Method for improving surface lithium coating of negative electrode, lithium-supplemented negative electrode and lithium ion secondary battery

A negative electrode and lithium replenishment technology, applied in the field of energy storage, can solve the problems of small gaps in negative electrode material particles, negative electrode sheet crushing and deformation, and transfer to the negative electrode surface, etc., to achieve the effect of simple process and improved first effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of surface roughened negative electrode 1: use 8000 mesh sandpaper to grind and polish the surface of the original negative electrode (negative electrode doped with silicon oxide, thickness 110um) to obtain surface roughened negative electrode 1, the average roughness of the surface of roughened negative electrode 1 is 390nm.

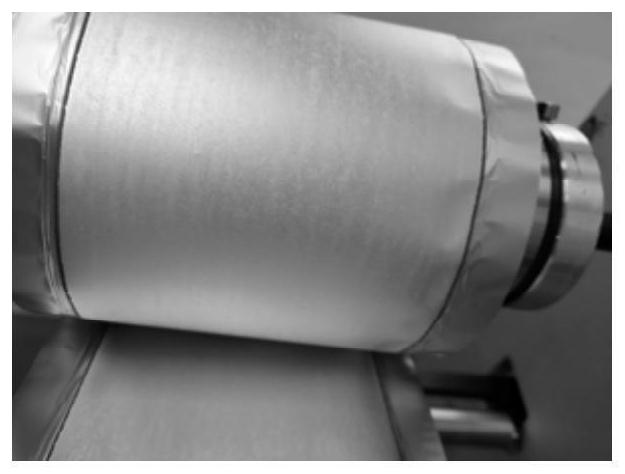

[0052] Lithium-supplementing negative electrode 1 preparation: In a dry workshop with a dew point of -45°C, use a 5um thick ultra-thin lithium foil as a lithium supplementing source, use the above-mentioned surface roughened negative electrode 1 as the negative electrode, and put the upper and lower rolls of lithium foil and the dried surface The roughened negative electrode 1 is composited into a lithium-supplementing negative electrode under a pressure of 5 MPa, such as figure 1 As shown, the metal lithium is all transferred to the surface of the negative electrode, and the surface of the lithium supplemented negative electrode is re...

Embodiment 2

[0054]Preparation of surface roughening negative electrode 2: 30 grams of acetylene black (Shenzhen Kejing Zhida Technology Co., Ltd., average particle size 30nm), 5 grams of polyvinylidene fluoride (PVDF) (Shenzhen Kejing Zhida Technology Co., Ltd.), solvent N-Methylpyrrolidone (NMP) (Shanghai Aladdin Biochemical Technology Co., Ltd.) 1000 grams, obtain uniform slurry by mechanical mixing, by means of dimple coater, on the original negative electrode (negative electrode doped with silicon oxide, thickness 110um ) surface coating to obtain roughened negative electrode 2 (roughened layer thickness 3um), the average roughness of the roughened negative electrode surface is 450nm; dry the roughened negative electrode in a vacuum oven at 80°C for 24 hours, and take it out for use.

[0055] Preparation of lithium-supplementing negative electrode 2: In a dry workshop with a dew point of -45°C, use a 5um thick ultra-thin lithium foil as a lithium supplementing source, use the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com