Patents

Literature

61results about How to "Solve the chalking problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

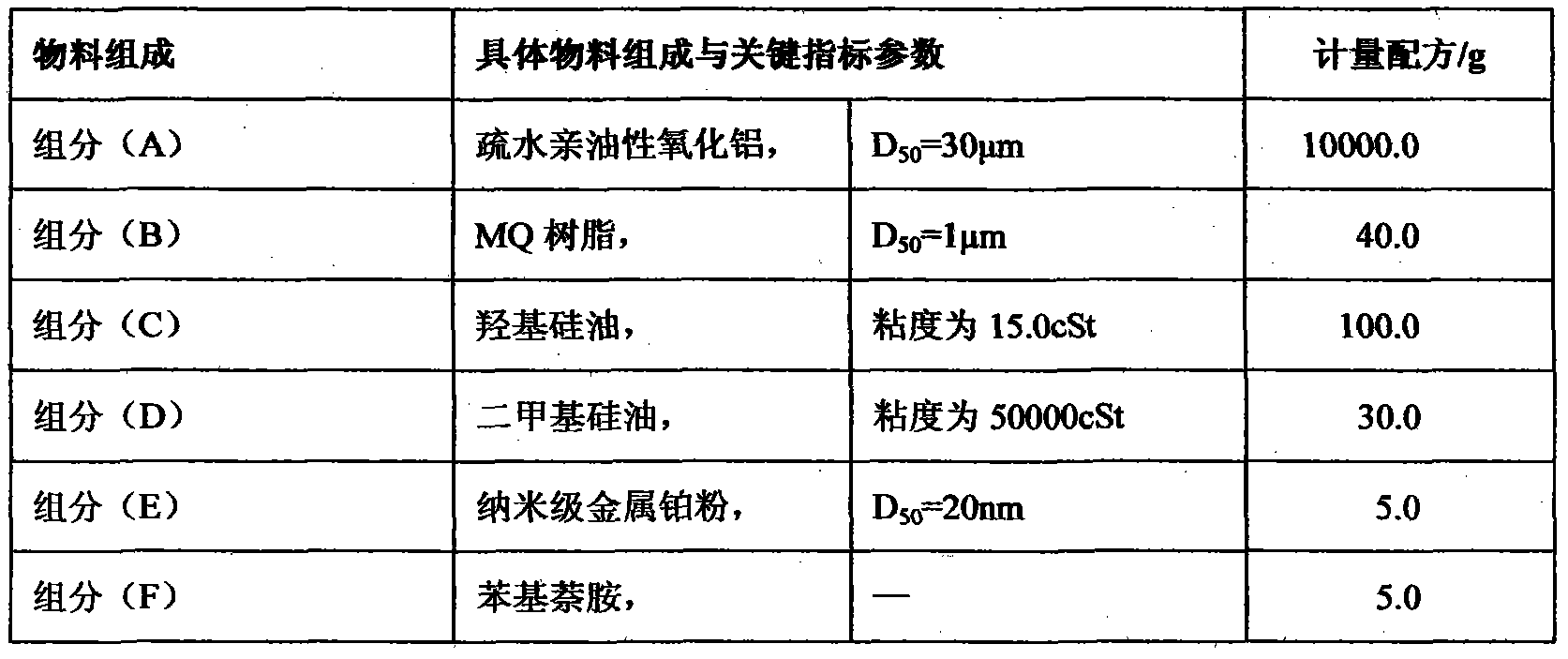

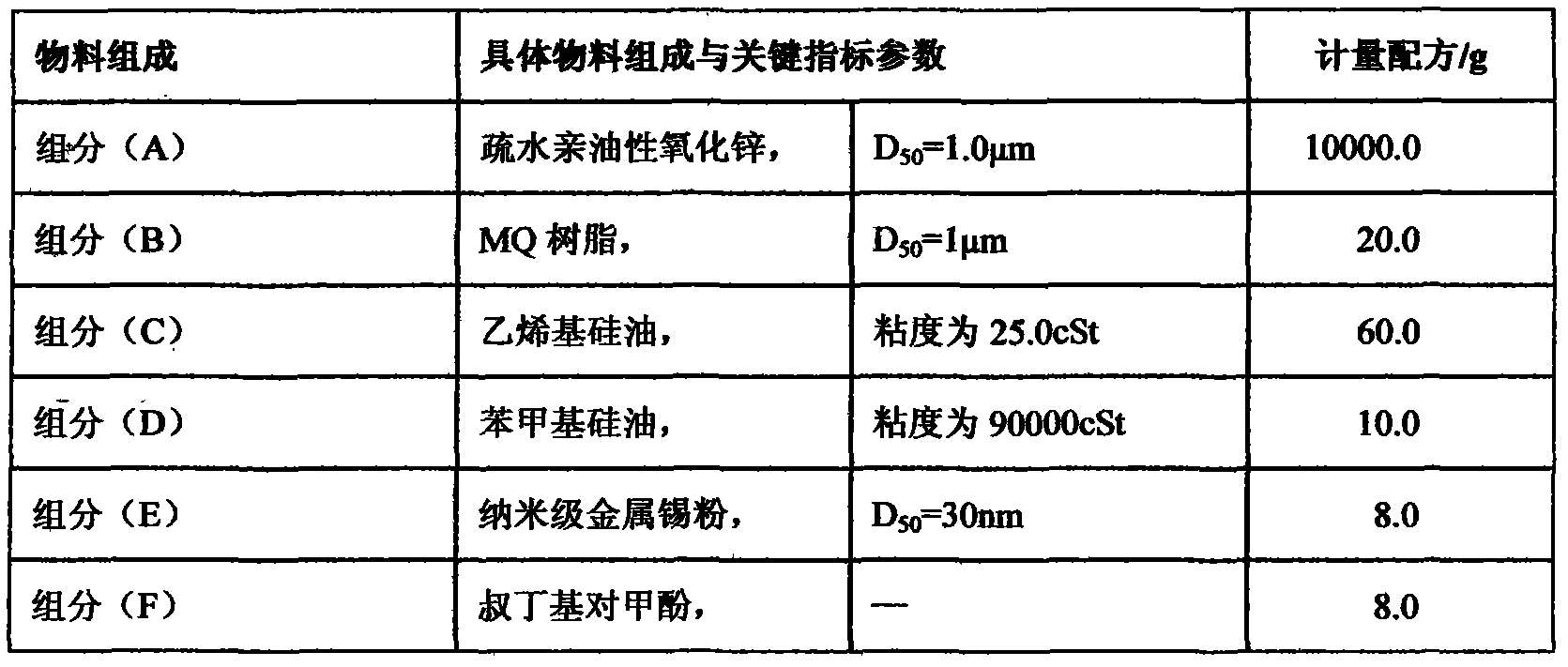

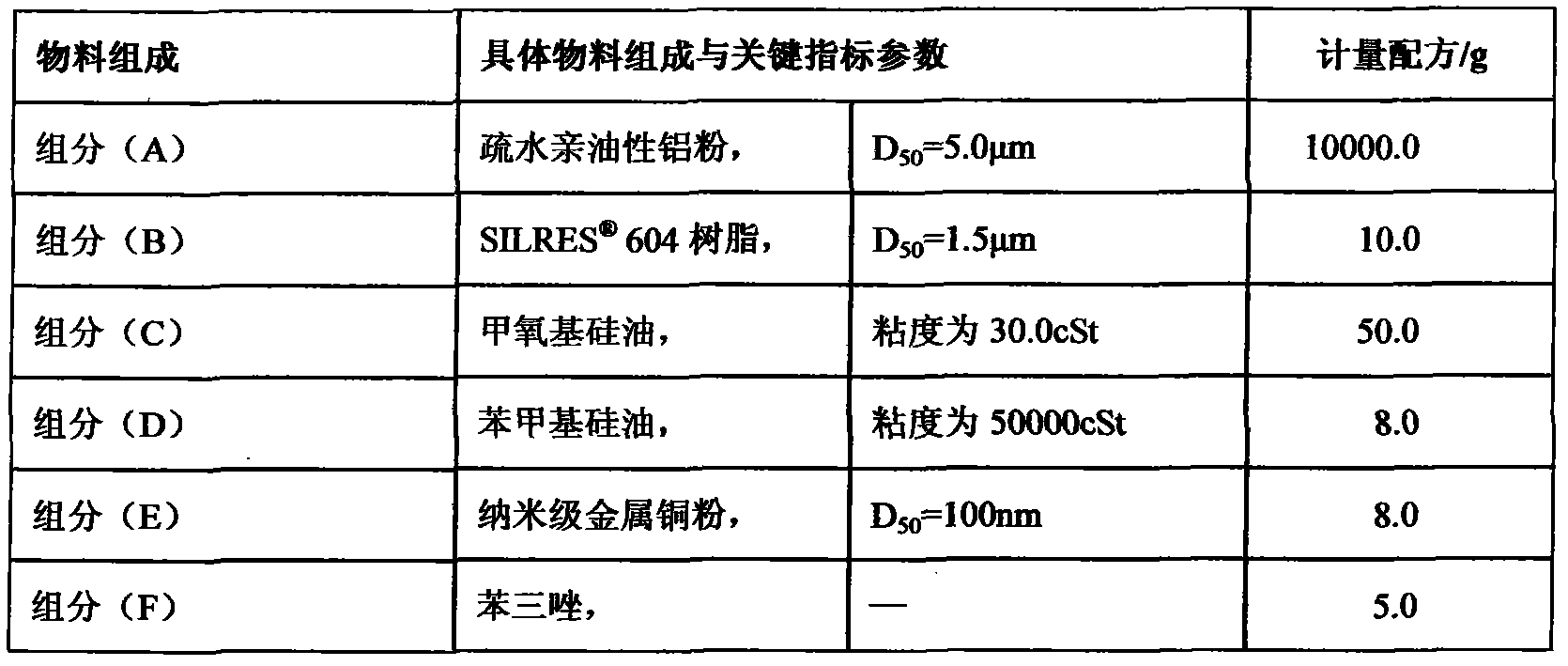

Thermal grease composition

ActiveCN102134474ASolve the chalking problemResolve fragmentationHeat-exchange elementsNano catalystThermal grease

The invention relates to the field of thermal interface materials, and more particularly, provides a thermal grease composition, which contains the following components: (A) 100.0 parts by weight of thermally conductive filler, (B) 0.1 to 8.0 parts by weight of active solid silicone resin, (C) 0.1 to 15.0 parts by weight of active silicone oil, (D) 0.1 to 9.0 parts by weight of macromolecular polysiloxane, (E) 0.1 to 3.0 parts by weight of nano catalyst, and (F) 0.1 to 3.0 parts by weight of additive. The thermal grease composition provided by the invention has good thermal conductivity and using weatherability, can effectively solve the technical difficulty that the thermal grease composition in the prior art is pulverized and crushed and the thermal conductivity is therefore reduced as the service time increases. The manufacturing process has simple, convenient and easy steps and the thermal grease composition is suitable for large-scale match production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

