Patents

Literature

36results about How to "Coating thickness is thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

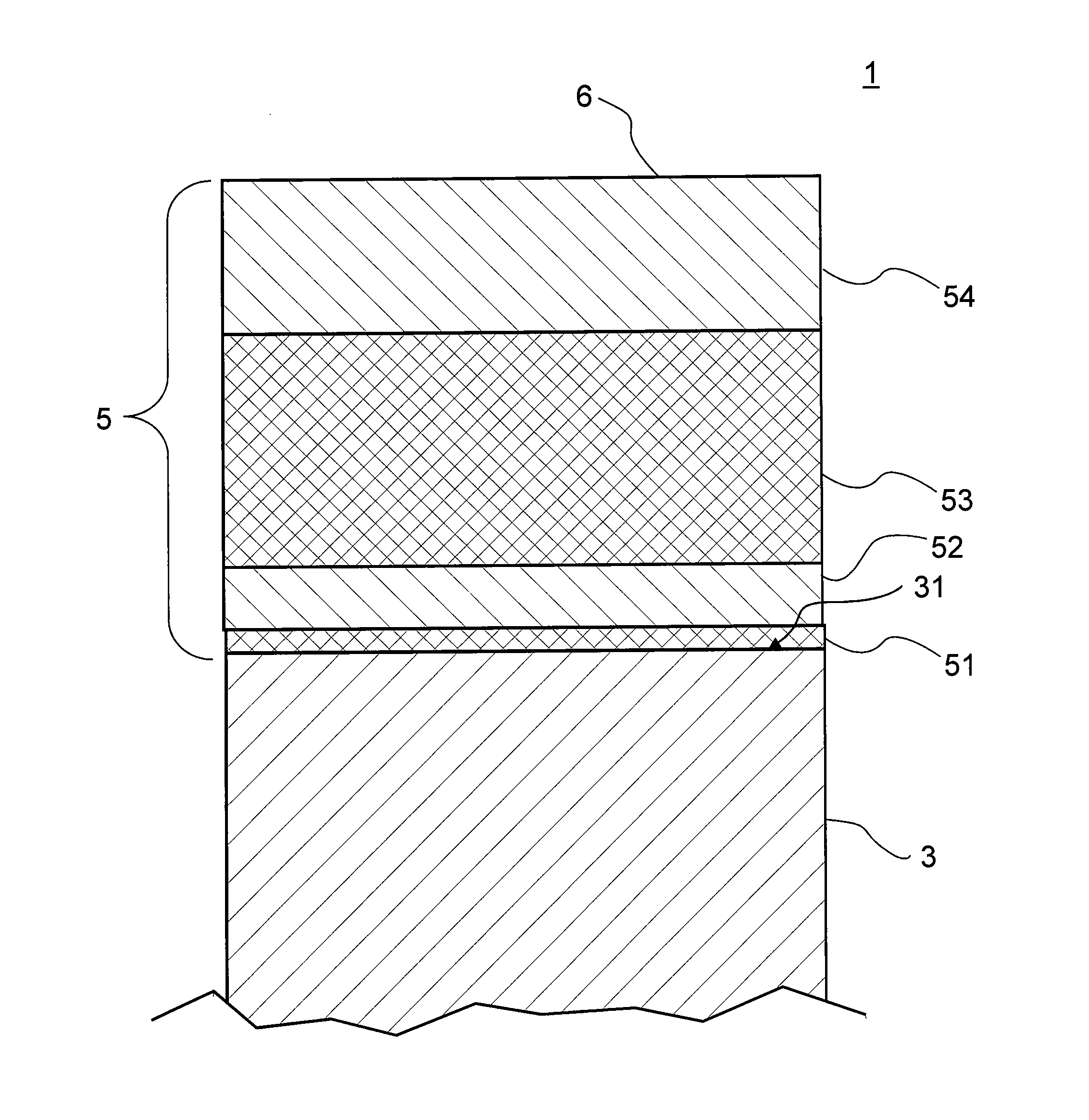

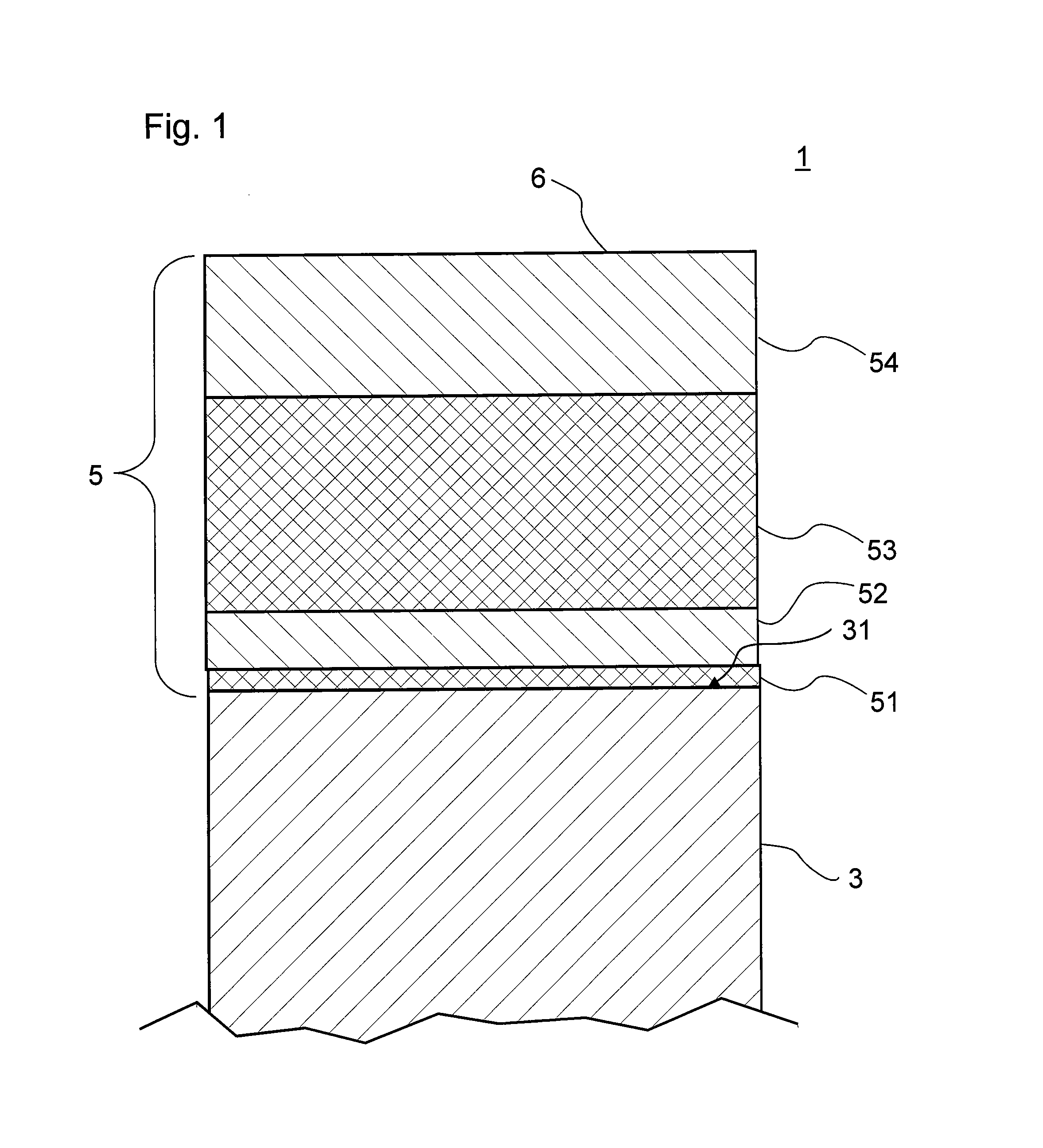

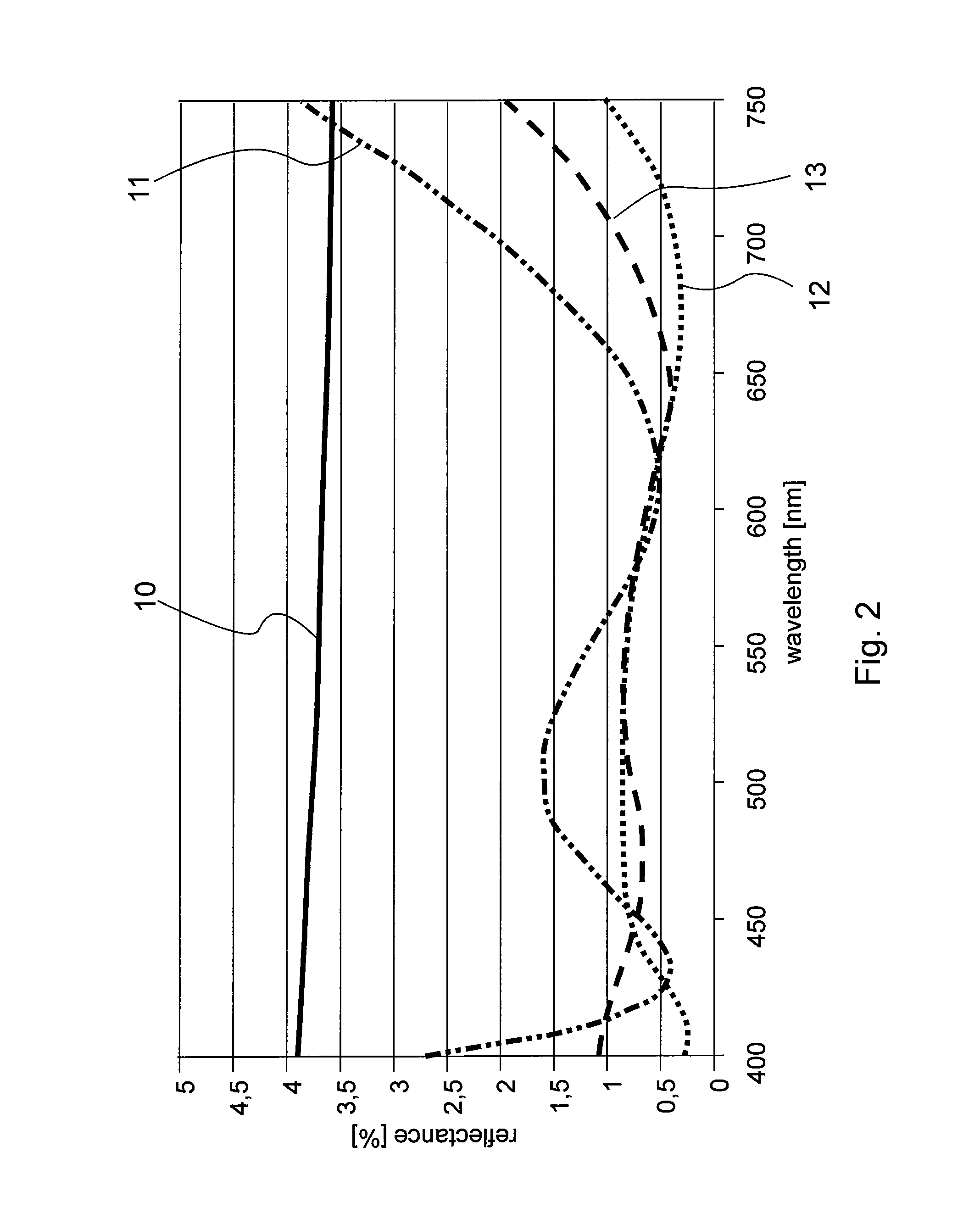

Substrate with antireflection coating and method for producing same

ActiveUS20120212826A1Decrease of antireflection effectHigh refractive indexElectric discharge tubesVacuum evaporation coatingRefractive indexSilicon oxide

A substrate is provided with an abrasion resistance antireflection coating. The coated substrate includes a multilayer antireflection coating on at least one side. The coating has layers with different refractive indices, wherein higher refractive index layers alternate with lower refractive index layers. The layers having a lower refractive index are formed of silicon oxide with a proportion of aluminum, with a ratio of the amounts of aluminum to silicon is greater than 0.05, preferably greater than 0.08, but with the amount of silicon predominant relative to the amount of aluminum. The layers having a higher refractive index include a silicide, an oxide, or a nitride.

Owner:SCHOTT AG

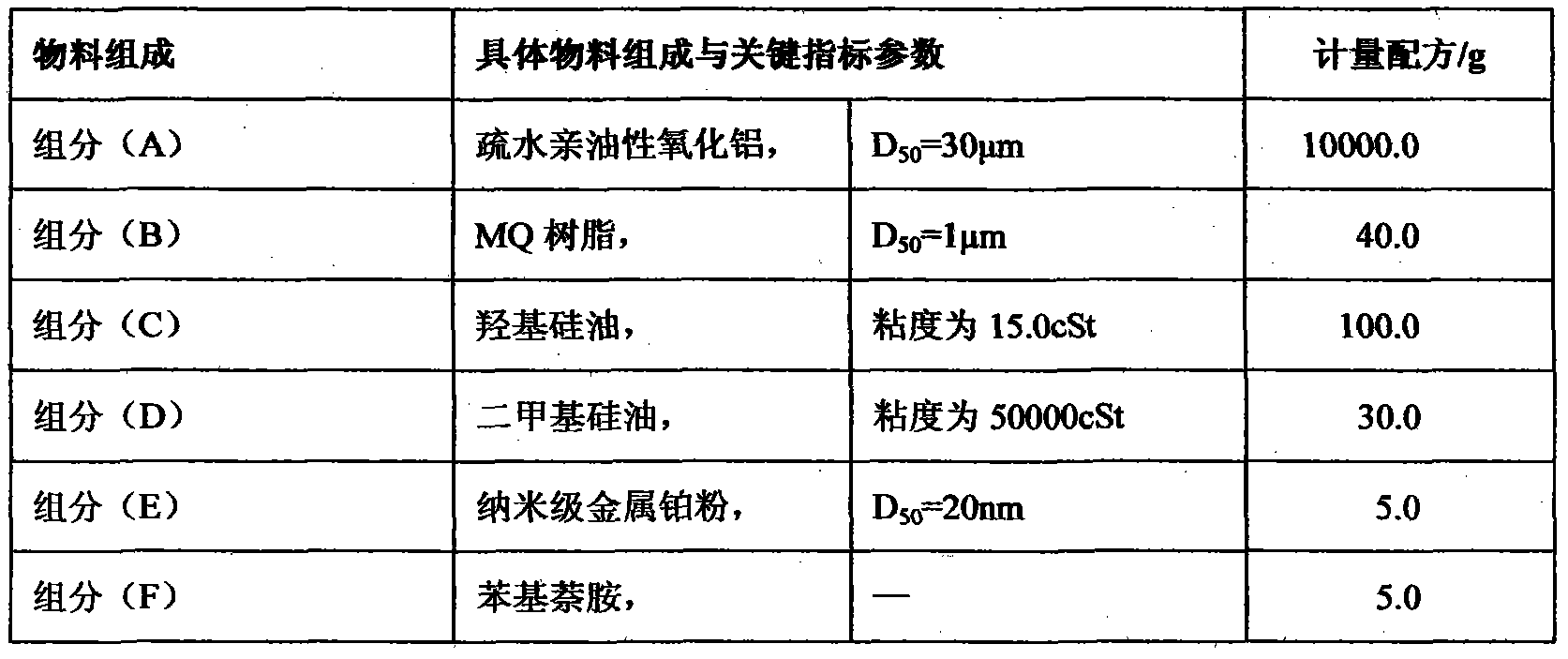

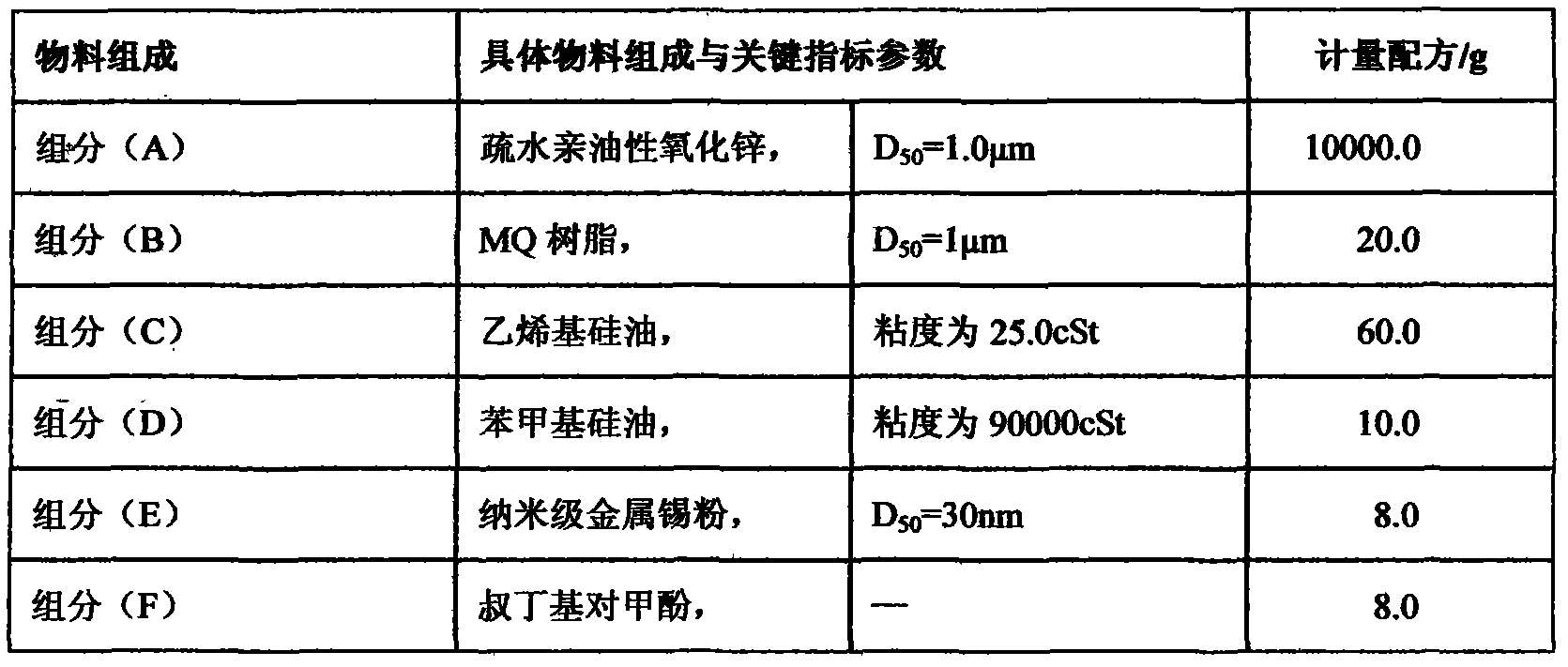

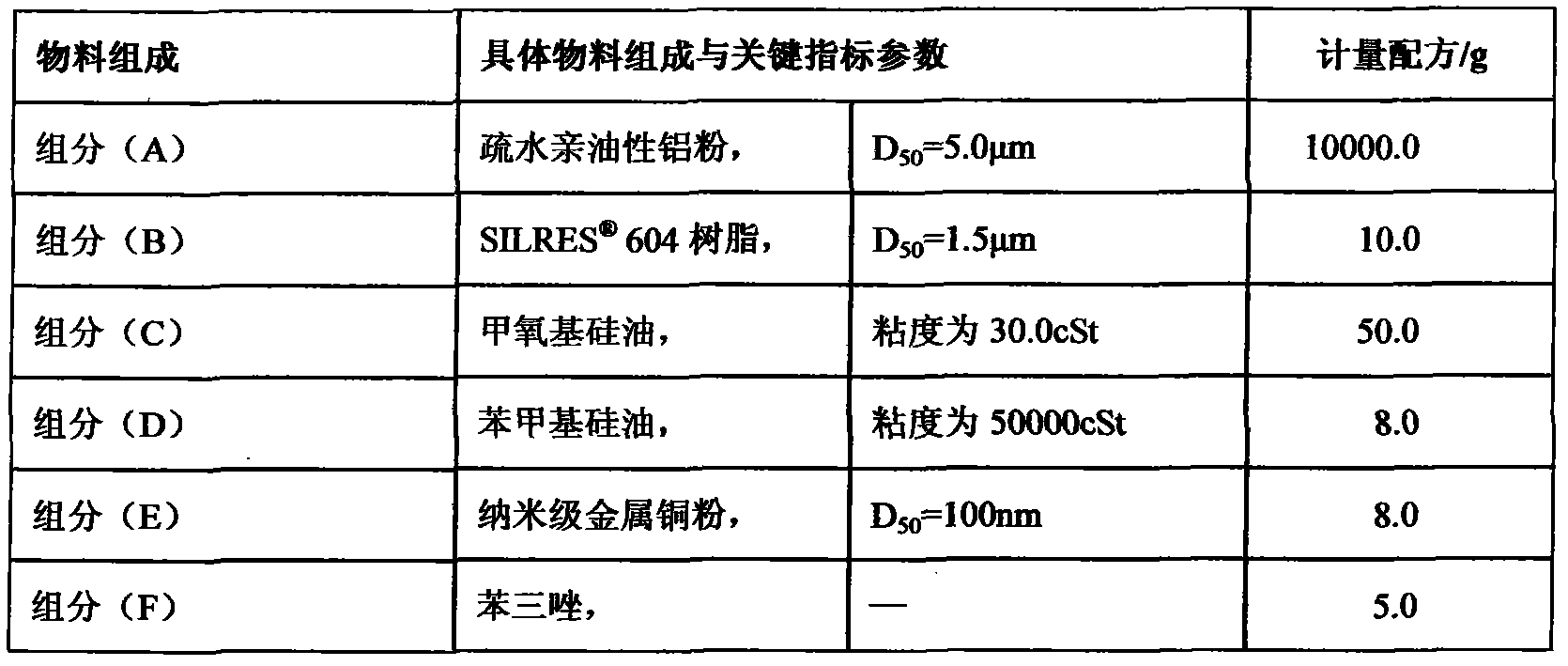

Thermal grease composition

ActiveCN102134474ASolve the chalking problemResolve fragmentationHeat-exchange elementsNano catalystThermal grease

