Hot-dipped aluminum-zinc alloy steel plate and preparation method thereof

An alloy steel plate and hot-dip aluminum technology, applied in the field of coating steel plate production, can solve the problems of poor yield strength and tensile strength, poor coating quality, and high production cost, and achieve thin coating thickness, simple composition design, and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the above-mentioned hot-dip aluminum-zinc alloy steel sheet, comprising the following steps:

[0038] Smelting-hot rolling-cold rolling-cleaning-annealing-hot-dip galvalume-post-plating cooling-finishing-stretch leveling-surface treatment-oiling-coiling-finished products;

[0039] The heating temperature of the slab during the hot rolling is 1230-1260°C, the time in the furnace is 180min-300min, the finishing temperature of the hot rolling is 840-900°C; the annealing temperature is 720-780°C, and the annealing time is 45-85s ; The coiling temperature is 580-640°C.

[0040] Among them, hot-rolling temperature and time, annealing temperature and time, and coiling temperature all have a great influence on the strength and elongation of the final hot-dip aluminum-zinc alloy steel sheet. Maintaining a suitable slab heating temperature and furnace time during hot rolling can ensure that alloy elements such as Ti are ...

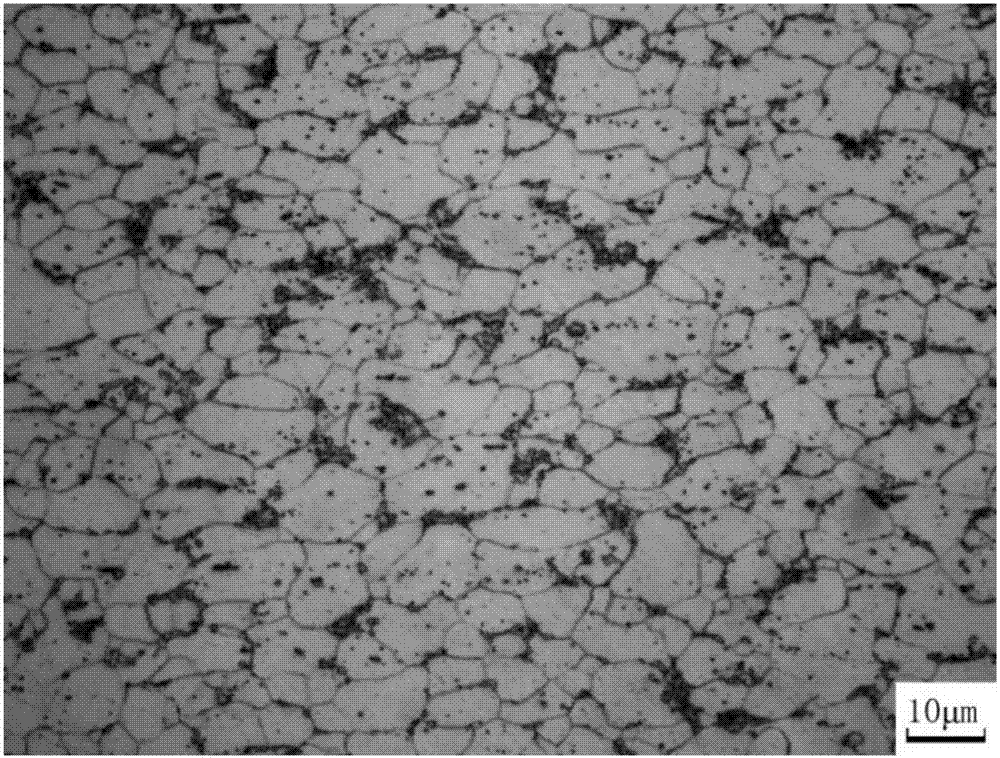

Embodiment 1

[0072] Embodiment 1 prepares hot-dip aluminum-zinc alloy steel plate with the method of the present invention

[0073] The slab with the chemical composition shown in Table 6 is used as the raw material, heated in a heating furnace at 1240°C, the time in the furnace is 253min, rough rolling for 5 passes, the temperature at the entrance of the finish rolling is 1050°C, and thermal connection through 6 stands Rolling, the final rolling temperature is 871°C, coiled by cooling to 618°C in the front section, and the cooling reduction rate is 72%. Degrease cleaning, annealing, and galvanizing are performed on the continuous hot-dip galvanizing line at a speed of 100m / min. Among them, the free alkalinity of the alkali washing tank is controlled at 75Pt, and the temperature is 80°C; the free alkalinity of the electrolytic cleaning solution is controlled at 75Pt, the temperature is 85°C, and the electrolytic current is controlled at 7000A. The annealing soaking temperature is 754°C, an...

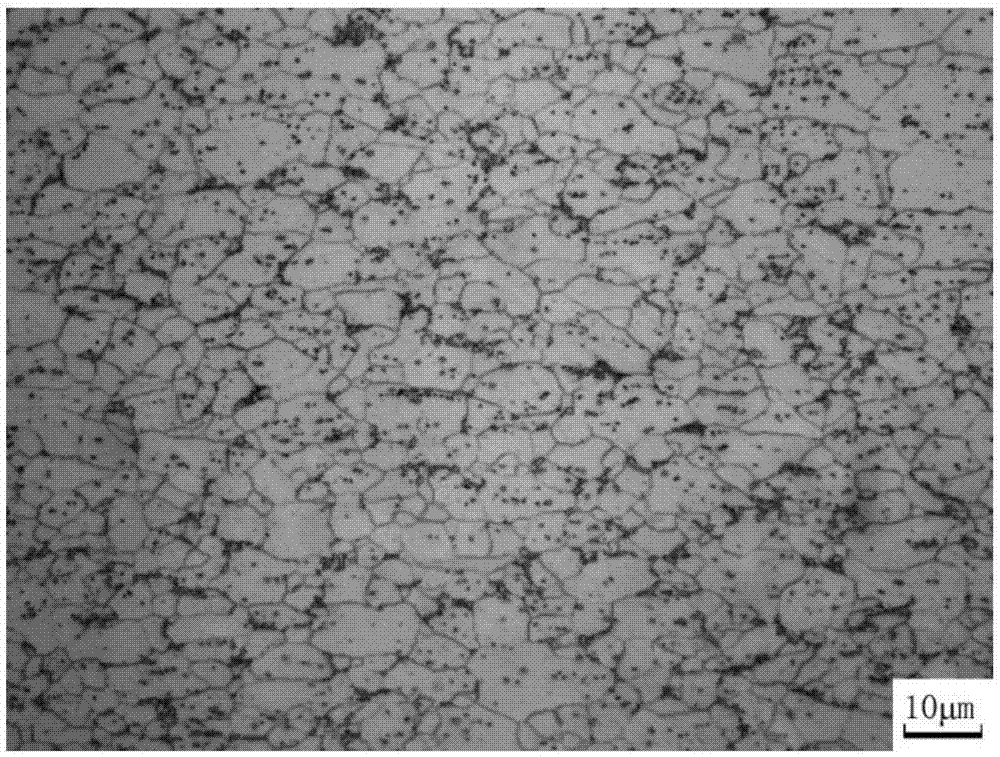

Embodiment 2

[0074] Embodiment 2 prepares hot-dip aluminum-zinc alloy steel plate with the method of the present invention

[0075] A hot-dip aluminum-zinc alloy steel sheet was prepared according to the method in Example 1. The control of different process parameters is shown in Table 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com