Patents

Literature

69results about How to "Does not affect electrochemical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

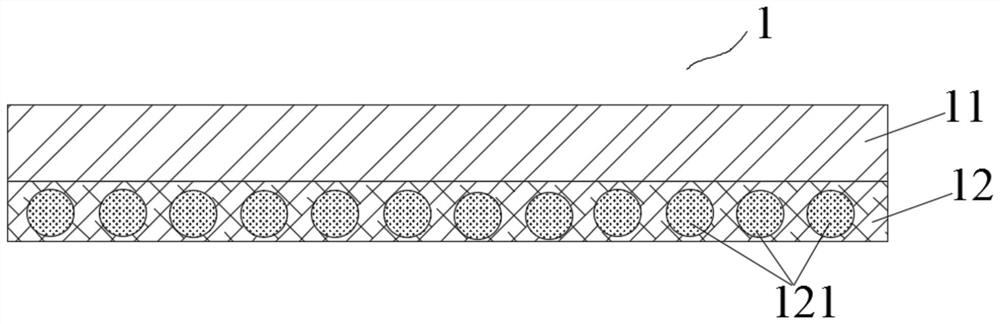

Capsule and lithium ion battery

ActiveCN103500806ADoes not affect electrochemical performanceImprove securitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsFlue gasPhysical chemistry

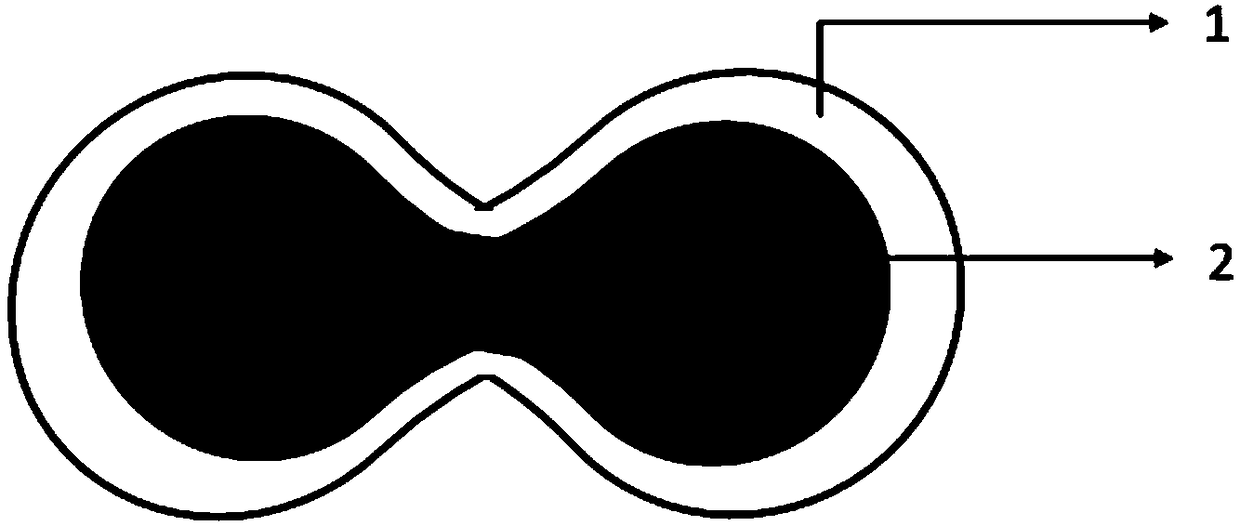

The invention provides a capsule and a lithium ion battery. The capsule is accommodated in the lithium ion battery and comprises a capsule wall and a capsule core. The melting point of the capsule wall ranges from 100 DEG C to 160 DEG C and is not dissolved in electrolyte of the lithium ion battery. The gasification temperature of is not lower than the melting point of the capsule wall and not higher than 400 DEG C. Gas generated by capsule core gasification is flame retardant. The flame-retardant gas is mixed with electrolyte steam and / or combustible flue gas / combustible smoke steam generated during thermal runaway of the lithium ion battery and sprayed out from the outer package of the lithium ion battery. The lithium ion battery comprises the capsule. When the lithium ion battery operates normally, the capsule does not affect electrochemical performance of the lithium ion battery. During thermal runaway of the lithium ion battery, the capsule wall cracks to release the capsule core, the capsule core is gasified to form the flame-retardant gas, the flame retardant function of the capsule is achieved, flame retardance is achieved, and safety performance of the lithium ion battery is improved.

Owner:NINGDE AMPEREX TECH

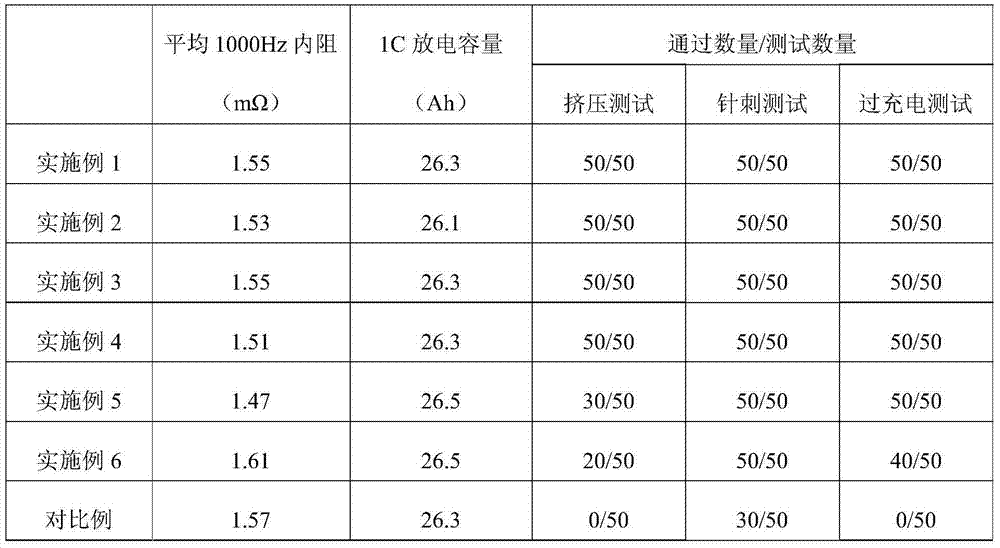

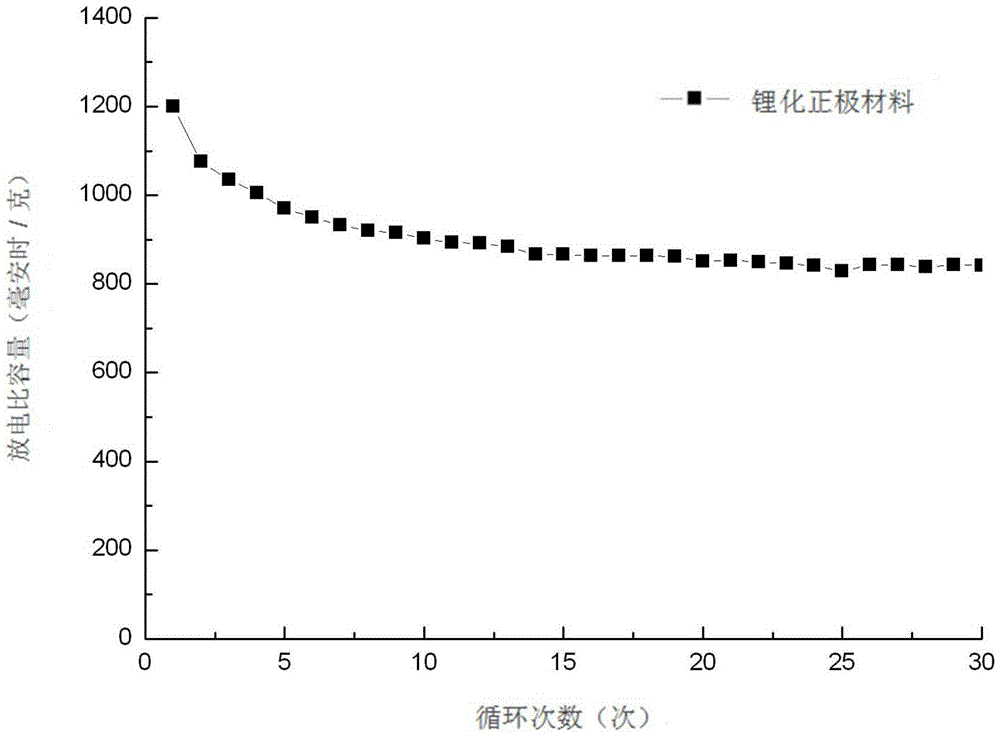

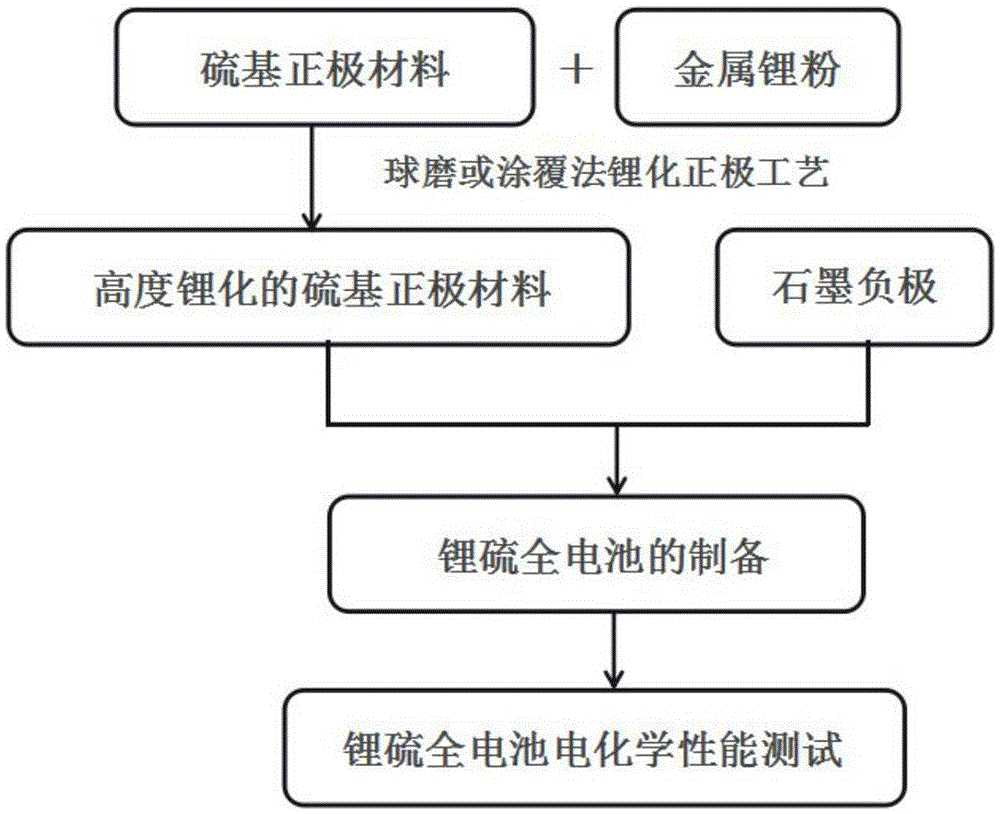

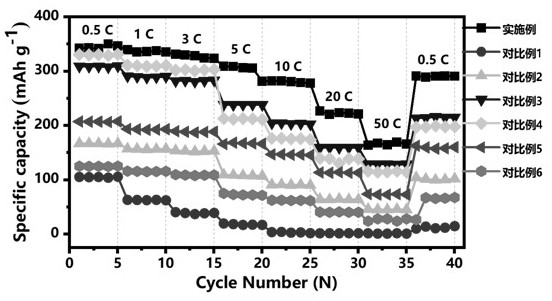

Positive electrode material for sulfur-based lithium ion battery and preparation method and application of positive electrode material

ActiveCN105609742AAvoid the problems of poor cycle performance and low specific capacityFix security issuesFinal product manufactureElectrode collector coatingSulfurLithium–sulfur battery

The invention relates to a positive electrode material for a sulfur-based lithium ion battery and a preparation method and application of the positive electrode material. During the preparation process of the positive electrode material for the sulfur-based lithium ion battery, a sulfur positive electrode material is lithiated with metal lithium powder; under the protection of an inert atmosphere, the metal lithium powder and a sulfur-based positive electrode such as a sulfur-carbon based composite material or a sulfur-polymer composite material are uniformly mixed by a ball milling method or a coating method; and a certain amount of an electrode is dropwise added into the mixture, and a high-lithiation positive electrode material is obtained after appropriate lithiation time. From the angle of the lithiated sulfur positive electrode, a metal lithium negative electrode is substituted to provide a lithium source, the usage and production cost of a lithium-sulfur battery is saved, meanwhile, the dendrite crystal problem brought by the metal lithium serving as the negative electrode is avoided, and thus, the safety of a lithium-sulfur battery system is improved.

Owner:HEBEI UNIV OF TECH

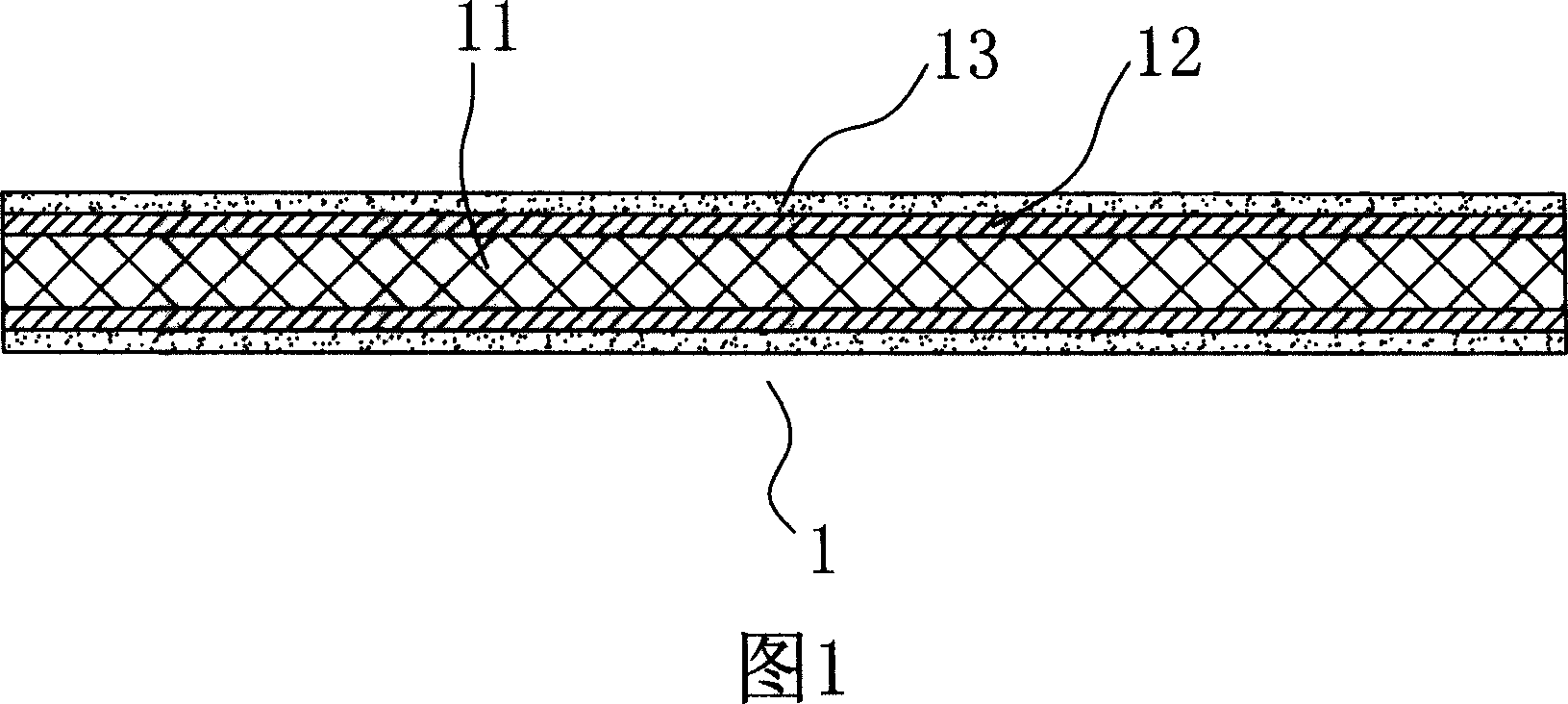

A secure lithium icon battery, improving method and making method of its anode slice

InactiveCN101055925AIncrease resistanceHigh surface resistanceElectrode manufacturing processesActive material electrodesElectrochemistryLithium-ion battery

The invention relates to a lithium ion battery technology field, in particular to a safe lithium ion battery, improvement method and the manufacturing method of its anode strip. The inventive method of improving the lithium ion battery safety is to raise the facial resistance of the anode strip, and to reduce the thermal conductivity of the anode strip, namely to cover a metal oxide material membrane layer on the anode strip surface of the lithium ion battery for raising the facial resistance of the anode strip and reducing the thermal conductivity of the anode strip. Use of the invention can raise the facial resistance of the anode strip, so after of the cathode current collector is in short circuit with the anode diaphragm, the resistance is greater, its current is smaller, resulting in a reduction of the produced, thereby the manufactured battery may easily pass through the short-circuit test, and the safety factor reaches the standard. At the same time the film layer formed by adopting the metal oxide, has a better hole for passing through lithium ions in its material interior structure, without any influence on the electrochemistry performance of the battery. The lithium ion battery that adopts this invention has a higher safety than the safety performance of the ordinary lithium ion battery.

Owner:DONGGUAN NEWPOWER ELECTRIC SCI & TECH

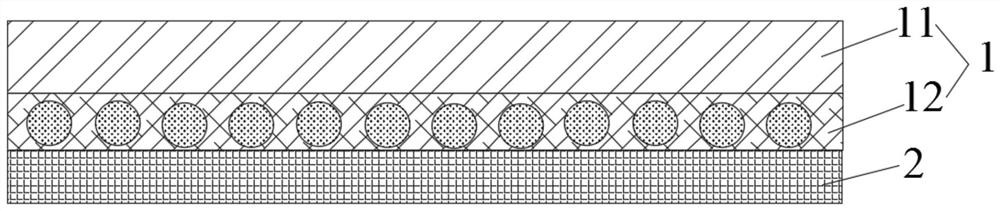

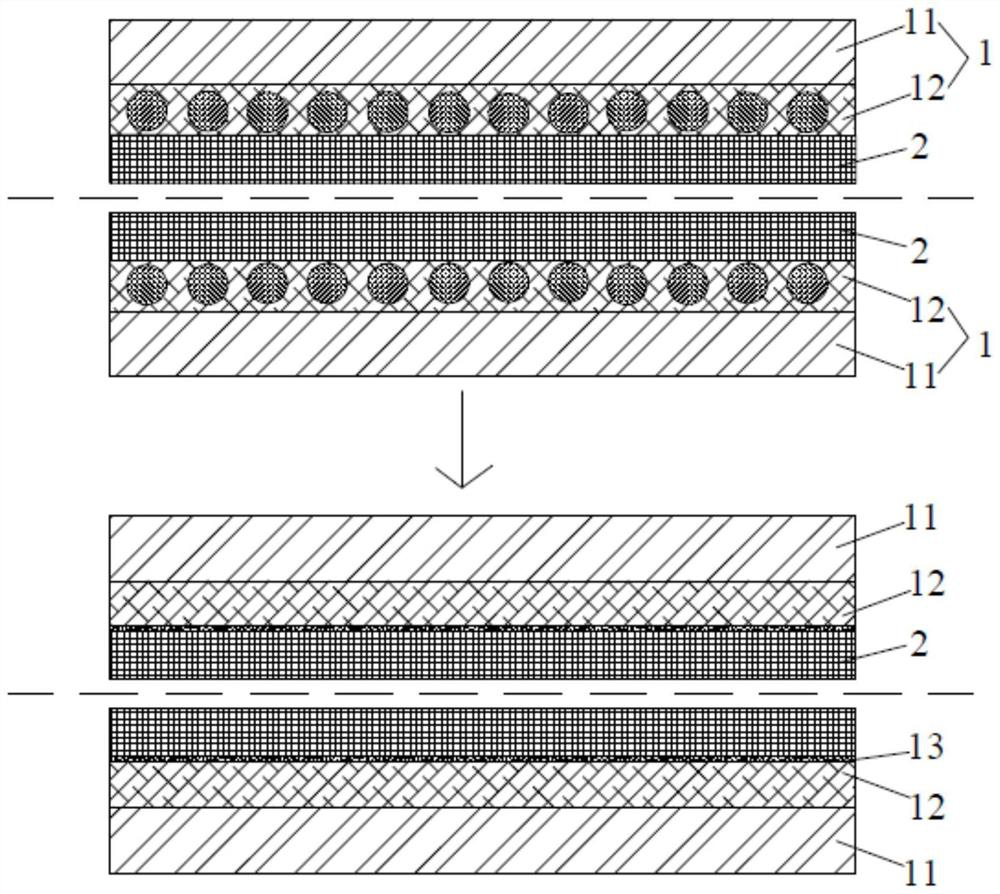

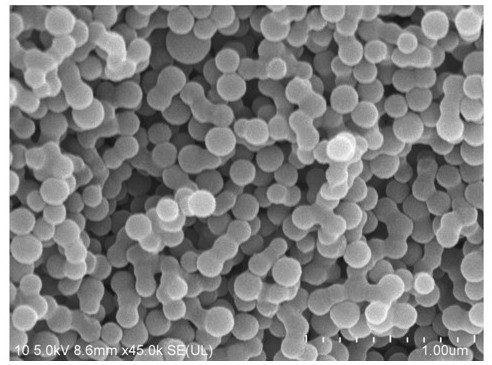

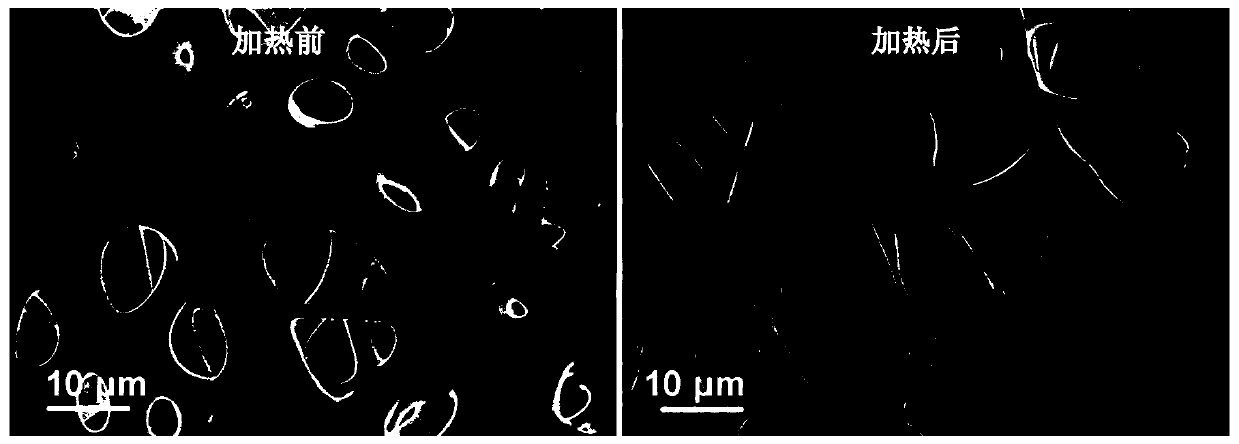

Microcapsule, preparation method thereof, and lithium ion battery

ActiveCN109461938ADoes not reduce energy densityAvoid thermal runawayCell electrodesFire rescueEngineeringFire retardant

The invention provides a microcapsule, comprising a capsule shell portion and a capsule core portion that is selected from one or both of an organic flame retardant and an inorganic flame retardant, wherein the outer surface of the capsule shell portion has a pile structure, and the capsule shell portion is made of polymer material. The application also provides a method of preparing the microcapsule, and a lithium ion battery. The microcapsule provided by the application is applied to the lithium ion battery, which can improve the safety of the lithium ion battery without affecting the electrochemical performance of the lithium ion battery.