The invention relates to the field of thermal interface materials, and more particularly, provides a thermal grease composition, which contains the following components: (A) 100.0 parts by weight of thermally conductive filler, (B) 0.1 to 8.0 parts by weight of active solid silicone resin, (C) 0.1 to 15.0 parts by weight of active silicone oil, (D) 0.1 to 9.0 parts by weight of macromolecular polysiloxane, (E) 0.1 to 3.0 parts by weight of nano catalyst, and (F) 0.1 to 3.0 parts by weight of additive. The thermal grease composition provided by the invention has good thermal conductivity and using weatherability, can effectively solve the technical difficulty that the thermal grease composition in the prior art is pulverized and crushed and the thermal conductivity is therefore reduced as the service time increases. The manufacturing process has simple, convenient and easy steps and the thermal grease composition is suitable for large-scale match production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

Method for performing anticorrosive hydrophobic modification on surface of aluminum alloy

InactiveCN101885934ACoating thickness is thinImprove adhesionAnti-corrosive paintsMetallic material coating processesSpray coatingLayer thickness

The invention discloses a method for performing anticorrosive hydrophobic modification on the surface of an aluminum alloy, which belongs to the technical field of corrosion prevention. The method specifically comprises the following steps of: (1) performing surface degreasing and oil removing on an aluminum alloy material by using conventional alkaline degreasing solution first, performing surface activation treatment by using reductive acidic cleaning solution, and then performing inactivation and sealing treatments on the activated surface; (2) preparing a composition with a hydrophobic effect, wherein the composition consists of a first component and a second component in a weight ratio of 9-16:1, the first component is prepared from the following materials in percentage by weight: 35 to 60 percent of fluorocarbon resin, 10 to 40 percent of anticorrosive pigment, 1 to 8 percent of organosilicon compound, 0.5 to 5 percent of dispersing agent, 0.5 to 3 percent of anti-settle agent and 10 to 40 percent of organic solvent, and the second component is a fatty series / aromatic series curing agent; and (3) performing anticorrosive hydrophobic modification on the surface of the aluminum alloy, namely coating the composition with the hydrophobic effect in the step (2) on the surface of the aluminum alloy after treatment in a brush coating, spray coating or dip coating mode, and curing the surface for about 12 hours. The anticorrosive hydrophobic coating layer obtained on the surface of the aluminum alloy by using the technique of the invention has the advantages of thin coating layer thickness, high adhesive force, sea water corrosion resistance, surface super-hydrophobic property and the like.

Owner:BEIJING UNIV OF CHEM TECH

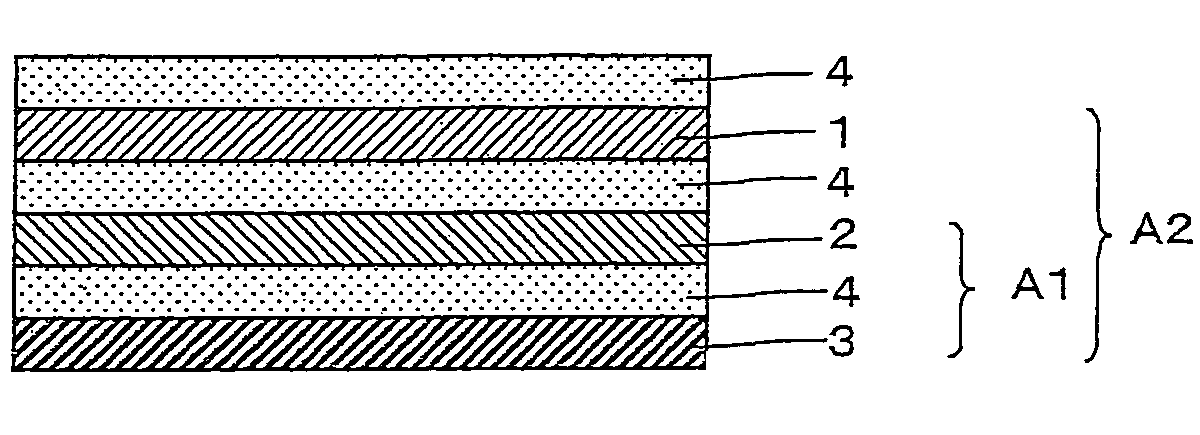

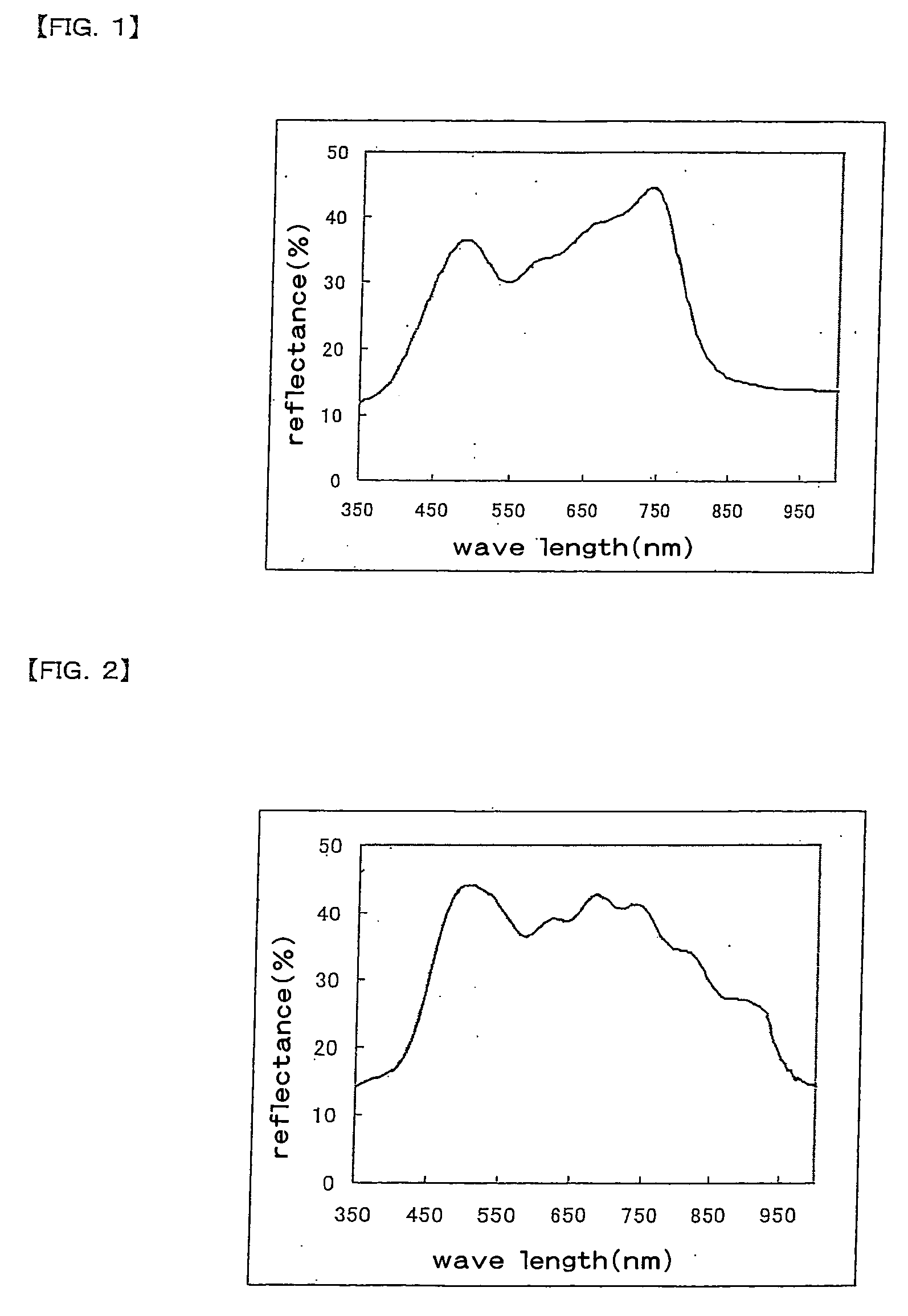

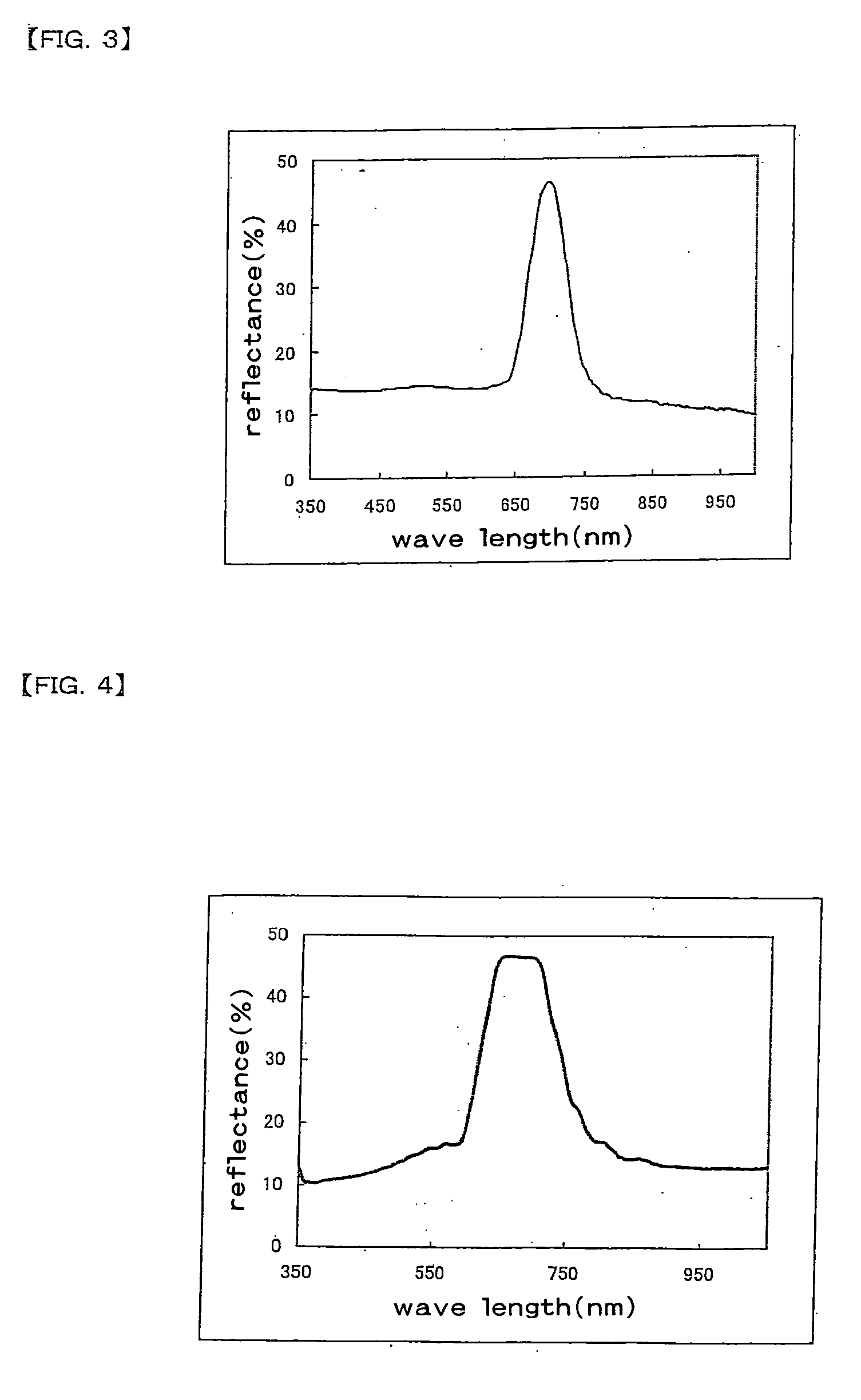

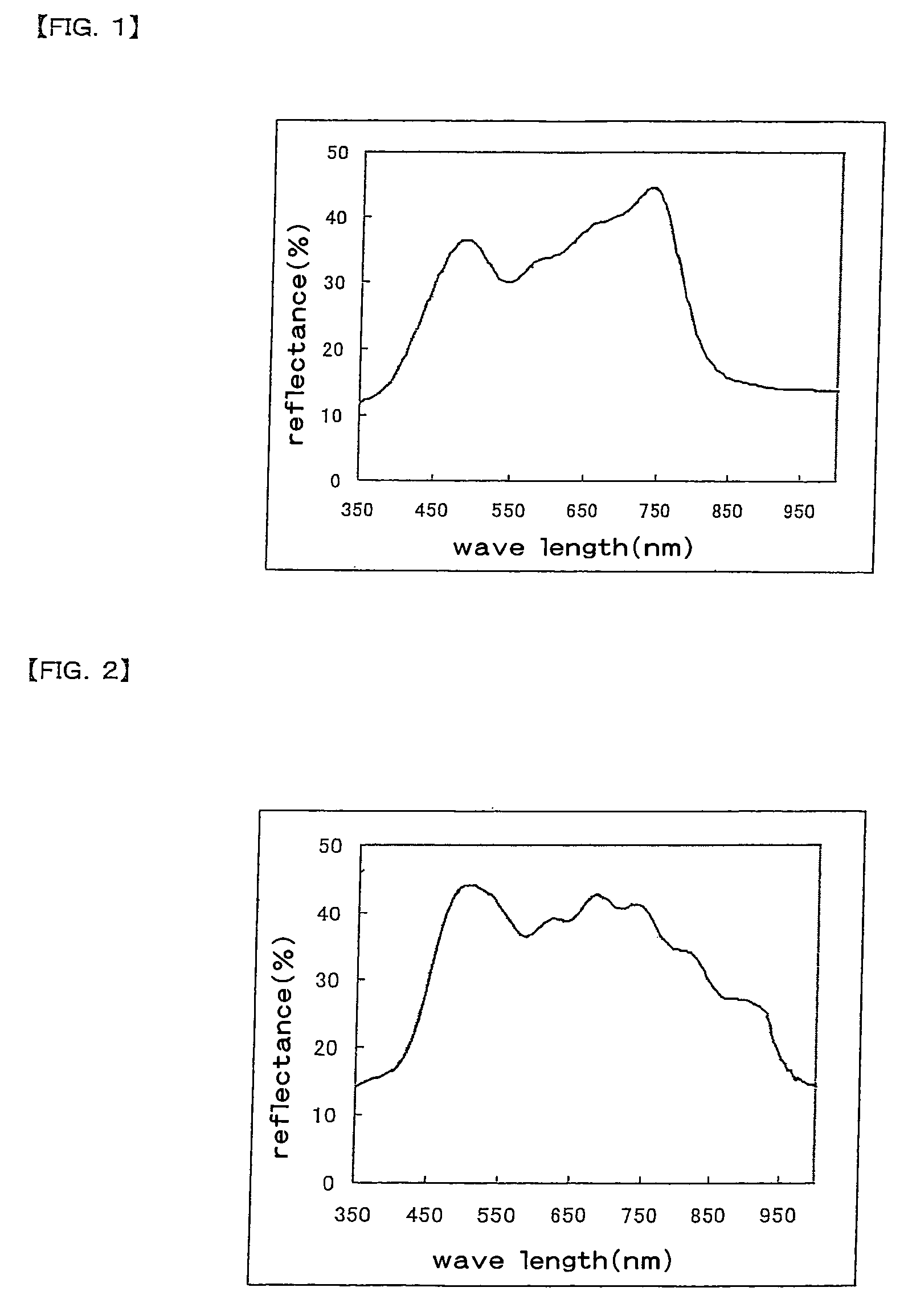

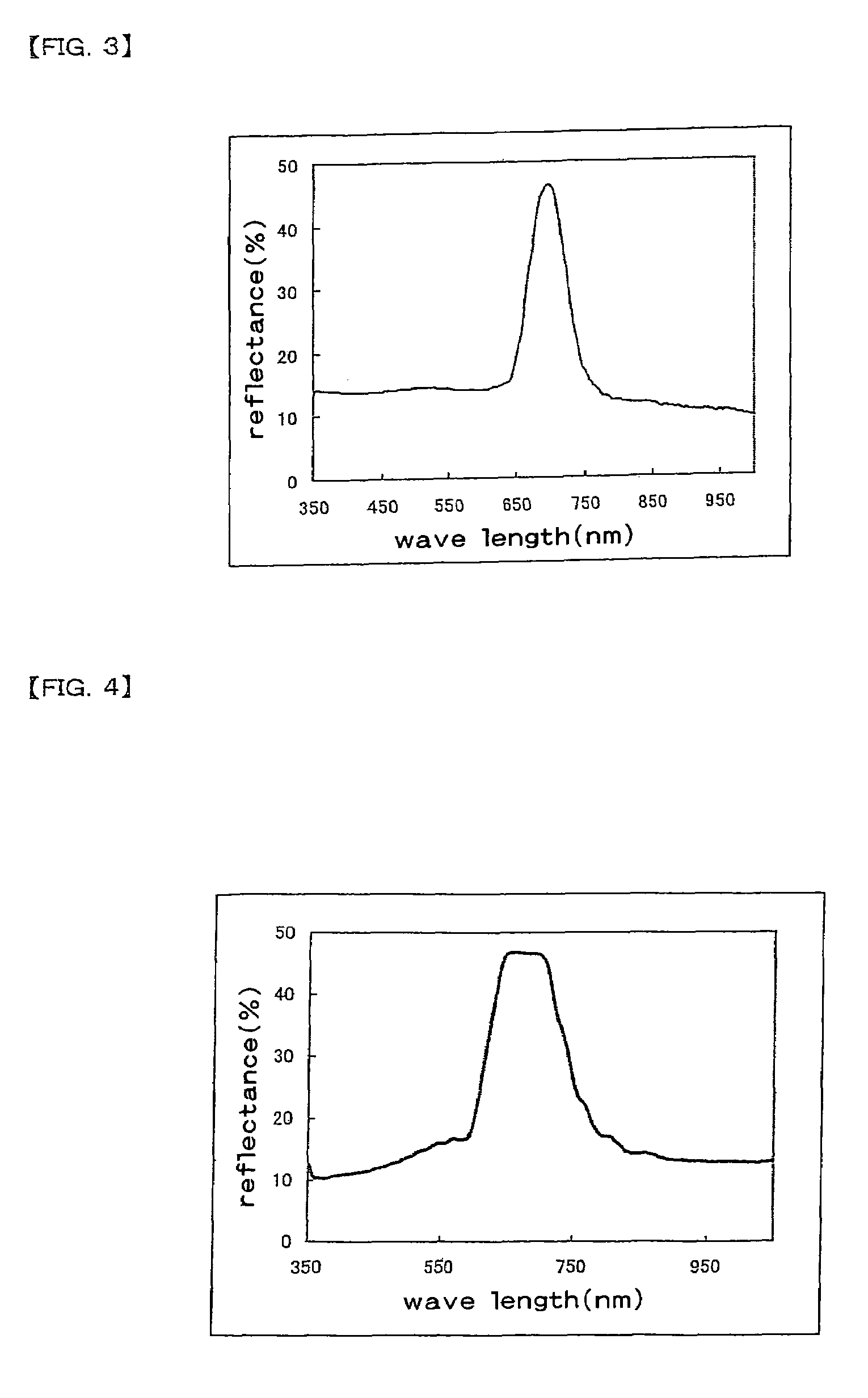

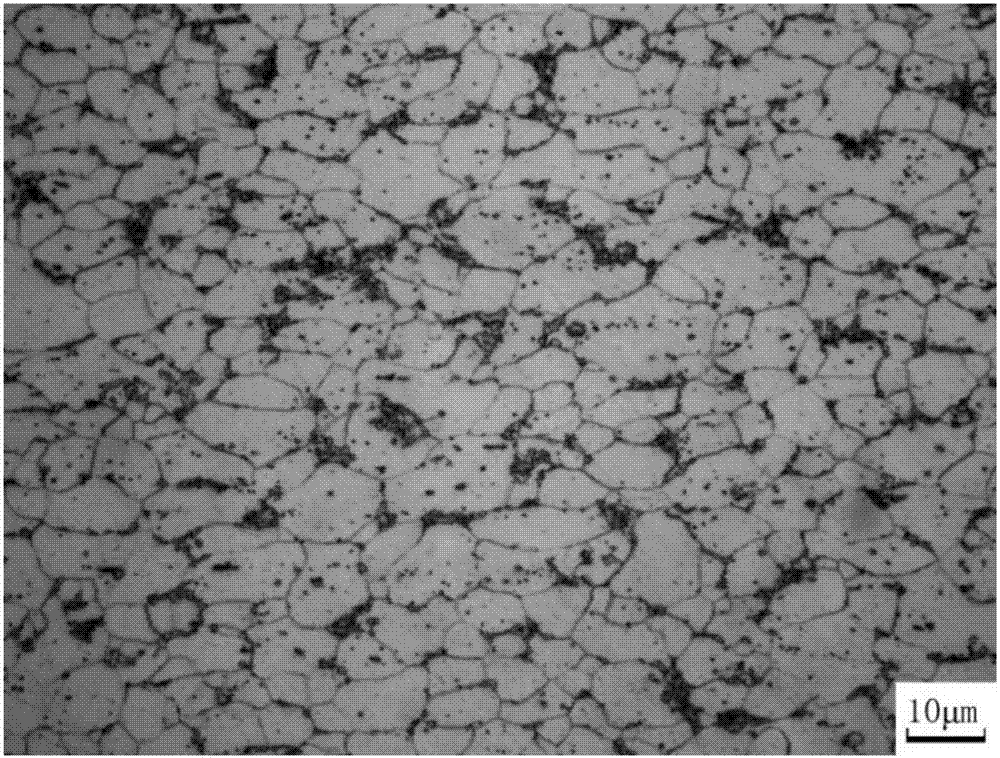

Broad-band-cholesteric liquid-crystal film, process for producing the same, circularly polarizing plate, linearly polarizing element,illiminator, and liquid-crystal display

