Method of producing spinel structured lithium titanate

A technology for structural lithium titanate and spinel, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of long process, difficult control of reaction conditions, high cost of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

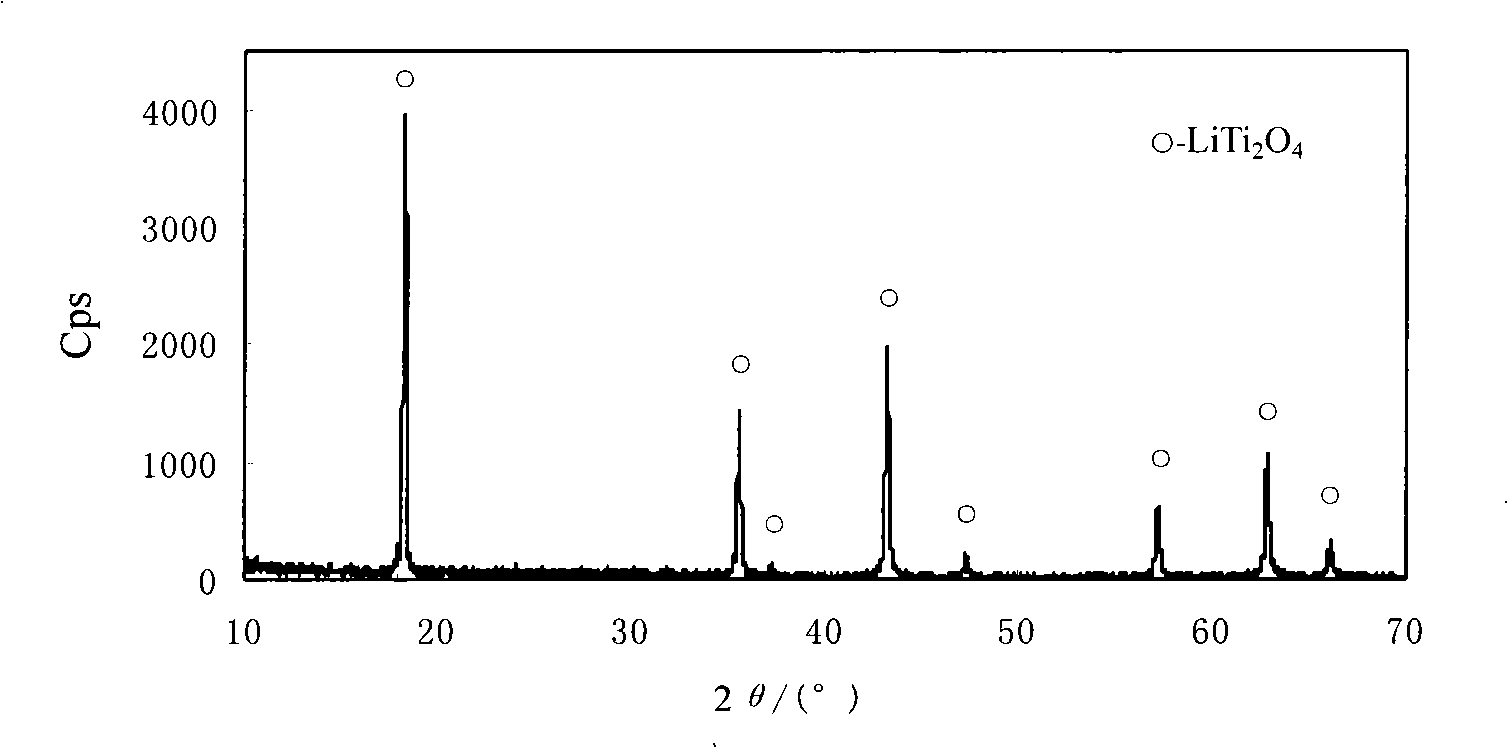

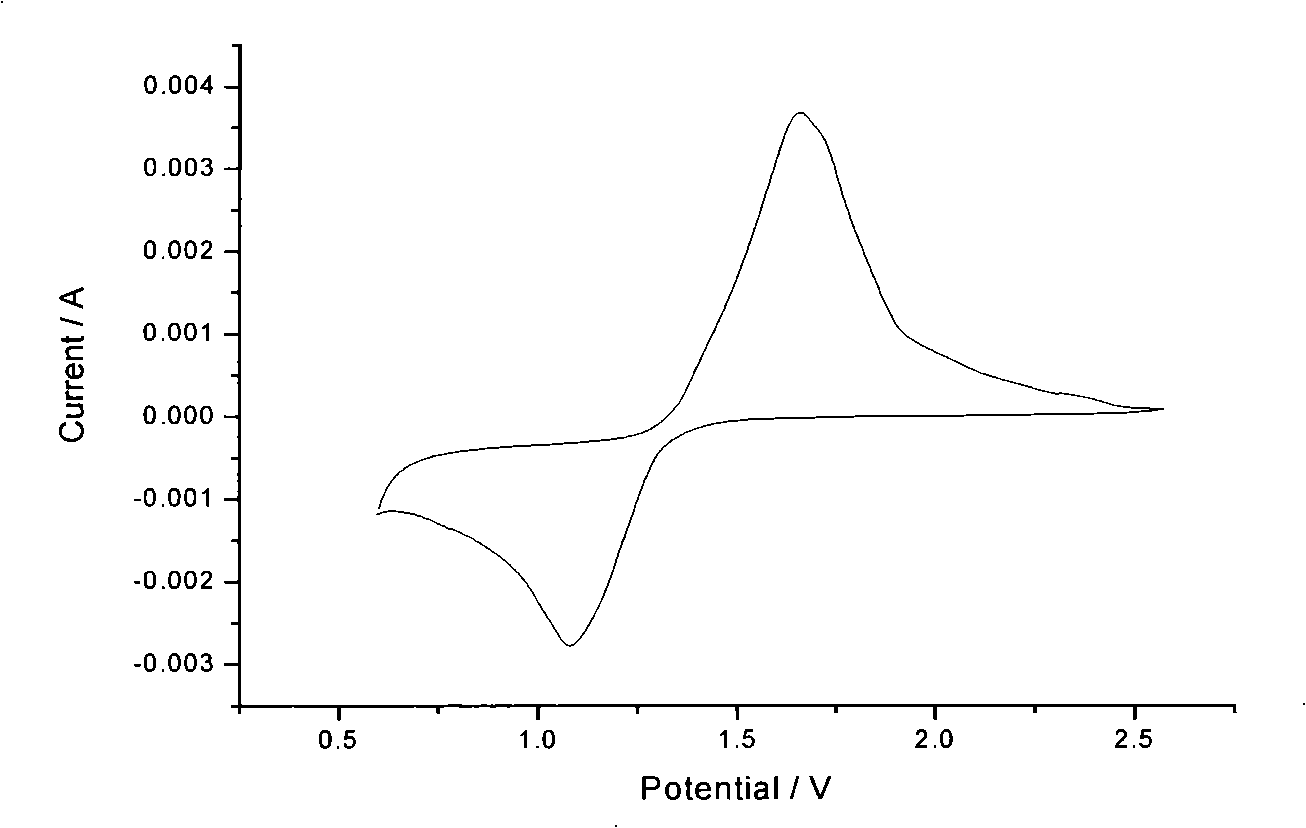

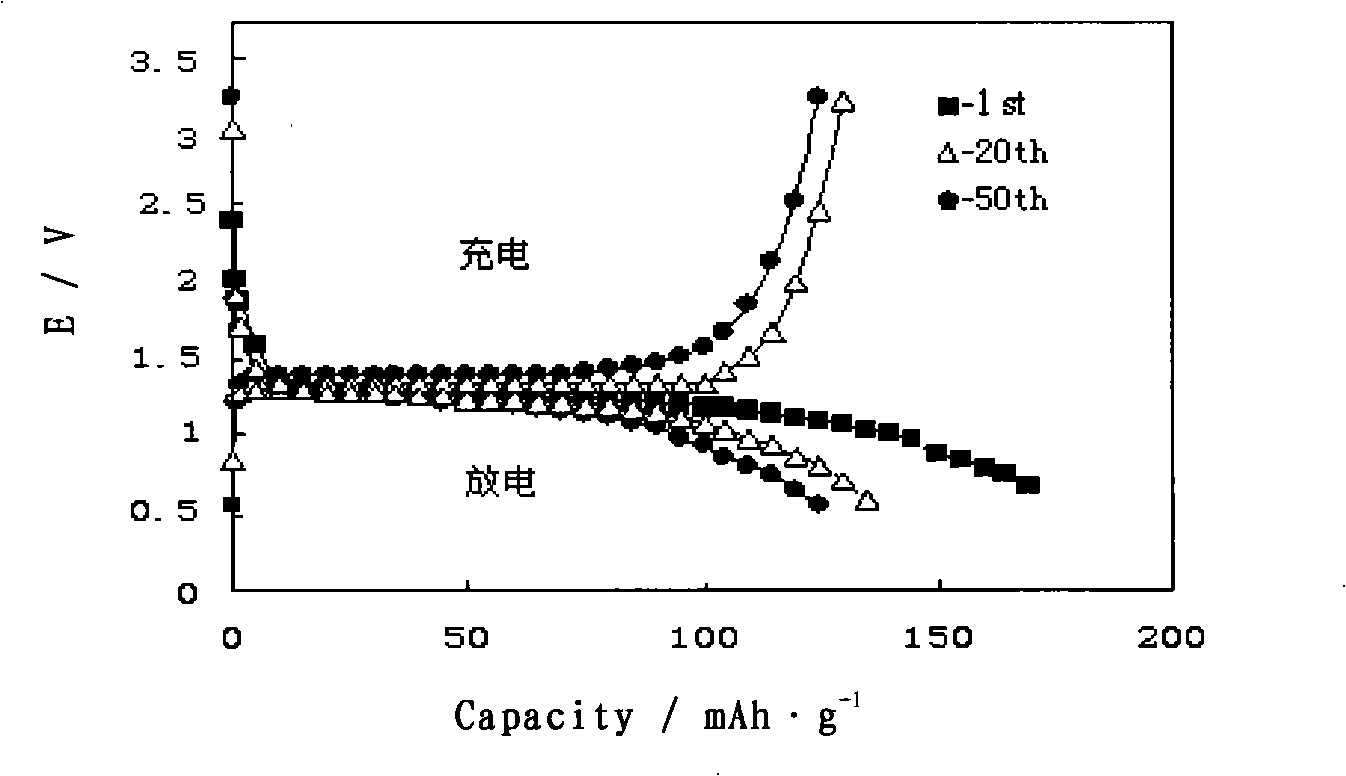

[0012] Accurately weigh 3.228g of commercially available analytical reagent titanium dioxide (mainly anatase, titanium dioxide ≥ 99.0%), lithium carbonate 0.762g (lithium carbonate ≥ 97.0%), carbon black 0.400g (ash content ≤ 0.2%), in 200mL agate Planetary ball milling in a tank for 2 hours, put the mixture in a 25mL corundum boat, place it in a tube furnace, feed in commercially available argon gas (Ar ≥ 99.996%) with a flow rate of 20L / h, react the material at 900°C for 30 hours, and cool naturally Take it out after reaching room temperature, transfer it to an agate ball mill jar and fill it with argon gas, and grind it with a planetary ball mill for 2 hours to obtain a dark blue spinel lithium titanate powder product. X-ray diffractometer measurement result shows that product is mainly spinel structure (see attached figure 1 ); its simulated battery Li / LiTi 2 o 4 There is a group of redox reversible peaks in the cyclic voltammetry curve, and the reaction potential is 1.3...

Embodiment 2

[0014] Accurately weigh 322.800g of commercially available analytical reagent titanium dioxide (mainly anatase, titanium dioxide ≥ 99.0%), lithium carbonate 76.200g (lithium carbonate ≥ 97.0%), carbon black 38.000g (ash content ≤ 0.2%), in 500mL agate Planetary ball milling in batches for 2 hours in a jar, put the mixture in a 500mL graphite crucible, put it in a SL63-7B vacuum carbon tube electric furnace (produced by Shanghai Electric Furnace Factory), and pump the vacuum to 10 -1 Pa, heated to 900°C for 8 hours, cooled to room temperature, taken out, transferred to an agate ball mill jar filled with argon, and ground for 2 hours with a planetary ball mill to obtain a dark blue spinel lithium titanate powder product. Its X-ray diffractometer measurement results and electrochemical performance are similar to those of Example 1, wherein the reversible lithium intercalation reaction potential is 1.34V, the specific capacity is 160mAh / g, and the charge and discharge performance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com