Porous polyolefine isolating film

A technology of polyolefin and separator, which is applied in the direction of electrical components, electrochemical generators, circuits, etc., can solve the problems of shrinkage or rupture of the separator, affect the safety performance of the battery, and maintain the high temperature state, so as to reduce the internal short circuit, Reduces the possibility of fire and explosion, increases the effect of polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Preparation of isolation membrane

[0023] Mixing and kneading a polyolefin mixture containing 5-95% by weight polyethylene A, 95-5% polyethylene B and a plasticizer (such as paraffin wax), wherein the average molecular weight of polyethylene A is 2×10 6 , the average molecular weight of polyethylene B is 1×10 5 -2×10 5 . The kneaded product is extruded into a jelly-like sheet, cooled and solidified, and then the obtained jelly-like sheet is stretched, dried and shaped to obtain the porous polyolefin isolation film of the present invention. The thickness of the isolation membrane is 35-80 μm, preferably 35-50 μm, preferably 40 μm; the porosity of the isolation membrane is 30-70%, preferably 30-50%, preferably 40%; the air permeability is 1000 seconds / 100ml , the average opening diameter is 0.001-1 μm, preferably 0.03 μm. According to the test, the cut-off temperature of the separator in Example 1 is 125°C, and the short-circuit temperature is 185°C.

[0024] It ...

Embodiment 2

[0032] 1) Preparation of isolation membrane

[0033] The preparation of the isolation film is the same as in Example 1, and the size of the isolation film is: 1500mm×54mm

[0034] 2) Preparation of positive electrode sheet

[0035] 85% by weight of lithium iron phosphate, 5% of carbon black and 5% of graphite are mixed and ground, dried and premixed to make positive electrode powder. Mix the mixed positive electrode powder with deionized water containing 5% by weight of acrylic polymer to prepare a slurry, the viscosity of which is between 6000-9000mPaS. Apply the slurry on both sides of the cable-stayed aluminum mesh, dry it at 110°C and roll it to form a positive electrode sheet with a thickness of 200 μm and a compacted density of 2.2 g / cm 3 . Finally, the positive electrode sheet is cut according to the size of 700mm×51mm.

[0036] 2) Preparation of negative electrode sheet

[0037] 93% by weight of natural graphite and deionized water containing 2% by weight of sodiu...

Embodiment 3

[0041] 1) Preparation of isolation membrane

[0042] The preparation of the isolation film is the same as in Example 1.

[0043] 2) Preparation of positive electrode sheet

[0044] Will Li 3 V 2 (PO 4 ) 3 , conductive agent and binder are evenly mixed in proportion, coated on the aluminum foil, compacted after drying, cut according to a certain size, and made into a positive electrode sheet.

[0045] 3) Preparation of negative electrode sheet

[0046] Li4Ti 5 o 12 , conductive agent and binder are mixed evenly in proportion, coated on the copper foil, dried and compacted, cut according to a certain size, and made into a negative electrode sheet.

[0047] 4) Preparation of battery

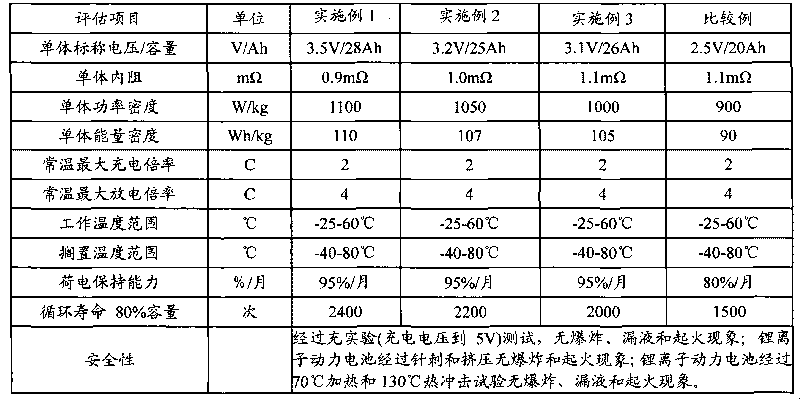

[0048] The positive electrode sheet, the negative electrode sheet and the separator are assembled, and the electrolyte is injected to obtain a lithium ion power battery. The battery evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com