Owner:SOUNDON NEW ENERGY TECH CO LTD

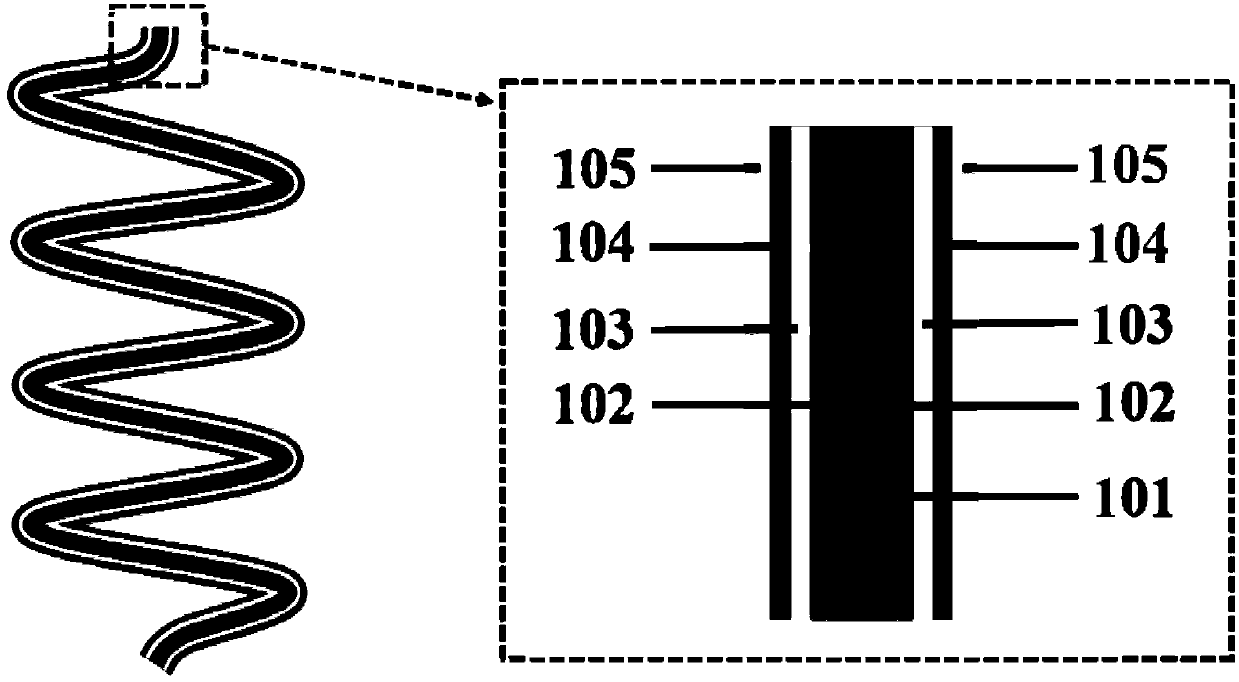

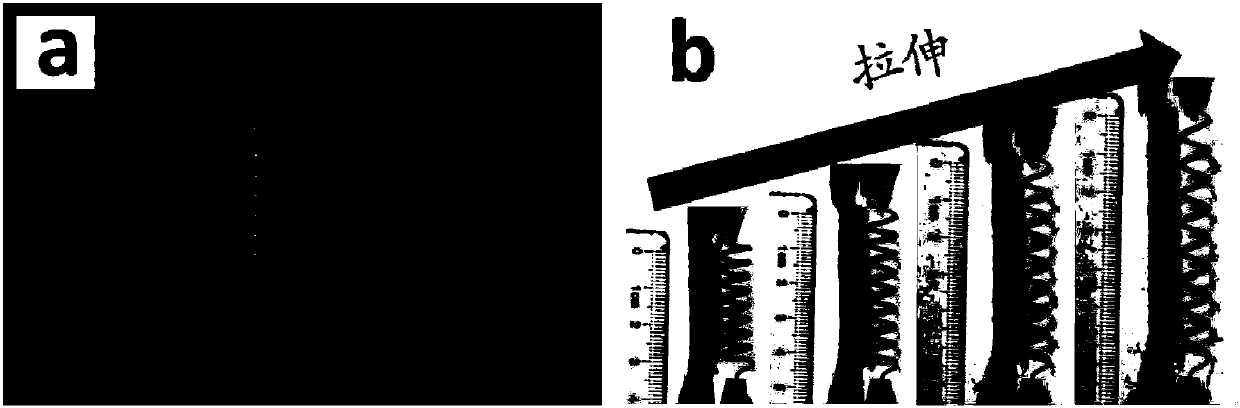

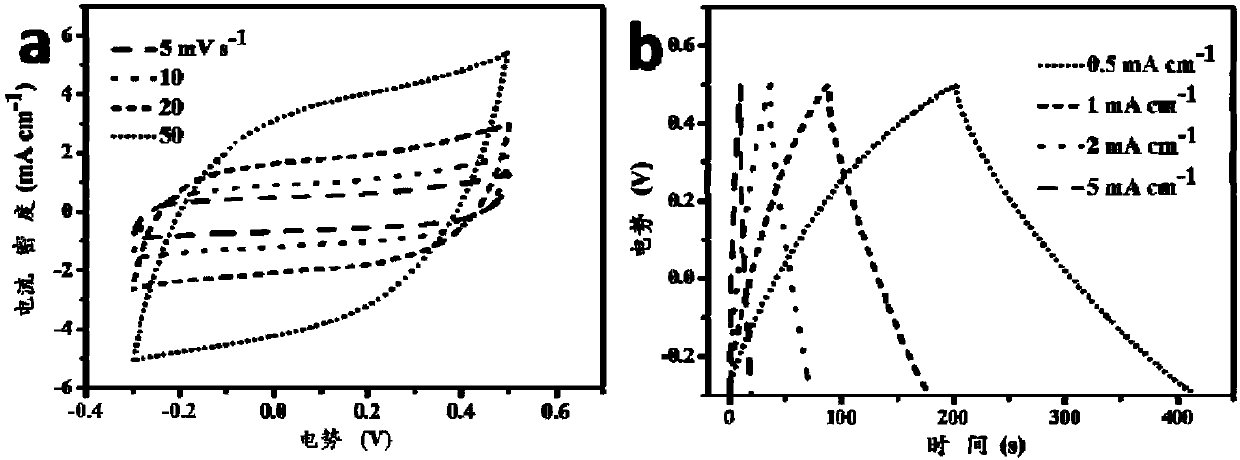

Stretchable supercapacitor with stainless steel spring adopted as base

InactiveCN107680828AGood stretchabilityEffective use of external spaceHybrid capacitor separatorsHybrid capacitor electrolytesConductive polymerCarbon nanotube

The invention discloses a stretchable supercapacitor with a stainless steel spring adopted as a base. The stretchable supercapacitor includes a stainless steel spring, an inner-layer electrode, an outer-layer electrode, and a gel electrolyte, wherein the stainless steel spring is adopted as the base of the stretchable supercapacitor, the inner-layer electrode and the outer-layer electrode are formed on the surface of the spring through in-situ growth or coat the surface of the spring, and the gel electrolyte is located between the two electrodes; the whole device is encapsulated with a flexible polymer material, so that the leak of the electrolyte can be prevented; the stainless steel spring, on the one hand, is adopted as a current collector of the inner-layer electrode, and on the otherhand, provides excellent stretchability for the device; the inner-layer electrode is made of a material such as a carbon material, a metal oxide and conductive polymer; the electrolyte is made of a polymer / electrolyte gel system such as PVA / H2SO4 and PVA / H3PO4; and carbon nanotubes or MXenes are wound so as to form the outer-layer electrode. The supercapacitor of the present invention can work normally under large tensile strain; the expected tensile strain of the supercapacitor can be as high as 100% under premise that the performance of the supercapacitor is not affected; and the outer spaceof the spring structural component can be efficiently utilized. The supercapacitor can be applied to systems such as high-speed train wireless monitoring systems.

Owner:SOUTHWEST JIAOTONG UNIV

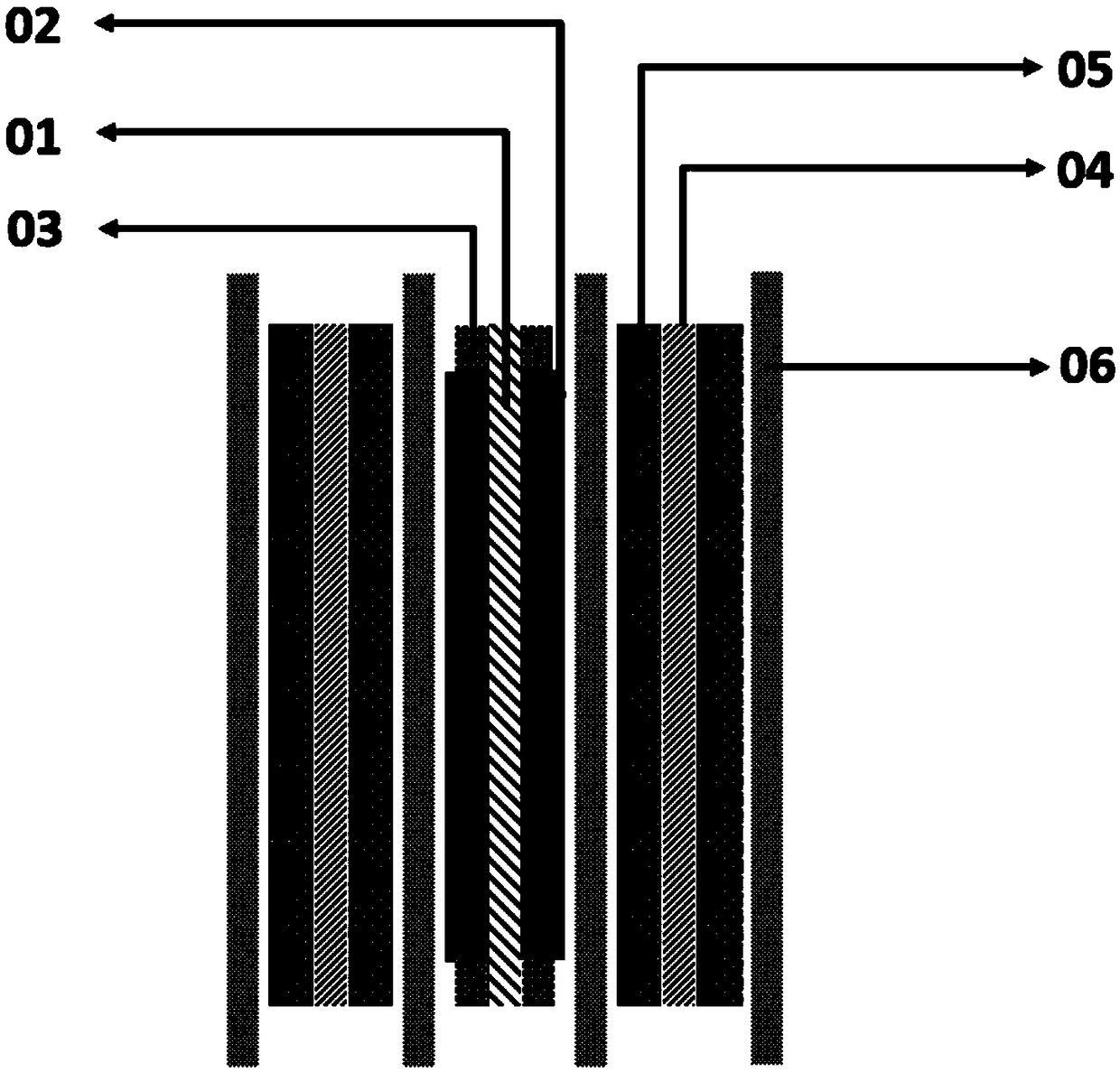

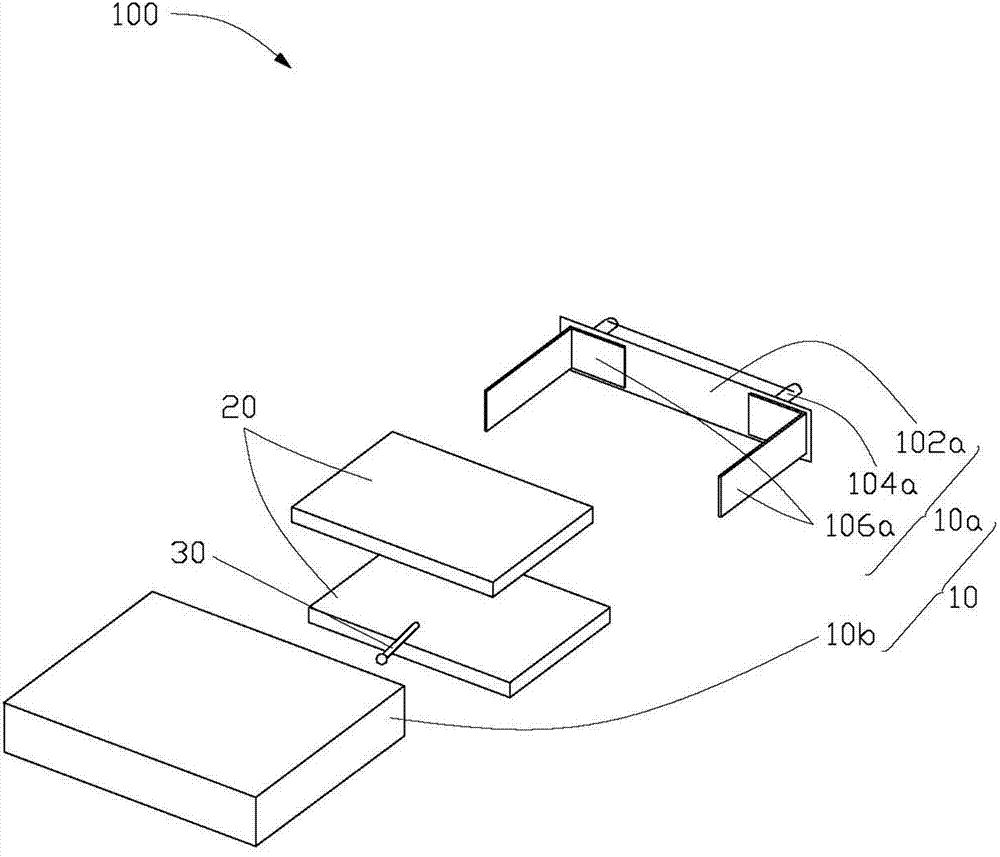

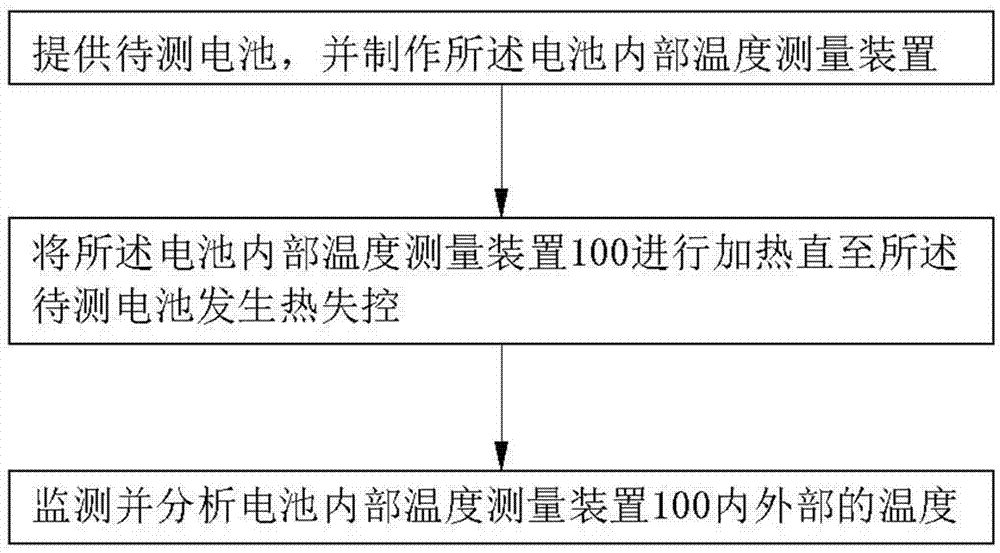

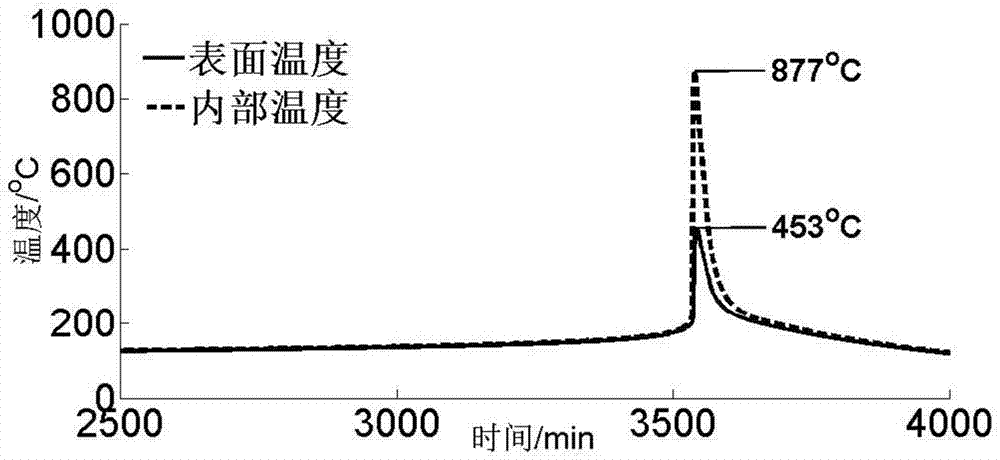

Measurement device for inner temperature of battery

ActiveCN103904381ADoes not affect electrochemical performanceAccurate measurementSecondary cellsMeasurement deviceElectrical battery

The invention relates to a measurement device for an inner temperature of a battery. The measurement device comprises a first packaging shell and a battery pack arranged in the first packaging shell, wherein the battery pack comprises at least two single batteries; the at least two single batteries are stacked; each single battery comprises a battery core and a second packaging shell; the second packaging shell is used for packaging the battery core; the measurement device for the inner temperature of the battery further comprises at least one temperature sensor; the at least one temperature sensor is arranged between the at least two single batteries and is clamped by the at least two single batteries.