InactiveUS20060127605A1Reduce the number of manufacturing stepsReduce the numberLiquid crystal compositionsPolarising elementsPhotoisomerizationDisplay device

A broad band cholesteric liquid crystal film of the present invention is a cholesteric liquid crystal film obtained by coating a liquid crystal mixture containing a polymerizable mesogen compound (a), a polymerizable chiral agent (b) and a photoisomerizable material (c) on a substrate to ultraviolet polymerize a coat of the liquid crystal mixture, and has a reflection bandwidth of 200 nm or more. A broad band cholesteric liquid crystal film of the present invention has a broad reflection band, is of a thin type and can be manufactured in less of manufacturing steps.

Owner:NITTO DENKO CORP

Sandwich Thermal Insulation Layer System and Method for Production

InactiveUS20090110904A1Low thermal conductivityCoating thickness is thinMolten spray coatingPretreated surfacesPorous coatingThermal insulation

A method produces thermal barrier coatings that adhere to components even at high temperatures and temperatures that change frequently. A gas-tight glass-metal composite coating is applied to the component and annealed. The corroded part of the gas-tight coating is then removed, and a second, porous coating is applied. The second coating can comprise a ceramic, in particular yttrium-stabilized zirconium oxide. A thermal barrier coating is provided that is a composite made of a gas-tight glass-metal composite coating and another porous coating disposed thereover. Because the boundary volume of the composite coating is partly crystallized to the other coating, superior adhesion within the composite is achieved. Thus, it is in particular possible to produce a composite made of silicate glass-metal composite coatings and yttrium-stabilized zirconium oxide that are temperature-stable for extended periods of time. Such a composite is particularly advantageous for use as a thermal barrier coating because it combines good protection against oxidation with low heat conductivity and susceptibility to aging.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

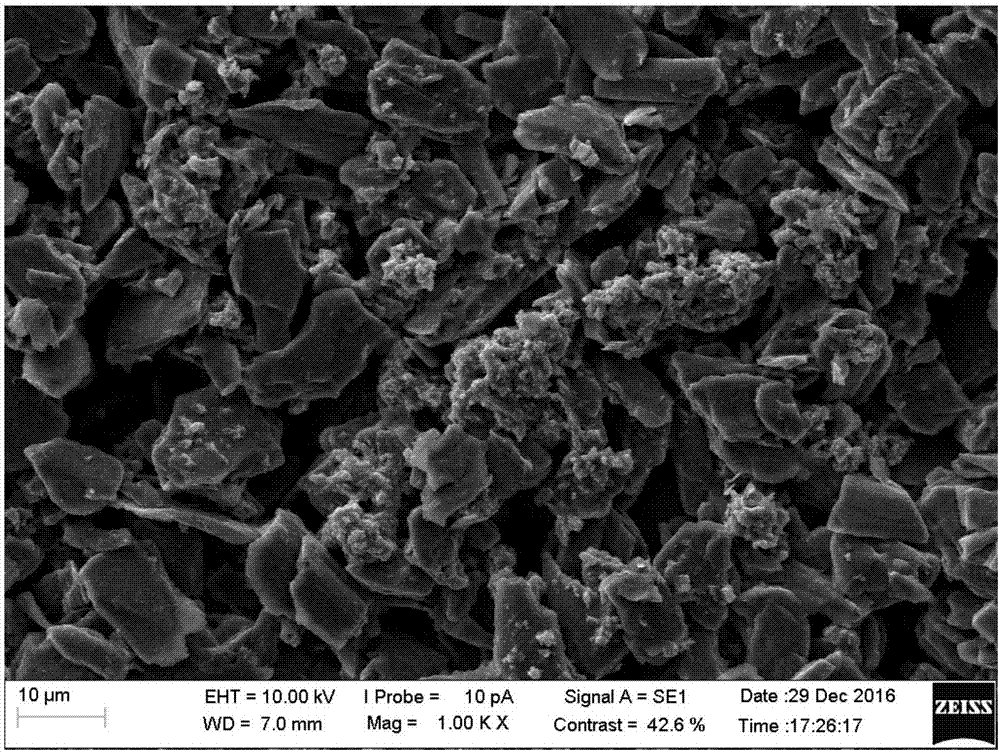

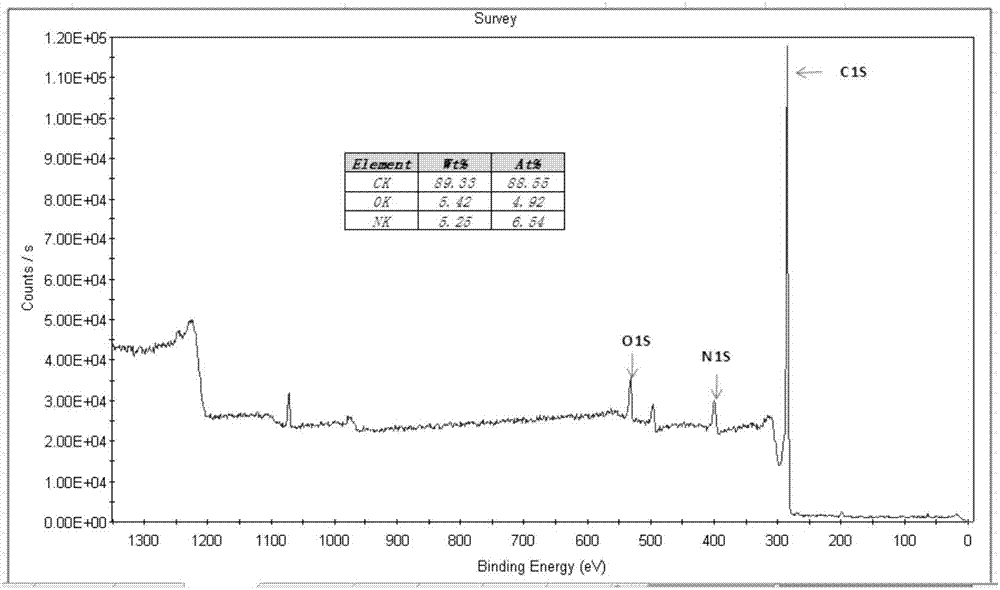

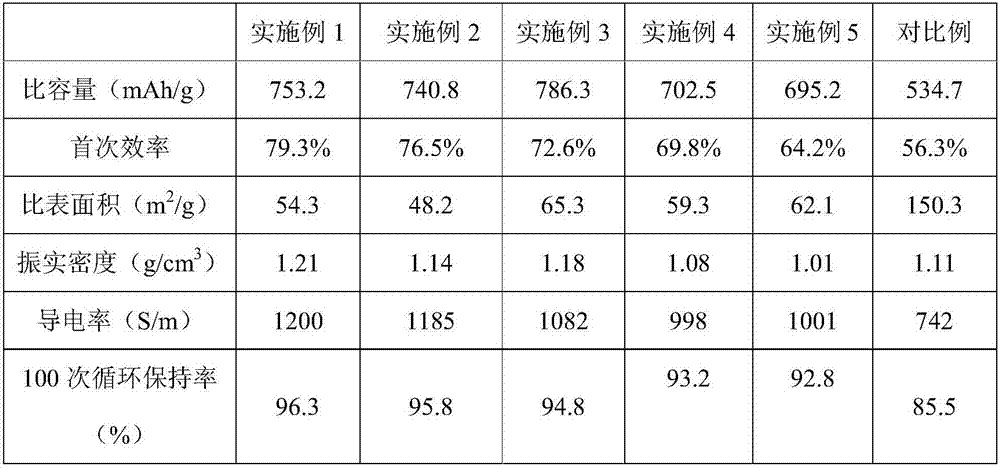

Graphene-based composite negative electrode material and preparation method thereof

ActiveCN107394135ASmall specific surface areaImprove first-time efficiencyCell electrodesSecondary cellsCarbonizationNitrogen doped graphene

The invention relates to a graphene-based composite negative electrode material and a preparation method thereof, and belongs to the field of a lithium ion battery. The preparation method of the graphene-based composite negative electrode material comprises the steps of (1) sequentially adding hydrogen peroxide, a nitrogen doping agent and silicate ester into a graphene oxide dispersion liquid to obtain a mixed solution; (2) performing hydrothermal reaction on the mixed solution in the step (1), performing solid-liquid separation, drying and pressing the obtained solid, and performing carbonization in an inert gas atmosphere to obtain a nitrogen-doped graphene and silicon dioxide composite material; and (3) adding the nitrogen-doped graphene and silicon dioxide composite material in the step (2) into a mixed solution of polyvinylpyrrolidone and a conductive macromolecular polymer, adding a reducing agent, and performing reaction for 1-6 hours under 50-120 DEG C to prepare the graphene-based composite negative electrode material. The graphene-based composite negative electrode material prepared by the method is high in specific capacity, stable in structure and excellent in electrochemical performance, and has a wide prospect in the field of a lithium ion battery negative electrode material.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

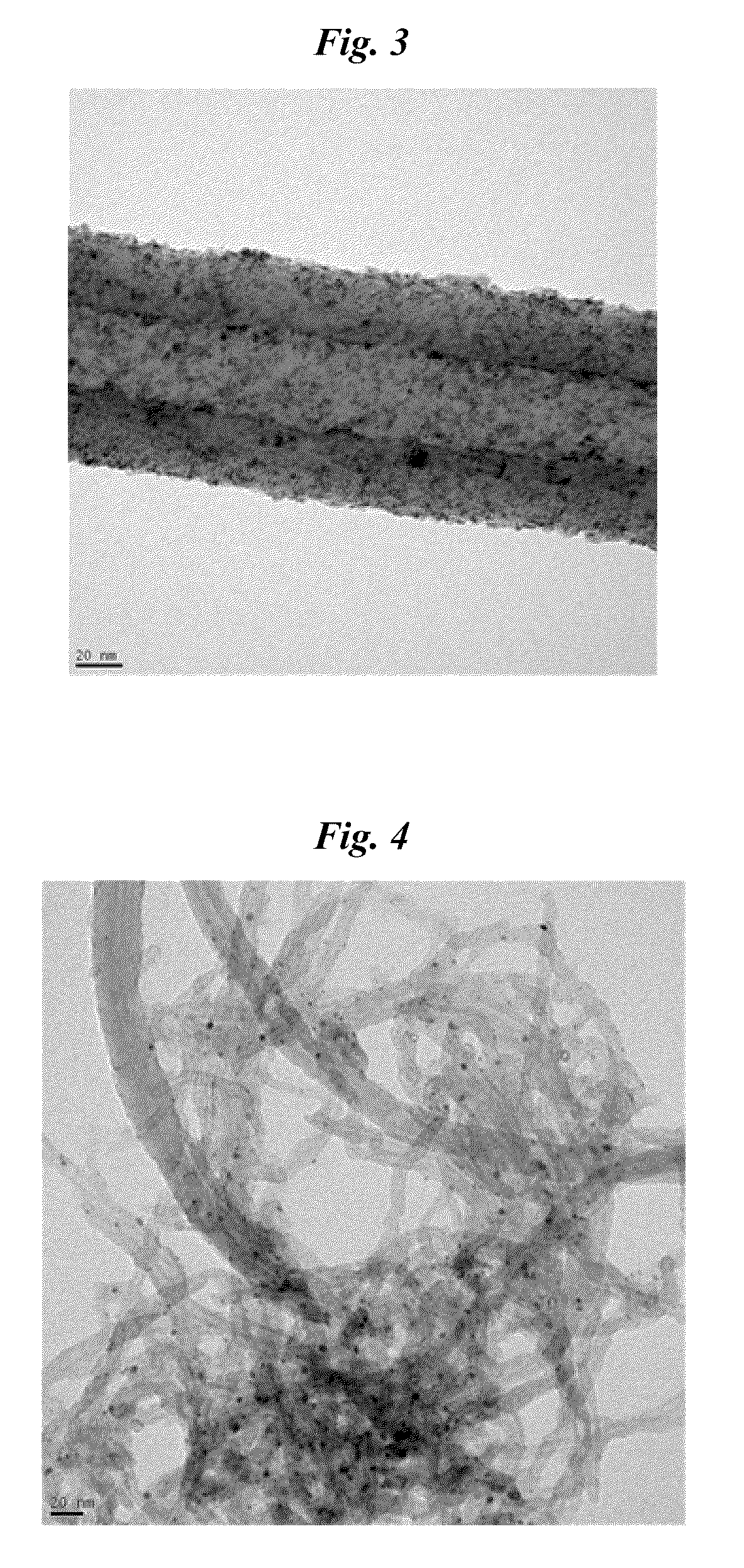

Carbon Nanofiber-Metal Composite and Method for Preparing the Same

InactiveUS20110160037A1Improve electromagnetic shielding performanceEasily form network structureMaterial nanotechnologyShielding materialsCarbon nanofiberElectromagnetic shielding

The present invention provides a carbon nanofiber-metal composite, which is formed by continuously coating a carbon nanofiber including a plurality of laminated truncated, conic graphenes with a metal. The carbon nanofiber-metal composite according to the present invention can have improved magnetic permeability and conductivity, and thus can be useful as an electromagnetic shielding material.

