Microcapsule, preparation method thereof, and lithium ion battery

A technology of lithium-ion batteries and microcapsules, which is applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc. It can solve the adverse effects of increasing the internal resistance of the isolation film, battery rate performance and low-temperature performance, and affecting lithium ion transmission. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The application also provides a method for preparing microcapsules, comprising the following steps:

[0040] A) mixing a polymer material, a flame retardant and an organic solvent to obtain an emulsion;

[0041] B) performing centrifugal spray drying on the emulsion in a centrifugal spray dryer to obtain microcapsules;

[0042] The flame retardant is selected from one or more of organic flame retardants and inorganic flame retardants;

[0043] The centrifugal spray dryer includes a centrifugal disc, a porous fence and a powder collector. The porous fence is arranged between the centrifugal disc and the powder collector. hole.

[0044] In the process of preparing microcapsules, the polymer material, flame retardant and organic solvent are first mixed to form an emulsion; in this process, the organic solvent is selected from acetone, ethanol, dimethyl carbonate, tetrahydrofuran and tetralin one or more. The solid content of the emulsion is 20wt%-75wt%, and in a specif...

Embodiment 1

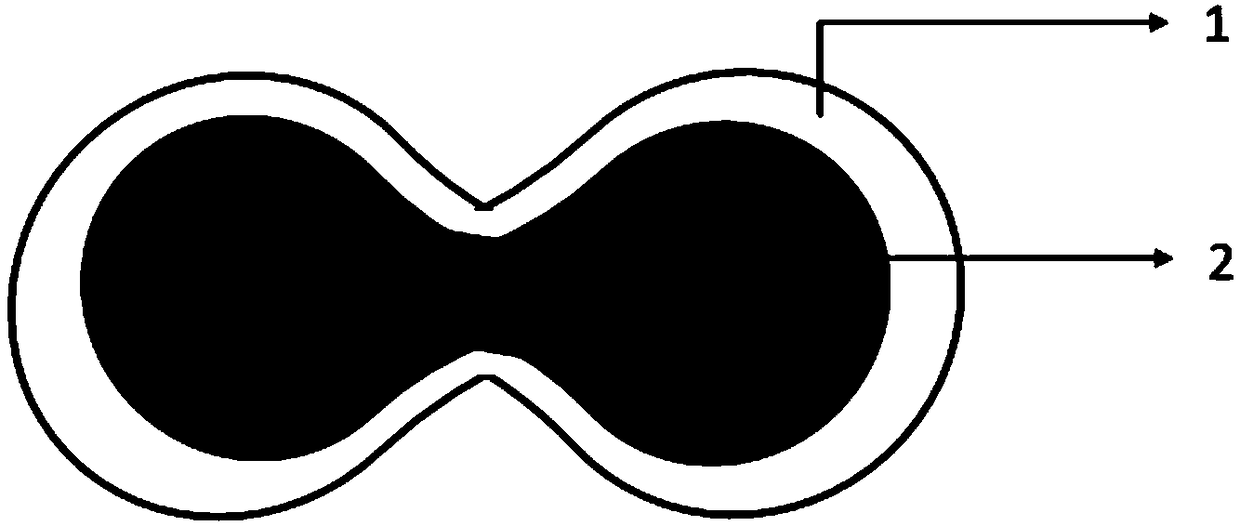

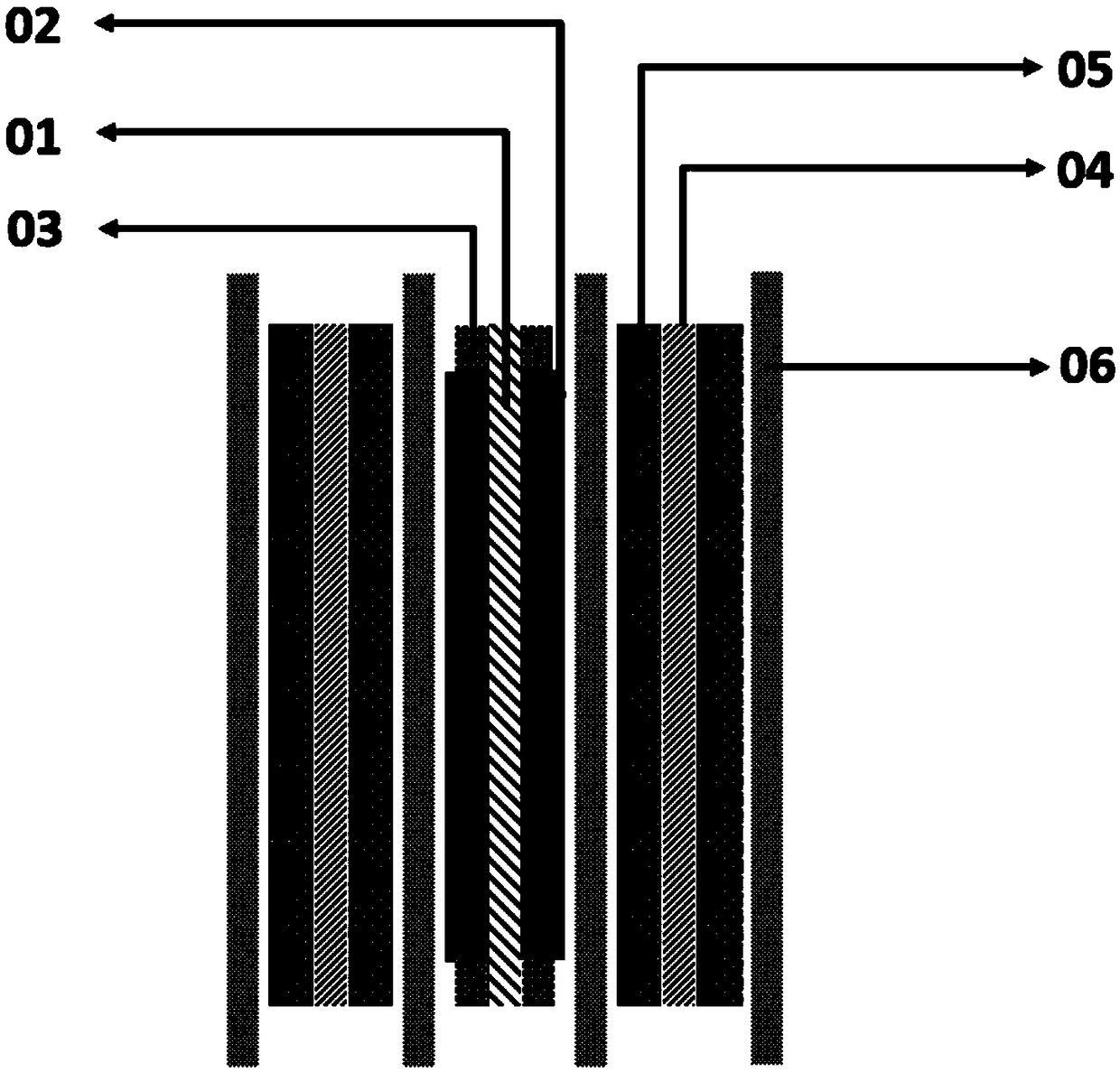

[0067] 1) Preparation of microcapsules: Add ammonium polyphosphate or hexaphenoxycyclotriphosphazene powder particles into ethylene-vinyl acetate copolymer emulsion at a mass ratio of 4:6, and stir evenly in a disperser to obtain a solid content of 60 % to 65% of the emulsion, and finally the above-mentioned emulsion is centrifugally spray-dried to make ammonium polyphosphate and hexaphenoxycyclotriphosphazene as the capsule core and ethylene-vinyl acetate copolymer as the capsule shell with dual-core microcapsules (such as signal figure 1 as shown, figure 1 1 is the capsule shell part, 2 is the capsule core part, such as Figure 12 as shown, Figure 12 Electron micrograph of the microcapsule prepared for this embodiment);

[0068] 2) Preparation of safety paint: the microcapsules containing inorganic flame retardants and organic flame retardants prepared in the above steps are mixed with ceramic powder, acrylic emulsion, binder, surfactant and solvent according to the weig...

Embodiment 2

[0073] The difference from Example 1 is that the weight ratios of microcapsules, boehmite, acrylic emulsion, binder and surfactant in the safety coating are 55%, 42.1%, 1%, 1%, and 0.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com