Owner:TSINGHUA UNIV +1

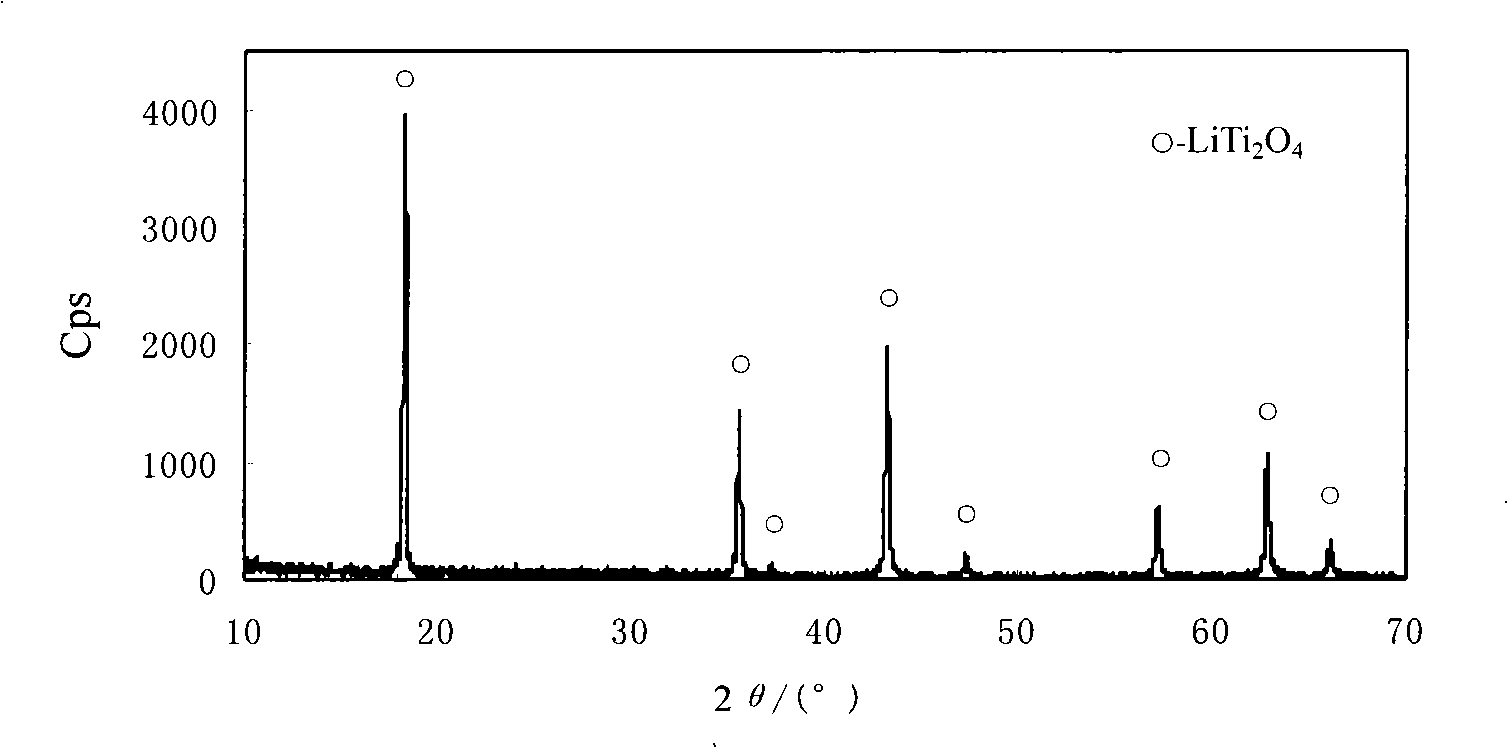

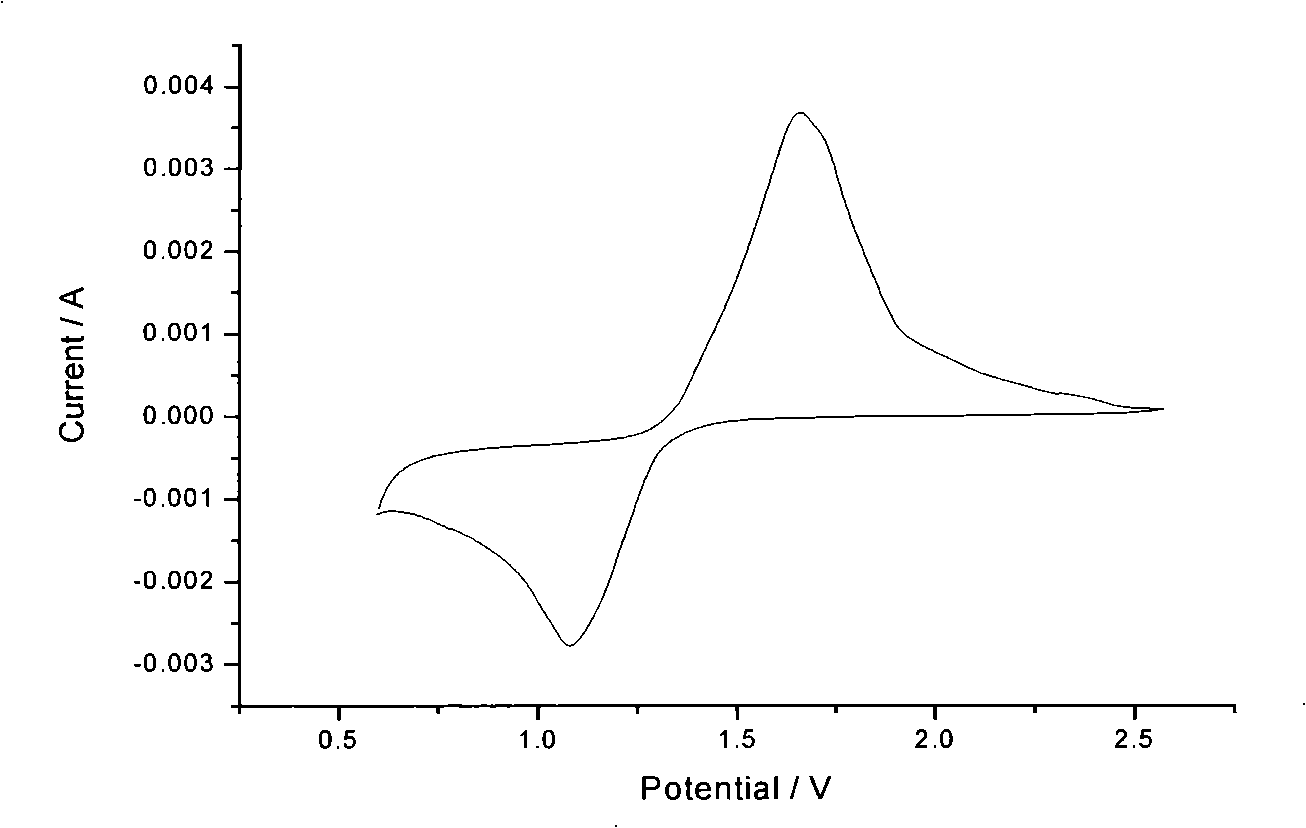

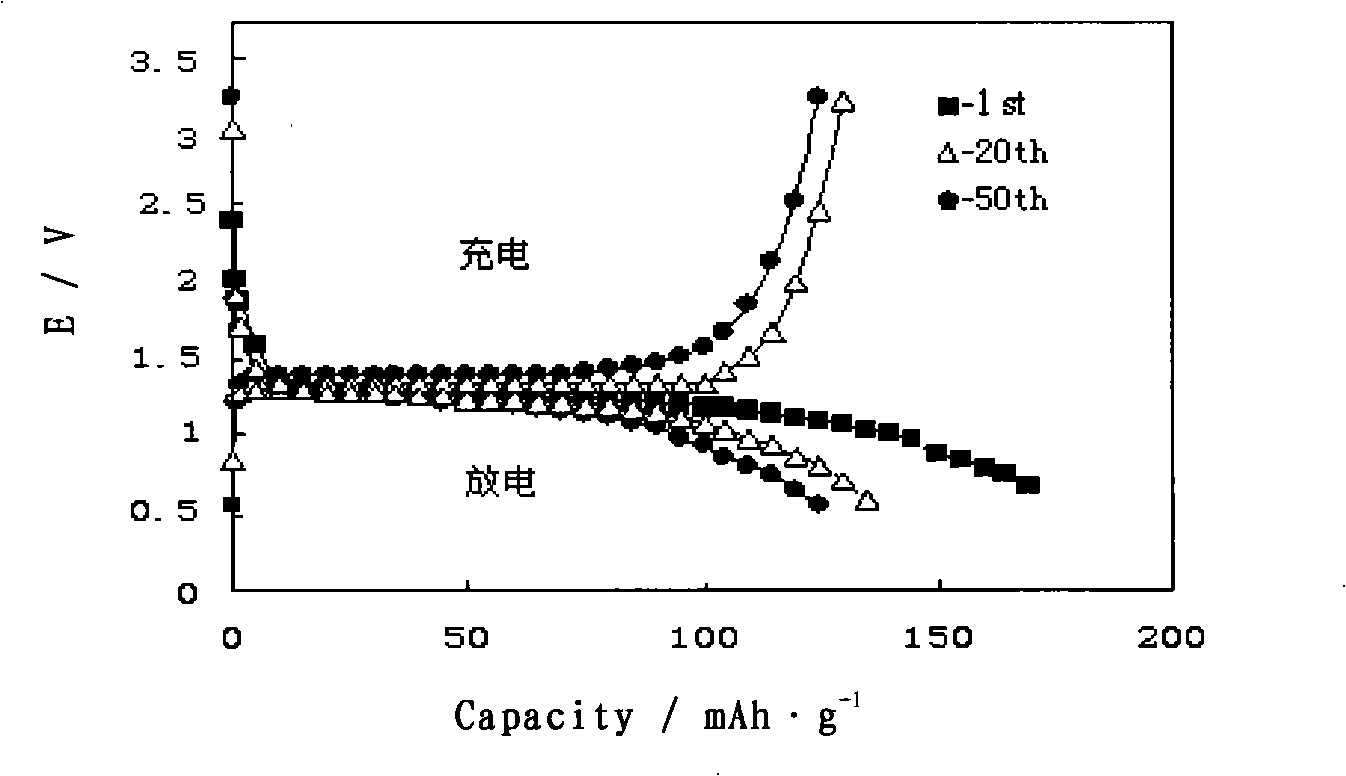

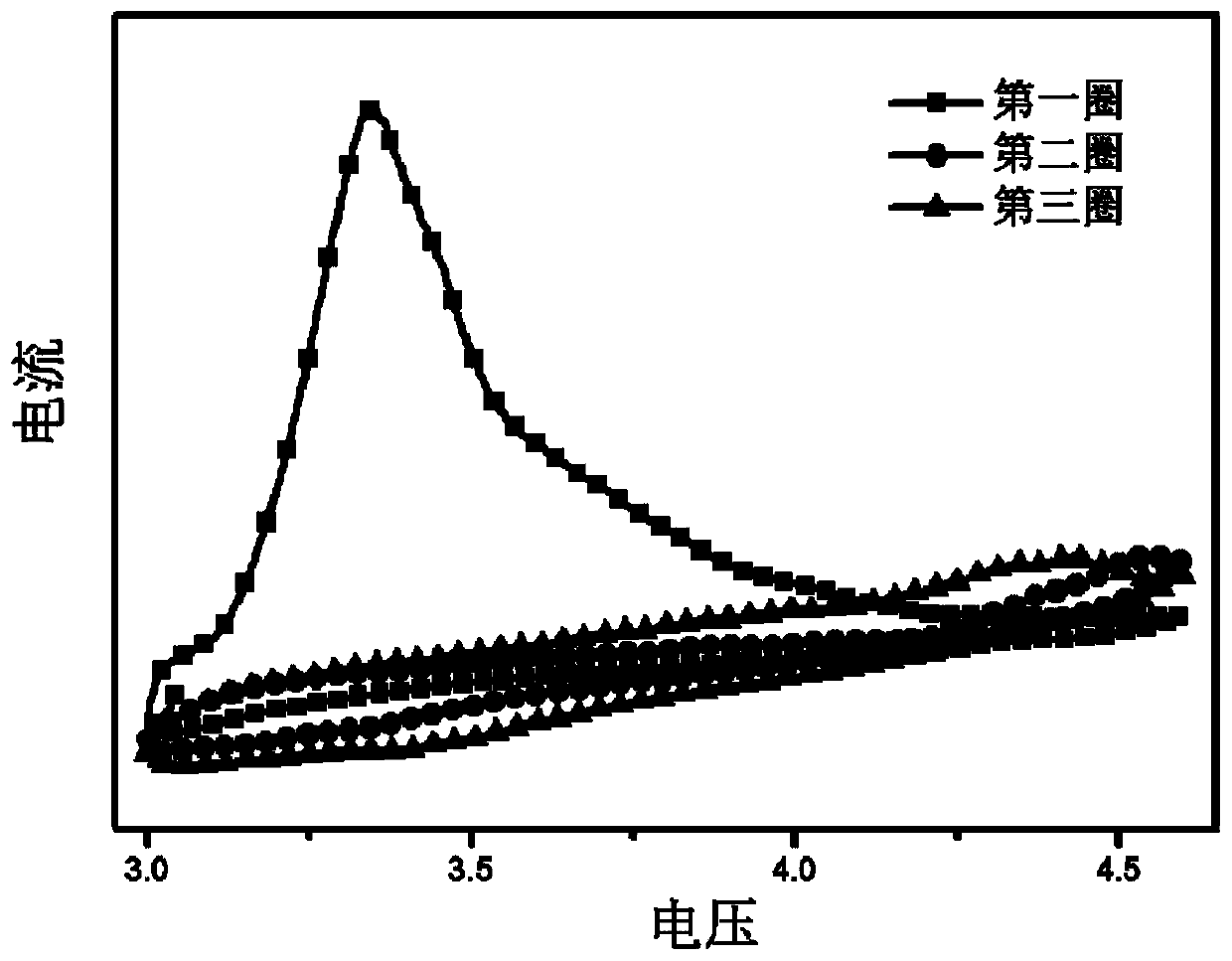

Method of producing spinel structured lithium titanate

InactiveCN101402469ADoes not affect electrochemical performanceImprove electrochemical performanceTitanium compoundsCarbon blackElectrochemistry

The invention discloses a method for preparing lithium titanate with a spinel structure. Lithium carbonate, titanium dioxide and carbon black which are low in price and easy to obtain are used as raw materials; the lithium titanate (LiTi2O4) is synthesized by a one-step solid phase reaction method. The raw materials are fully mixed and react for 4 to 36 hours at a temperature between 700 and 1,300 DEG C under an argon atmosphere or a vacuum atmosphere to prepare the lithium titanate (LiTi2O4) with the spinel structure which is pure or contains a little carbon black. A product is ground through a planetary ball mill; the granularity of the product reaches between 0.5 and 5 mu m; and the cycle ratio capacity of the product reaches between 100 and 160 mAh / g. The method has a simple process and low prices of raw materials and is suitable for industrial production; and the product has excellent electrochemical performance and can be used a material for the cathode of a high-performance lithium ion battery.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

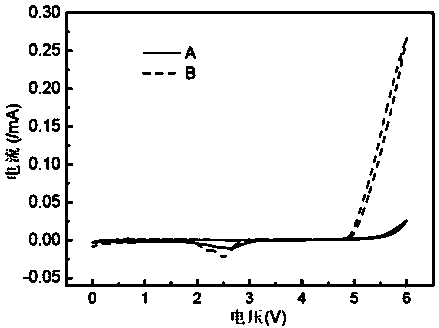

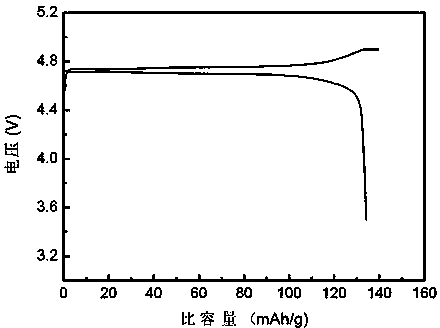

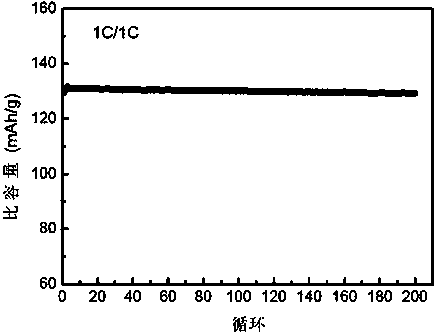

High-voltage electrolyte for lithium ion battery and application of high-voltage electrolyte

InactiveCN104282944AImprove high pressure resistanceImprove interface film-forming propertiesSecondary cellsIonSolvent

The invention discloses a high-voltage electrolyte for a lithium ion battery and an application of the high-voltage electrolyte. The high-voltage electrolyte is prepared from the following components including a non-aqueous solvent, lithium salts, a first kind of additive and a second kind of additive, wherein the non-aqueous solvent is a carbonate solvent; the first kind of additive contains fluoro alkenyl ether, and a chemical formula of the first kind of additive is as follows: CHF2CF=CHOCFHCF3; the second kind of additive is one or a mixture of the following components of 1,3-lactone allylsulfonate, 1,4-lactone butene sulfonate and vinylene carbonate. Matched with a lithium nickel manganese oxide material, the lithium ion electrolyte provided by the invention is capable of meeting the requirement of recycling of the lithium ion battery under a high voltage condition, so that the cycling stability of a lithium nickel manganese oxide battery under the high voltage condition is excellent.

Owner:SHANGHAI POWER ENERGY STORAGE BATTERY SYST ENG TECH +1

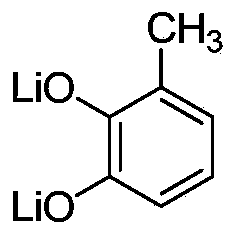

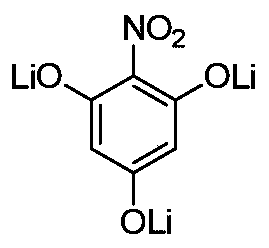

Preparation method of organic pre-lithiated material

ActiveCN111128567ARich typeHigh specific capacity for delithiationHybrid capacitor electrodesDouble layer capacitorsOrganic solventSimple aromatic ring

The invention belongs to the field of lithium batteries, and particularly relates to a preparation method of an organic pre-lithiated material. The preparation method of the organic pre-lithiated material comprises the following steps: 1. weighing a certain amount of aromatic cyclic phenol organic matters, dissolving in an anhydrous organic solvent, stirring to dissolve to obtain a uniform solution, slowly adding a lithium salt into the uniform solution, and carrying out stirring reaction; and 2, adding n-hexane into the reaction solution, filtering to obtain solid powder, washing with an n-hexane / tetrahydrofuran mixed solvent, repeating for three times, and drying the obtained solid powder to obtain the final positive electrode organic pre-lithiation material product. The preparation method of the organic pre-lithiated material provided by the invention has the advantages that the structure is adjustable, the lithium intercalation potential is proper, the organic pre-lithiated material can be directly doped into a positive electrode, and the safety is good.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