Owner:CHEIL IND INC

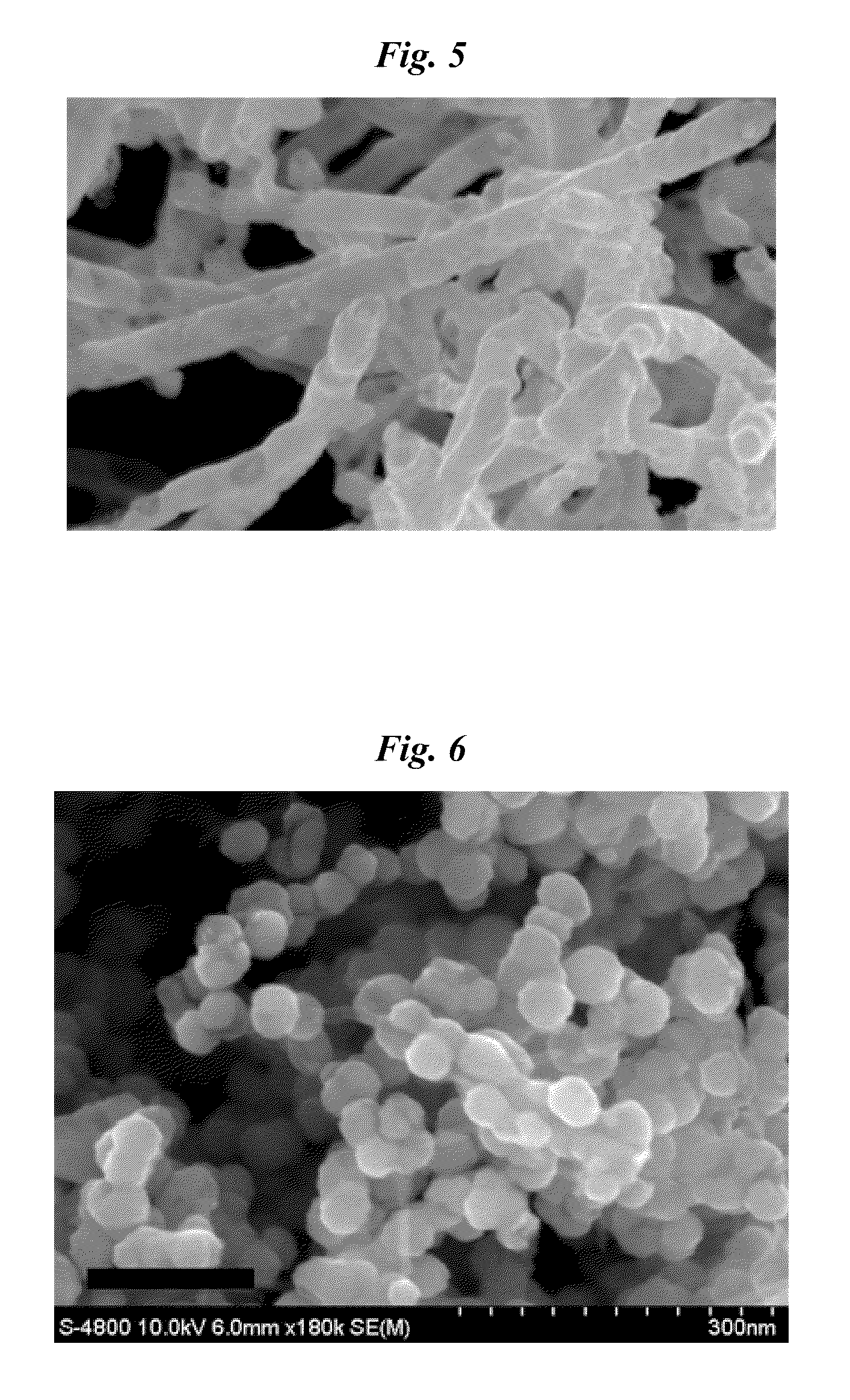

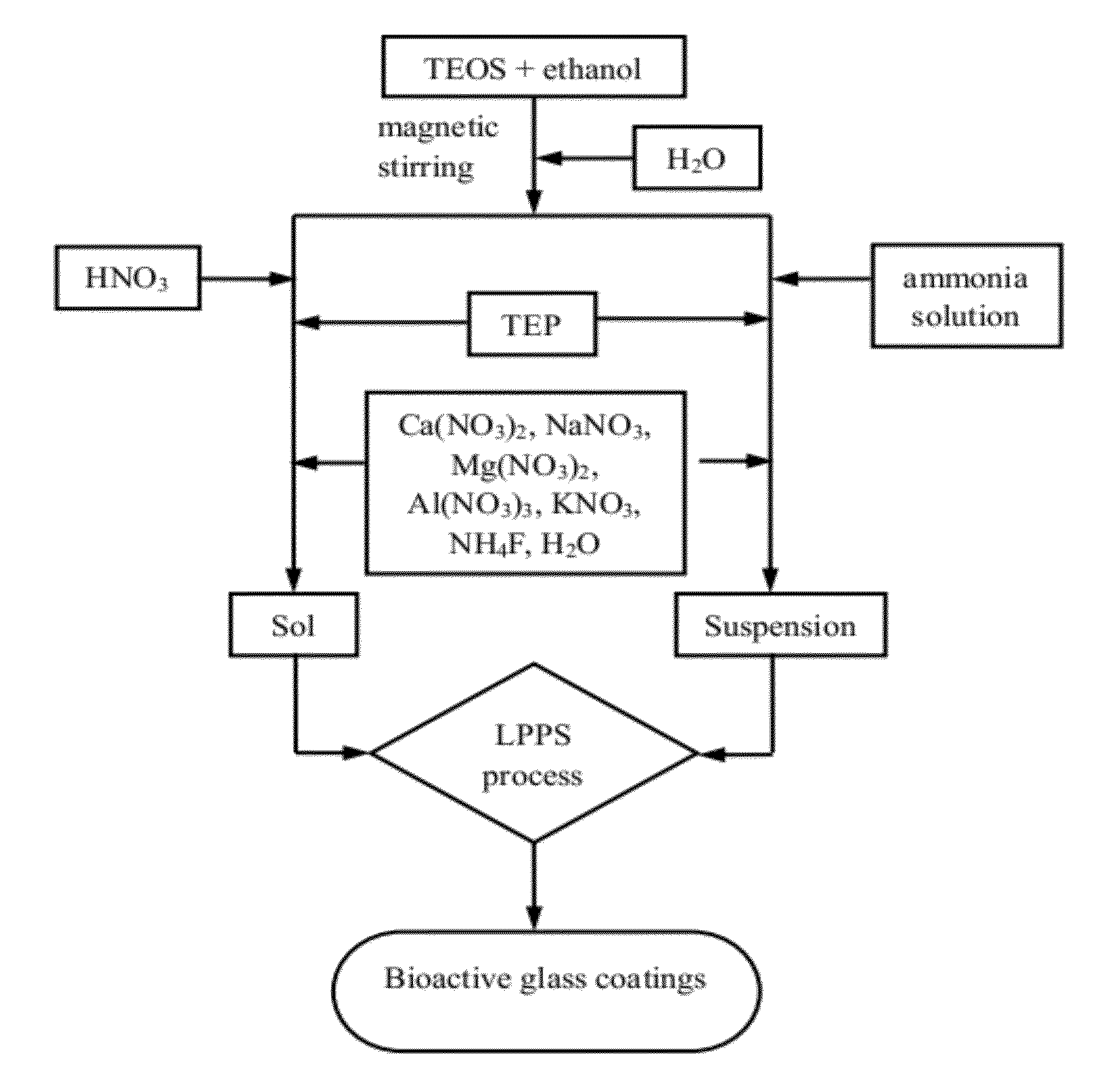

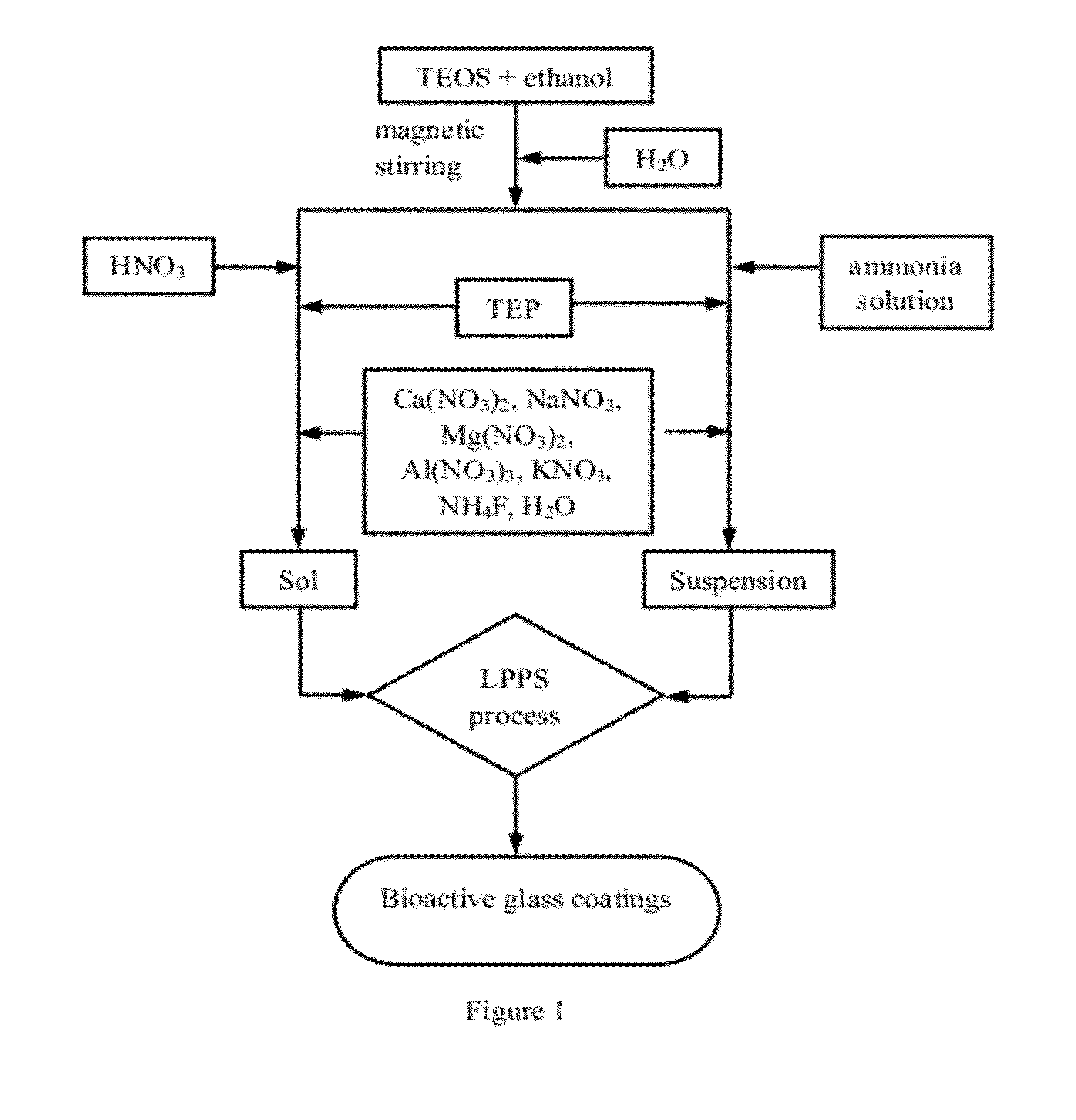

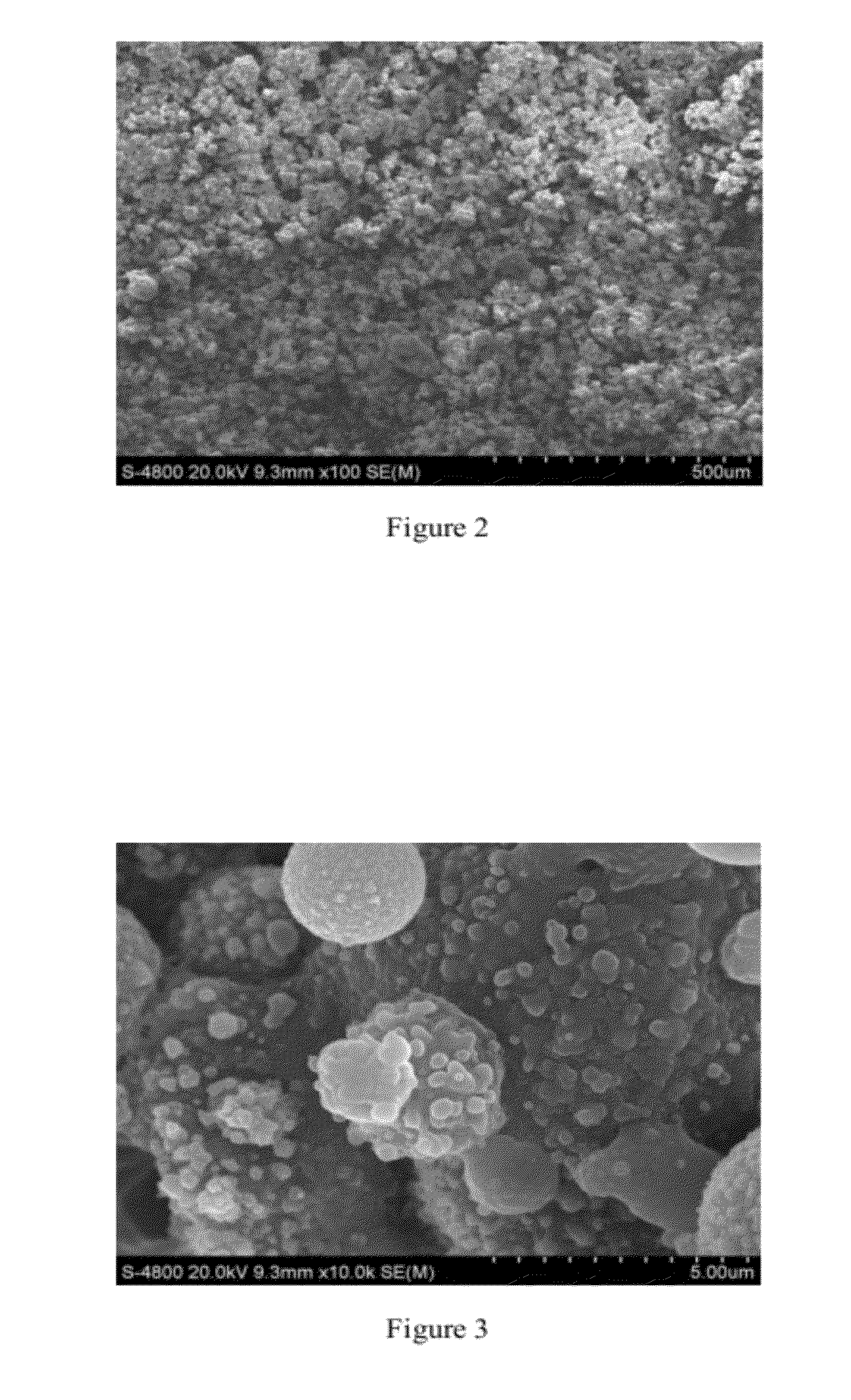

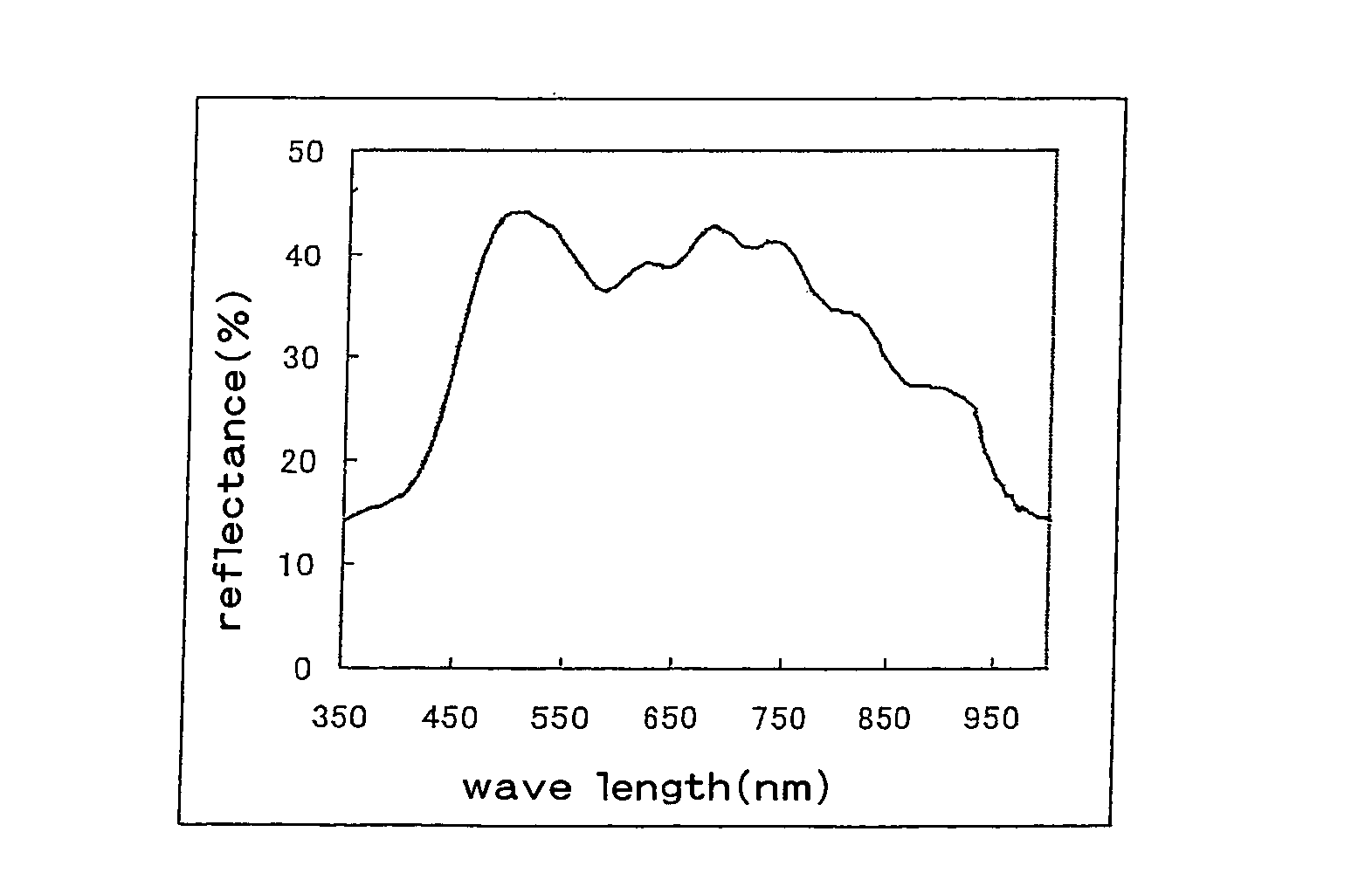

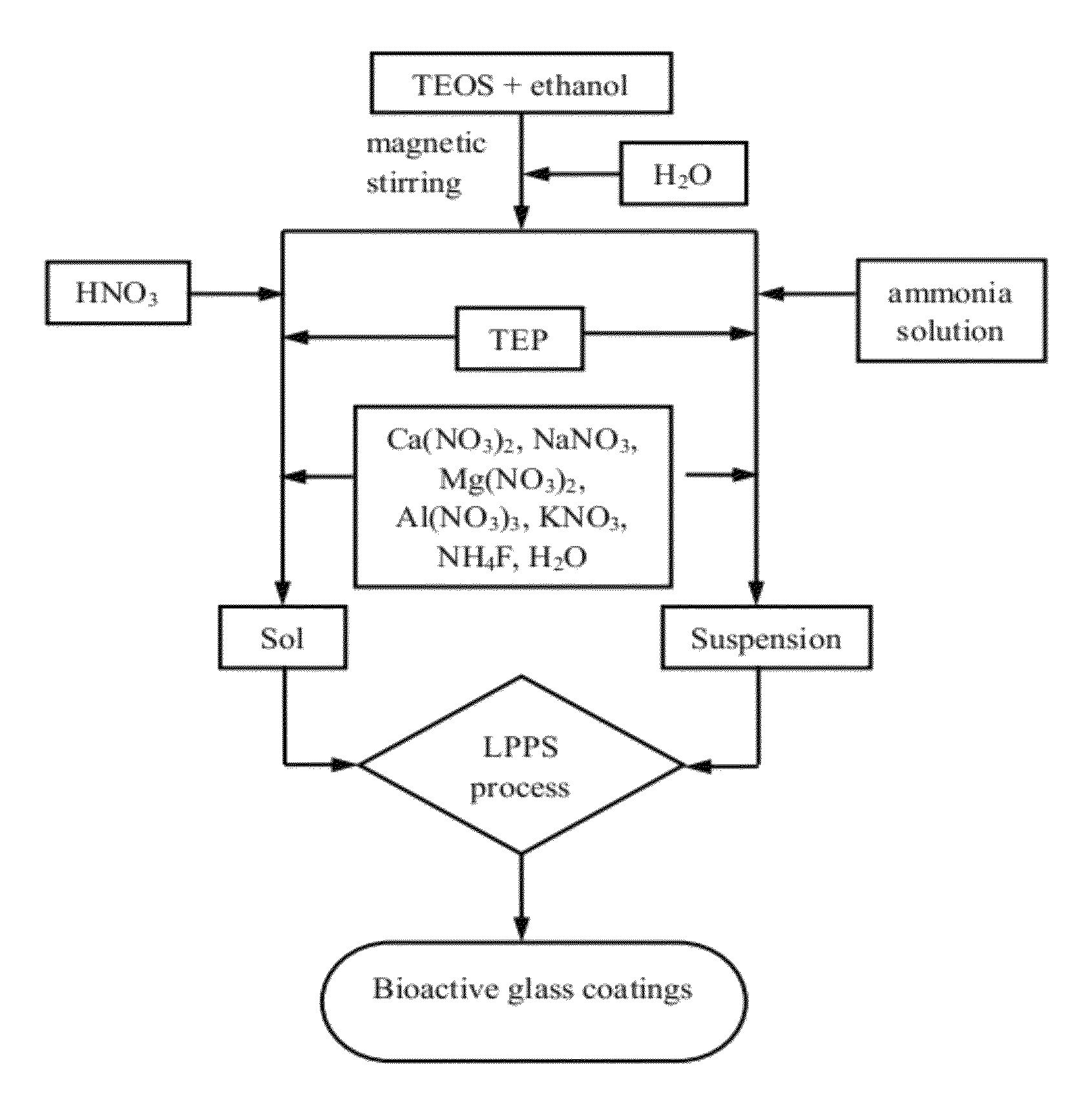

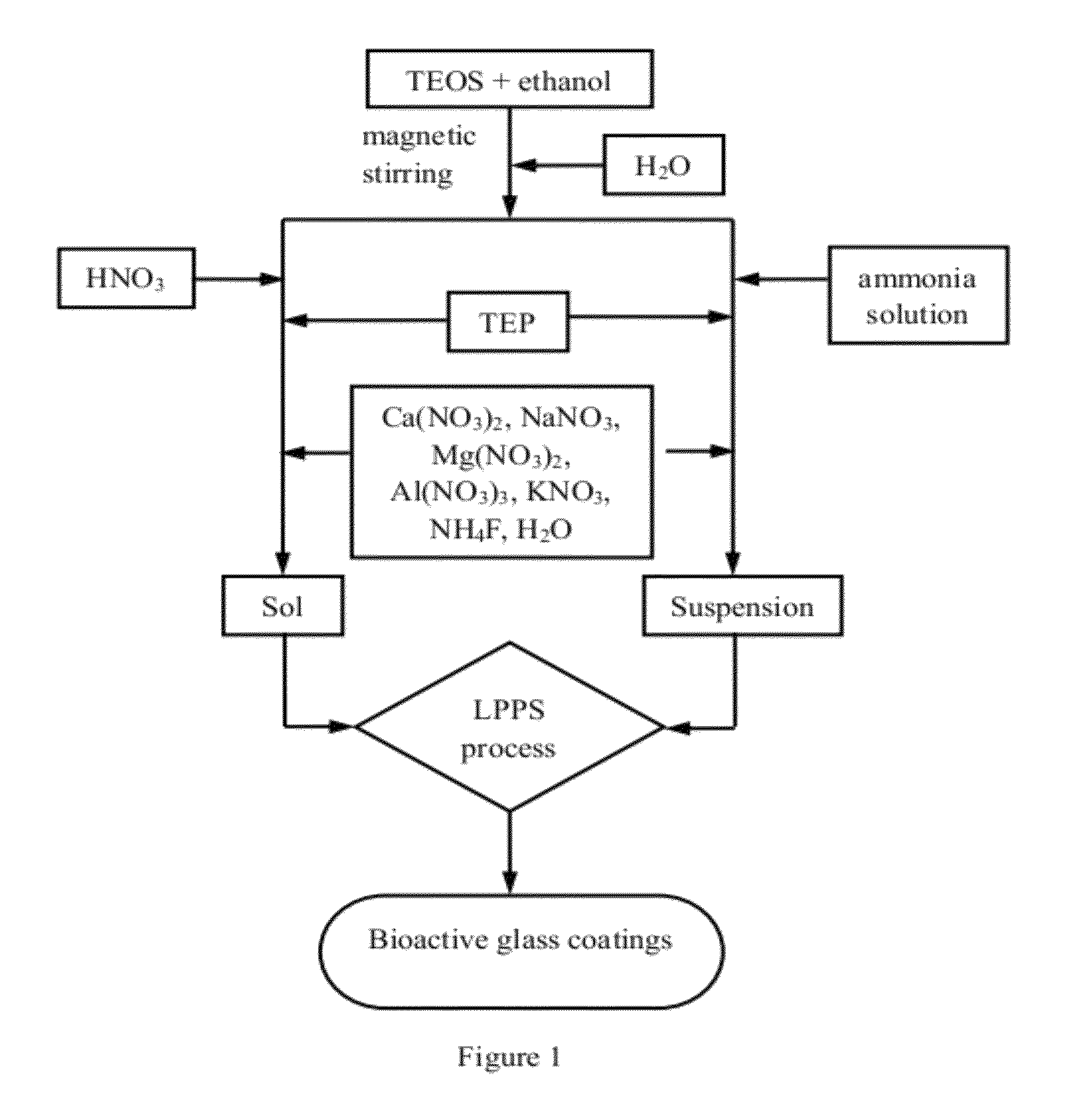

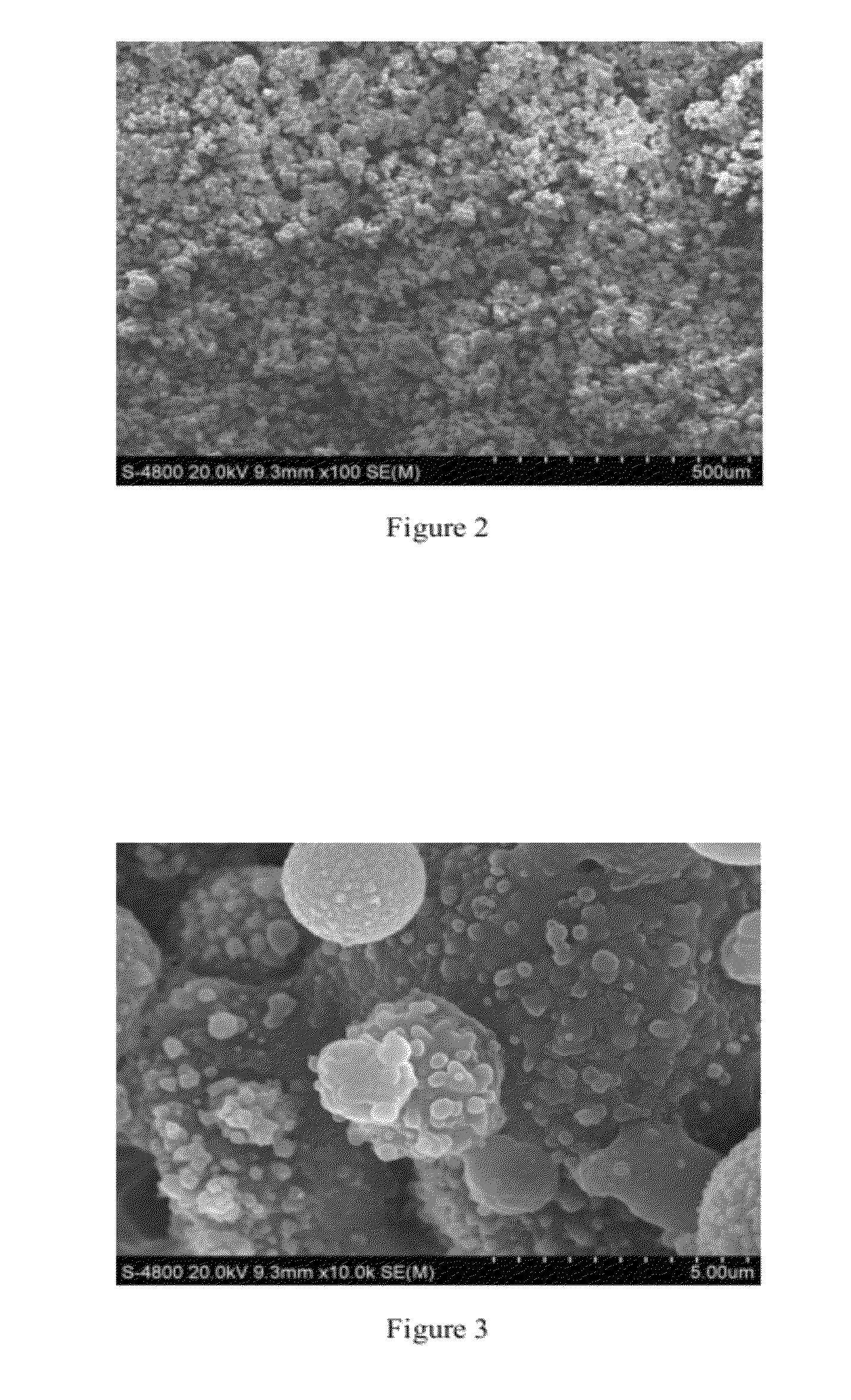

Method for preparation of bioactive glass coatings by liquid precursor thermal spray

InactiveUS20120058250A1Coating thickness is thinLow production efficiencyMolten spray coatingPretreated surfacesThermal sprayingChemical composition

The present invention belongs to the field of biomedical material, and is particularly related to a method of preparing bioactive glass coatings by liquid precursor thermal spray. The objective of the present invention is to overcome the shortcomings of the air plasma spraying where the powder feedstock preparation is complicated and time-consuming, and sol-gel or other wet chemistry method where the synthesized coating generally has thin coating thickness and with low production efficiency. Therefore, a new method is provided for preparation of bioactive glass coatings. In this method, organic and inorganic raw materials were first weighed in accordance with the chemical composition of bioactive glasses, and sol or suspension was prepared; then the sol or suspension was used as the feedstock for thermal spray, and was deposited on the biomedical materials substrate, at high temperature to form the bioactive glass coating. The invention possesses the following advantages: simple operation, less complicated procedures, synthesis with high efficiency, low production cost, suitable for industrial production, and so on. This method can be used to prepare bioactive glass coatings.

Owner:SICHUAN UNIV

Non-slip coating material, as well as preparation method and coating method thereof

ActiveCN103571322ACoating thickness is thinImprove skid resistancePretreated surfacesPolyurea/polyurethane coatingsEthyleneCoating

The invention relates to a non-slip coating material for vinyl flooring. The non-slip coating material adopts PMU (polymethyl urea) as a non-slip agent. The invention further relates to a preparation method and a coating method of the non-slip coating material, and a non-slip coating obtained by utilizing the non-slip coating material has the advantages of thin thickness of the coating and good non-slip performance.

Owner:PPG COATINGS TIANJIN

Broad-band-cholesteric liquid-crystal film, process for producing the same, circularly polarizing plate, linearly polarizing element, illiminator, and liquid-crystal display

InactiveUS7393570B2Reduce the numberReduce light timeLiquid crystal compositionsPolarising elementsDisplay deviceMesogen

A broad band cholesteric liquid crystal film of the present invention is a cholesteric liquid crystal film obtained by coating a liquid crystal mixture containing a polymerizable mesogen compound (a), a polymerizable chiral agent (b) and a photoisomerizable material (c) on a substrate to ultraviolet polymerize a coat of the liquid crystal mixture, and has a reflection bandwidth of 200 nm or more. A broad band cholesteric liquid crystal film of the present invention has a broad reflection band, is of a thin type and can be manufactured in less of manufacturing steps.

Owner:NITTO DENKO CORP