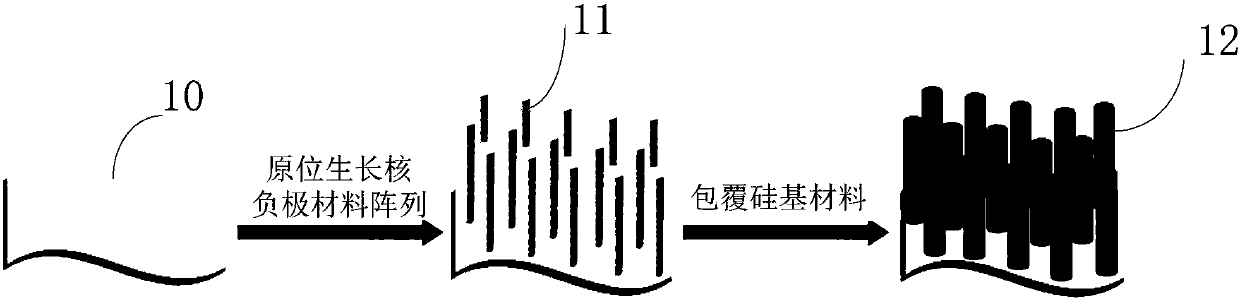

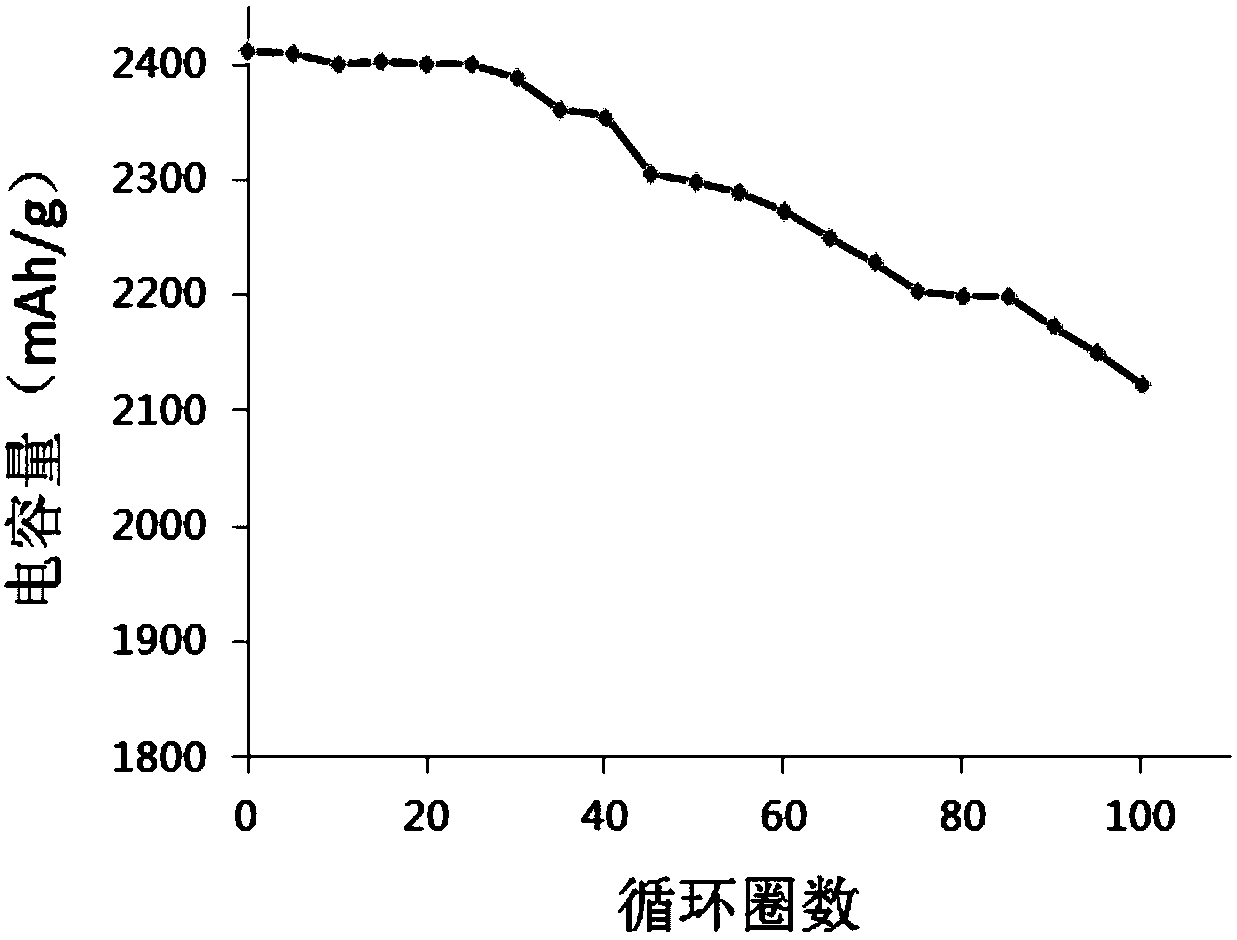

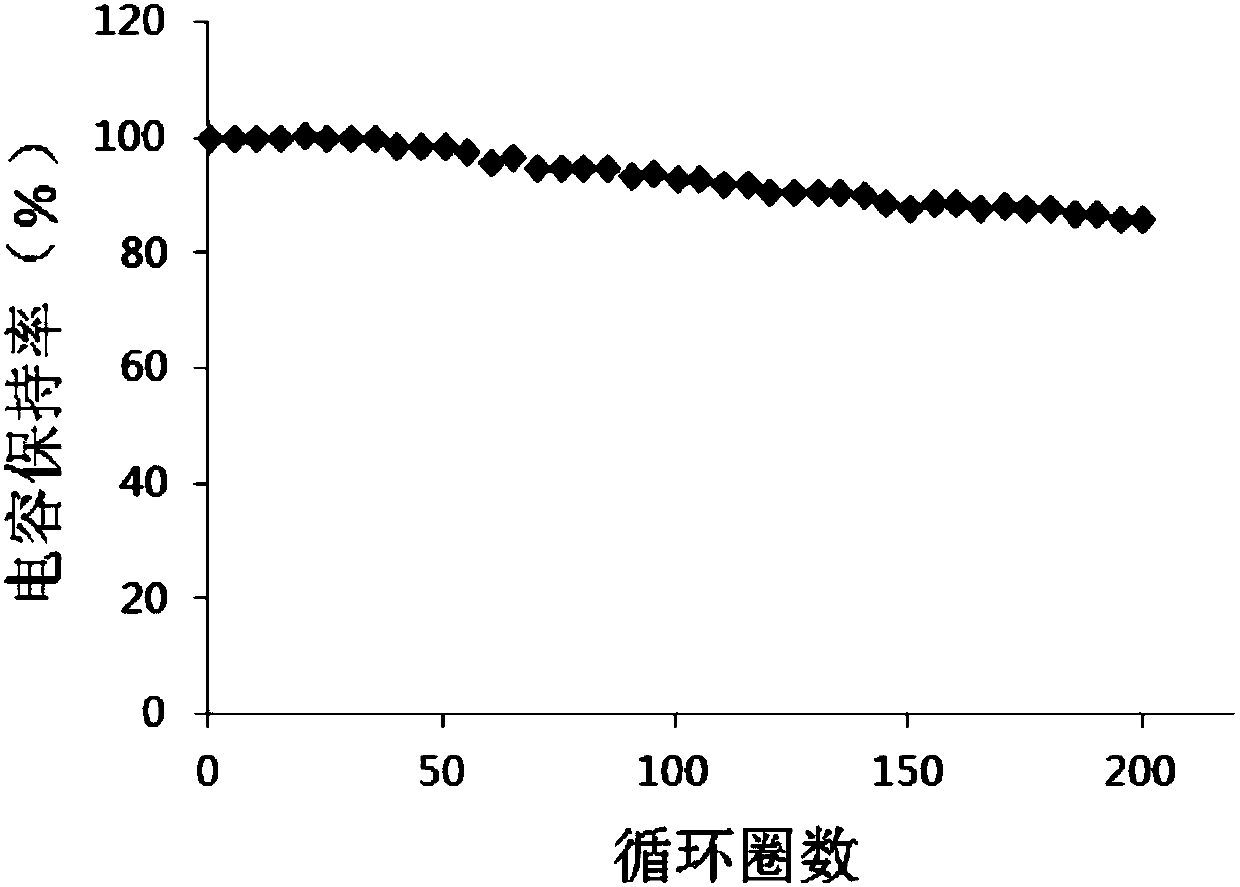

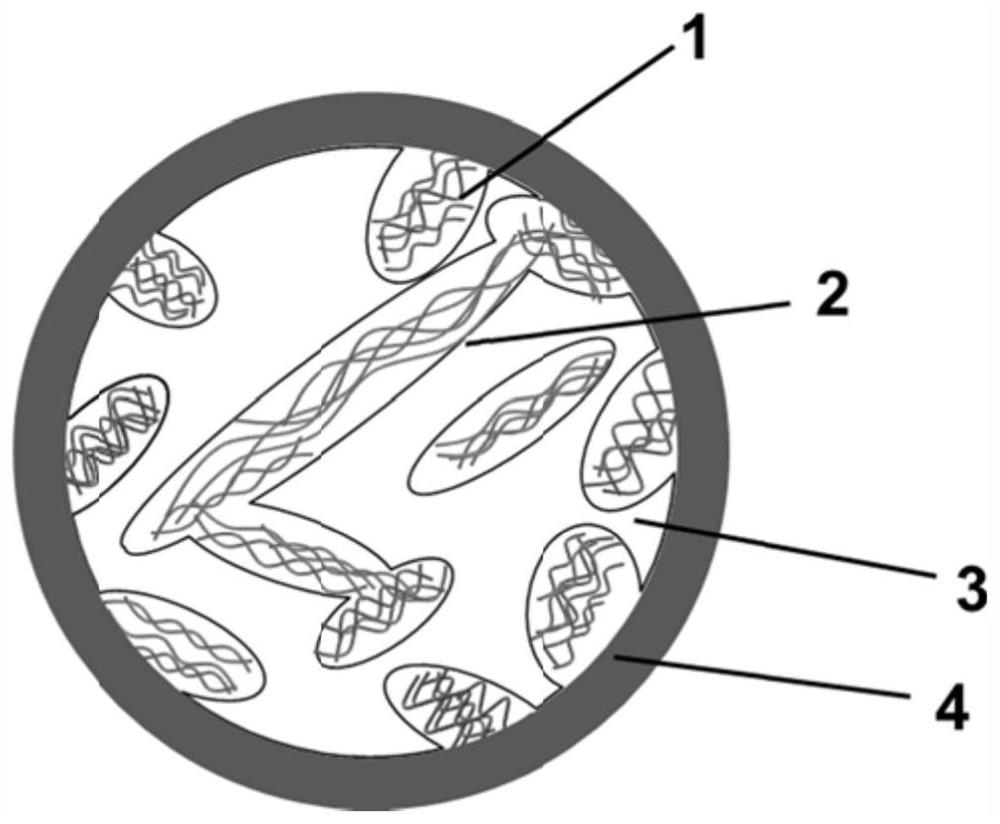

Silicon-based composite negative electrode plate, preparation method, and lithium ion secondary battery

InactiveCN107799723AIncrease capacityExtended service lifeCell electrodesSecondary cellsHigh ratePorous carbon

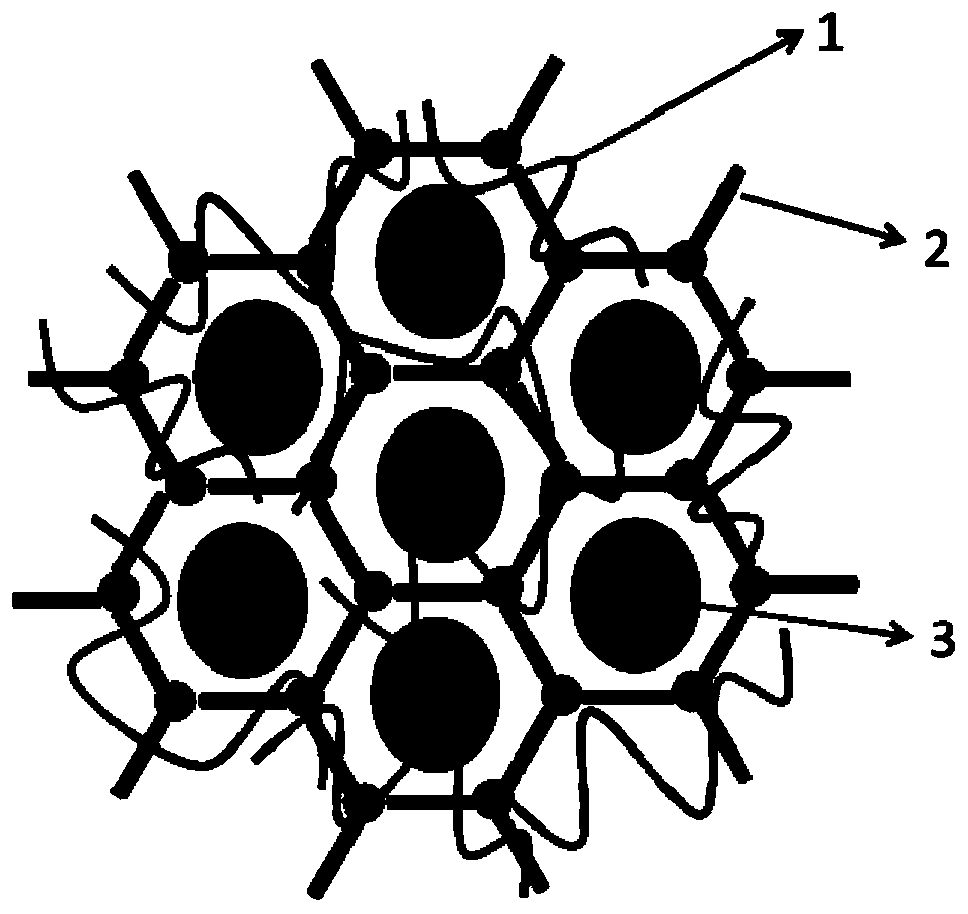

The invention provides a silicon-based composite negative electrode plate. The silicon-based composite negative electrode plate comprises a current collector, and a one-dimensional silicon-based shell-core composite structure array arranged on the current collector. According to the one-dimensional silicon-based shell-core composite structure array, a core negative electrode material formed on thecurrent collector via in-suit growth is taken as the core, and a silicon-based material is taken as a shell; the core negative electrode material is one or mixture of a plurality of ingredients selected from carbon nano tube, carbon nanofiber, porous carbon, graphene, lithium-intercalation metal and alloy, lithium titanate, a transition metal oxide, a bimetal oxide, a metal sulfide, a metal nitride, and a metal phosphide; and the core negative electrode material is arranged on the current collector in the manner of a one-dimensional vertical structure array. The silicon-based composite negative electrode plate possesses high-rate performance and high cycling stability, is capable of improving problems such as the low-rate performance of silicone and pulverization and polarization caused by swelling, increasing electrode capacity, and prolonging cycle life. The invention also provides a preparation method of the silicon-based composite negative electrode plate, and a lithium ion secondary battery containing the silicon-based composite negative electrode plate.