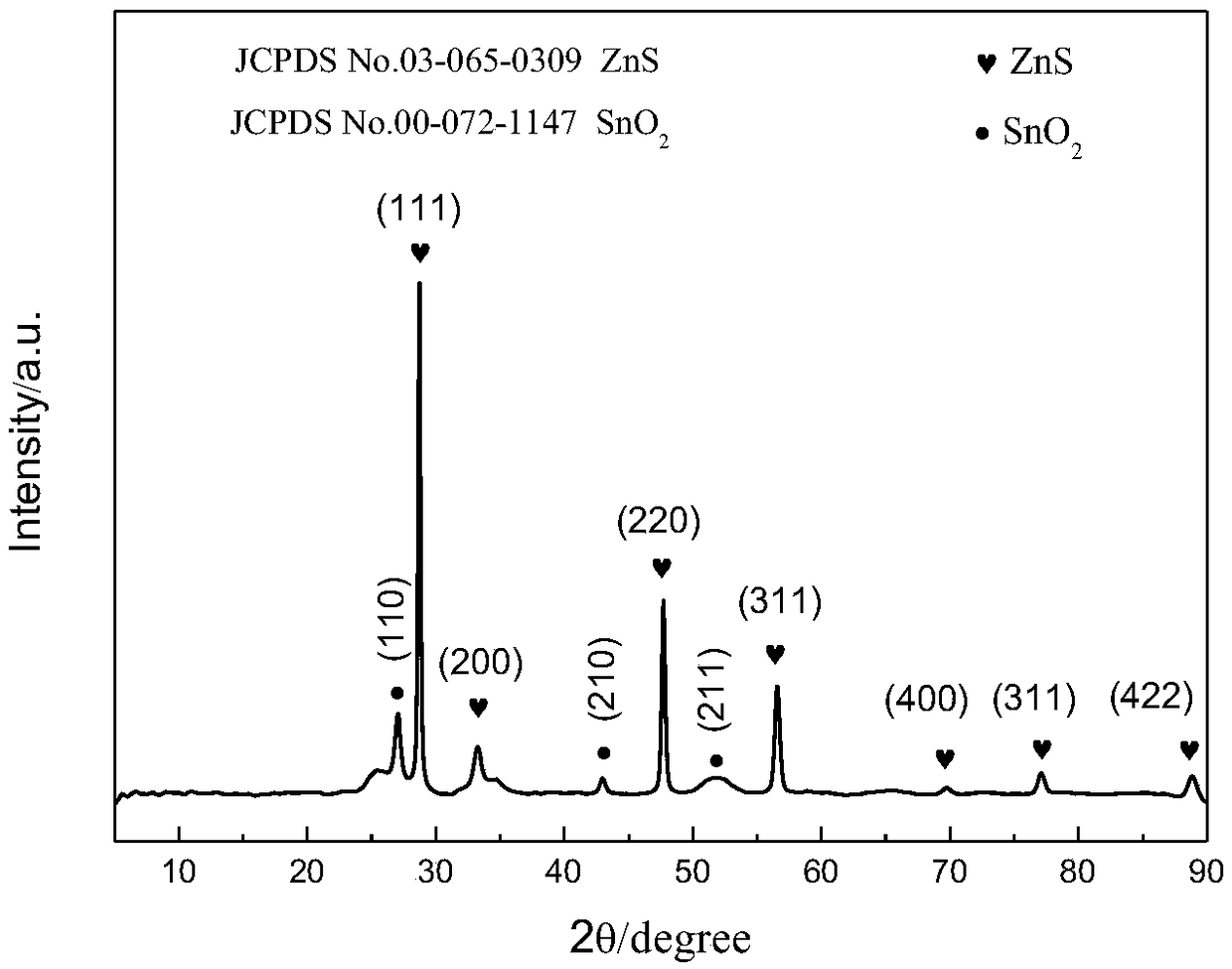

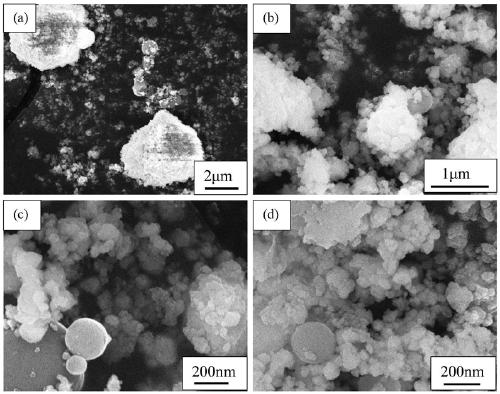

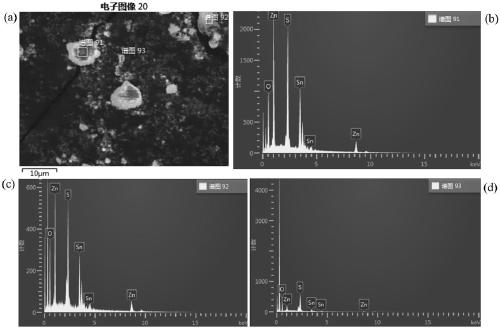

Method for preparing cathode material ZnS/C-SnO2 of sodium ion battery by utilizing tin sludge

ActiveCN109378458ARealize comprehensive high-value recyclingEasy to operateCell electrodesSecondary cellsTinningSludge

The invention relates to a method for preparing a cathode material ZnS / C-SnO2 of a sodium ion battery by utilizing tin sludge. The method comprises the following steps: S1, washing and drying tin sludge to obtain an SnO2 material; S2, preparing a ZnS / C composite material by a one-step hydrothermal method, namely performing a hydrothermal reaction by using zinc salt, sulfur source and organic carbon source as raw materials, collecting precipitate and drying to obtain a composite material precursor after the reaction is completed, roasting the composite material precursor in an inertial atmosphere to obtain a ZnS / C composite material; and S3, mixing the SnO2 material prepared in the step S1 with the ZnS / C composite material prepared in the step S2 in a proportion to prepare the cathode material ZnS / C-SnO2 of a sodium ion battery. According to the method, the problem that tin sludge generated in tinning is not properly recycled can be solved, the problem of high cost of SnO2 can be solvedby preparing the cathode material of a sodium ion battery from the tin sludge, the cost for raw materials can be effectively reduced, the concept of low cost for sodium ion batteries can be met, andcomprehensive utilization of resources can be realized.

Owner:NORTHEASTERN UNIV

Safe lithium ion battery

InactiveCN111342116AImprove securityDoes not affect electrochemical performanceSecondary cells servicing/maintenanceMolecular sievePhysical chemistry

The invention creatively provides a safe lithium ion battery. The outer surface of a negative current collector on the outermost layer in a battery cell of the battery is coated with a molecular sievecoating, and the molecular sieve coating comprises the following components in percentage by weight: 70-90% of a molecular sieve, 10-30% of a conductive agent and 10-20% of a binder. According to thelithium ion battery provided by the invention, the outer surface of a negative plate on the outermost layer of the battery cell is coated with the molecular sieve coating for selective adsorption, and the molecular sieve coating is arranged on the surface, far away from the positive plate side, of a first negative plate which does not participate in the chemical reaction of the battery, so that the electrochemical performance of the battery cell is not reduced, gas generated by the battery cell can be effectively adsorbed, and the safety performance of the battery cell is obviously improved.

Owner:TIANJIN ENERGIES

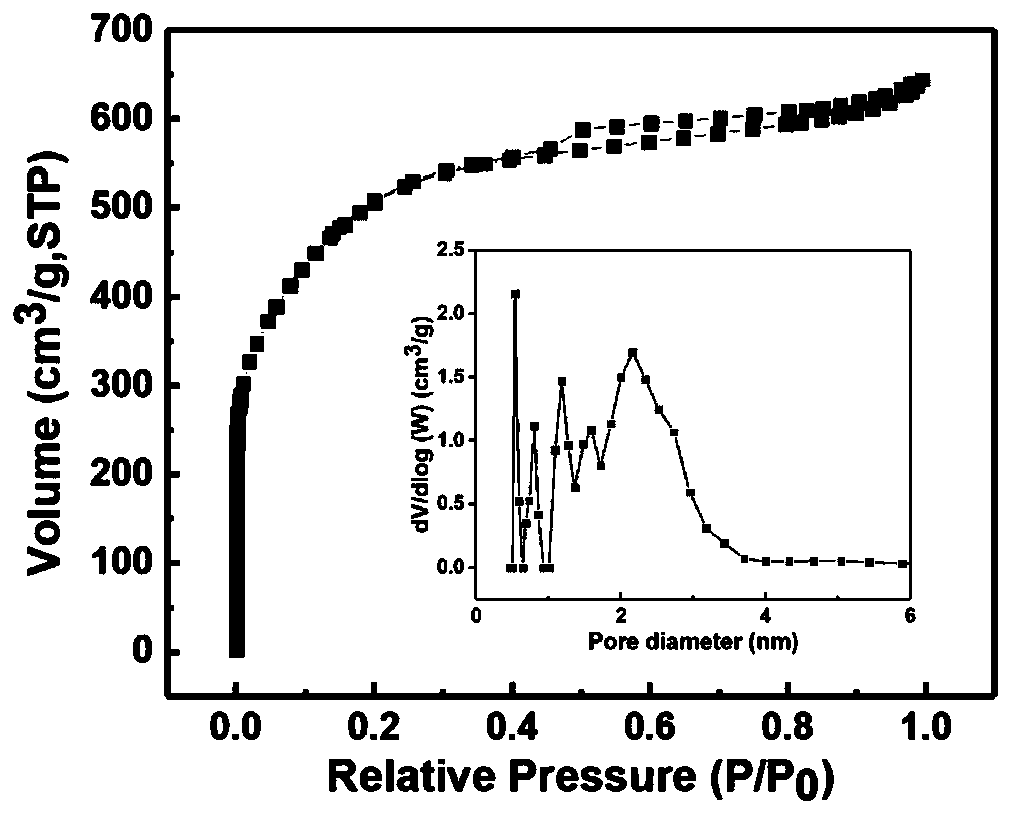

Carbon nanotube/graphene/activated carbon composite electrode material and preparation method and application thereof

ActiveCN110797202AImprove performanceOvercome the disadvantage of single pore structureHybrid capacitor electrodesHybrid/EDL manufactureElectrolytic agentActivated carbon

The invention relates to a carbon nanotube / graphene / activated carbon composite electrode material and a preparation method and application thereof. The carbon nanotube / graphene / activated carbon composite electrode material is prepared by the steps of adding activated carbon, carbon nanotubes and graphene oxide into a dispersant aqueous solution, uniformly mixing, adding the mixed solution into a reactor, stirring, carrying out a co-reduction reaction under the conditions of a reducing agent and a certain temperature, and finally filtering, cleaning and drying the obtained reaction product to obtain the high-performance carbon nanotube / graphene / activated carbon ternary composite electrode material. The carbon nanotube / graphene / activated carbon composite electrode material has a hierarchicalthree-dimensional porous structure, a high specific surface area and excellent conductivity, overcomes the defect of single pore structure of the activated carbon, enables the activated carbon to still have high specific capacity and high rate performance in an organic electrolyte, can be used as an electrode material of a supercapacitor, and is widely applied to the field of electrochemical material preparation.

Owner:威海三合永新能源科技有限公司

Method for determining performance of PTC material for lithium-ion batteries

InactiveCN106970123AFast glass transition temperatureFast measurementElectrical testingMaterial electrochemical variablesVitrificationComposite electrode

The invention relates to a method for determining the performance of a PTC material for lithium-ion batteries. The method comprises: 1) measuring the glass transition temperature of a PTC material; 2) measuring the PTC effect generation temperature of a PTC composite electrode; 3) measuring the resistance of the lithium-ion battery of the PTC composite electrode at different temperatures; and 4) detecting the electrochemical performance and the safety performance of the lithium-ion battery of the PTC composite electrode. According to the present invention, by determining the performance of the material, the PTC material for the lithium-ion batteries can be accurately selected so as to improve the safety of the lithium-ion energy storage battery.

Owner:CHINA ELECTRIC POWER RES INST +2

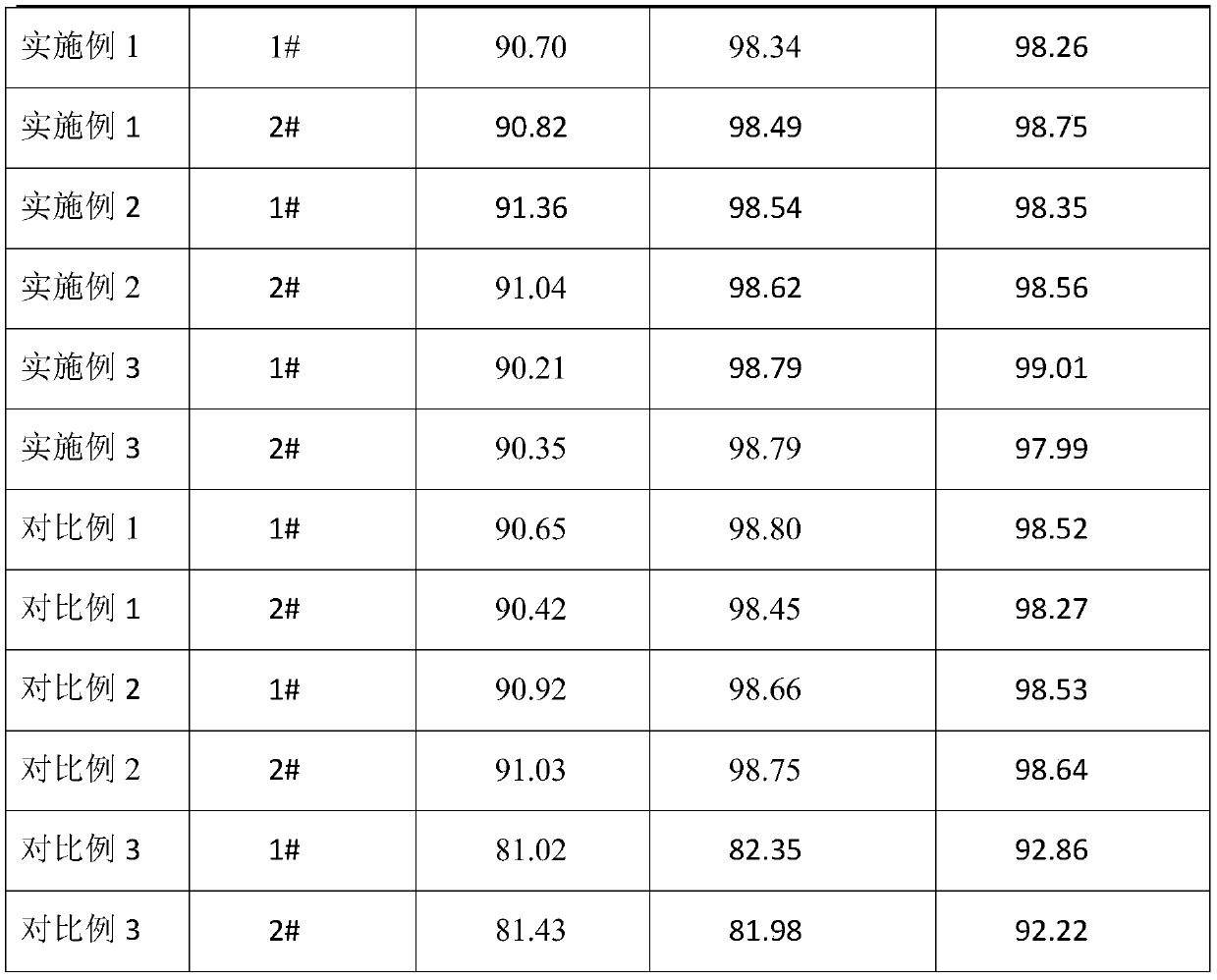

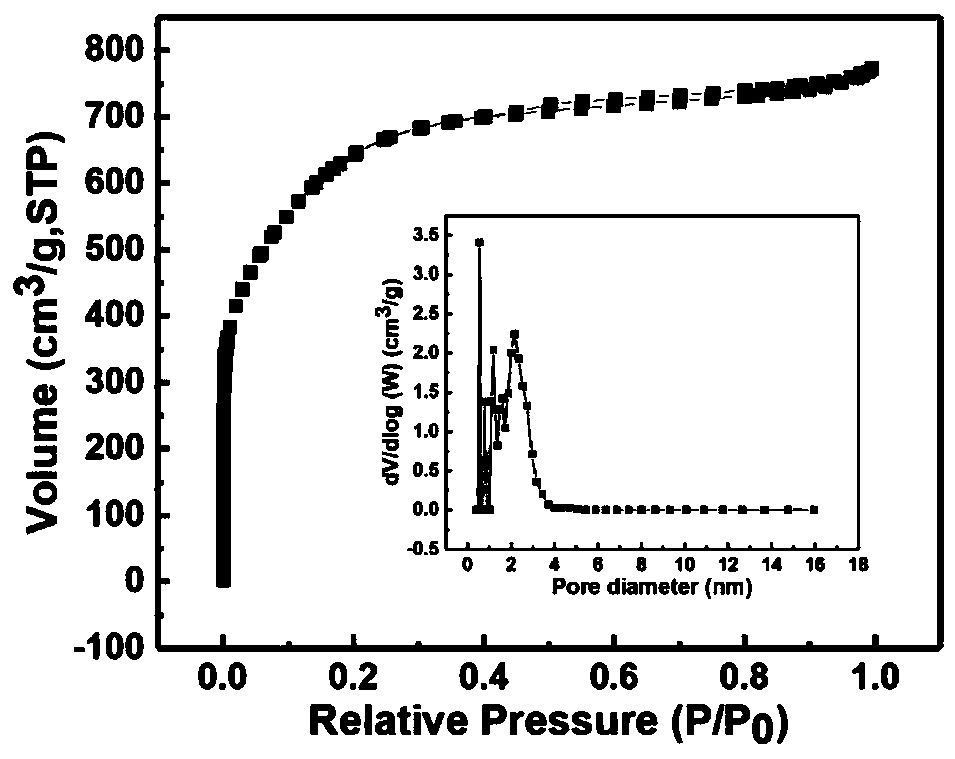

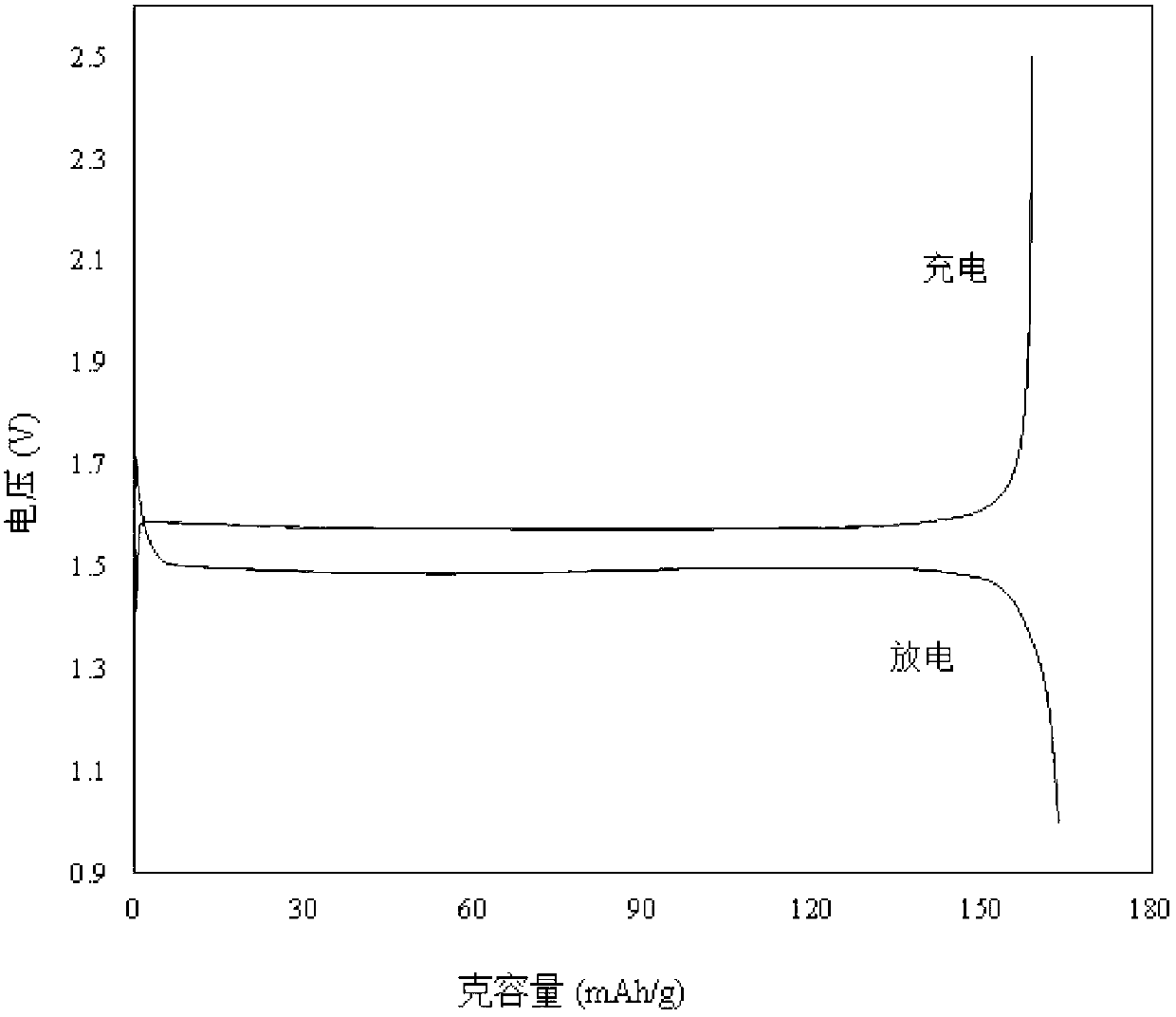

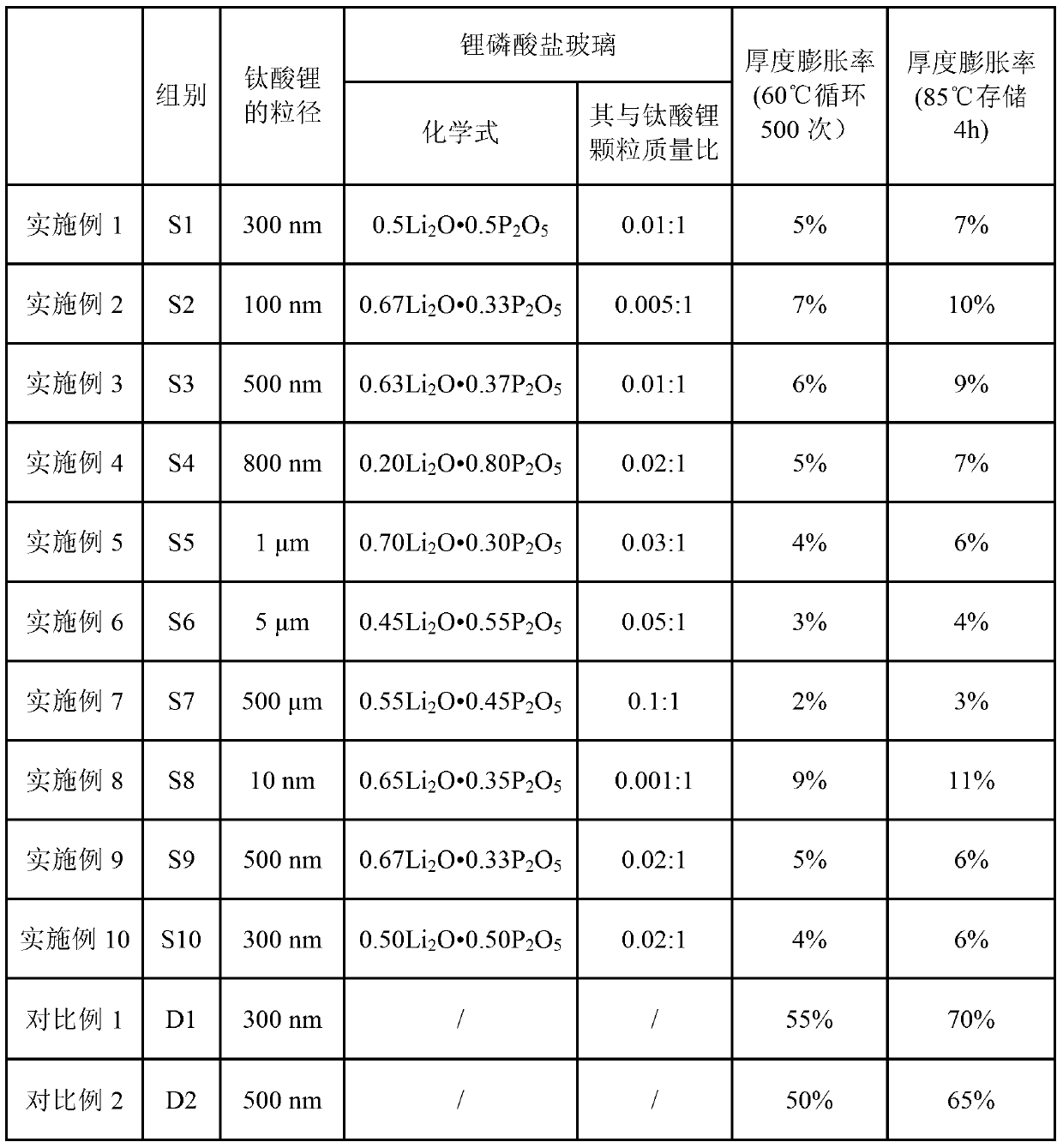

Lithium titanate composite material and preparation method and application thereof

