Capsule and lithium ion battery

A lithium-ion battery and capsule technology, applied in secondary batteries, battery pack components, non-aqueous electrolyte storage batteries, etc., can solve the problem of not being able to prevent the reaction of lithium-ion batteries, affecting the electrochemical performance of lithium-ion batteries, and affecting the formation of negative electrode SEI films And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

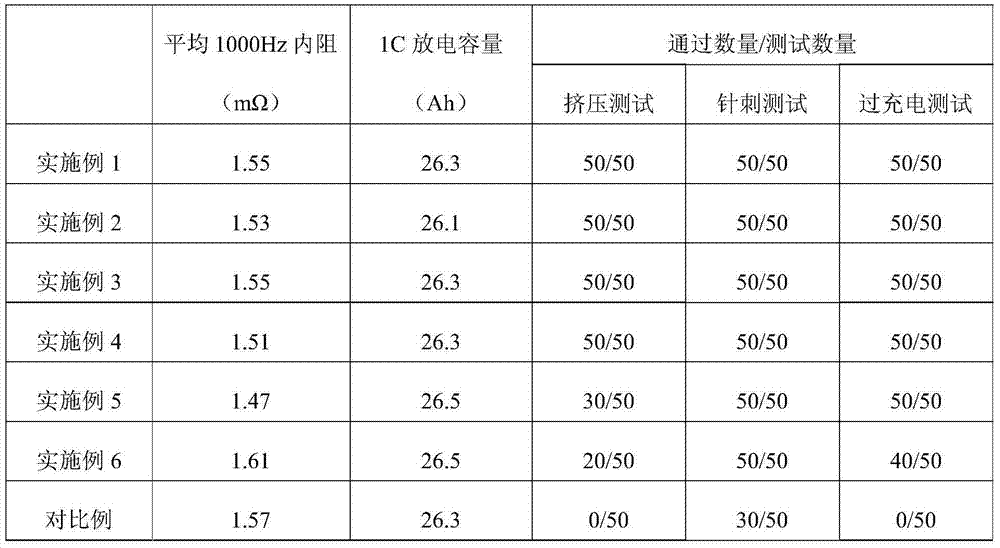

Examples

Embodiment 1

[0027] Capsule preparation: Polyurea as the capsule wall material and trimethyl phosphate (TMP) as the capsule core material were uniformly mixed by in-situ polymerization, and NH 4 Cl is an acid catalyst for acidification for 3 hours, and the final pH value is 2.0, then add styrene-maleic anhydride as an emulsifier, continue to stir vigorously (rotation speed greater than 2000r / min), and then solidify at 70°C for 2 hours to obtain a median particle size of A fluid spherical solid capsule of 100 μm has a wall thickness of 5 μm.

[0028] Preparation of lithium-ion batteries:

[0029]A Preparation of lithium-ion battery positive electrode sheet: the positive electrode active material nickel cobalt lithium manganese oxide, binder polyvinylidene fluoride (PVDF), conductive agent conductive carbon black and solvent N-methylpyrrolidone at a mass ratio of 90:5:5 Mix evenly, and obtain a uniformly dispersed positive electrode slurry by high-speed stirring, and then evenly coat the po...

Embodiment 2

[0034] Capsule preparation: mix polyamide as capsule wall material with dimethyl phosphate (DMMP) as capsule core material by in-situ polymerization, and mix with NH 4 Cl is an acidic catalyst for acidification for 4 hours, and the final pH value is 2.0. Then add styrene-maleic anhydride as an emulsifier, continue to stir vigorously (rotation speed greater than 2000r / min), and then cure at 70°C for 2 hours to obtain a median particle size of The fluid spherical solid capsule of 30 μm has a wall thickness of 0.5 μm.

[0035] Preparation of lithium-ion battery: except that the capsule prepared in this embodiment (i.e. embodiment 2) is used and the mass percentage of the capsule relative to the electrolyte solution is 20%, the rest is the same as in embodiment 1.

Embodiment 3

[0037] Preparation of capsules: Mix gelatin as the capsule wall material and cumyl diphenyl phosphate as the capsule core material under the condition of 70°C / 3MPa, then add Span 80 and glutaraldehyde, and continue stirring Mix evenly, and finally cool under the condition of 30° C. / 3 MPa to obtain a fluid spherical solid capsule with a median particle size of 300 μm and a wall thickness of 50 μm.

[0038] Preparation of lithium-ion battery: the same as in Example 1 except that the capsule prepared in this example (i.e. Example 3) is used and the mass percentage of the capsule relative to the electrolyte solution is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com