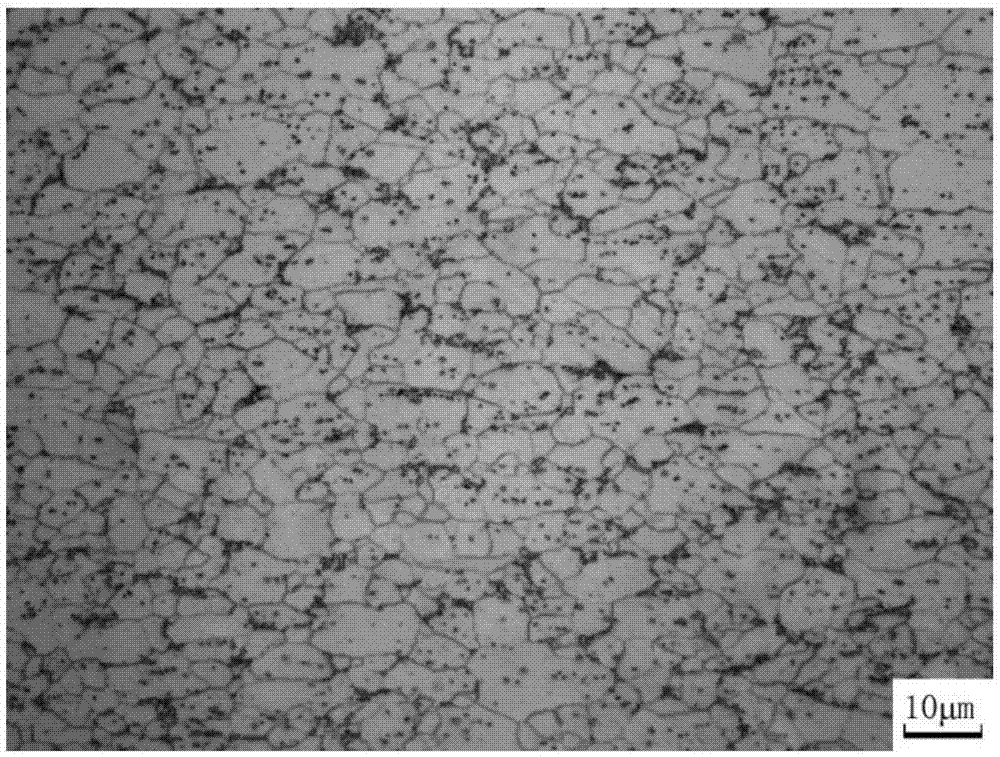

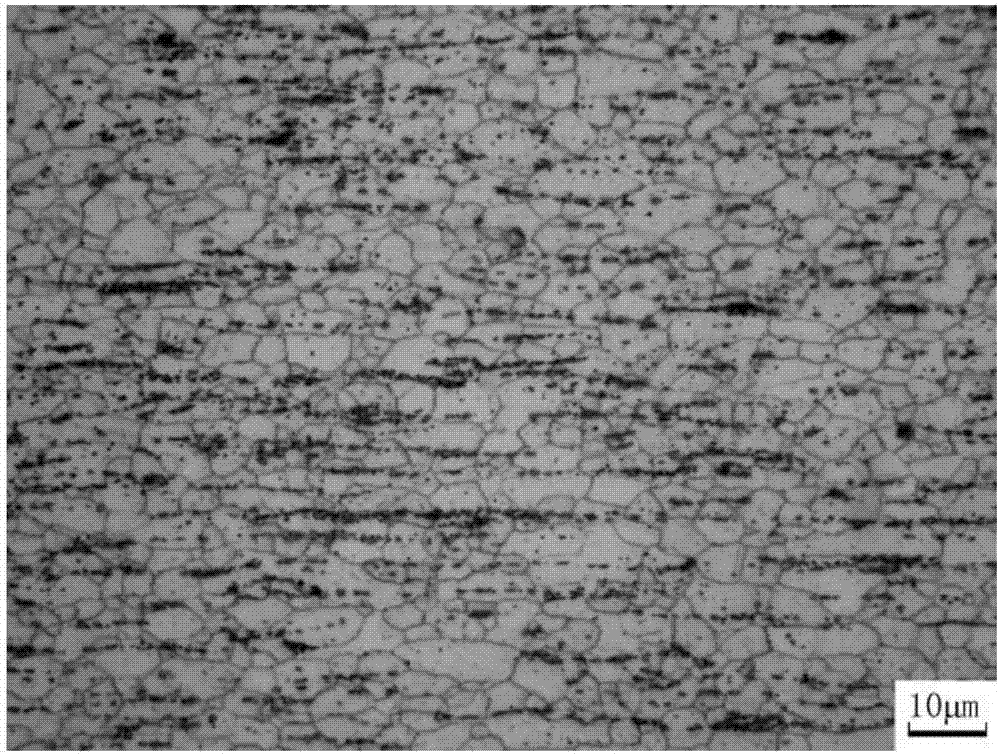

Hot-dipped aluminum-zinc alloy steel plate and preparation method thereof

The invention belongs to the technical field of clad steel sheet production, particularly relates to a hot-dipped aluminum-zinc alloy steel plate and a preparation method thereof. Aiming at the problems that the hot-dipped aluminum-zinc alloy steel plate produced through the prior art has poor strength, low coating quality and high cost, the invention provides the hot-dipped aluminum-zinc alloy steel plate, and the base material of the steel plate consists of the following components according to weight percentage, 0. 15-0.20% of C, less than or equal to 0.07% of Si, 0.2-0.5% of Mn, 0.02-0.05% of P, less than or equal to 0.015% of S, 0.04-0.06% of Ti, 0.020-0.070% of Al, and the balance of Fe and unavoidable impurities; the preparation method includes the following steps: smelting, hot rolling, cold rolling, cleaning, annealing, hot dipping aluminum-zinc, cooling after hot dipping, finishing, tension levelling, surface treating, greasing, rolling, and getting a product; the heating temperature of a slab during hot rolling is 1230-1260 DEG C and the time in a furnace is 180-300 min; the finish rolling temperature of hot rolling is 840-900 DEG C; the annealing temperature is 720-780 DEG C, and the annealing time is 45-85 s; and the rolling temperature is 580-640 DEG C. The alloy steel plate disclosed by the invention is high in strength, high in ductility, low in coating thickness, uniform and compact in zinc spangle, and high in quality.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

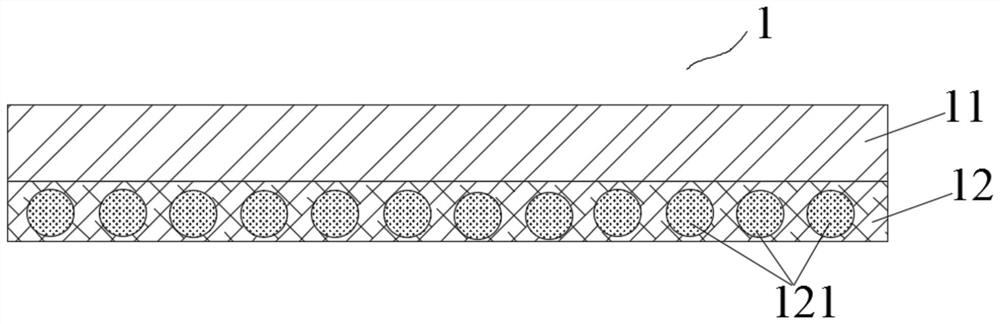

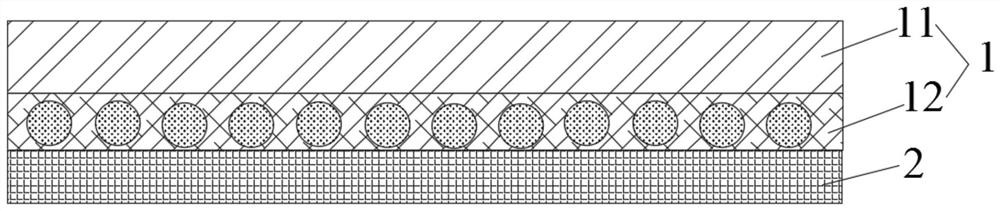

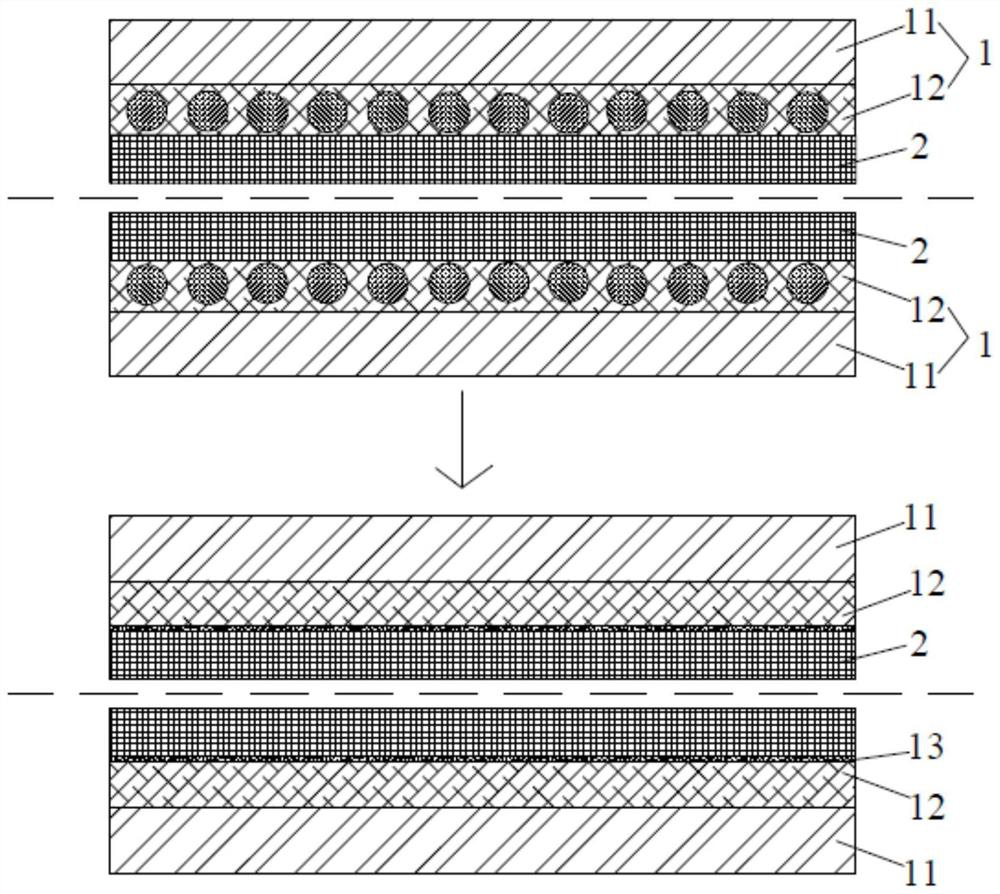

Current collector, electrode plate and lithium ion battery

PendingCN113394406ADoes not affect electrochemical performanceReduce generationFinal product manufactureElectrode carriers/collectorsElectrical batteryLithium-ion battery

The invention provides a current collector, an electrode plate and a lithium ion battery. The current collector comprises a base material and a safe coating applied on at least one surface of the base material, the safe coating comprises flame-retardant particles, a heat-resistant additive, a conductive agent and a binder; and the flame-retardant particles are converted into an insulating layer between the base material and the safe coating at 80-180 DEG C. According to the current collector, the base material is coated with the safe coating with safety, the flame-retardant particles are added into the safe coating, the flame-retardant particles do not change during the normal use temperature period of a battery and do not influence the electrochemical performance of the battery; and when the temperature exceeds the normal use temperature of the battery, and reaches 80-180 DEG C, the flame-retardant particles can be decomposed and converted into the compact insulating layer between the base material and the safe coating, so that the contact between an active substance and the base material is greatly blocked, the transmission of lithium ions and electrons is hindered, and a short-circuit switch is cut off in time, and therefore, the purpose of preventing the thermal runaway of the battery is achieved.