ActiveCN103280568AAvoid direct contactInhibitory responseCell electrodesHigh temperature storageSlurry

The invention provides a lithium titanate composite material and a preparation method and application thereof. The lithium titanate composite material comprises lithium titanate particles and lithium phosphate glass coated on the surface of the lithium titanate particles. The preparation method comprises the following steps of: uniformly mixing the lithium titanate particles and the mixture of a lithium source and a phosphorus source in a liquid system solvent to obtain uniformly-mixed liquid; performing ball milling on the uniformly-mixed liquid to form slurry; taking out the slurry and drying to obtain the precursor powder of the composite material; calcining the precursor powder of the composite material; and cooling and breaking to obtain the lithium titanate composite material of which the lithium phosphate glass is coated by the lithium titanate on the surface. The lithium titanate composite material is used as an active substance of a lithium ion battery or an electrode material of a capacitor. The lithium titanate composite material can suppress expansion of a lithium ion battery when applied to the lithium ion battery, improves the high-temperature storage and cycle performance of the lithium ion battery, increases the diffusion coefficient of lithium ions in the active substance, and is favorable for improving the rate capability of lithium titanate.

Owner:NINGDE AMPEREX TECH

Preparation method of aqueous high rate sodium ion battery

InactiveCN108183269AImprove securityGood charge and discharge performanceFinal product manufactureSecondary cellsIonChemistry

The invention discloses a preparation method of an aqueous high rate sodium ion battery. The method includes the steps of: firstly taking a sodium source, a vanadium source, and ammonium dihydrogen phosphate as the raw materials to prepare a precursor, and then performing sintering at certain temperature to obtain a sodium ion battery positive electrode material; mixing the prepared sodium ion battery positive electrode material with a conductive agent and a binder, then adding the mixture into an organic solvent, and performing stirring to obtain a positive slurry, then coating a current collector surface with the slurry, and conducting drying and rolling to obtain a positive plate; then preparing a negative plate; preparing an electrolyte solution, finally superimposing the prepared positive plate, negative plate and a diaphragm, and conducting stacking winding with a winding machine into a coiled battery core, and putting the battery core in a battery shell, injecting the prepared electrolyte solution, and performing sealing to obtain the sodium ion battery. The sodium ion battery prepared by the method provided by the invention has good safety and excellent cycling performance.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

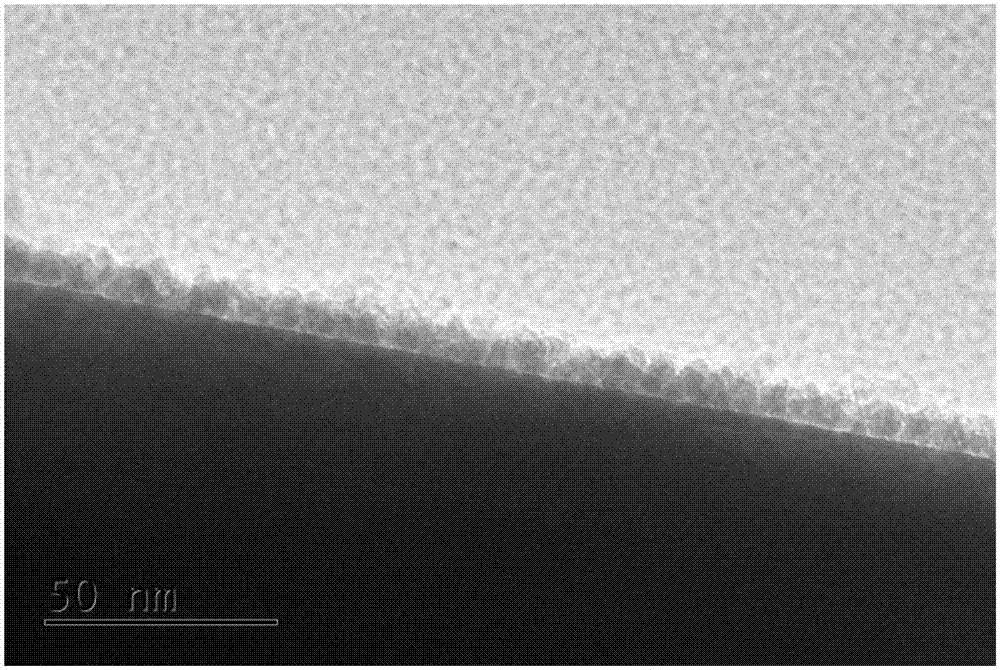

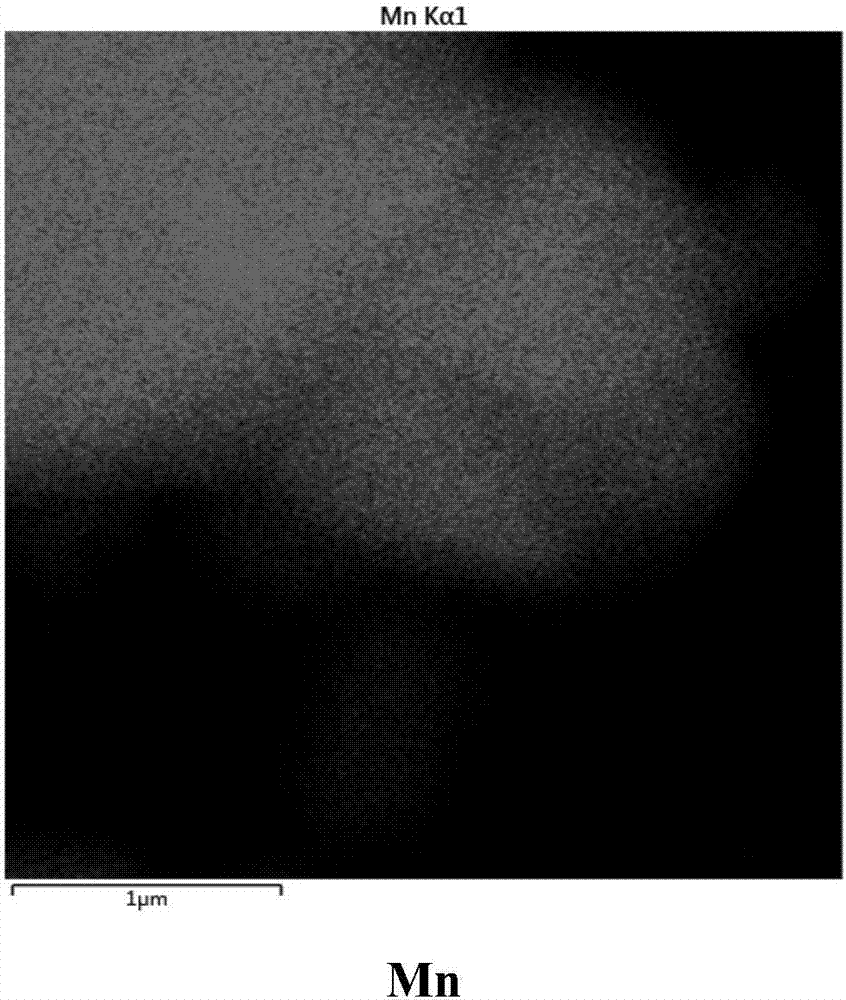

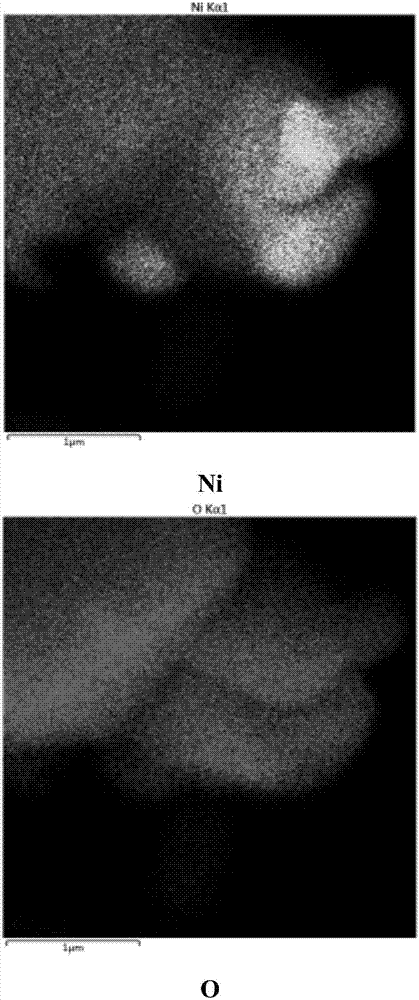

Method for uniformly doping surface of material with metal ions, and product thereof, and application of product

ActiveCN107978755AReduce corrosionReduced responseCell electrodesSecondary cellsLithium-ion batterySide reaction

The invention relates to a method for uniformly doping the surface of a material with metal ions, and a product thereof, and application of the product. The method mainly comprises the following steps: uniformly depositing a nanolayer of metal ions on the surface of a material (such as a positive electrode material); carrying out special heat treatment to realize inward penetration and doping of the metal ions on the surface of the substrate material within a specific thickness range; and acquiring a quantitatively-doped surface nanolayer on the surface of the substrate material. The positiveelectrode material prepared by using the method can effectively realize passivation of the surface and is reduced in the degree of side reactions and improved in the stability of the material; meanwhile, doping of the metal ions is only carried out in a range of 1 to 30 nm deep from the surface, and the body structure of the material is not affected, so the material can retain its original ion transmission characteristics and overcome the problem of unfavorable influence of traditional coating on the electrochemical performance of the material, and thus, the material has high practical application prospects in the field of lithium ion batteries.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Current collector, electrode plate and lithium ion battery

PendingCN113394406ADoes not affect electrochemical performanceReduce generationFinal product manufactureElectrode carriers/collectorsElectrical batteryLithium-ion battery

The invention provides a current collector, an electrode plate and a lithium ion battery. The current collector comprises a base material and a safe coating applied on at least one surface of the base material, the safe coating comprises flame-retardant particles, a heat-resistant additive, a conductive agent and a binder; and the flame-retardant particles are converted into an insulating layer between the base material and the safe coating at 80-180 DEG C. According to the current collector, the base material is coated with the safe coating with safety, the flame-retardant particles are added into the safe coating, the flame-retardant particles do not change during the normal use temperature period of a battery and do not influence the electrochemical performance of the battery; and when the temperature exceeds the normal use temperature of the battery, and reaches 80-180 DEG C, the flame-retardant particles can be decomposed and converted into the compact insulating layer between the base material and the safe coating, so that the contact between an active substance and the base material is greatly blocked, the transmission of lithium ions and electrons is hindered, and a short-circuit switch is cut off in time, and therefore, the purpose of preventing the thermal runaway of the battery is achieved.