Owner:HUAWEI TECH CO LTD

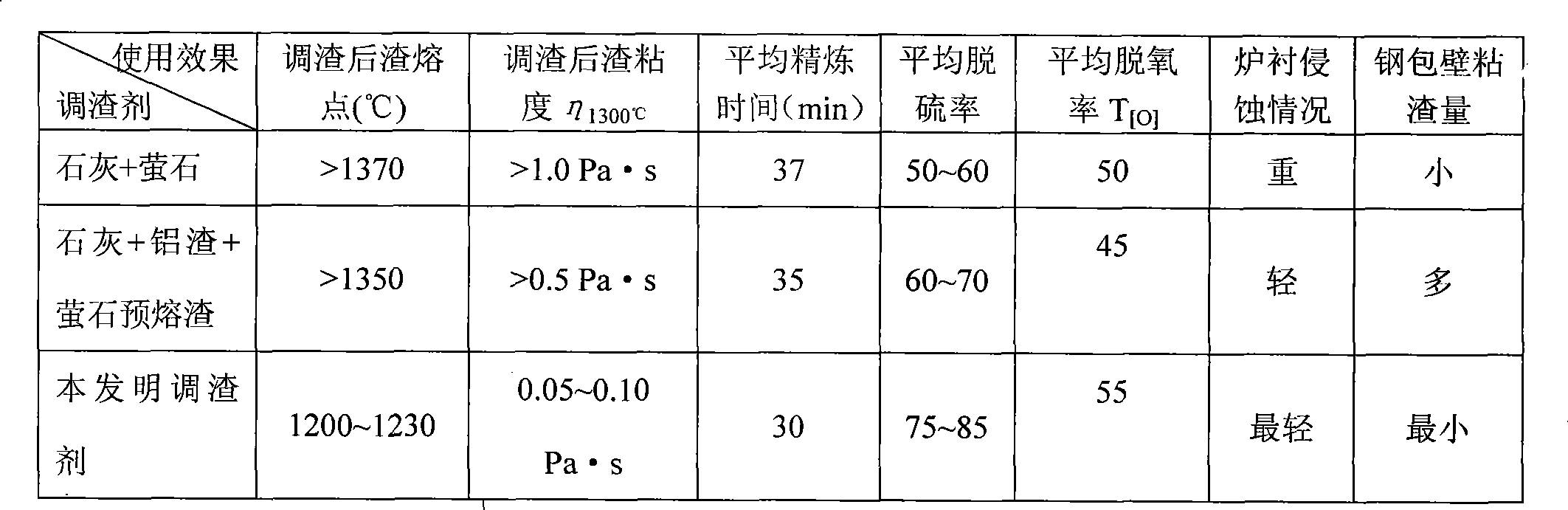

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

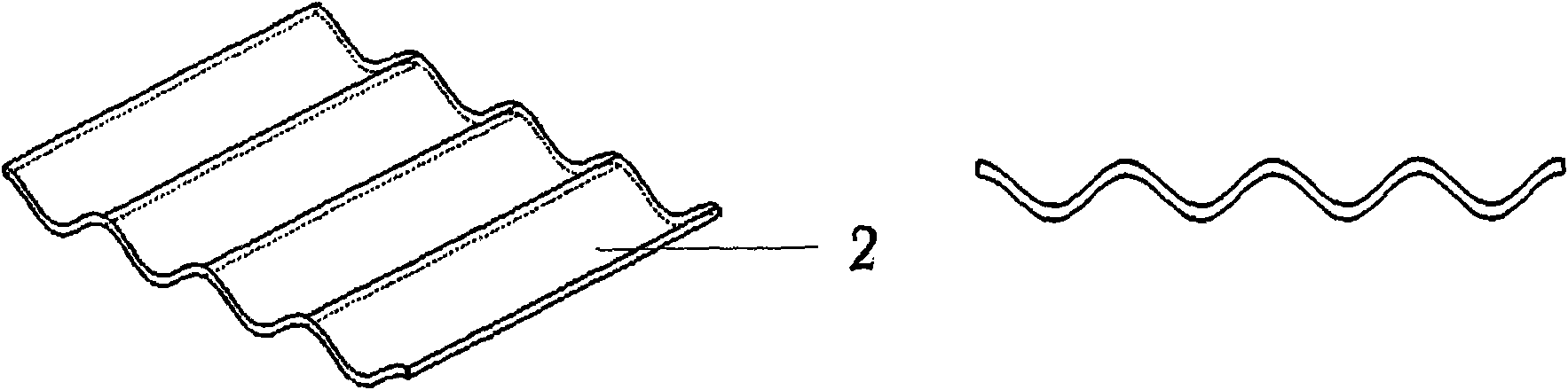

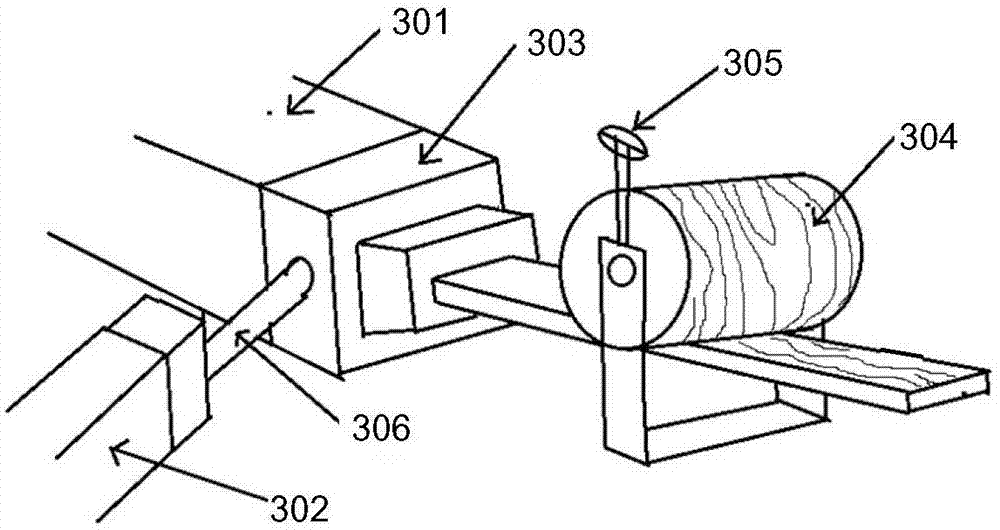

Magnetic refrigeration working medium bed and preparation method