Owner:HUIZHOU LIWINON ELECTRONIC TECH CO LTD

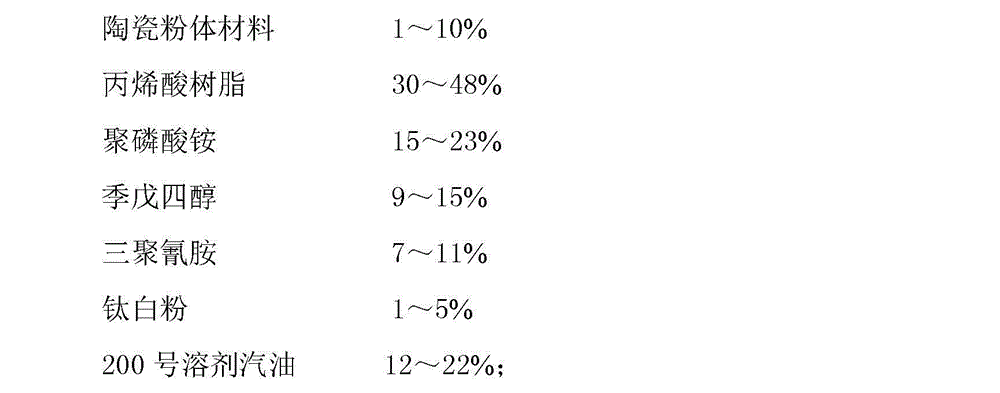

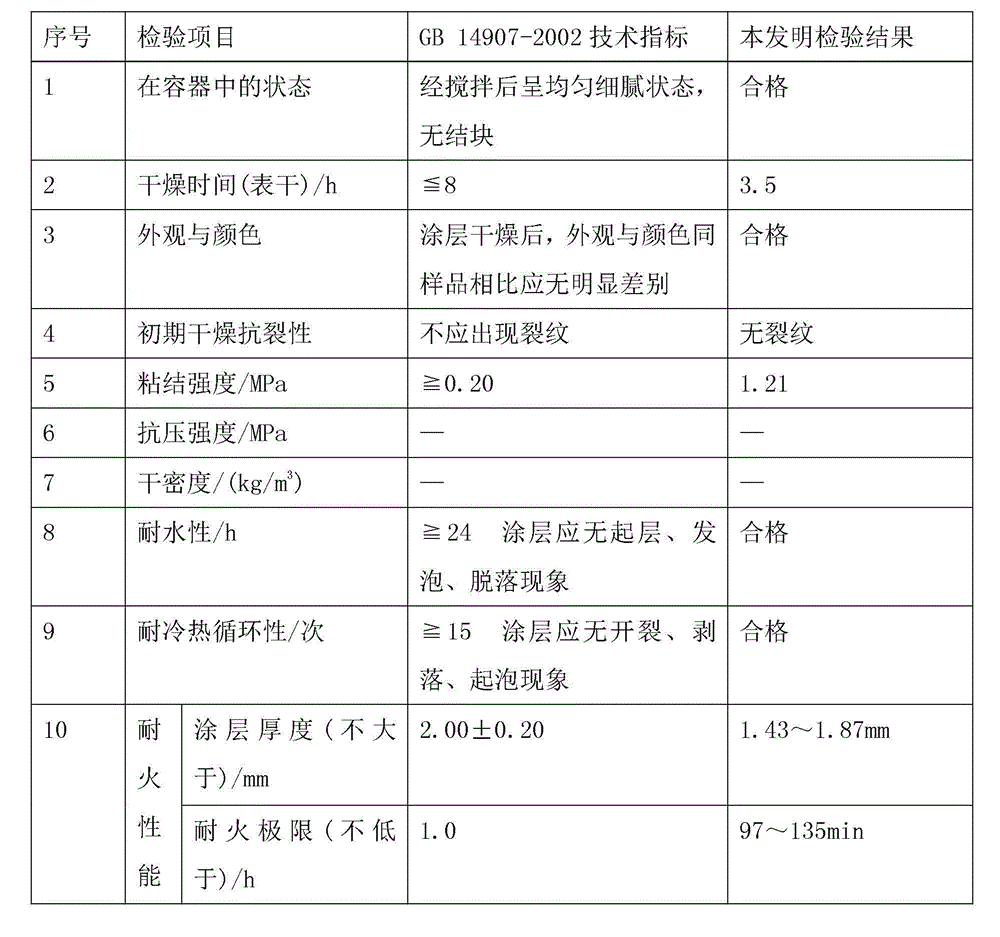

Steel structure active fire retardant coating and preparation method thereo

InactiveCN102911574ACoating thickness is thinExcellent fire resistance performanceFireproof paintsAntifouling/underwater paintsActivation functionPentaerythritol

The invention discloses a steel structure active fire retardant coating which comprises the following components in percentage by weight: 1-10% of ceramic powder material, 30-48% of acrylic resin, 15-23% of ammonium polyphosphate, 9-15% of pentaerythritol, 7-11% of melamine, 1-5% of titanium dioxide and 12-22% of solvent gasoline No.200. A preparation method provided by the invention is simple, and the fire retardant coating is prepared by adding a certain amount of ceramic powder material with bioactivity function based on the existing fire retardant coating. Because the ceramic powder material has activation function, the activity of the coating is improved, so that the fire retardant coating has better fire endurance performance than the existing fire retardant coating, and the required coating thickness is also thinner.

Owner:湖北联飞翔汽车科技有限公司

Sandwich thermal insulation layer system and method for production

InactiveUS7998601B2Low thermal conductivityCoating thickness is thinMolten spray coatingPretreated surfacesPorous coatingThermal insulation

A method produces thermal barrier coatings that adhere to components even at high temperatures and temperatures that change frequently. A gas-tight glass-metal composite coating is applied to the component and annealed. The corroded part of the gas-tight coating is then removed, and a second, porous coating is applied. The second coating can comprise a ceramic, in particular yttrium-stabilized zirconium oxide. A thermal barrier coating is provided that is a composite made of a gas-tight glass-metal composite coating and another porous coating disposed thereover. Because the boundary volume of the composite coating is partly crystallized to the other coating, superior adhesion within the composite is achieved. Thus, it is in particular possible to produce a composite made of silicate glass-metal composite coatings and yttrium-stabilized zirconium oxide that are temperature-stable for extended periods of time. Such a composite is particularly advantageous for use as a thermal barrier coating because it combines good protection against oxidation with low heat conductivity and susceptibility to aging.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

Bovine enterovirus egg yolk antibody and preparation

PendingCN114539396ARich treatment methodsAvoid passingEgg immunoglobulinsDigestive systemAntiendomysial antibodiesRumen

Aiming at the physiological characteristics of ruminants, in order to solve the problems of digestion and inactivation of the egg yolk antibody in the rumen, the invention creatively provides two preparation modes, one is an intestinal preparation which can prevent the egg yolk antibody from passing through the rumen, and research shows that after the intestinal preparation is applied to calves, the intestinal preparation has a treatment effect on calf diarrhea caused by BEV infection, and the intestinal preparation can be used for treating the diarrhea of the calves caused by BEV infection. The effect is close to that of a traditional drug therapy, but compared with an antibiotic therapy, the method is more environment-friendly and safer; the other one is a rumen bypass preparation which can be added as a part of daily ration concentrate and is convenient to use, after the egg yolk antibody is prepared into the rumen bypass preparation, the egg yolk antibody can be prevented from being degraded in the rumen and released in the intestinal tract at a fixed point, and the treatment effect on diarrhea caused by BEV infection is achieved.

Owner:NANYANG NORMAL UNIV

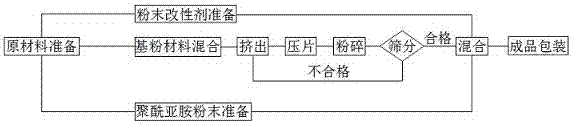

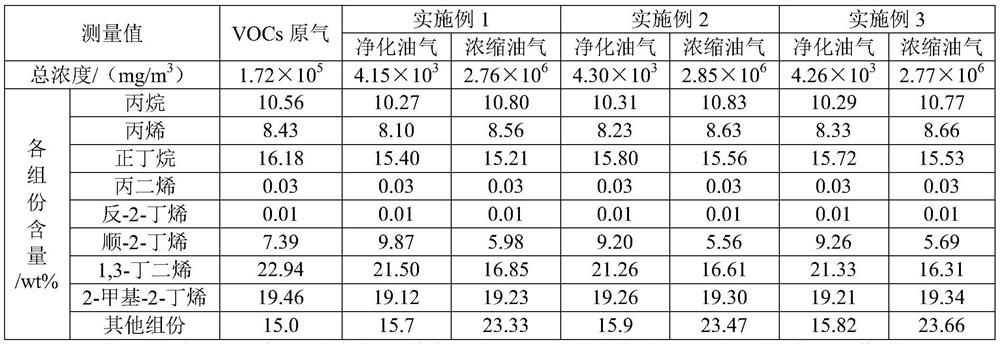

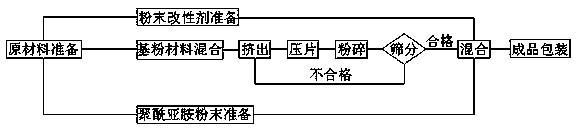

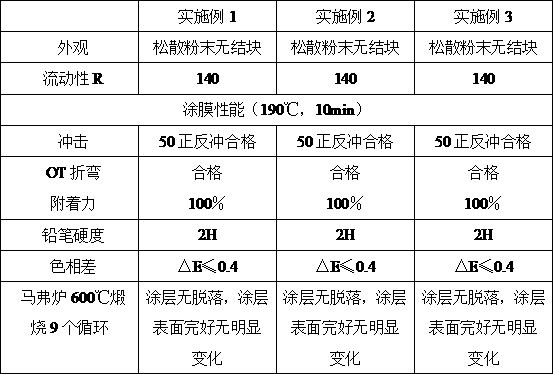

Powder coating for automobile exhaust pipe and silencer and preparation method thereof

ActiveCN107459926AImprove high temperature resistanceGuaranteed high temperature performancePowdery paintsFused glassMuffler

The invention discloses a powder coating for an automobile exhaust pipe and a silencer and a preparation method thereof. The adopted materials in parts by weight are as follows: 50-60 parts of methyl phenyl silicone resin, 20-30 parts of unleaded low-temperature fused glass powder, 15-20 parts of polyimide powder, 3-5 parts of a flatting agent, 2-3 parts of a silane coupling agent KH550, 1-2 parts of a titanate coupling agent, 15-20 parts of inorganic ceramic pigment, 1 part of benzoin and 0.8 part of white carbon black. The prepared powder coating is uniform and bright in color, has a better decorating effect, has an excellent high temperature resisting property and can meet the requirement on the surface coating of the automobile exhaust pipe and the silencer.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

Polymer stent coating stability enhancing sterilization process

The invention provides a polymer stent coating stability enhancing sterilization process, comprising the steps of getting biodegradable polymers and working to prepare into a biodegradable stent, coating to prepare into a drug elution stent, the drug being rapamycin, after being dried, holding to a balloon catheter, together with a drying agent and a deoxidizing agent being placed into a paper plastic bag to pack, using an aluminum foil bag sealing for the outer package, in the packaging process through an air flow meter set filling in the outer package an proper amount of idle gas, and conducting radioactive sterilization. The process can obviously lower the drug germinated degradation on the stent, thereby increasing the drug content on the drug elution tent, the process does not require increasing the thickness of the coating layer to reach the target drug load content.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

Drying method and preparation method for lost foam

ActiveCN110102709ANot prone to cracking problemsAvoid destructionFoundry mouldsFoundry coresAgricultural engineeringSaturated water vapor

The invention discloses a drying method for a lost foam, and the drying method comprises the following steps of: step 1, sending a coated foam mold to a coating drying room, and pre-drying the coatedfoam mold under the condition of circulating hot air, wherein the temperature of the circulating hot air is 30-35 DEG C, the wind speed is 1.5M / S-2.5M / S, the wind pressure is 0.1Pa-0.6Pa, the humidityof the drying room is 30%-35%, and the drying time is 2h-3h; step 2, sending the foam mold pre-dried in the step 1 to a stokehold drying room, and drying the foam mold under the condition of the circulating hot air, wherein the temperature of the circulating hot air is 30-50 DEG C, the wind speed is 0.5M / S-1.5M / S, the wind pressure is 0.1Pa-0.6Pa, the humidity of the drying room is 15%-20%, and the drying time is 6h-8h. The invention further discloses a preparation method for the lost foam. The invention has the organic combination of realizing the humidity, the flow of air and the temperature, prevents the saturated water vapor in the coating from being in an expanded state, and the water loss outside the coating being dried and shrunk quickly to cause the phenomenon of coating cracking.

Owner:安徽南凯元机械有限公司

High bath strength acrylic resin with long branched chain structure

InactiveCN101338010ARaise the crystallization temperatureShort crystallization timePolypropyleneGrafting

The invention relates to the technical field of polypropylene resin materials, in particular to high melt strength polypropylene resin containing a long-chain branch structure, which comprises the following components by weight percentage: 68 percent to 89 percent of polypropylene, 10 percent to 30 percent of macromonomer with peroxy groups, 0.5 percent to 1.5 percent of graft accelerators and additives of the rest. All the components are added into a high-speed mixer to stir and mix evenly, are fed into a double screw extruder with 36:1 to 48:1 L / D to carry out the melt grafting reaction, and are extruded out for granulation after the reaction is completed. The high melt strength polypropylene resin solves the problem of the difficult hot forming of the ordinary polypropylene resin, has higher crystallization temperature, shorter crystallization time and wider processing temperature range, the process is easy to master, thereby hot forming parts are allowed to demolded under a higher temperature to shorten the forming cycle. The high melt strength polypropylene resin can be molded on ordinary hot forming equipment into thin-walled pressure vessels with large draw ratio and uniform vessel wall.

Owner:东莞金富亮塑胶颜料有限公司 +1

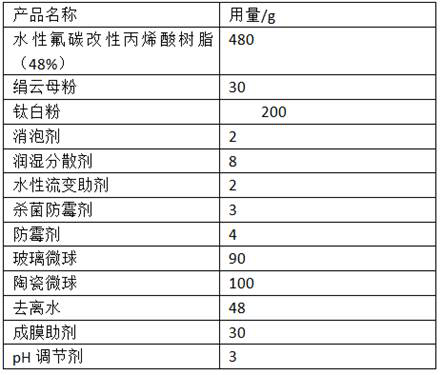

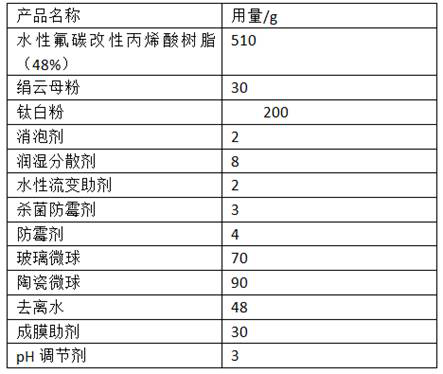

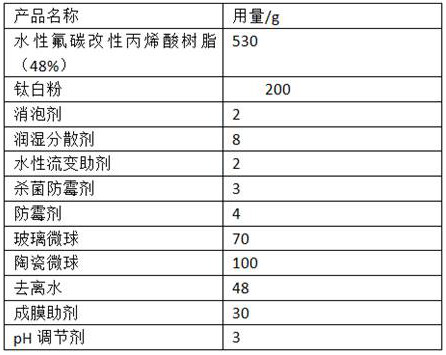

Waterborne fluorocarbon modified acrylic polyurethane coating

PendingCN111662627AReduce loadExcellent corrosion protectionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceAlcohol

The invention discloses a waterborne fluorocarbon modified acrylic polyurethane coating which comprises a component A and a component B. The ratio of the component A to the component B is (3: 1)-(10:1), wherein the component A is prepared from the following components in percentage by mass: 45-65% of waterborne fluorocarbon modified acrylic resin, 3%-5% of sericite powder, 15%-25% of titanium dioxide, 0.2%-1% of a defoaming agent, 0.3%-0.8% of a wetting dispersant, 0.1%-0.6% of a water-based rheological additive, 0.3%-0.6% of a bactericidal preservative, 0.4%-0.8% of a mildew preventive, 3%-15% of glass microspheres, 5%-15% of ceramic microspheres, 1%-15% of deionized water, 2%-5% of a coalescing agent and 0.3%-0.6% of a pH regulator; and the component B is prepared from a dimer / trimer ofHDI, alcohol ether and an alcohol ester solvent. The waterborne fluorocarbon modified acrylic polyurethane coating is a two-component waterborne polyurethane reflective heat-insulation anticorrosivecoating used on the surfaces of equipment such as steel vacuum pipelines and steel storage tanks of high-speed trains. The reflective heat-insulation anticorrosive coating has good reflective, heat-insulation and anticorrosive capabilities, achieves excellent effects in environmental protection, heat-insulation and anticorrosive properties, and is lighter in weight, convenient to coat and longer in service life.

Owner:张建华

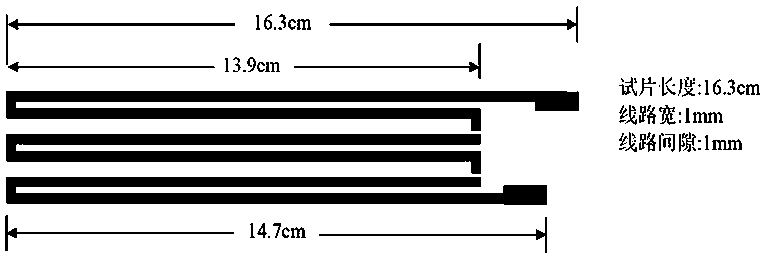

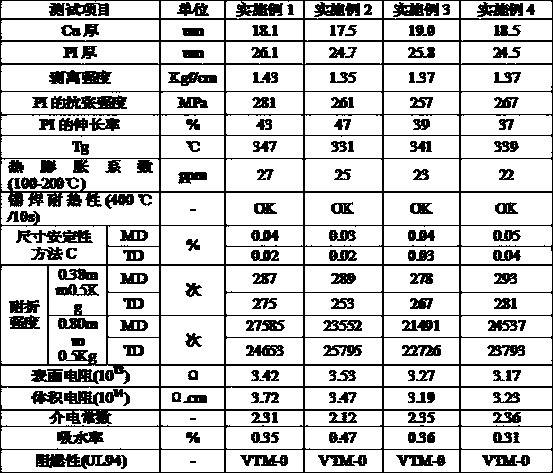

Preparation method for polyamide acid resin and preparation method for double-sided flexible copper-clad plate

InactiveCN109503836AImprove heat resistanceGood chemical resistanceLamination ancillary operationsLaminationHeat resistanceProton

The invention discloses a preparation method for polyamide acid resin and a preparation method for a double-sided flexible copper-clad plate. The preparation method for the polyamide acid resin is asfollows: under the protection of nitrogen, aromatic diamine monomer is dissolved into an aprotic polar solvent, and after stirring for dissolution at 25 DEG C to 50 DEG C, an aromatic diamine monomersolution with the mass concentration of 6 to 9 percent is obtained; after being cooled to 0 DEG C to 25 DEG C, the aromatic diamine monomer solution is added with an aromatic dianhydride monomer, wherein the molar ratio of the aromatic diamine monomer to the aromatic dianhydride monomer is (1:0.95) to (1:1.05), and after 6 to 10 hours of polymerization reaction, standing for defoaming is carried out, so that the polyamide acid resin is obtained. The invention further discloses the method for preparing the double-sided flexible copper-clad plate by utilizing the polyamide acid resin. Accordingto the invention, the reaction for preparing the polyamide acid resin is simple and controllable, and the polyamide acid resin has excellent heat resistance and chemical resistance; and the prepared double-sided flexible copper-clad plate has good heat resistance, high dimensional stability and excellent chemical resistance, and properties such as peel strength and elongation are excellent.