Owner:HUIZHOU LIWINON ELECTRONIC TECH CO LTD

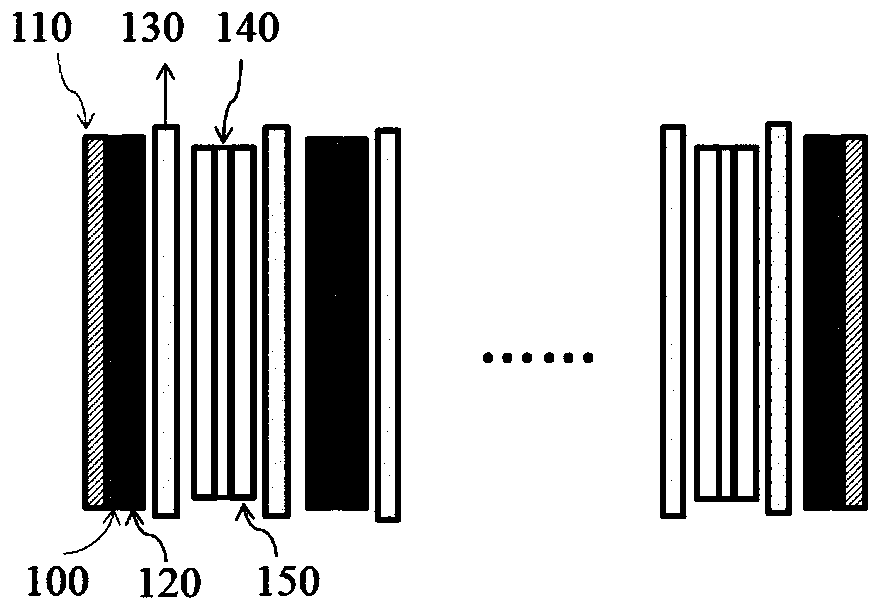

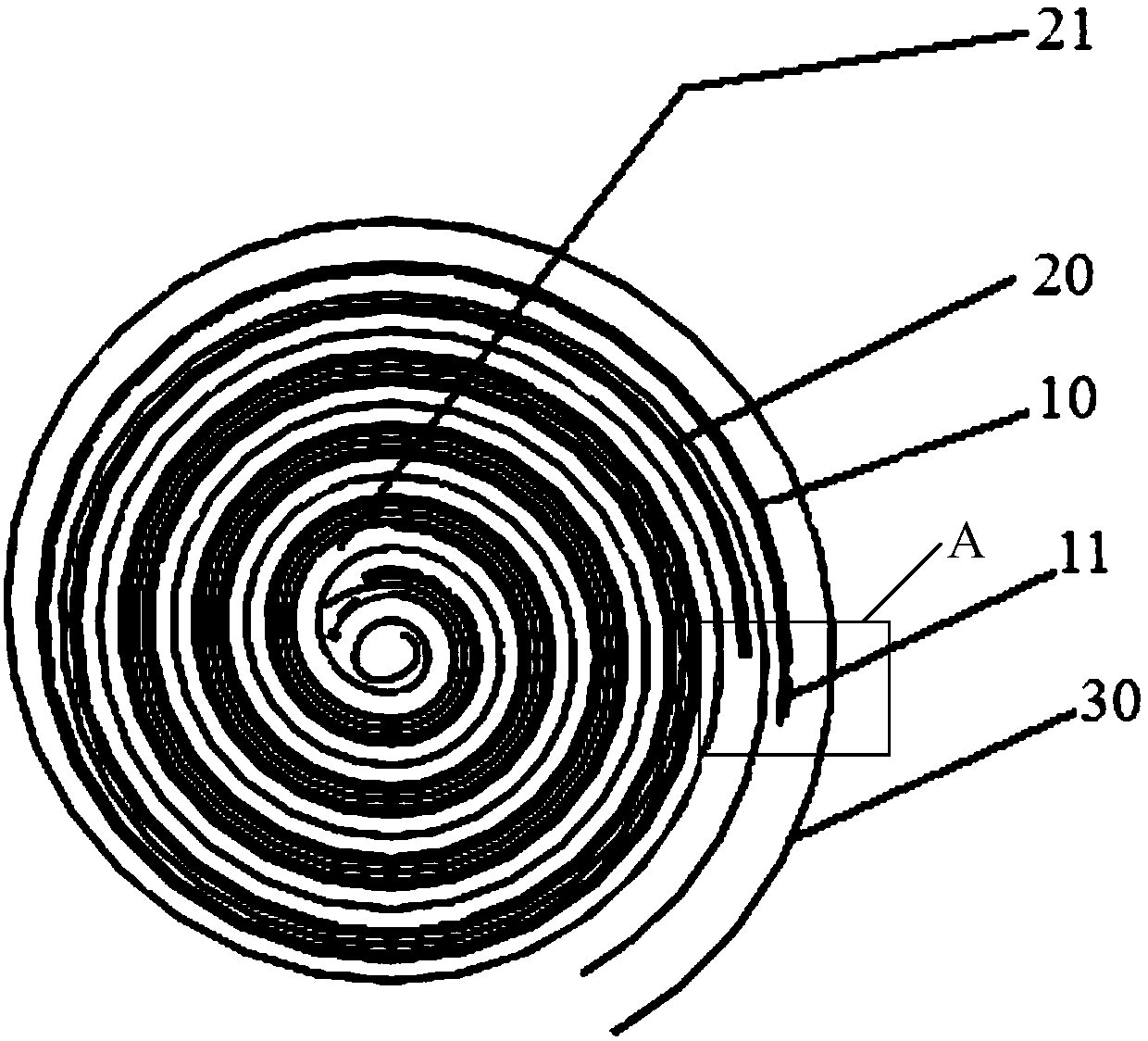

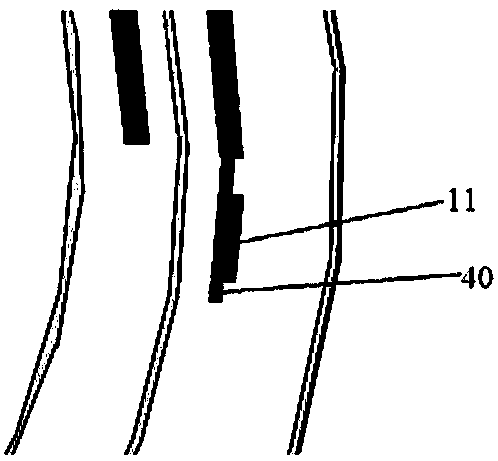

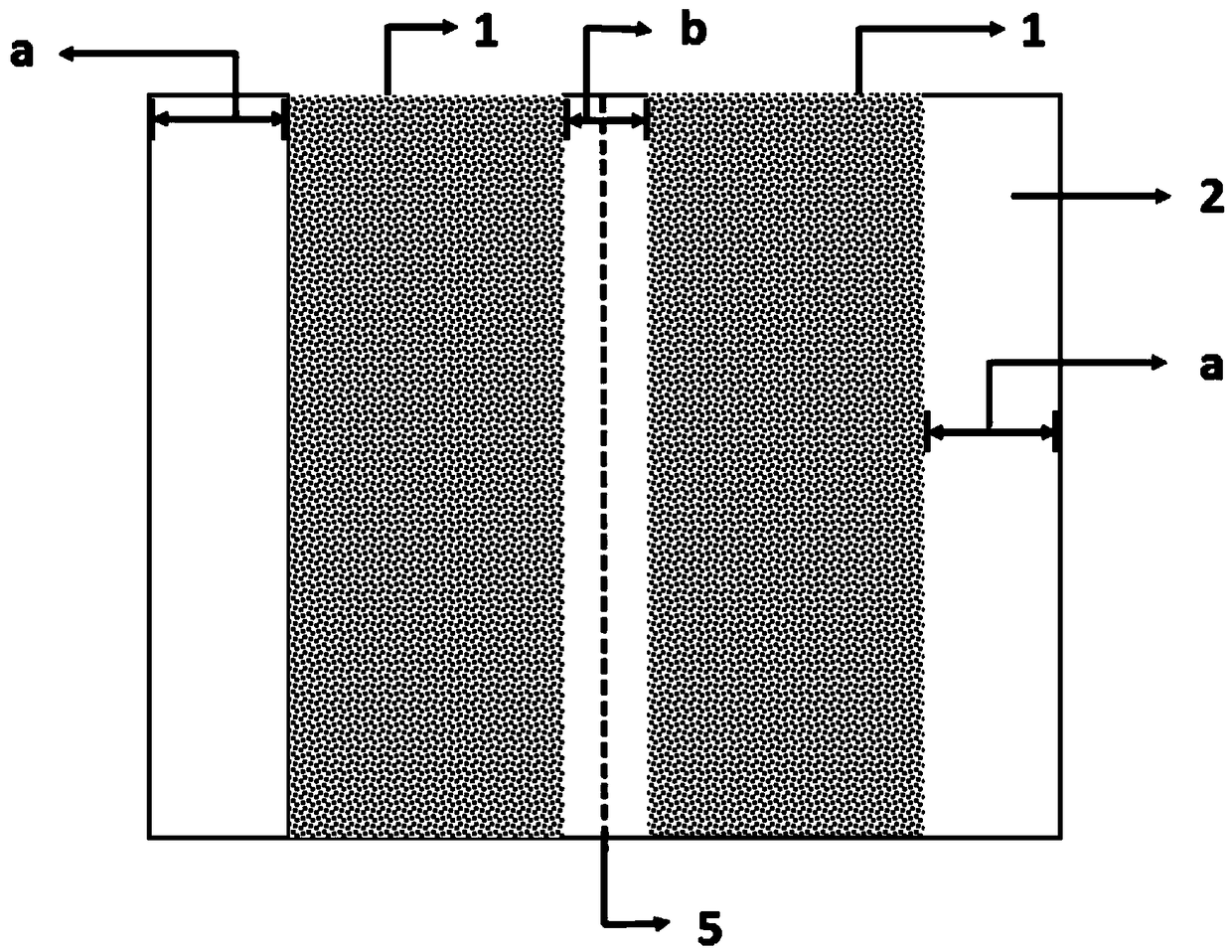

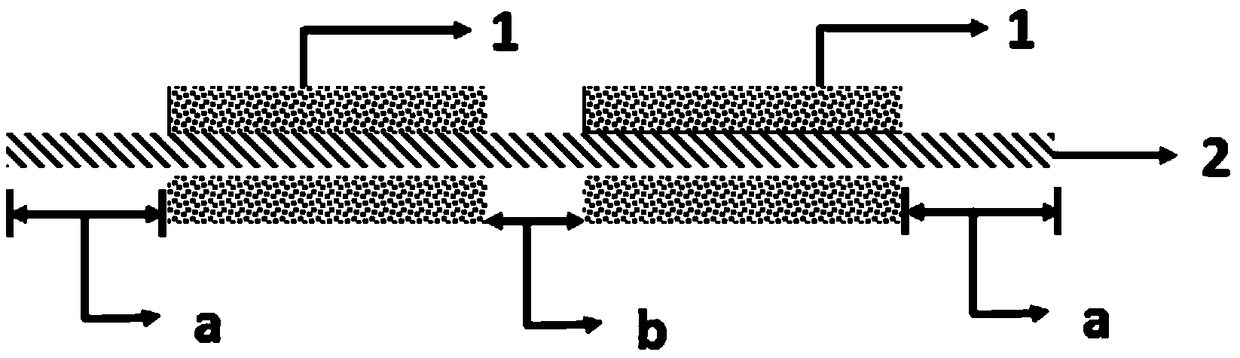

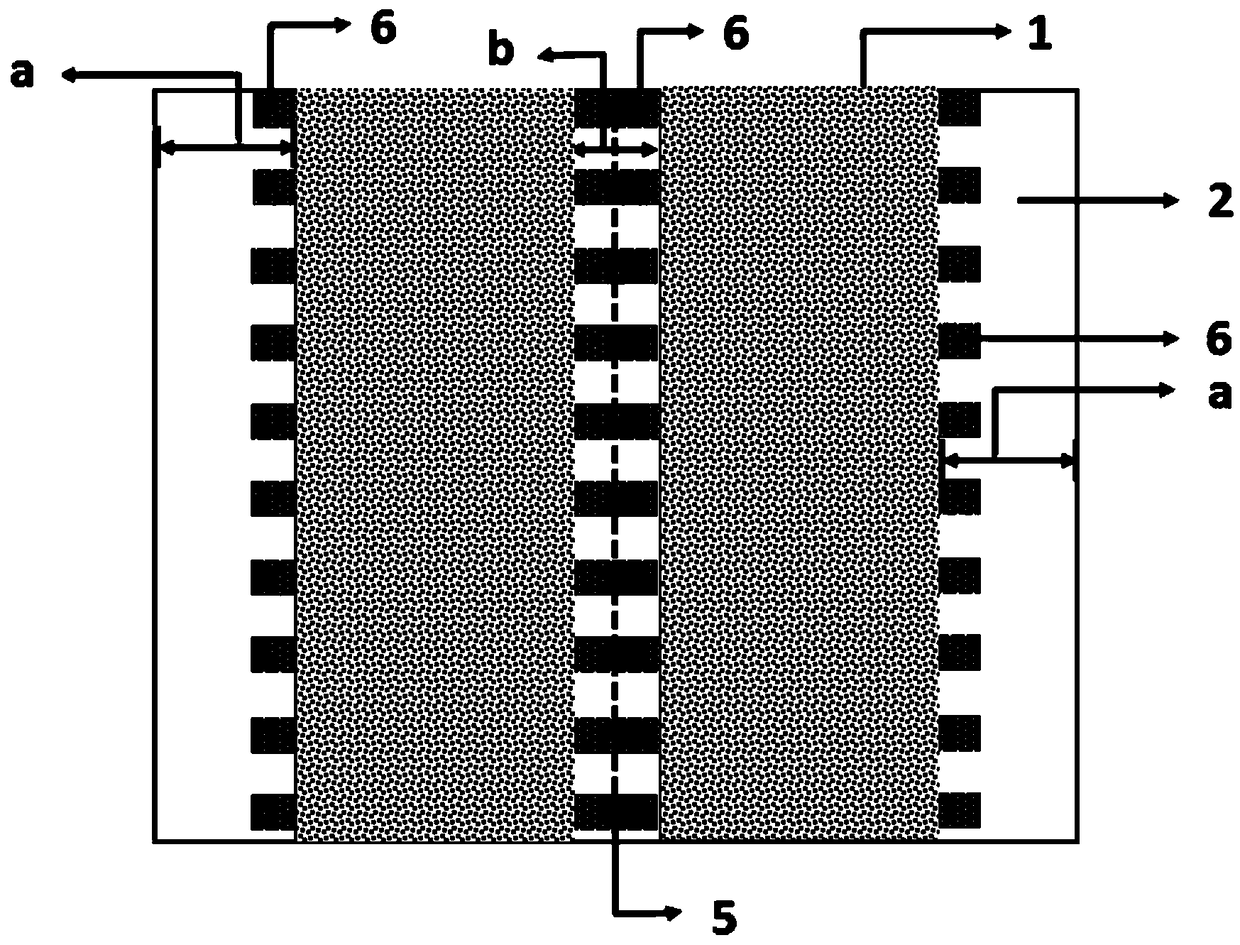

Safe lithium ion battery coil core and lithium ion battery

PendingCN107732318AHigh mechanical strengthImprove securityFinal product manufactureSecondary cellsEngineeringElectrochemistry

The invention discloses a safe lithium ion battery coil core and a lithium ion battery containing the safe lithium ion battery coil core. The safe lithium ion battery coil core is formed by winding anegative plate, a positive plate and a diaphragm stacked between the negative plate and the positive plate, wherein an electrode plate on the outer side of the safe lithium ion battery coil core is the negative plate; the tail end of the negative plate on the outer side of the safe lithium ion battery coil core is a blank tail end without a negative active layer; a negative tab is electrically connected to the surface, which deviates from the inner side of the safe lithium ion battery coil core, of the blank tail end; a temperature-resistant insulating layer is bound to the surface, which faces the inner side of the safe lithium ion battery coil core, of the blank tail end; and the temperature-resistant insulating layer and the negative tab are in negative correspondence at an electric connection point on the surface of the blank tail end. The safe lithium ion battery coil core and the lithium ion battery with the same disclosed by the invention have high safety and excellent electrochemical performance.

Owner:DONGGUAN CHUANGMING BATTERY TECH

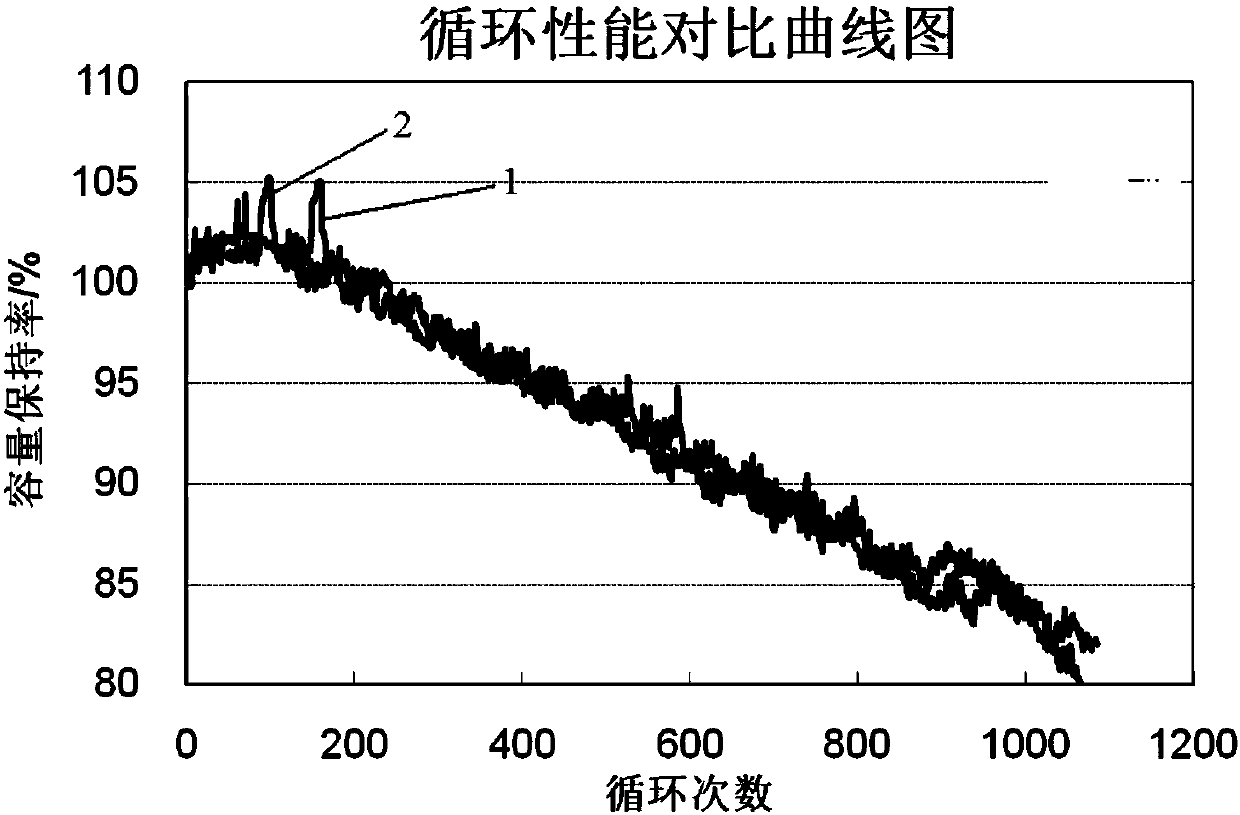

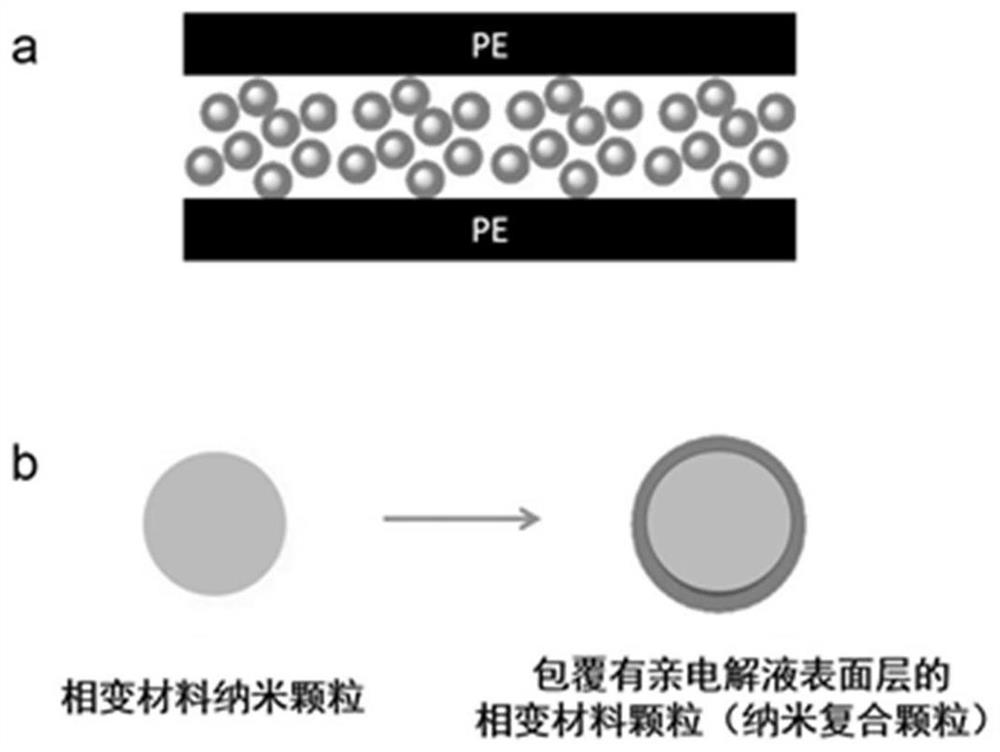

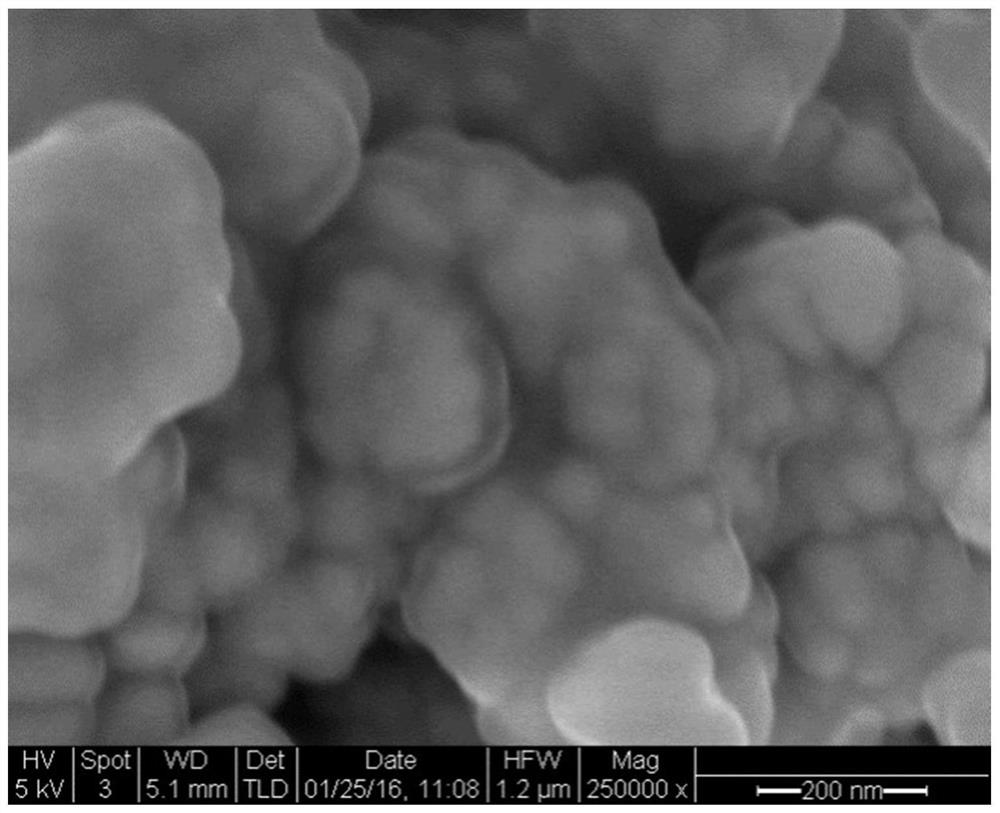

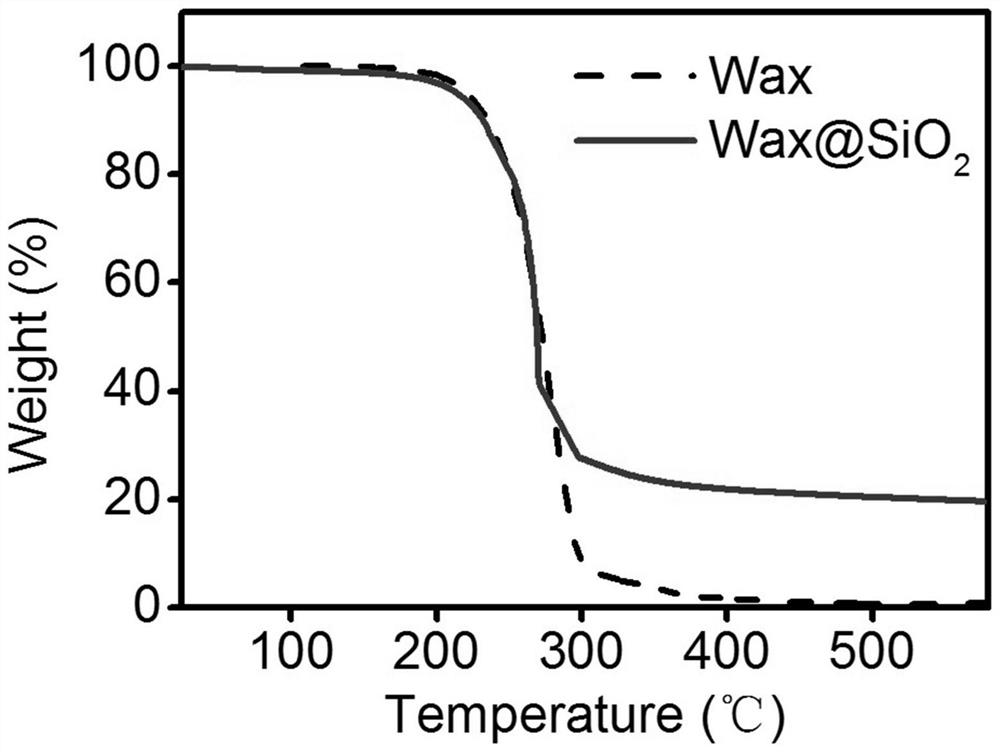

Composite particle for battery, battery separator, and lithium ion battery

InactiveCN111916632AEnsure safetyTemperature controlSecondary cellsCell component detailsElectrical batteryLithium-ion battery

The invention belongs to the field of batteries, and particularly relates to a composite particle for a battery, a battery diaphragm and a lithium ion battery. The composite particle for the battery comprises a phase change particle and an inorganic compound coating layer coating the surface of the phase change particle, wherein the phase change particles are paraffin, crystalline hydrated salt ormolten salt; and the inorganic compound coating layer is silicon dioxide, attapulgite, kaolinite, montmorillonite, hydrotalcite, vermiculite, sepiolite, mica, illite, diatomite, titanium dioxide, zinc oxide, aluminum oxide or nanocellulose. The composite particle for the battery provided by the invention can effectively control the internal temperature of the lithium ion battery, reduce the internal temperature fluctuation of the lithium ion battery during charging and discharging, absorb part of heat during thermal runaway, reduce the heat release amount of the battery to a certain extent, ensure the safety of the lithium ion battery, and does not affect the electrochemical performance of the battery.

