Safe lithium ion battery

A lithium-ion battery, safety technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc. The effect of simple process, improved safety performance and low cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

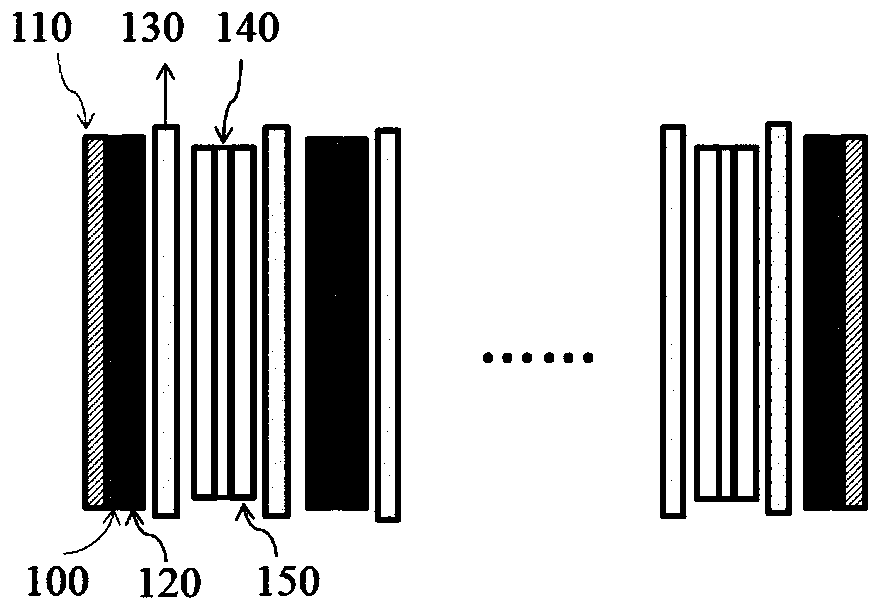

[0030] A safe lithium-ion battery: comprising a positive electrode sheet, a first negative electrode sheet, a second negative electrode sheet, a diaphragm and an electrolyte.

[0031] The first negative electrode sheet is prepared by a conventional method, the first negative electrode sheet is an electrode sheet coated with a negative electrode active material coating on both sides, and the negative electrode active material coating is made of an active material, a conductive agent, a binding agent and a solvent, and the active material Graphite is selected, acetylene black is selected as the conductive agent, a mixture of SBR and CMC is selected as the binder, the mass ratio of active material: conductive agent: binder is 95:5:5, copper foil is selected as the current collector, and water is the solvent.

[0032] The positive electrode sheet is prepared by a conventional method. The coating of the positive electrode sheet is made of positive electrode active material, conducti...

Embodiment 2

[0036] The difference from Example 1 is that the composition ratio of the molecular sieve coating in the second negative electrode sheet is different, and the specific ratio is: molecular sieve: binder: conductive agent = 80:10:10.

Embodiment 3

[0038] This example is basically the same as Example 1, except that the conductive agent used in the molecular sieve coating in the second negative electrode sheet is simple Cu particles, and the ratio of molecular sieve: binder: conductive agent is 70:10:10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com