Owner:广东圣帕新材料股份有限公司

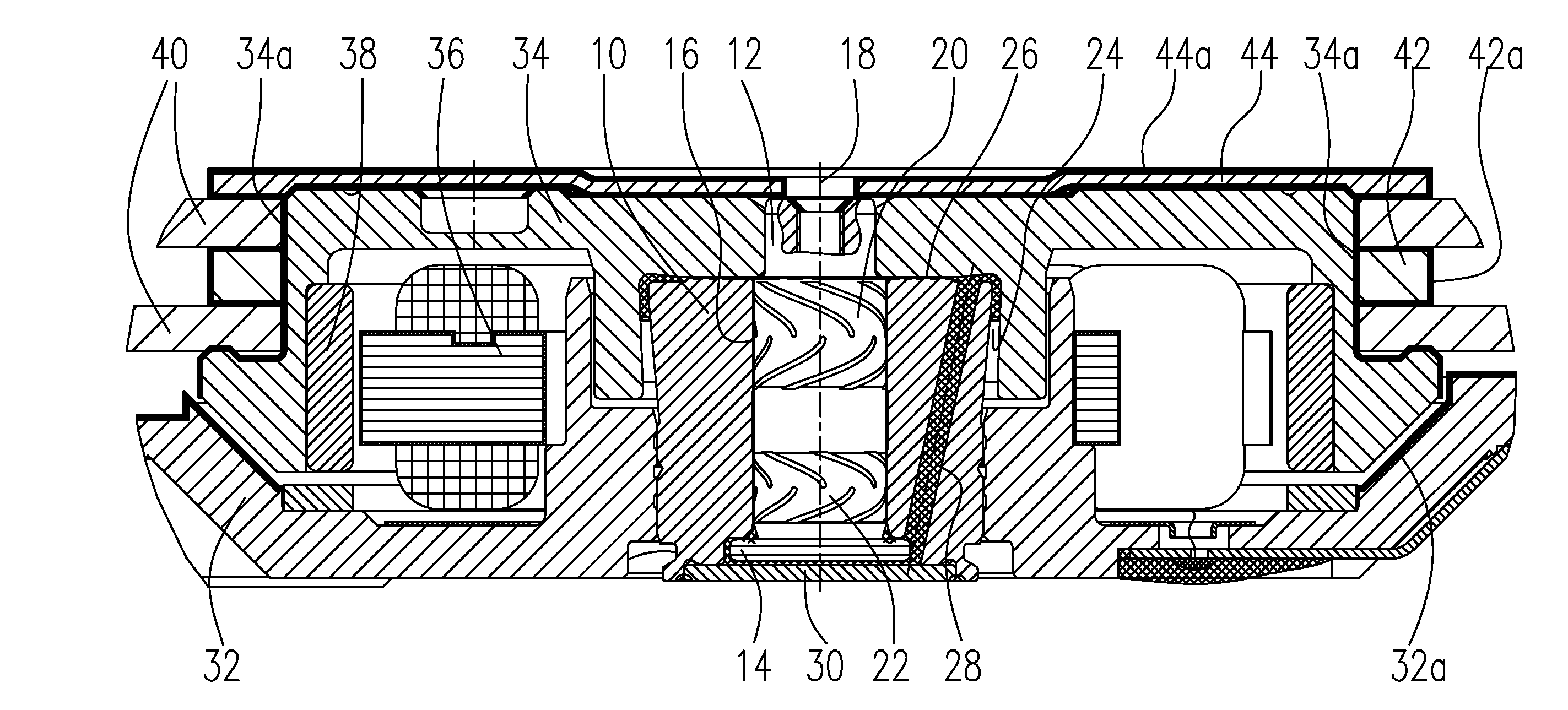

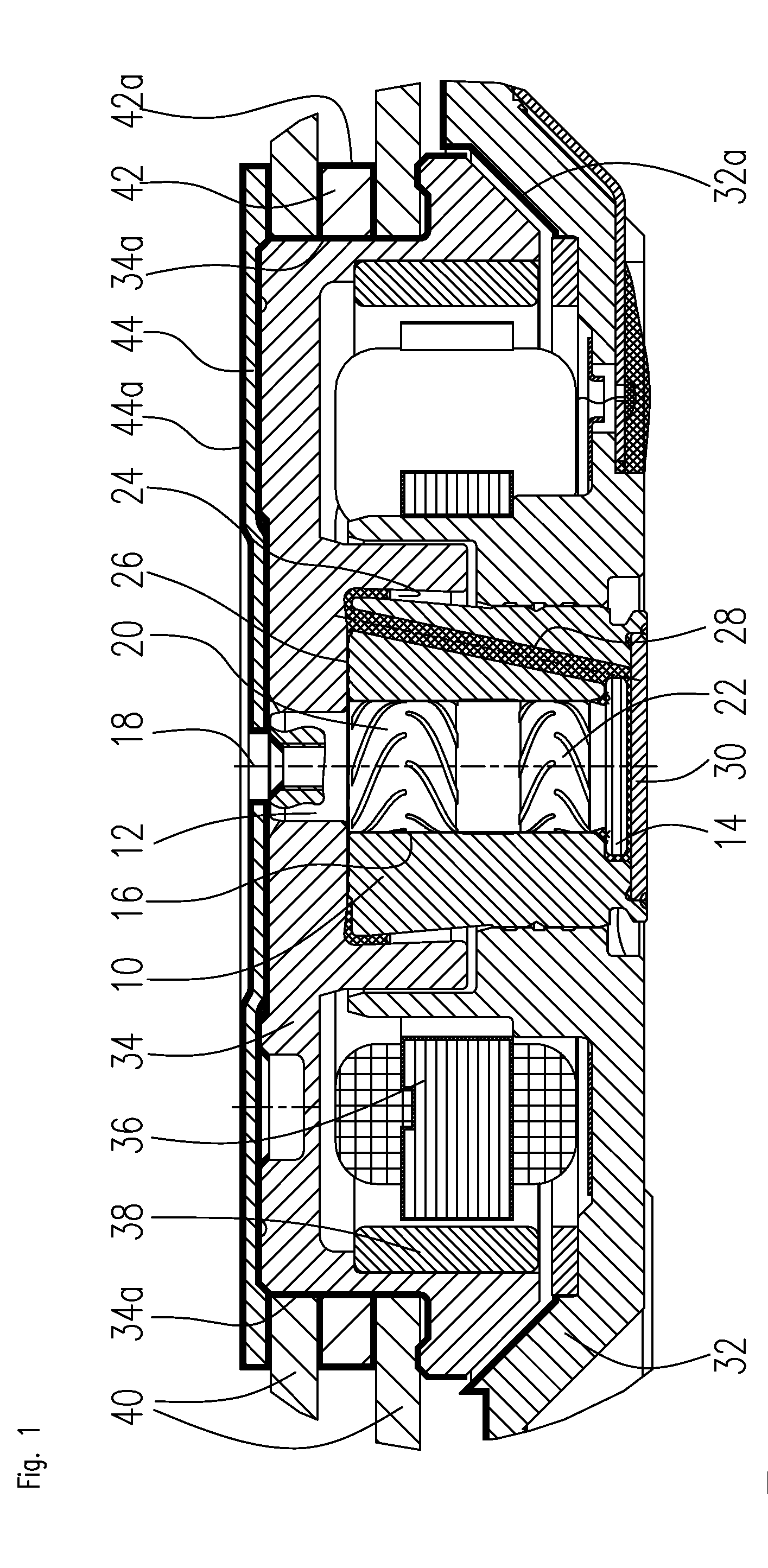

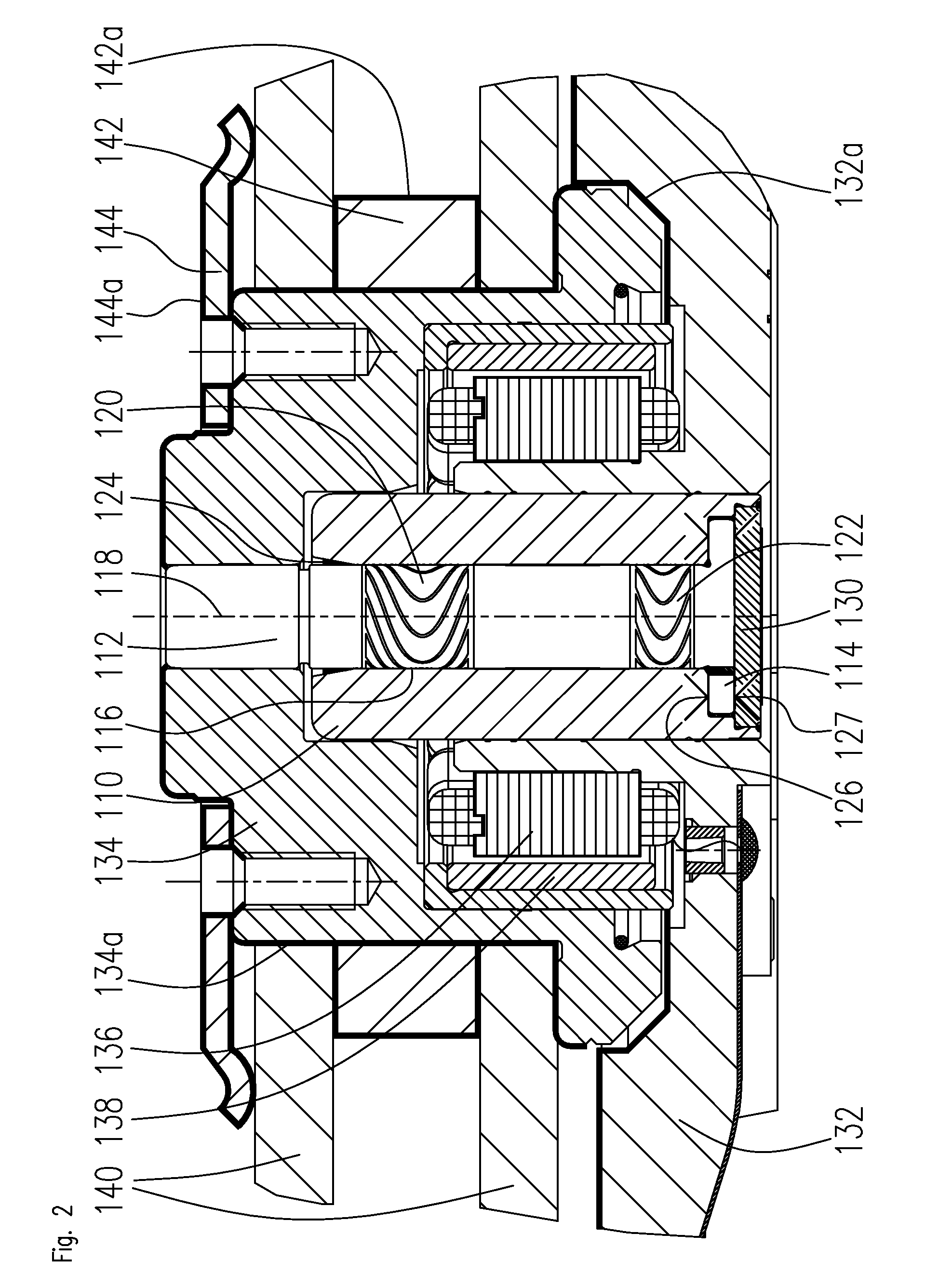

Spindle motor for driving a hard disk drive

ActiveUS20120162820A1Reduce the risk of contaminationReduce riskRecord information storageMechanical energy handlingHard disc driveWear resistant

The invention relates to a spindle motor, preferably for driving a hard disk drive, having a stationary motor component and a rotatable motor component that is rotatably supported with respect to the stationary motor component and that is driven by an electromagnetic drive system, at least one storage disk being fixed to the rotatable motor component using some means of mounting and fastening. According to the invention, at least parts of the rotatable motor component and at least parts of the means of mounting and fastening have a wear resistant surface coating or are subjected to a wear resistant surface treatment.

Owner:MINEBEAMITSUMI INC

Graphene composite metal film and preparation method thereof

ActiveCN106374111ACoating thickness is thinLow coating resistanceElectrode carriers/collectorsComposite filmGraphite

The present invention relates to the field of graphene metal composite materials, and discloses a graphene metal composite film and a preparation method thereof. The method comprises: (1) mixing graphite and a liquid-phase medium, and mechanically stripping to obtain a mixture containing graphite and graphene; (2) carrying out centrifugal separation on the mixture containing graphite and graphene, and collecting the graphene-containing supernatant; and (3) optionally drying the graphene-containing supernatant, mixing with a binder to obtain a mixed solution containing the graphene and the binder, and coating the mixed solution onto a metal substrate. According to the present invention, the graphene metal composite film prepared by using the method has advantages of thin coating thickness and low coating resistance, wherein the thickness of the electric conduction coating can be as thin as 0.2 [mu]m and the coating resistance can be as low as 2.2*10<-6>omega.cm through the following embodiment; and the method is simple and easy to perform, has the low cost, and is suitable for popularization and application.

Owner:北京中科云腾科技有限公司

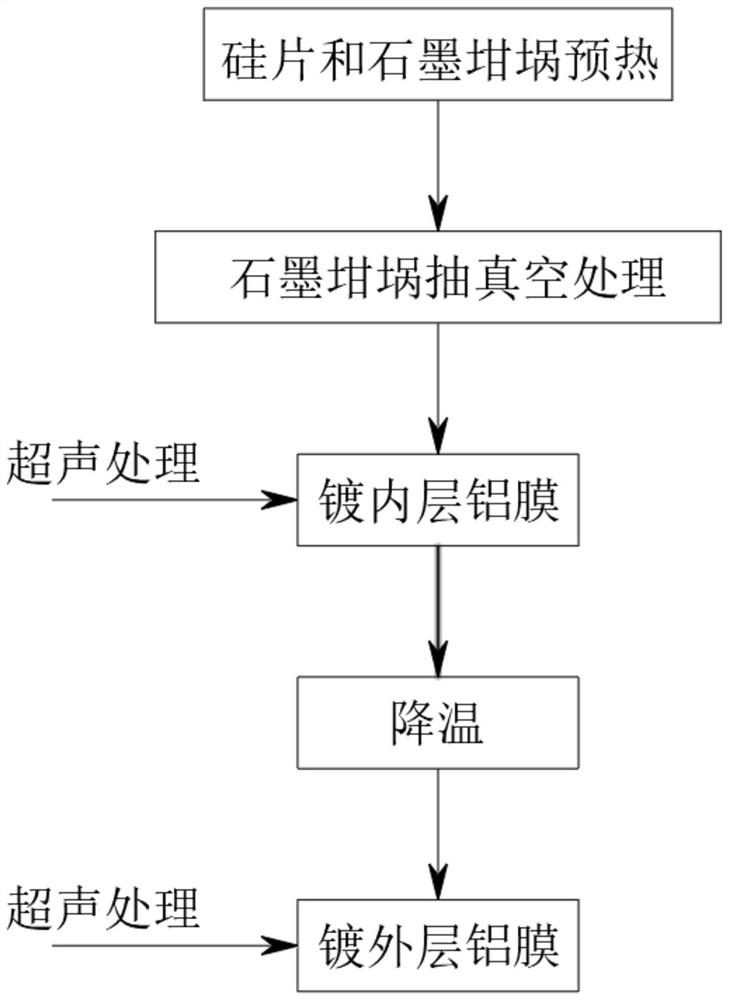

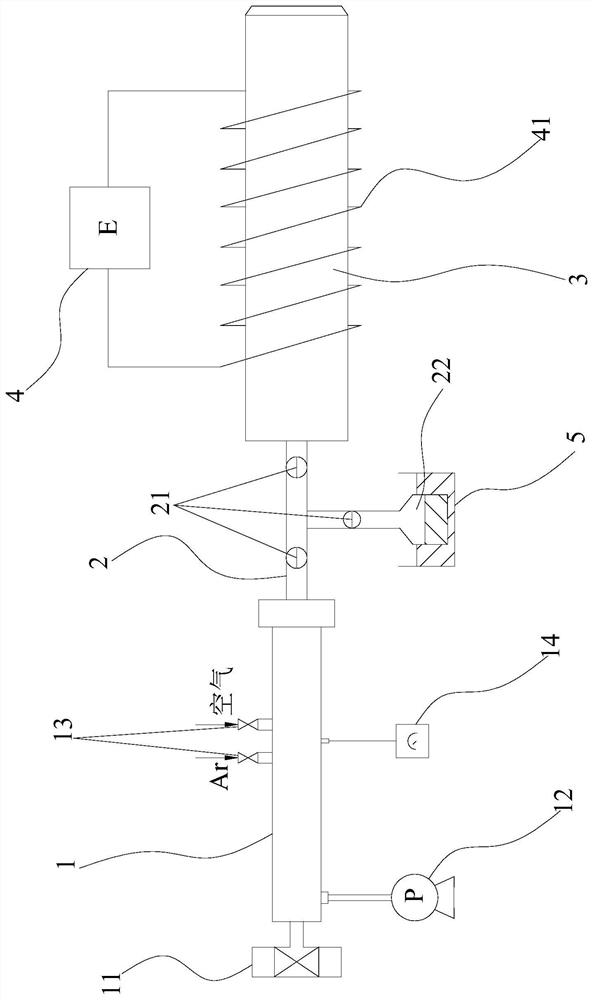

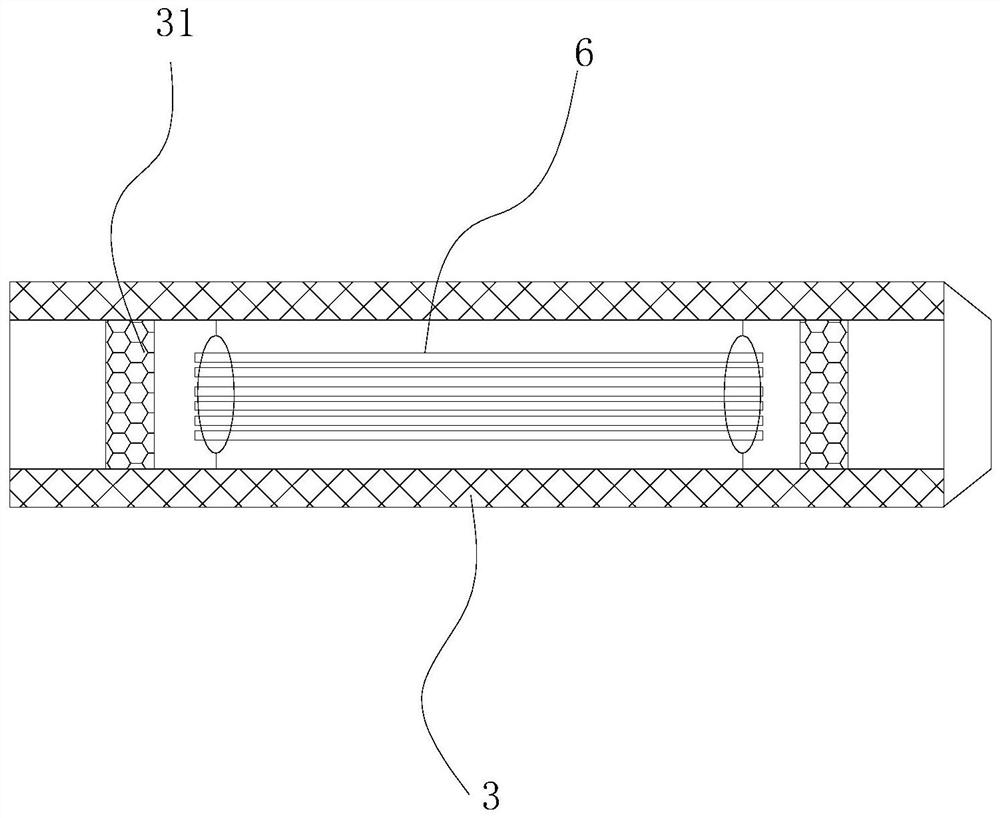

Graphite crucible aluminum evaporation process for semiconductor production

PendingCN114481031AGood adhesionImprove uniformityVacuum evaporation coatingSputtering coatingUltrasonic technologySilicon chip

The invention discloses a graphite crucible aluminum evaporation process for semiconductor production, and relates to the technical field of semiconductor production. The method comprises the following steps: preheating a silicon wafer and a graphite crucible to 45-55 DEG C; placing the preheated silicon wafer on an objective table of a graphite crucible, and then vacuumizing the graphite crucible; after vacuumizing is completed, a high-purity aluminum steam source is ignited, aluminum steam is generated, an ultrasonic generator is started, ultrasonic treatment is conducted on the aluminum steam under the action of an ultrasonic external field, and the treated aluminum steam diffuses towards the silicon wafer and falls onto the silicon wafer to form an inner-layer aluminum film. According to the method, the coating film is divided into the inner-layer coating film and the outer-layer coating film, so that the adhesiveness of the coating film is better, the ultrasonic technology is adopted for assisting the coating film, the dispersity is higher, higher uniformity, thinner coating thickness and higher precision can be achieved, and the problems that an existing semiconductor aluminum evaporation process is low in aluminum film thickness quality control capability and poor in quality control capability are solved. The uniformity of the aluminum film is not ideal, and the product quality is low.

Owner:丹东安顺微电子有限公司

A kind of graphene composite metal film and preparation method thereof

ActiveCN106374111BCoating thickness is thinLow coating resistanceElectrode carriers/collectorsConductive coatingGraphite

The present invention relates to the field of graphene metal composite materials, and discloses a graphene metal composite film and a preparation method thereof. The method comprises: (1) mixing graphite and a liquid-phase medium, and mechanically stripping to obtain a mixture containing graphite and graphene; (2) carrying out centrifugal separation on the mixture containing graphite and graphene, and collecting the graphene-containing supernatant; and (3) optionally drying the graphene-containing supernatant, mixing with a binder to obtain a mixed solution containing the graphene and the binder, and coating the mixed solution onto a metal substrate. According to the present invention, the graphene metal composite film prepared by using the method has advantages of thin coating thickness and low coating resistance, wherein the thickness of the electric conduction coating can be as thin as 0.2 [mu]m and the coating resistance can be as low as 2.2*10<-6>omega.cm through the following embodiment; and the method is simple and easy to perform, has the low cost, and is suitable for popularization and application.