Owner:TSINGHUA UNIV +1

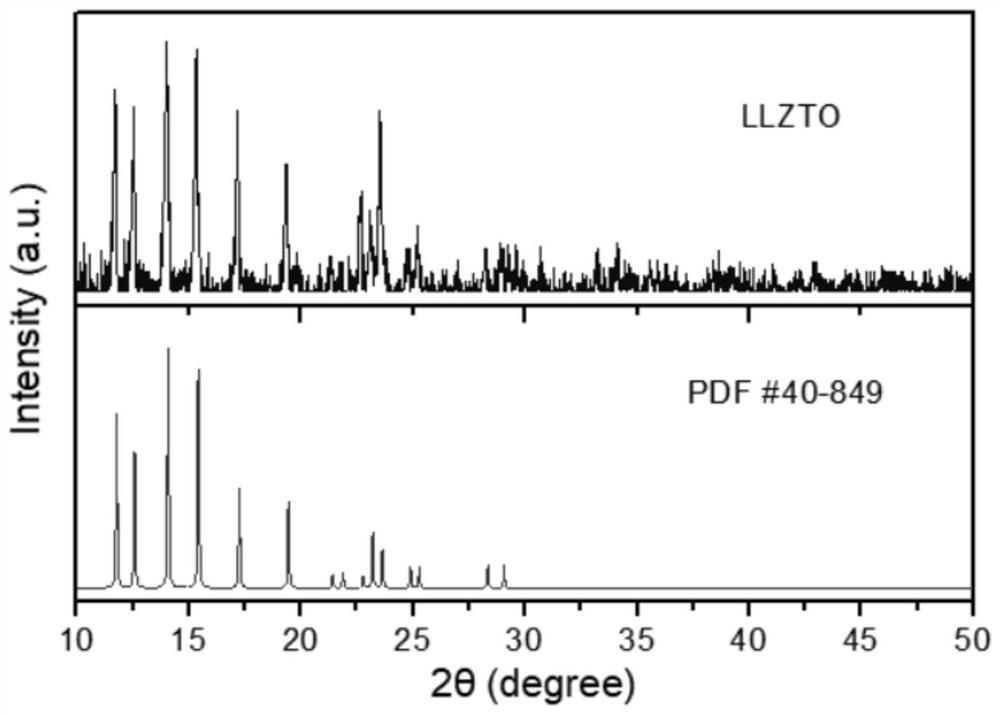

High-safety composite solid electrolyte and preparation method thereof

InactiveCN112290083AImprove ionic conductivityInhibit side effectsSolid electrolytesSecondary cells servicing/maintenanceSolid state electrolyteLithium-ion battery

The invention belongs to the technical field of batteries, and relates to a composite solid electrolyte and a preparation method thereof. The electrolyte comprises a polymer, a lithium salt, a flame retardant and an inorganic solid electrolyte, the mass ratio of the lithium salt to the polymer is (0.4-0.8): 1, the mass ratio of the flame retardant to the polymer is (0.2-0.5): 1, and the mass ratioof the inorganic solid electrolyte to the polymer is (5-50): 100. The electrolyte adopts an organic-inorganic composite structure, so that side reaction can be effectively avoided, the ionic conductivity of lithium ions is improved, the conductivity of the lithium ions at room temperature can reach 10<-4> Scm<1>, and an electrochemical stability window is about 5V. Besides, by adding the flame retardant, the electrolyte has the characteristic of non-combustibility, and the potential safety hazard of combustion and even explosion caused by preheating of the liquid electrolyte in the traditional lithium ion battery is avoided.

Owner:西安越遴新材料研究院有限公司

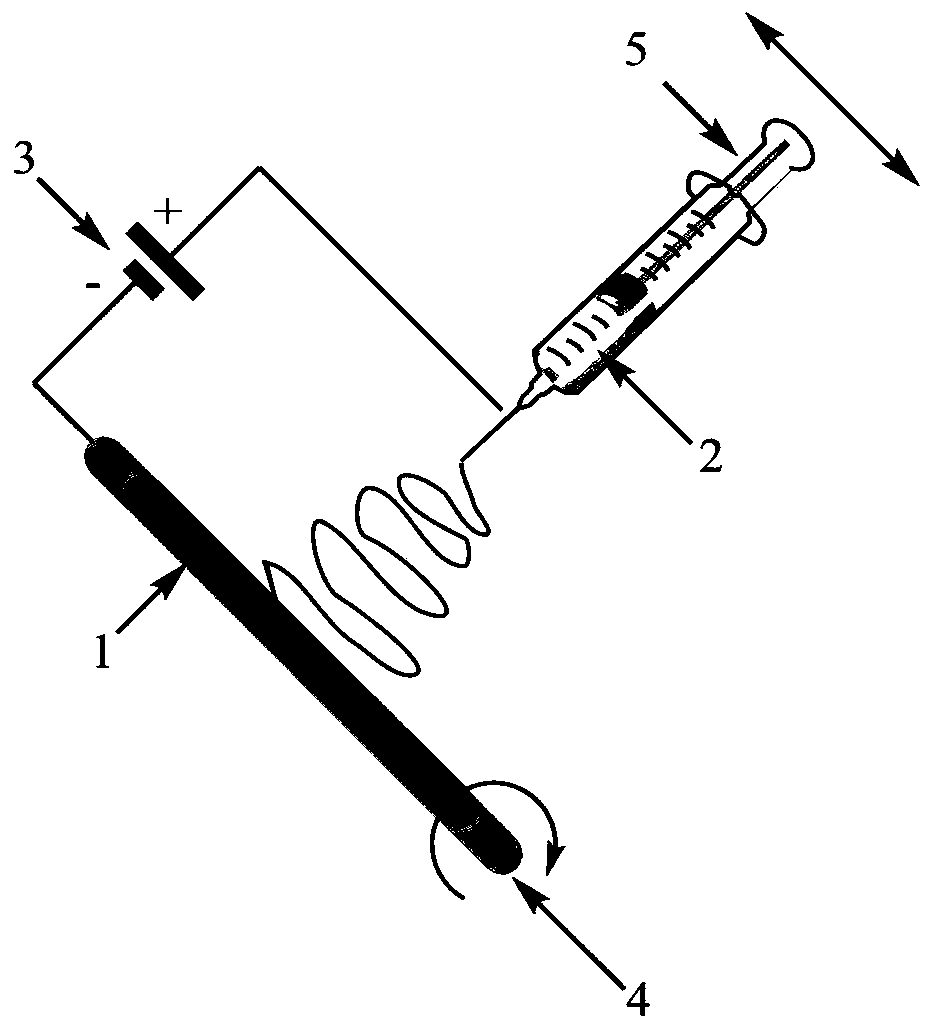

Manufacturing method of high-energy-density aluminum shell lithium ion battery

InactiveCN113078364AIncrease energy densityIncrease gram capacityFinal product manufactureElectrode carriers/collectorsElectrical batteryHigh energy

The invention provides a manufacturing method of a high-energy-density aluminum shell lithium ion battery, which comprises the following steps: S1, preparing a positive plate and a negative plate, assembling an aluminum shell battery, keeping insulation between the aluminum shell and the positive plate and the negative plate of the battery, and then injecting a pre-lithiation electrolyte into the aluminum shell battery; S2, connecting the aluminum shell with the positive electrode of an external power supply, connecting the negative plate with the negative electrode of the external power supply, and charging with small current for pre-lithiation; and S3, removing the pre-lithiated electrolyte, injecting a functional electrolyte, and then performing activation and sealing to obtain the high-energy-density aluminum shell lithium ion battery. According to the method, in-situ lithium pre-embedding of the negative electrode of the lithium ion battery can be accurately controlled, so that lithium consumption in the processes of negative electrode film forming and the like in the first-time charging process is compensated, gram volume exertion of the positive electrode material in the actual lithium ion battery is improved, and due to the fact that additional auxiliary electrodes or electrode materials do not need to be added in the lithium pre-embedding process, andoperation is simple and convenient. And the capacity and the energy density of the lithium ion battery can be improved.

Owner:CENT SOUTH UNIV

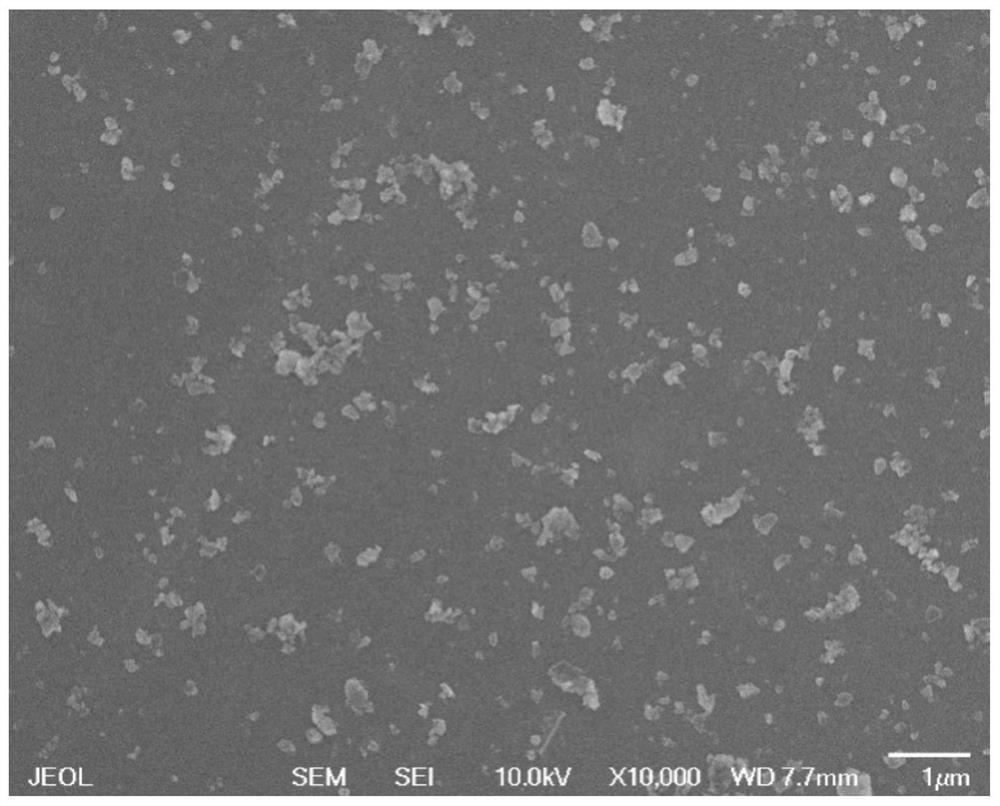

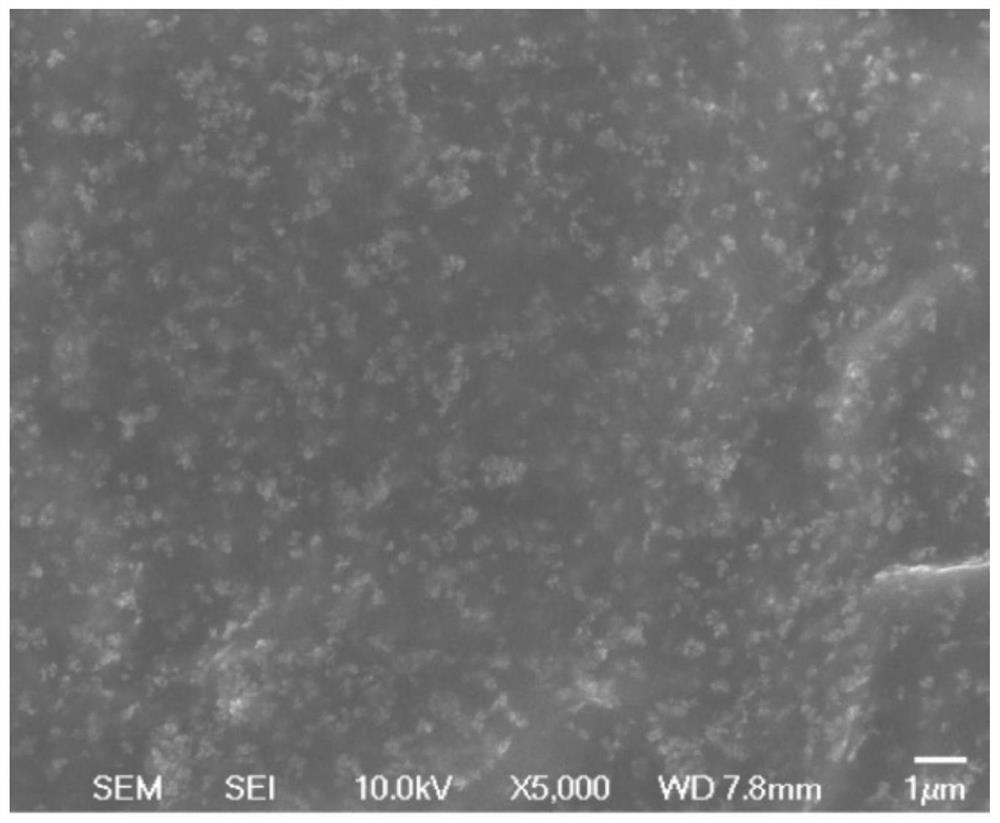

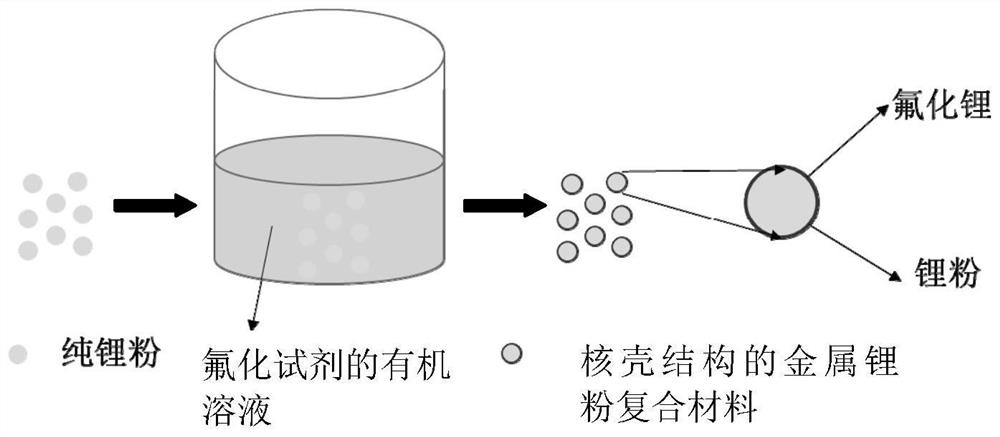

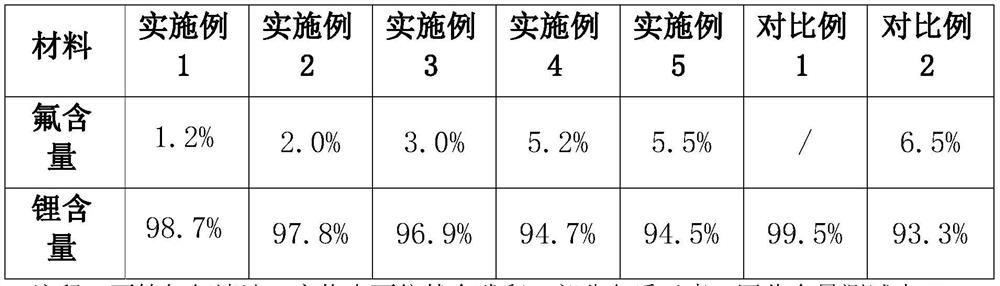

Metal lithium powder composite material and preparation method thereof, silicon-oxygen negative electrode and lithium ion battery

PendingCN114094098ASimple preparation processMild conditionsNegative electrodesSecondary cellsMetallic lithiumElectrical battery

The invention belongs to the technical field of batteries, and particularly relates to a preparation method of a metal lithium powder composite material, which comprises the following steps: obtaining an organic solution of metal lithium powder and a fluorinating reagent; and carrying out mixed reaction on the organic solution of metal lithium powder and a fluorinating reagent in an inert atmosphere at the temperature of 0-90 DEG C to obtain the metal lithium powder composite material. According to the preparation method of the metal lithium powder composite material, the preparation process is simple, the condition is mild, high-temperature calcination is not needed, water and oxygen are strictly controlled, the application flexibility of the preparation method is improved, and meanwhile the preparation safety is improved. The method has better application performance in the aspect of pre-lithiation reagents, can effectively improve the first effect of silicon-oxygen lithium ion batteries and the like, and does not affect the electrochemical performance of a battery system.

Owner:SHANGHAI CENAT NEW ENERGY

A lithium ion battery have a high safety electrode sheet and a method for manufacturing that same

ActiveCN109193025AFreeze fastAvoid contact short circuitFinal product manufactureCell component detailsRoom temperaturePole piece

The invention discloses a lithium ion battery with high safety pole piece, including a housing, a bare battery core is arranged in the shell, the bare cell includes a cathode electrode sheet and an anode electrode sheet. The cathode pole piece and the anode pole piece are staggered or wound, an isolation film is arranged between the anode pole piece and the cathode pole piece, two sides of the anode pole piece or the cathode pole piece with one end of the pole ear and two sides of the opposite end of the pole ear are provided with a plurality of adhesive strips, and the adhesive strips and theadjacent isolation film are adhered and connected. The adhesive strips can be rapidly solidified at room temperature, melted when the high temperature fixture is formed and bonded to the insulating film under pressure. Bonding of the insulating film can prevent the short circuit of cathode-anode contact caused by the shrinkage of the insulating film at high temperature, thereby improving the safety performance of the cell. The invention is applied to the technical field of batteries.

Owner:桑顿新能源科技(长沙)有限公司

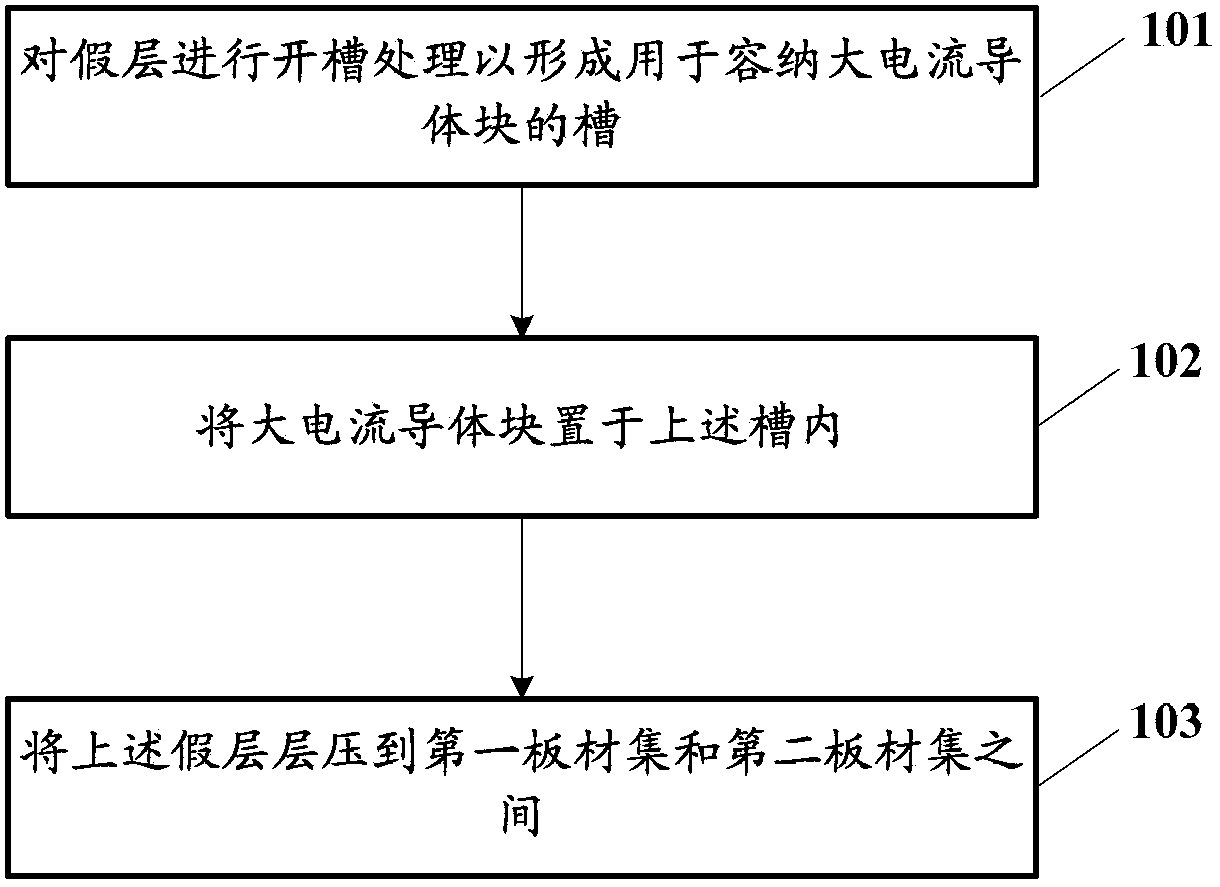

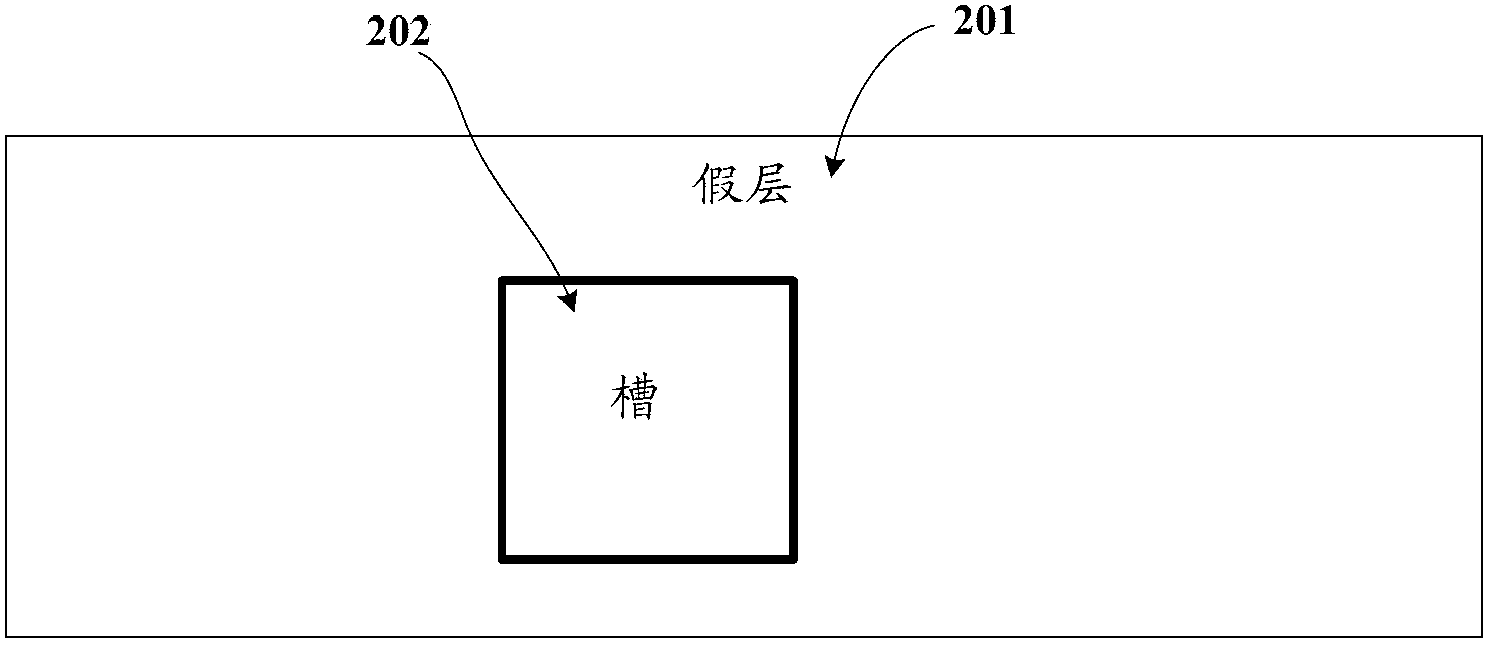

Large-current printed circuit board machining method and large-current printed circuit board

ActiveCN104113990ADoes not affect wiringImprove reliabilityPrinted circuit assemblingPrinted circuit detailsPrinted circuit boardEngineering

The embodiments of the invention disclose a large-current printed circuit board and a machining method thereof. The large-current printed circuit board machining method may comprises the following steps: the slotting process is performed on a false layer to form a slot for accommodating a large-current conductor block; the large-current conductor block is placed in the slot; the false layer is laminated between a first sheet set and a second sheet set, wherein the first sheet set and / or the second sheet set comprises at least one layer of circuit pattern layer; and the large-current conductor block is in connection and conduction with the circuit pattern layer in the first sheet set and / or the second sheet set. According to the scheme of the embodiments of the invention, the PCB reliability can be improved, and the occupation of the large-current conductor block on the circuit layer wiring space can be reduced.