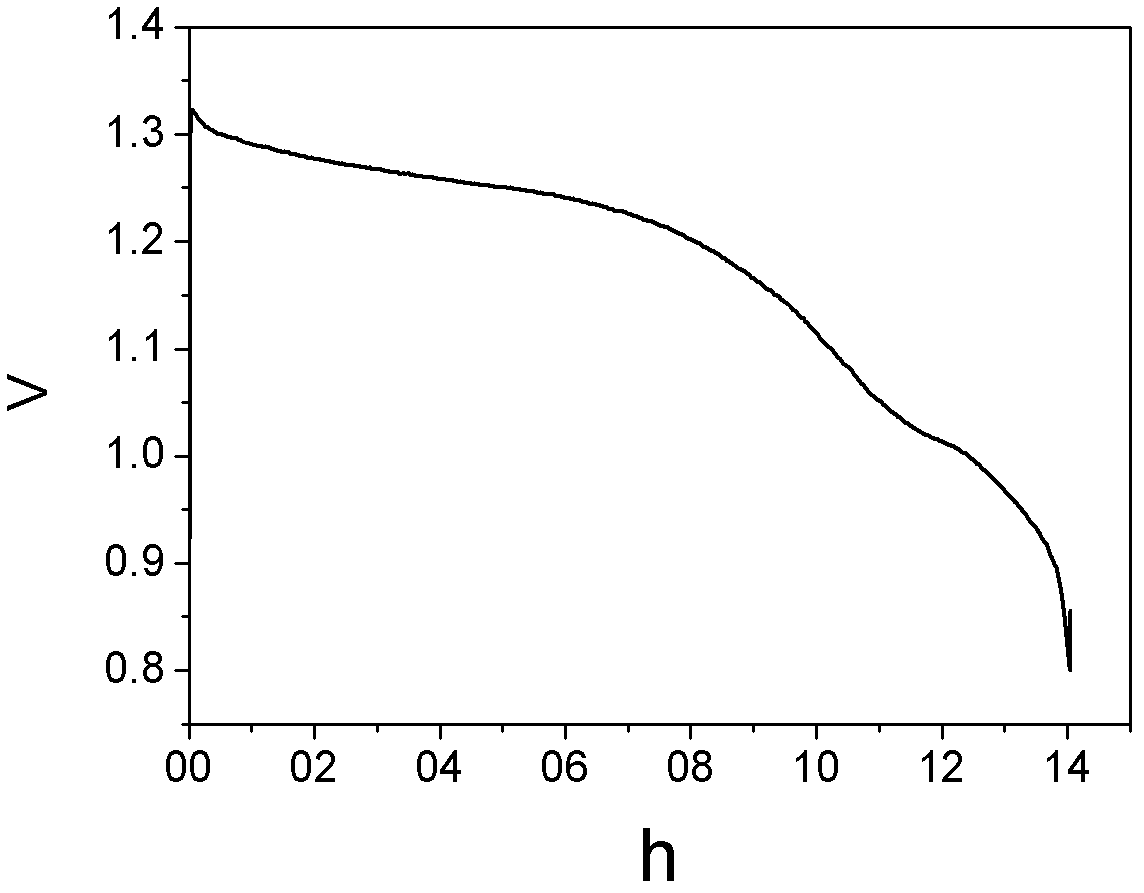

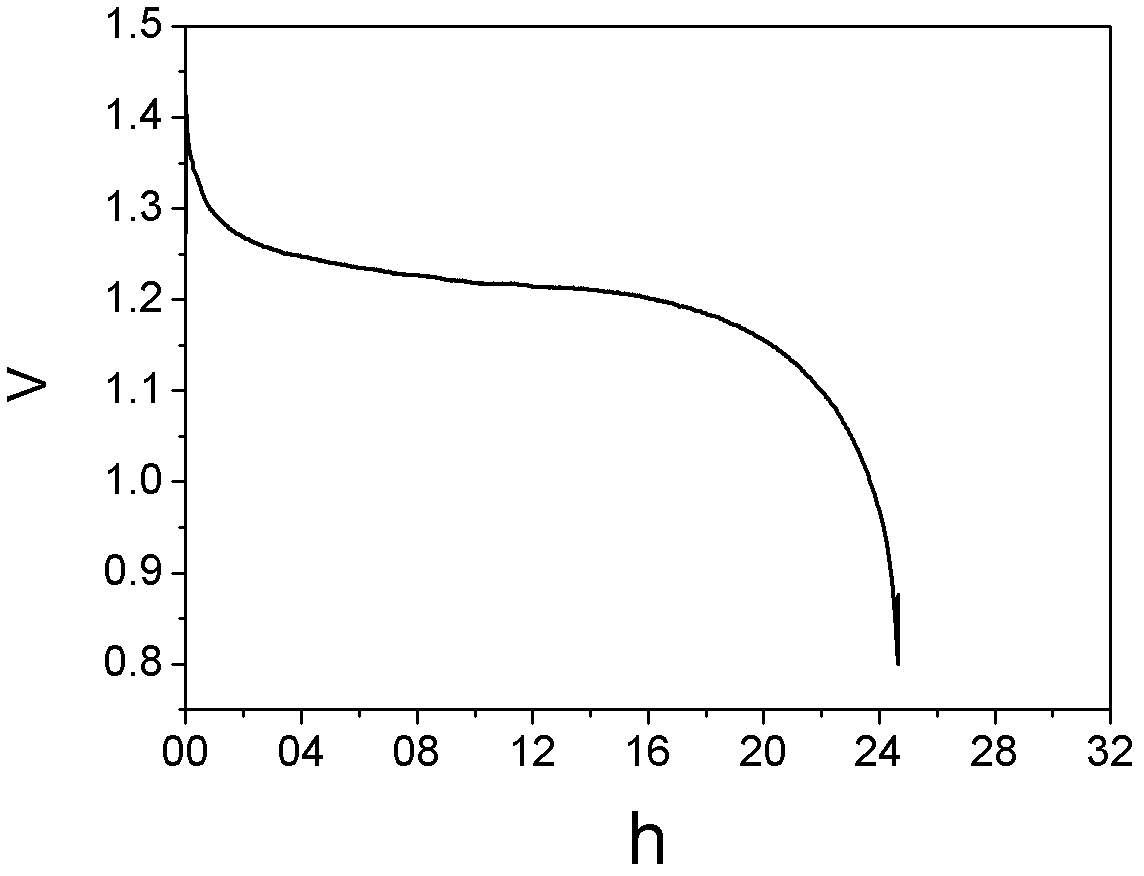

ActiveCN102466364AImprove thermal efficiencySolve the chalking problemEnergy efficient heating/coolingMachines using electric/magnetic effectsLower limitWorking temperature