Owner:北京中科云腾科技有限公司

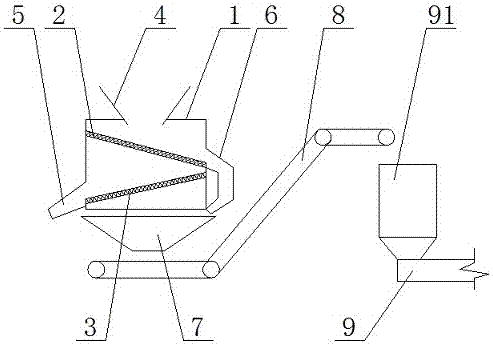

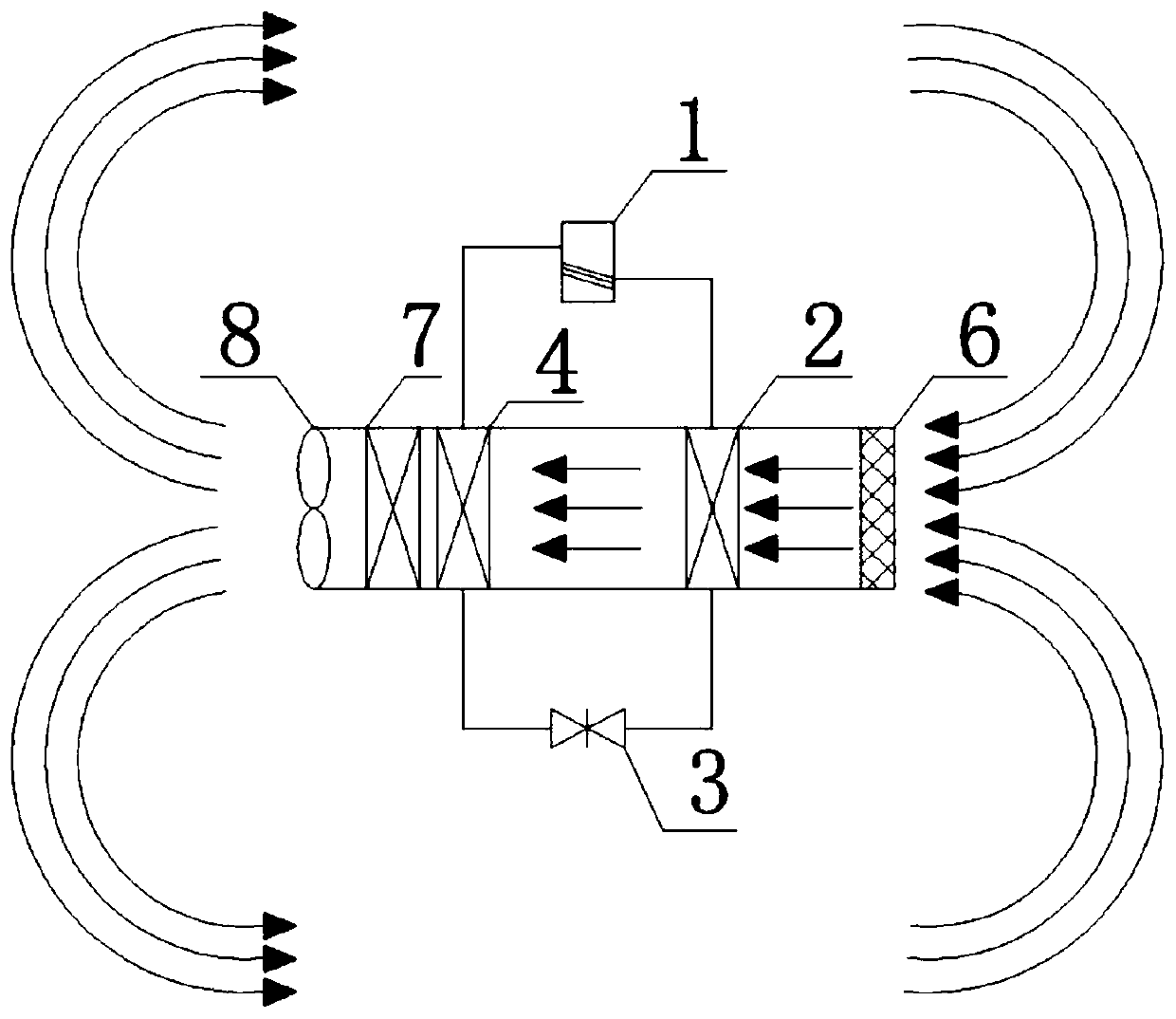

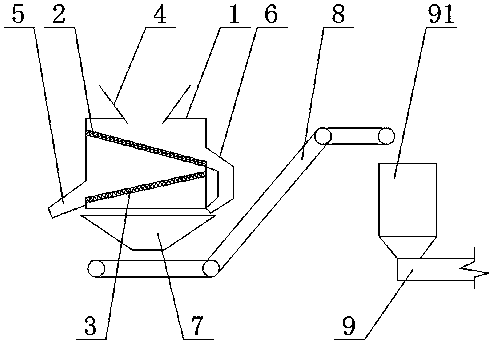

A coating method for hollow fiber membranes used for oil and gas recovery

ActiveCN108097055BCoating thickness is thinHigh oil and gas recovery efficiencySemi-permeable membranesPhysical chemistryPolyvinylidene difluoride

The invention relates to the technical field of separation membranes, in particular to a coating method for hollow fiber membranes used for oil and gas recovery. The hollow fiber membrane base membrane is placed in a coating device with a mixed atmosphere of argon and air, and the low-temperature plasma is used for glow discharge. Polymerization The monomer solution is plated on the hollow fiber membrane base membrane. The hollow fiber membrane coating method of the present invention uses glow discharge low-temperature plasma polymerization to coat the polyvinylidene fluoride hollow fiber membrane base membrane, the method is convenient, the operation is simple, the coating thickness of the obtained hollow fiber membrane is relatively thin, and the oil gas recovery efficiency High, can reach more than 97%.

Owner:ZHEJIANG OCEAN UNIV

A kind of automobile exhaust pipe and muffler powder coating and preparation method thereof

ActiveCN107459926BImprove high temperature resistanceGuaranteed high temperature performancePowdery paintsMufflerExhaust pipe

The invention discloses a powder coating for an automobile exhaust pipe and a silencer and a preparation method thereof. The adopted materials in parts by weight are as follows: 50-60 parts of methyl phenyl silicone resin, 20-30 parts of unleaded low-temperature fused glass powder, 15-20 parts of polyimide powder, 3-5 parts of a flatting agent, 2-3 parts of a silane coupling agent KH550, 1-2 parts of a titanate coupling agent, 15-20 parts of inorganic ceramic pigment, 1 part of benzoin and 0.8 part of white carbon black. The prepared powder coating is uniform and bright in color, has a better decorating effect, has an excellent high temperature resisting property and can meet the requirement on the surface coating of the automobile exhaust pipe and the silencer.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

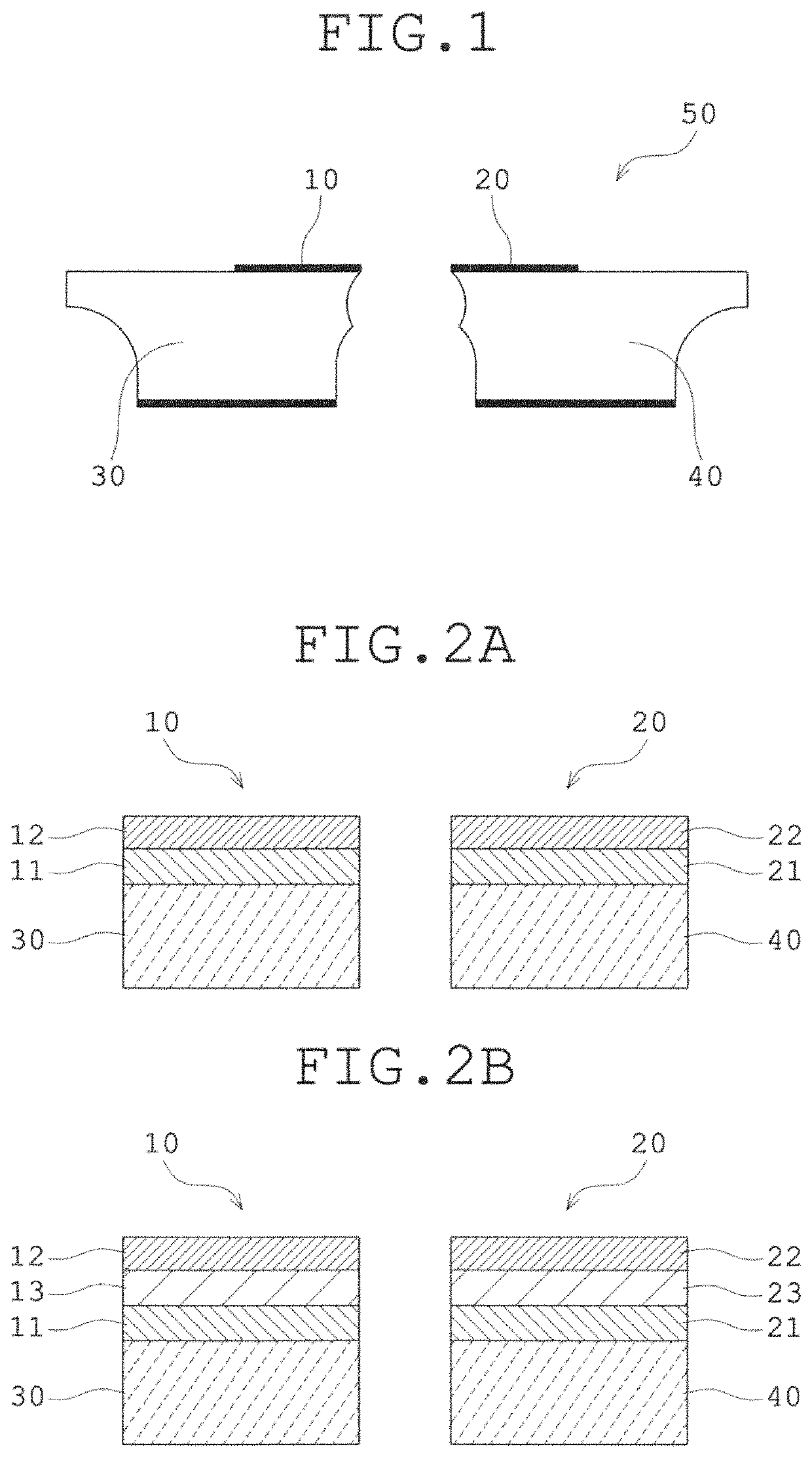

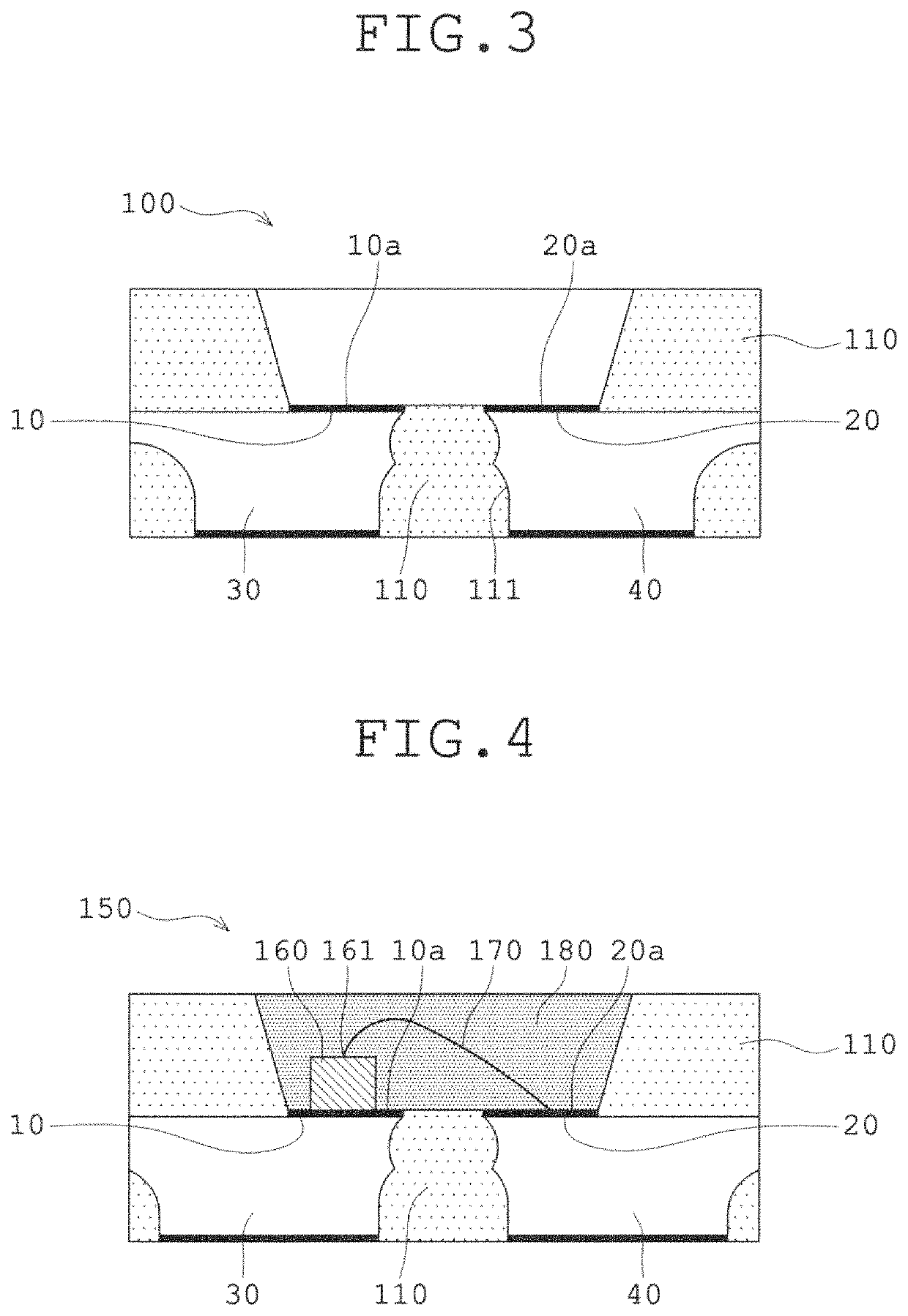

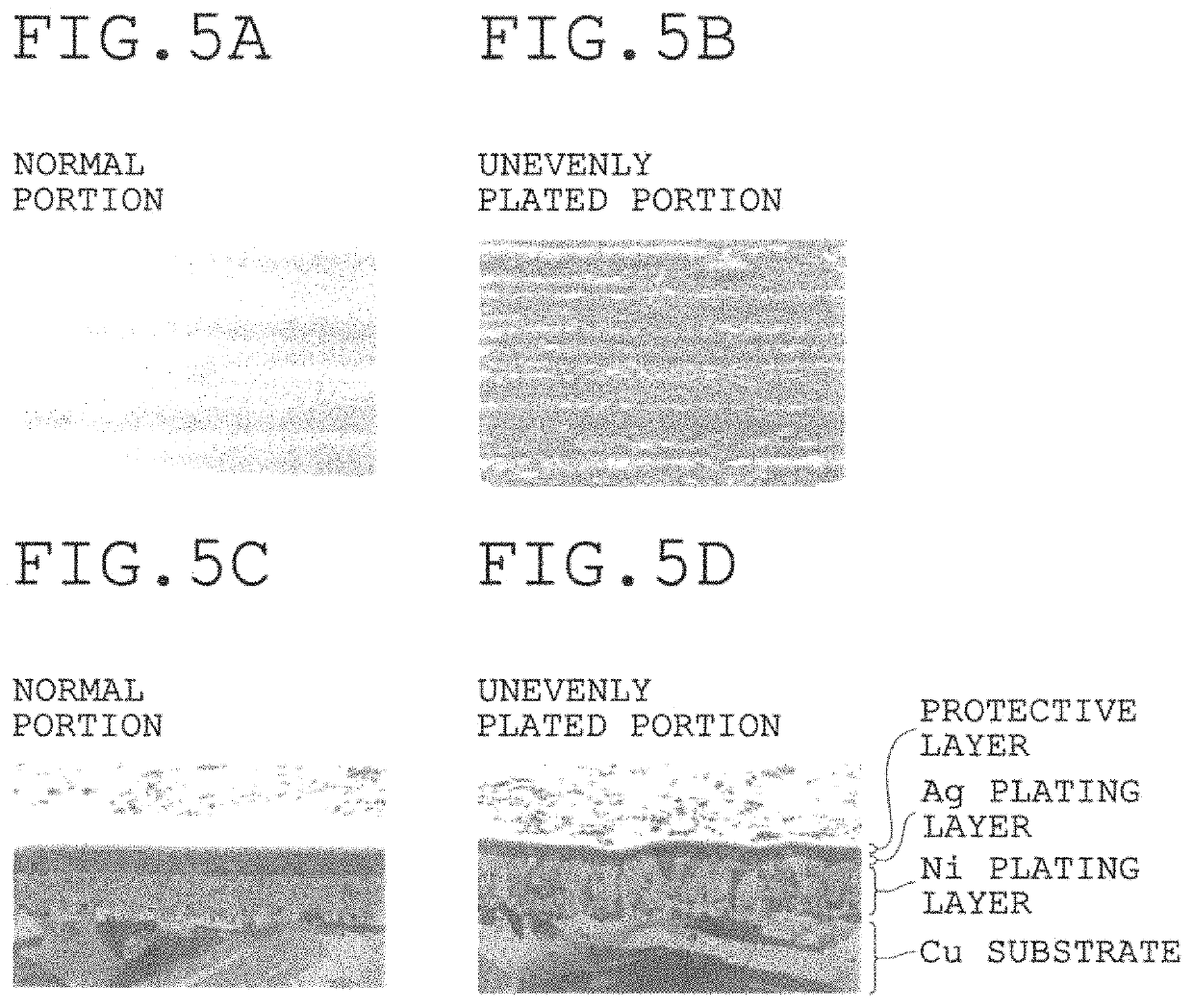

Lead frame, resin-equipped lead frame, optical semiconductor device, and method for manufacturing lead frame

ActiveUS10886206B2Prevent appearanceLow costSemiconductor/solid-state device detailsSolid-state devicesDevice materialLead frame

A lead frame for use in an optical semiconductor device has a die pad portion on which an optical semiconductor element is mounted and a lead portion electrically connectable with the optical semiconductor element. A surface on a lead frame substrate forming a part of or an entirety of the die pad portion and the lead portion is laminated with a glossy Ni plating layer having a gloss of 2.0-3.5 and a noble metal plating layer including an Ag plating layer, as an uppermost layer, having a gloss of 1.6 or more.

Owner:CHANG WAH TECH

Method for performing anticorrosive hydrophobic modification on surface of aluminum alloy

InactiveCN101885934BCoating thickness is thinImprove adhesionAnti-corrosive paintsMetallic material coating processesSpray coatingBiological activation

Owner:BEIJING UNIV OF CHEM TECH

Method for preparation of bioactive glass coatings by liquid precursor thermal spray

InactiveUS8852667B2Coating thickness is thinLow production efficiencyMolten spray coatingPharmaceutical containersChemical compositionThermal spraying

The present invention belongs to the field of biomedical material, and is particularly related to a method of preparing bioactive glass coatings by liquid precursor thermal spray. The objective of the present invention is to overcome the shortcomings of the air plasma spraying where the powder feedstock preparation is complicated and time-consuming, and sol-gel or other wet chemistry method where the synthesized coating generally has thin coating thickness and with low production efficiency. Therefore, a new method is provided for preparation of bioactive glass coatings. In this method, organic and inorganic raw materials were first weighed in accordance with the chemical composition of bioactive glasses, and sol or suspension was prepared; then the sol or suspension was used as the feedstock for thermal spray, and was deposited on the biomedical materials substrate, at high temperature to form the bioactive glass coating. The invention possesses the following advantages: simple operation, less complicated procedures, synthesis with high efficiency, low production cost, suitable for industrial production, and so on. This method can be used to prepare bioactive glass coatings.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com