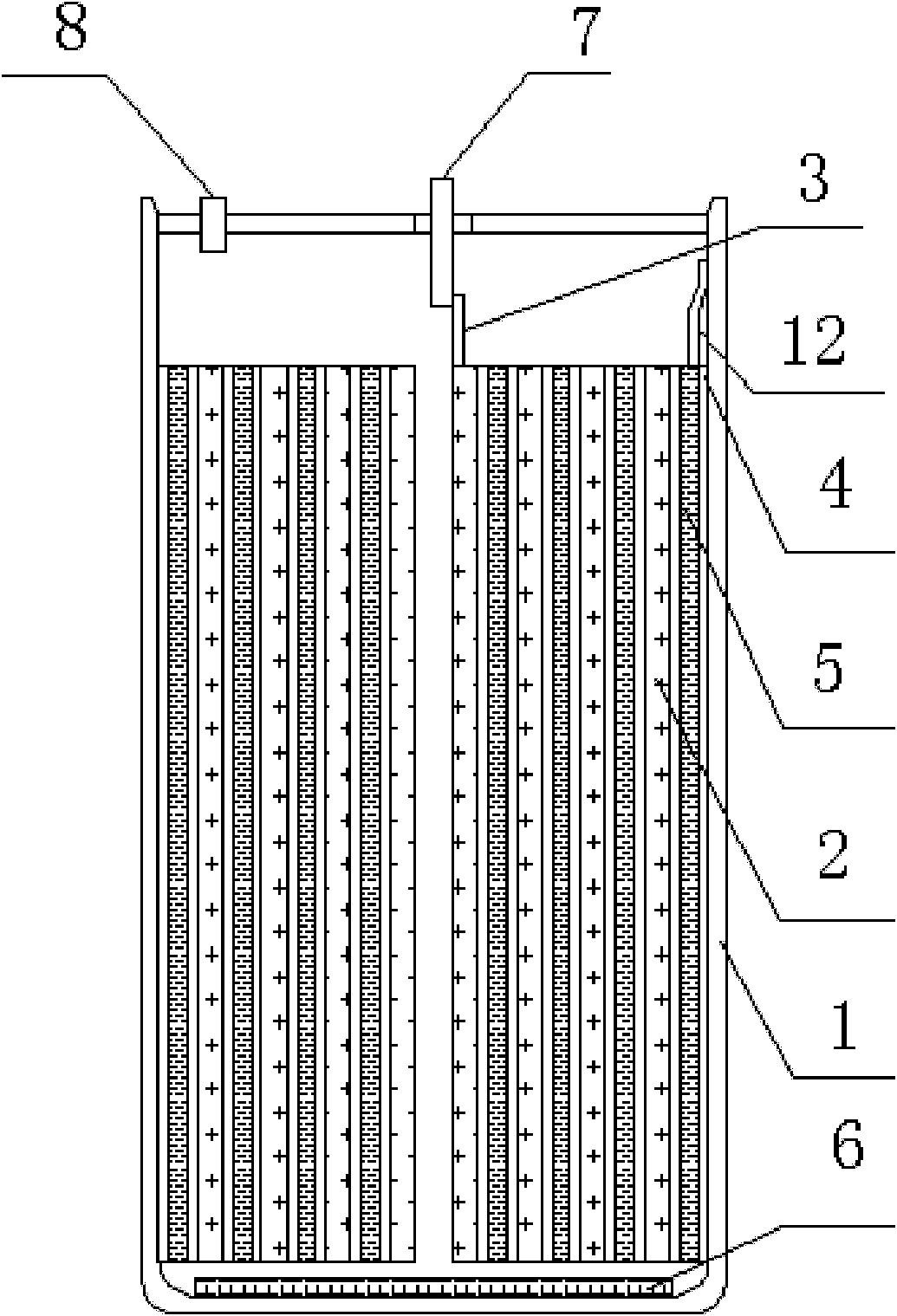

[0080] Referring to the accompanying drawings, it can be seen that the structure of the high-capacity cylindrical lithium-manganese battery of the present invention includes a steel shell 1 positioned outside, a metal connection bar 10 in the middle of the steel shell 1, and a positive electrode core 13 surrounded by a positive electrode sheet 2. The cylindrical structure that connecting bar 10 is wound into (as Figure 7 , Figure 8 As shown), a diaphragm 4 is wrapped around the outer surface of the positive electrode cell 13, a lithium strip 5 is between the diaphragm 4 and the steel case 1, the cover group 9 is located at the upper end of the steel cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com