The invention discloses a magnetic refrigeration working medium bed, which is a cylindrical object comprising n magnetic refrigeration working medium bed assemblies, wherein n is 1-1000. The n magnetic refrigeration working medium bed assemblies are obtained by being arranged from high to low according to the Curie temperature or the phase-transition temperature of chosen magnetic refrigeration material; and each magnetic refrigeration working medium assembly is a flat sheet shaped assembly, a straight-wave flake-like assembly or a zigzag wavy flake-like assembly, so that a runner with high specific surface area and low resistance is conveniently formed. The preparation method comprises the following steps: firstly, preparing magnetic refrigeration powder material of which the Curie temperature or the phase-transition temperature is between the upper limit and the lower limit of a magnetic refrigerator working temperature zone; then, respectively dipping the magnetic refrigeration powder material into a bonding colloid; respectively putting into a die, and pressurizing to obtain flake-like magnetic refrigeration working medium bed assemblies; and arranging the obtained assembliesinto the cylindrical magnetic refrigeration working medium bed from high to low according to the Curie temperature point or the equivalent Curie temperature point of the chosen magnetic refrigeration material. The magnetic refrigeration working medium bed has the advantages of big heat-transfer specific surface area, small working medium flowing resistance, high magnetic refrigerator thermotechnical efficiency and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

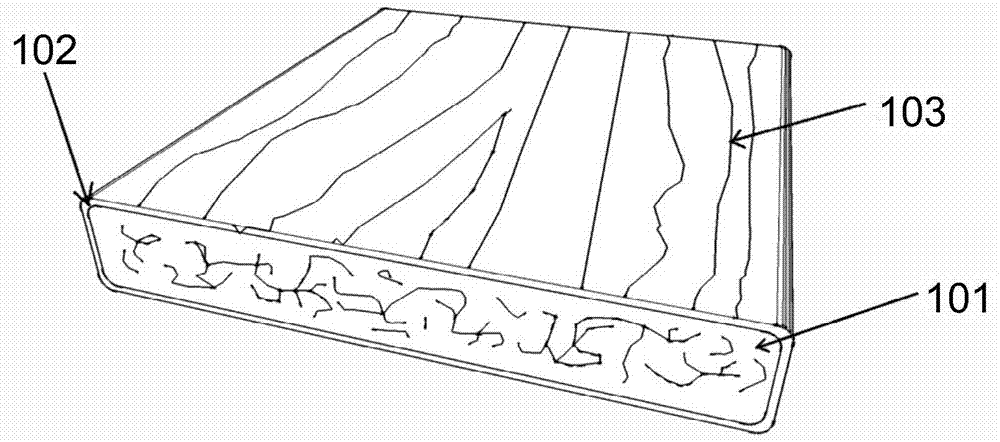

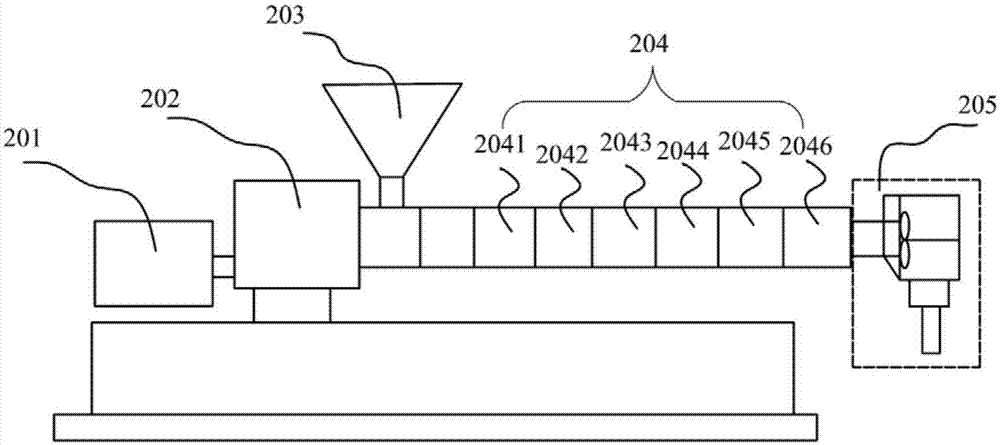

Wood-grain-imitated co-extruded plastic-wood profile and preparation method thereof

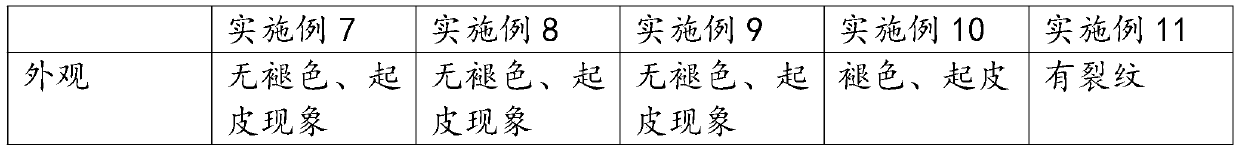

ActiveCN104723635AImprove anti-corrosion performanceImprove aging resistanceSynthetic resin layered productsSurface layerAging resistance

The invention provides a wood-grain-imitated co-extruded plastic-wood profile. The wood-grain-imitated co-extruded plastic-wood profile comprises a surface layer and a base material, wherein the adding amounts of plastic and a functional aid in the surface layer are more than the adding amounts of the plastic and the functional aid in the base material, so that the cost is favorable to be reduced; the surface layer is subjected to color adjustment by virtue of a main color and a secondary color (a third color can be increased according to requirements), so that the effects of the color shade and the layer variability of the surface layer can be well achieved. The invention further provides a preparation method of the wood-grain-imitated co-extruded plastic-wood profile. The preparation method comprises the processes of granulation, synchronous extrusion and surface treatment. According to the preparation method, surface layer particles including main color particles and secondary color particles are respectively granulated and are uniformly mixed for co-extruding the surface layer, and the surface layer is subjected to surface treatment in a 'hot plate and cold roller' manner. The co-extruded plastic-wood profile prepared by virtue of the preparation method is low in cost, excellent in water resistance, corrosion resistance and aging resistance and durable, further has the grains, color gradation and texture of imitated and natural wood, so that the user experience is improved.