Owner:SHENNAN CIRCUITS

Preparation method and application of lithium battery negative plate

ActiveCN114759164AImprove conductivityBig spaceNegative electrodesSecondary cellsCurrent collectorHigh conductivity

The preparation method specifically comprises the following steps: uniformly mixing a core-shell structure magnetic nano template which takes polyaniline as a shell and Fe3O4 as a core with a negative electrode material, a binder, a conductive agent and a solvent water to prepare negative electrode slurry, coating the surface of a current collector with the negative electrode slurry, and drying to obtain the lithium battery negative electrode plate. The preparation method comprises the following steps: preparing a thick electrode from magnetic nano Fe3O4, directionally assembling the magnetic nano Fe3O4 on the surface of a current collector by loading a magnetic field, recycling the magnetic nano Fe3O4 in the thick electrode through microwave heating and a magnetic recycling device, and constructing a three-dimensional network channel with high conductivity in the thick electrode to effectively improve the conductivity of the electrode, shorten ion and electron migration paths and improve the conductivity of the electrode. A multi-dimensional open permeation channel is provided, the wettability of an electrolyte is enhanced, the electrode tortuosity is reduced, the gradient porosity is generated, a molecular-level channel beneficial to lithium ion transportation is formed, and high-speed conduction of lithium ions is promoted.

Owner:新乡市中天新能源科技股份有限公司

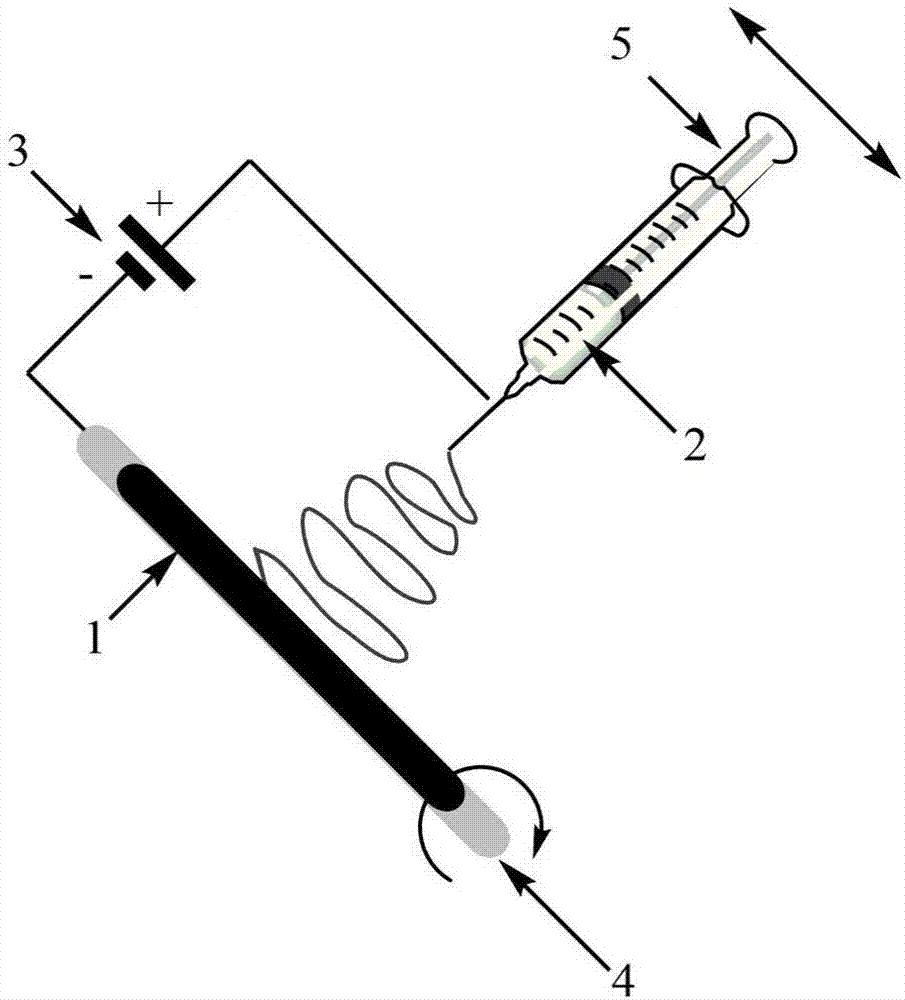

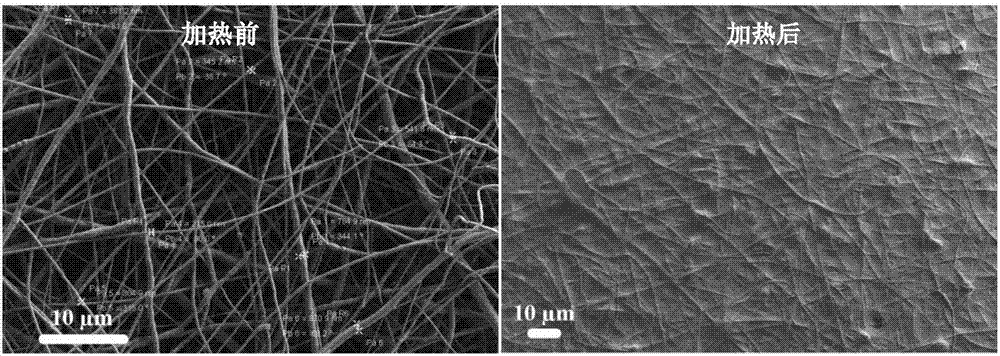

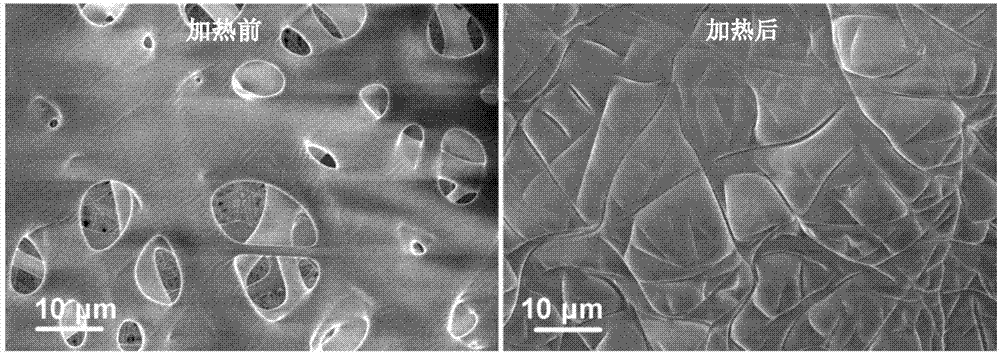

Safety diaphragm used for secondary cells, and preparation method thereof

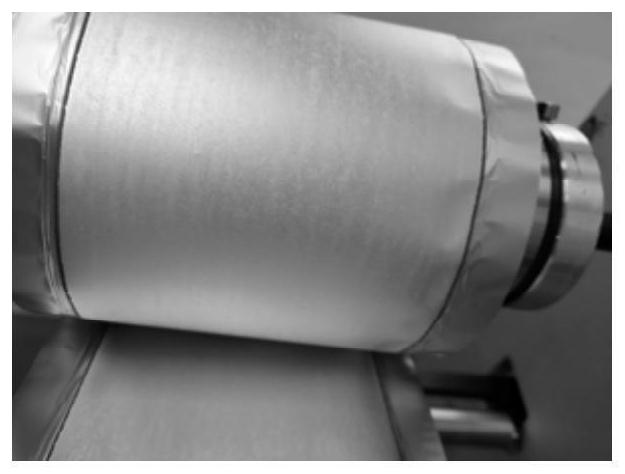

ActiveCN107046118ADoes not affect porosityGuaranteed breathabilityCell component detailsElectrospinningRoom temperature

The invention provides a safety diaphragm used for secondary cells, and a preparation method thereof. The safety diaphragm used for secondary cells possesses heat sealing performance and excellent permeability, and no bonding agent is used in the preparation method. the preparation method comprises following steps: preparation of a spinning solution, wherein at room temperature, a certain amount of a heat sensitive material is dissolved in a spinning solution as a spinning solute, and an obtained mixture is stirred to be uniform so as to obtain an electrostatic spinning solution; electrostatic spinning, wherein a high temperature resistant non-woven fabric diaphragm is taken as a base film, and electrostatic spinning of the electrostatic spinning solution onto the base film is carried out, wherein the temperature is room temperature, positive high voltage is controlled to be +5KV to +20KV, negative high voltage is controlled to be -1KV to -10KV, the left-right horizontal movement speed of a syringe is controlled to be 10 to 60mm*min<-1>, the rolling speed of a collector is controlled to be 10 to 60mm*min<-1>, the injection speed of the electrostatic spinning solution is controlled to be 0.02 to 0.5mm*min<-1>, and the collecting time is controlled to be 10 to 1200min, so that the safety diaphragm used for secondary cells is obtained via drying. The safety diaphragm used for secondary cells comprises the base film, and a spinning layer directly attached onto the base film.

Owner:SHENZHEN JANAENERGY TECH CO LTD

Capsules and lithium-ion batteries

ActiveCN103500806BDoes not affect electrochemical performanceImprove securitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrolytic agentEngineering

Owner:NINGDE AMPEREX TECH

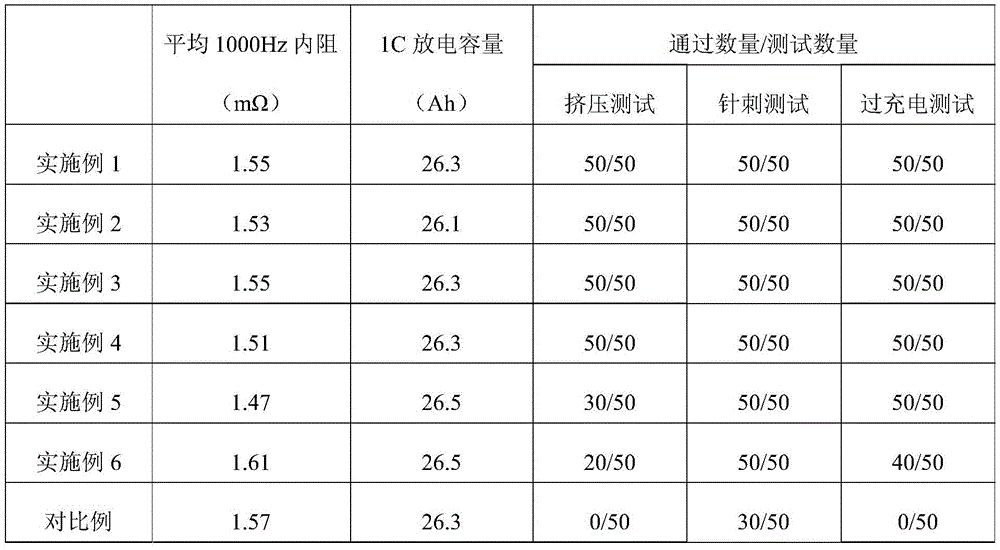

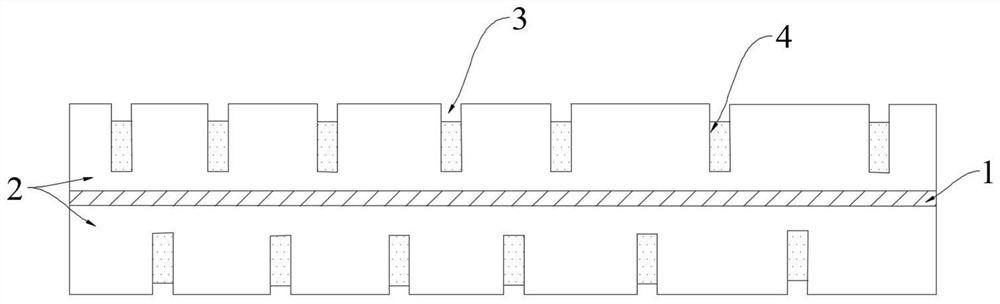

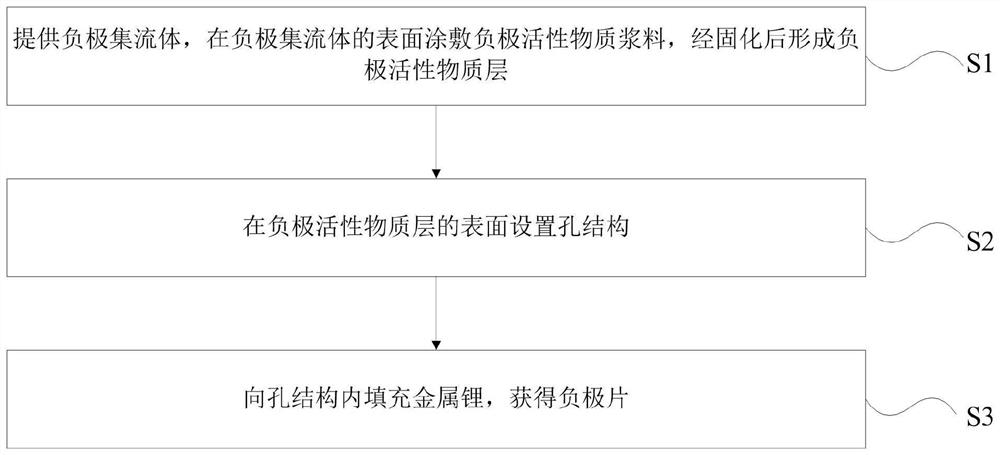

Negative plate, preparation method thereof and battery

PendingCN114583295AShorten the diffusion distanceIncrease energy densityFinal product manufactureNegative electrodesMetallic lithiumBattery cell

The invention provides a negative electrode plate and a preparation method thereof and a battery, the negative electrode plate comprises a negative electrode current collector and a negative electrode active material layer arranged on at least one side surface of the negative electrode current collector, the negative electrode active material layer is provided with a pore structure, and metal lithium is embedded in the pore structure. The pore structure is arranged in the negative electrode active material layer, and the metal lithium is embedded in the pore structure, so that the electrochemical performance of the battery cell is not influenced while lithium is supplemented, and the risk of short circuit of the battery cell caused by lithium separation penetrating through the diaphragm in the battery cell circulation process is avoided as the metal lithium is embedded in the pore structure; and the safety of the battery cell in the circulation process is effectively improved.

Owner:ZHUHAI COSMX POWER CO LTD

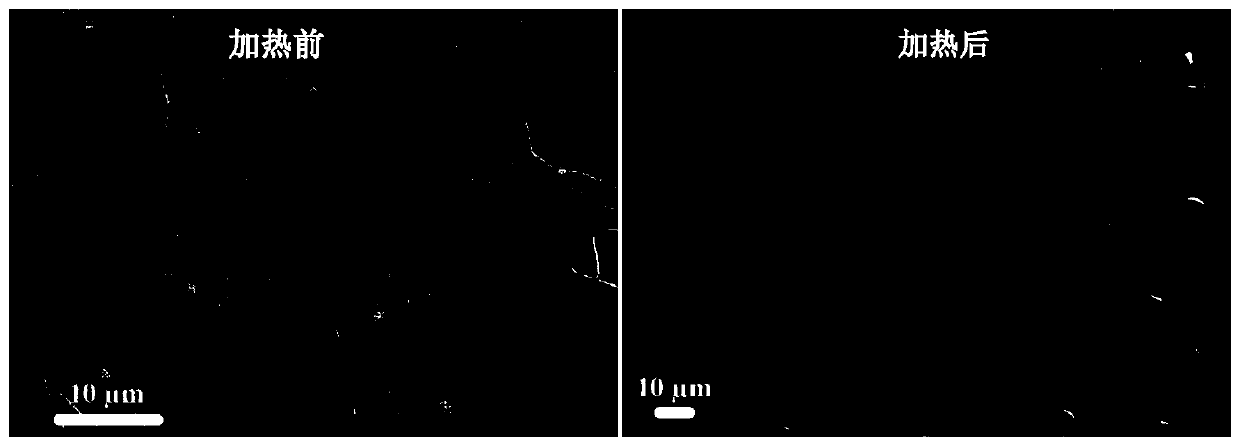

Method for improving surface lithium coating of negative electrode, lithium-supplemented negative electrode and lithium ion secondary battery

PendingCN114171798ASimple processImprove the first effectFinal product manufactureNon-aqueous electrolyte accumulator electrodesPhysicsMetallic lithium

The invention discloses a method for improving lithium coating on the surface of a negative electrode, a lithium-supplemented negative electrode and a lithium ion secondary battery. The method for improving lithium covering on the surface of the negative electrode comprises the steps that a coarsening layer is formed on the surface of a negative electrode active material layer of the negative electrode, the coarsening layer has evenly-distributed nanoscale roughness, ultra-thin metal lithium or a lithium alloy film with the thickness of 1-50 microns is compounded to the coarsening layer through pressure, and the lithium supplementing negative electrode is obtained. The process is simple and easy to operate, and can be used for batch production and application.

Owner:CHINA ENERGY LITHIUM

Safety diaphragm for secondary battery and preparation method thereof

ActiveCN107046118BDoes not affect porosityGuaranteed breathabilityCell component detailsSpinningElectrical battery

The invention provides a safety separator for a secondary battery that has heat sealing properties and excellent gas permeability without using an adhesive and a preparation method thereof. The method for preparing a safety separator for a secondary battery according to the present invention is characterized in that it includes the following steps: a spinning solution configuration step: at room temperature, a certain amount of heat-sensitive material is dissolved in a spinning solvent as a spinning solute In the process, stir evenly to obtain an electrospinning solution; the electrospinning process: use a high-temperature resistant non-woven fabric diaphragm as a base film, and electrospin the electrospinning solution on the base film, and the spinning conditions are: room temperature, positive high pressure It is +5 KV~+20 KV, the negative high voltage is ‑1KV~‑10KV, and the left and right translation speed of the syringe is 10~60 mm min ‑1 , the rolling speed of the collector is 10~60mm·min ‑1 , the exit speed of electrospinning solution is 0.02~0.5mm min ‑1 , the collection time is 10-1200min, and the safety separator for secondary batteries is obtained after drying, wherein the safety separator for secondary batteries includes a base film and a spinning layer directly attached to the base film.

Owner:SHENZHEN JANAENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com