Current collector, electrode plate and lithium ion battery

A current collector and positive electrode technology, applied in the field of lithium batteries, can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

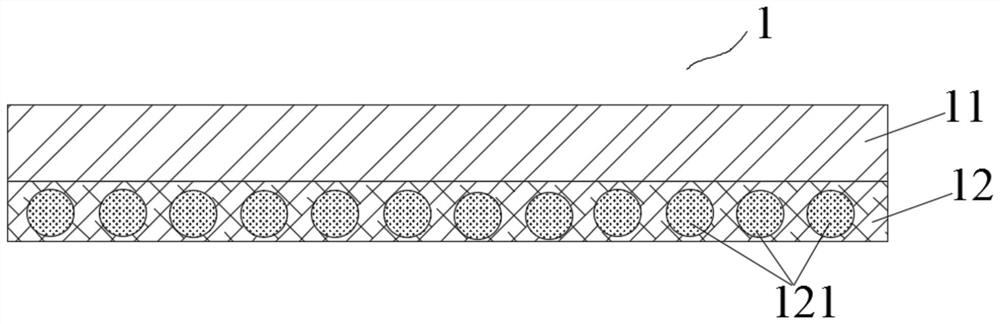

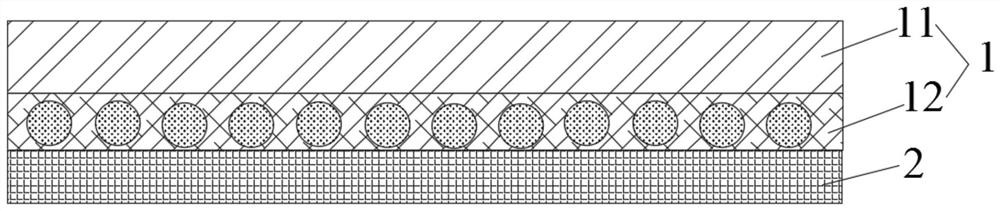

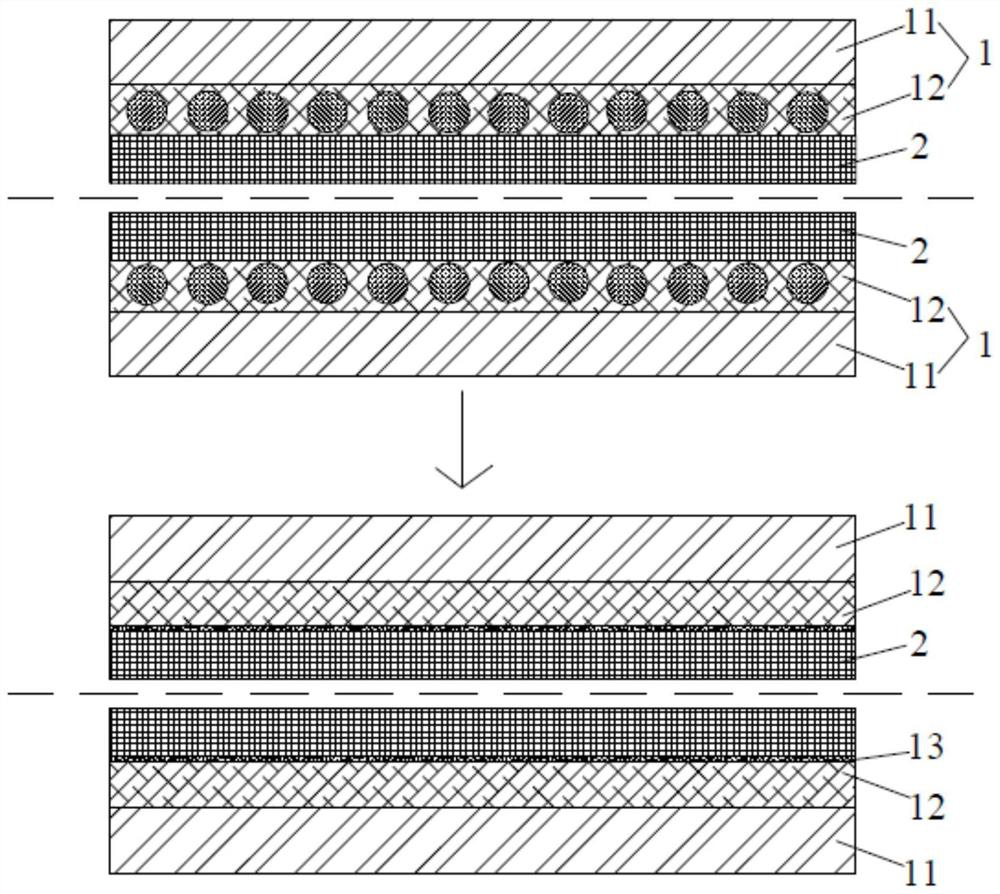

[0054] A current collector, comprising a substrate 11 and a safety coating 12 coated on at least one surface of the substrate 11; the safety coating 12 includes flame-retardant particles 121, heat-resistant additives, conductive agents and binders; The flame retardant particles 121 are transformed into an insulating layer 13 between the substrate 11 and the safety coating 12 at 80-180°C.

[0055] Concrete preparation method is:

[0056] S1. Selection of substrate: aluminum foil with a thickness of 10 μm is used as the substrate 11 of the current collector 1;

[0057] S2. Configuration of safety coating slurry: mix and stir flame-retardant particle 121 powder, heat-resistant additive, conductive agent, and adhesive according to the dry weight ratio of 10:80:2:8, and disperse them evenly in NMP solvent. Stir well and filter for later use;

[0058] S3. Coating of the safety coating: coating the safety coating 12 slurry on at least one surface of the aluminum foil by means of gr...

Embodiment 2~8

[0063] The difference from Example 1 is the content of various substances in the safety coating, the particle size of the flame-retardant particles and the heat-resistant additive, and the details are shown in Table 1 below. The rest are the same as in Embodiment 1, and will not be repeated here.

[0064] Table 1

[0065]

[0066] It can be seen from the above test results that the current collectors with the safety coating of the present invention can greatly increase the pass rate of the acupuncture test and the unilateral extrusion test of the lithium-ion battery compared with the current collectors without the safety coating. It can be seen that the current collector provided by the present invention, due to the addition of flame-retardant particles, will decompose and transform into a layer between the base material and the safety coating when the temperature exceeds the normal use temperature of the battery and reaches 80-180°C. The dense insulating layer greatly blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com