A kind of automobile exhaust pipe and muffler powder coating and preparation method thereof

A technology for powder coatings and automobile exhaust, applied in powder coatings, coatings and other directions, can solve the problems of poor decorative performance of surface texture coatings, large particle size gaps, uneven coatings, etc., to achieve excellent decorative effects and color. Brilliant, high-quality finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

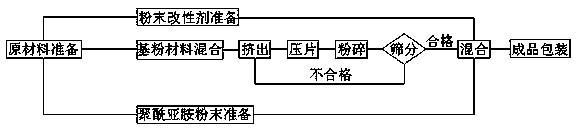

Method used

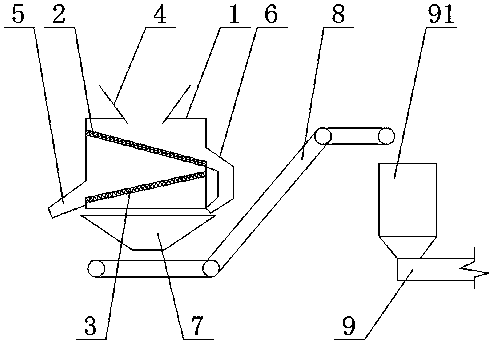

Image

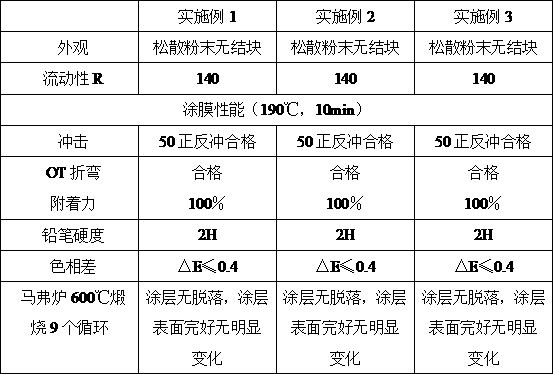

Examples

Embodiment 1

[0047] Produce a kind of automobile exhaust pipe and muffler powder coating, its specific steps are as follows:

[0048] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0049] Methylphenyl silicone resin 50kg;

[0050] Lead-free low temperature molten glass powder (300 mesh) 20kg;

[0051] Polyimide powder (300 mesh) 15kg;

[0052] Leveling agent 3kg;

[0053] Silane coupling agent KH550 2kg;

[0054] Titanate coupling agent 1kg;

[0055] Inorganic ceramic pigment 15kg;

[0056] Benzoin 1kg;

[0057] White carbon black 0.8kg;

[0058] b. Add the methyl phenyl silicone resin prepared in step a, lead-free low temperature molten glass powder, leveling agent, silane coupling agent KH550, titanate coupling agent, inorganic ceramic pigment and benzoin into the mixer Misai Carat cylinder, pre-mixing, mixing time: low speed 2 minutes, high speed 6 minutes; low speed speed is 100r / min, high speed speed is 280r / min;

[0059] c. Put the homog...

Embodiment 2

[0065] Produce a kind of automobile exhaust pipe and muffler powder coating, its specific steps are as follows:

[0066] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0067] Methylphenyl silicone resin 55.3kg;

[0068] Lead-free low temperature molten glass powder (300) 22.6kg;

[0069] Polyimide powder (300) 17.8kg;

[0070] Leveling agent 4kg;

[0071] Silane coupling agent KH550 2.6kg;

[0072] Titanate coupling agent 1.5kg;

[0073] Inorganic ceramic pigment 18.4kg;

[0074] Benzoin 1kg;

[0075] White carbon black 0.8kg;

[0076] b. Add the methyl phenyl silicone resin prepared in step a, lead-free low temperature molten glass powder, leveling agent, silane coupling agent KH550, titanate coupling agent, inorganic ceramic pigment and benzoin into the mixer Misai Carat cylinder, pre-mixing, mixing time: low speed 2 minutes, high speed 6 minutes; low speed speed is 100r / min, high speed speed is 280r / min;

[0077] c. Put the h...

Embodiment 3

[0083] Produce a kind of automobile exhaust pipe and muffler powder coating, its specific steps are as follows:

[0084] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0085] Methylphenyl silicone resin 60kg;

[0086] Lead-free low-temperature molten glass powder (300 mesh) 30kg;

[0087] Polyimide powder (300 mesh) 20kg;

[0088] Leveling agent 5kg;

[0089] Silane coupling agent KH550 3kg;

[0090] Titanate coupling agent 2kg;

[0091] Inorganic ceramic pigment 20kg;

[0092] Benzoin 1kg;

[0093] White carbon black 0.8kg;

[0094] b. Add the methyl phenyl silicone resin prepared in step a, lead-free low temperature molten glass powder, leveling agent, silane coupling agent KH550, titanate coupling agent, inorganic ceramic pigment and benzoin into the mixer Misai Carat cylinder, pre-mixing, mixing time: low speed 2 minutes, high speed 6 minutes; low speed speed is 100r / min, high speed speed is 280r / min;

[0095] c. Put the hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com