Preparation method and application of lithium battery negative plate

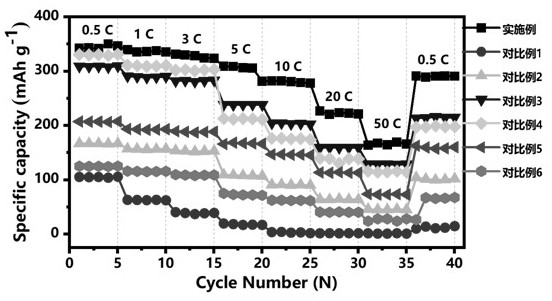

A negative electrode sheet and lithium battery technology, applied in battery electrodes, secondary batteries, inductors/transformers/magnets, etc., can solve problems such as large concentration polarization, increased difficulty, and potential safety hazards, and achieve a large loss tangent , good thermal stability, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

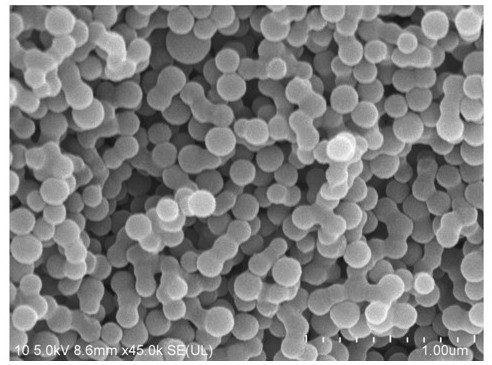

[0032] Step S1: put 1mol·L −1 FeCl 3 ·6H 2 O solution and 0.5mol·L −1 FeSO 4 ·7H 2 Add 50 mL of each O solution into a three-necked round-bottomed flask, stir in an oil bath at 60 °C for 30 min under nitrogen protection, and then add 10 mL with a concentration of 1 mol·L -1 NH 3 ·H 2 O adjusted the pH of the mixed system to 11, and after cooling to room temperature, the black nano-Fe was separated by a magnetic field. 3 O 4 The particles were washed alternately with ethanol and deionized water for several times, and then dried at 60 °C to obtain nano-Fe 3 O 4 particle;

[0033] Step S2: put 0.03g nano Fe 3 O 4 The particles were mixed with 0.04 mmol dodecylbenzene sulfonic acid and 0.0267 mmol hydrochloric acid in deionized water, and then 20 mL was added to a concentration of 0.5 mol L -1 Aniline, with the addition of aniline, the emulsion quickly turned white, continue to stir for 30min, add 30mL dropwise to the reaction solution with a concentration of 1mol·L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com