A lithium ion battery have a high safety electrode sheet and a method for manufacturing that same

A lithium-ion battery and high-safety technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve problems such as inability to insulate and limit the width of the insulating layer, and reduce the risk of tab breakage Risk, method is simple and easy to implement, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

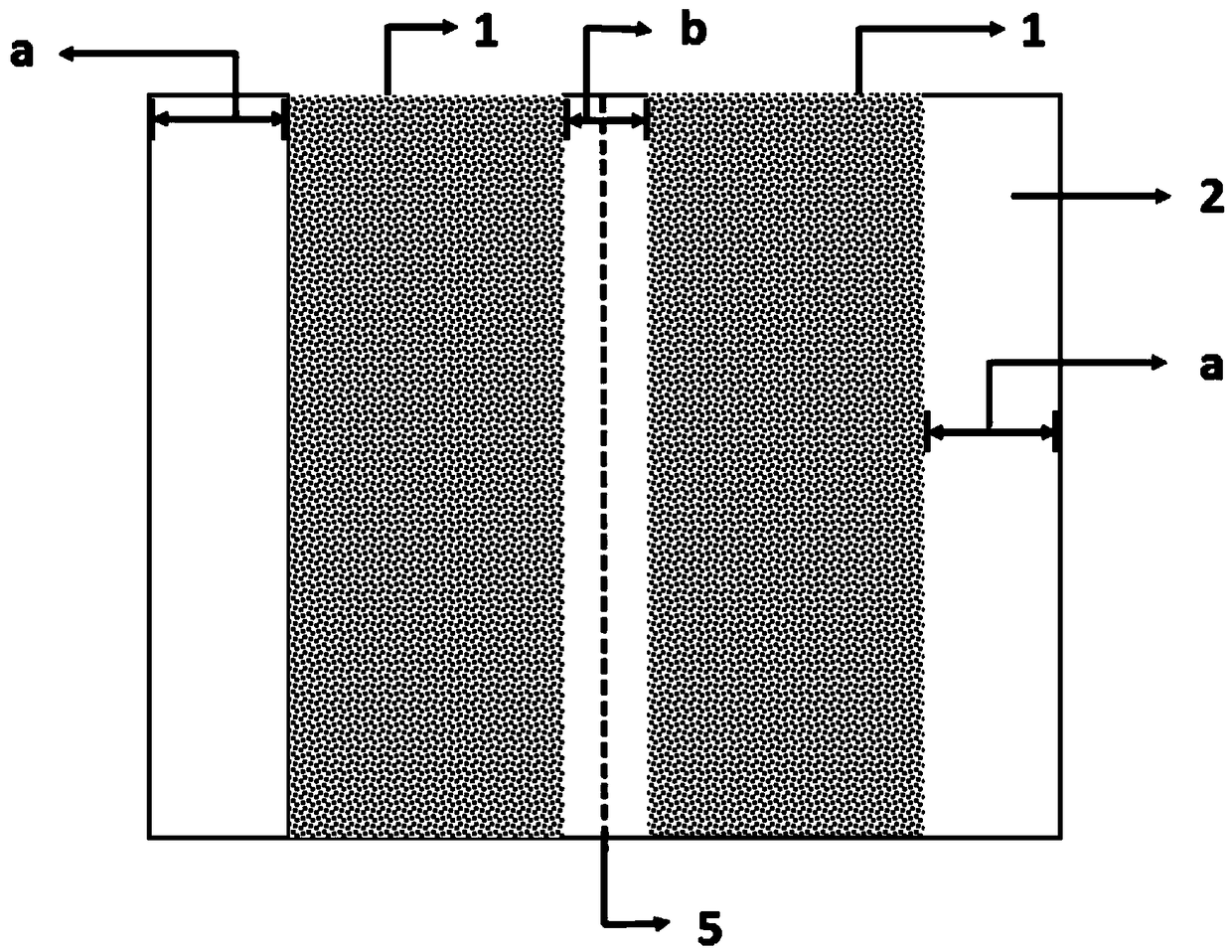

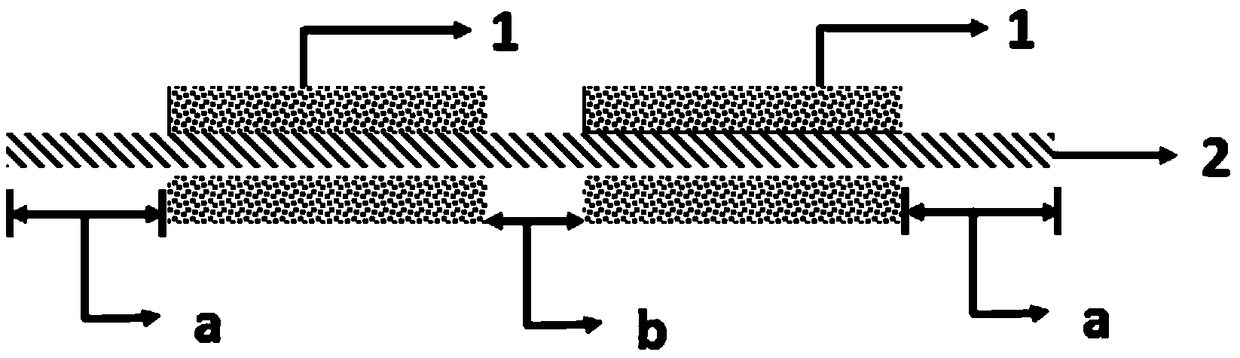

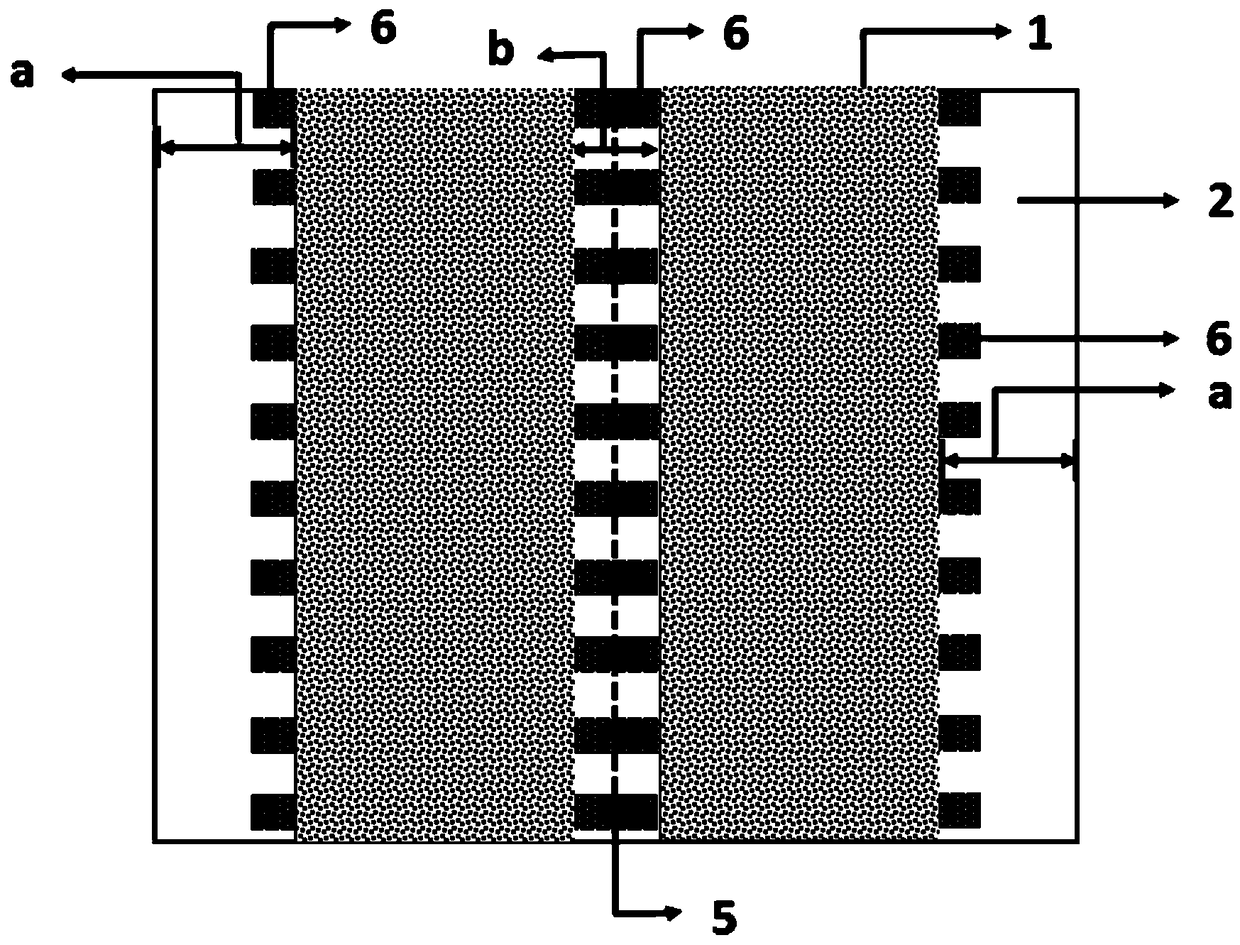

[0058] A lithium-ion battery with high-safety pole pieces includes a casing 14 made of aluminum-plastic film. The casing 14 is provided with a bare cell, the bare cell includes a cathode pole piece and an anode pole piece, the cathode pole piece and the anode pole piece are stacked or wound in an alternate manner, and an isolation is provided between the anode pole piece and the cathode pole piece. Membrane 15, the two sides of one end of the anode pole piece or the cathode pole piece with tabs and the two sides of the end opposite to the tabs are provided with several adhesive strips 6, and the adhesive strips 6 are pasted and connected with the adjacent isolation film 15. The cathode pole piece includes a cathode current collector 2, and both sides of the cathode current collector 2 are provided with cathode active material coating strips 1, and the two cathode active material coating strips 1 overlap; the anode pole piece includes an anode current collector 8, and both sides...

Embodiment 2

[0086] The difference from Example 1 is that the length of the strip 6 is 4mm, the length direction of the strip 6 is the same as that of the cathode active material coating strip 1, and the distance between adjacent strips 6 is 2mm.

Embodiment 3

[0088] The difference from Example 1 is that the length of the rubber strips 6 is 6 mm, and the distance between adjacent rubber strips 6 is 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com