Owner:湖南格林美资源利用有限公司 +2

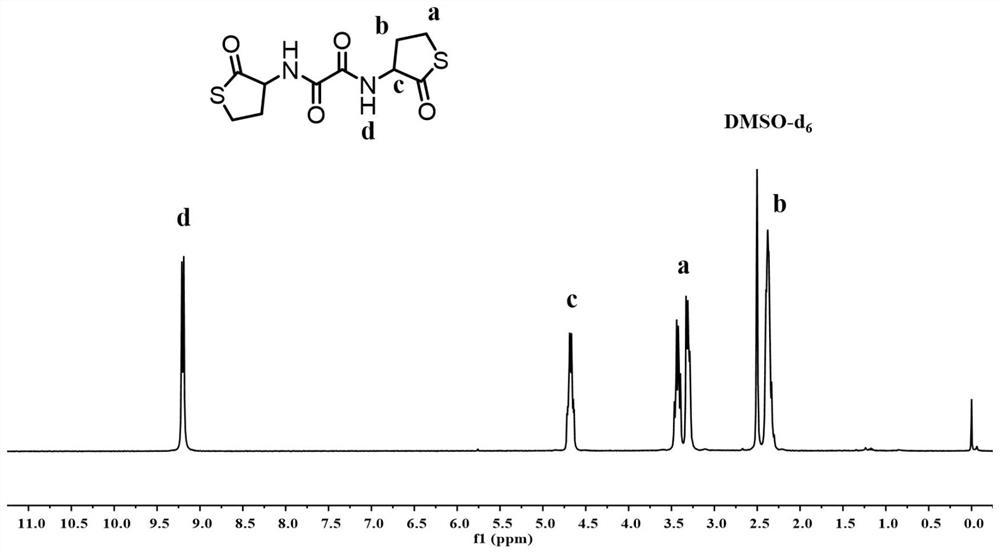

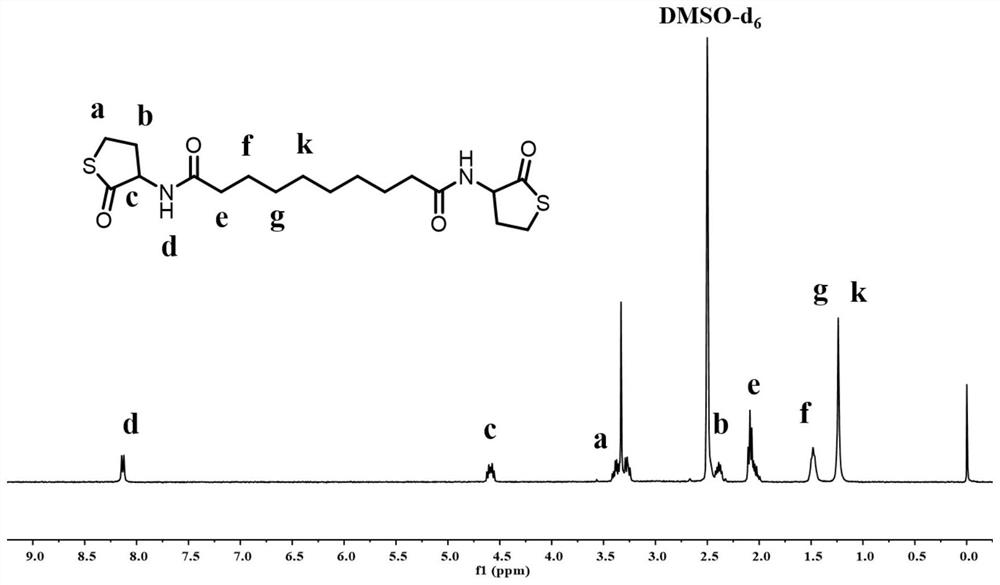

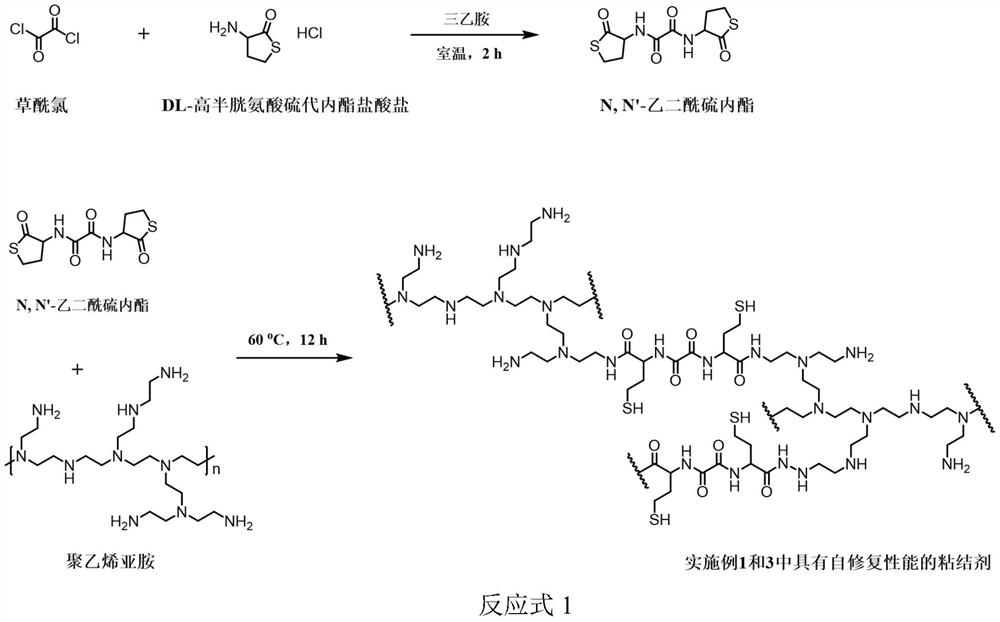

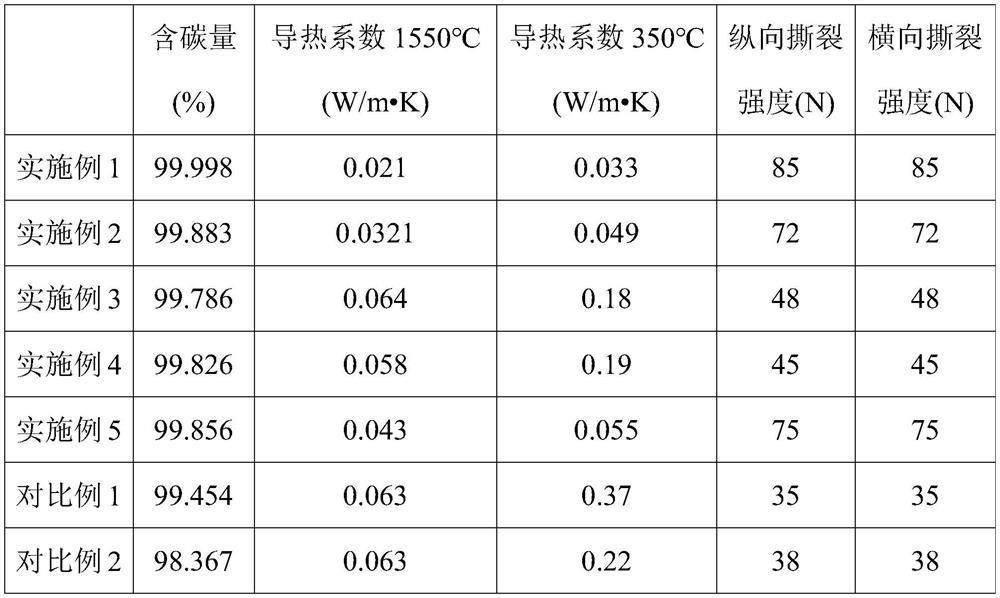

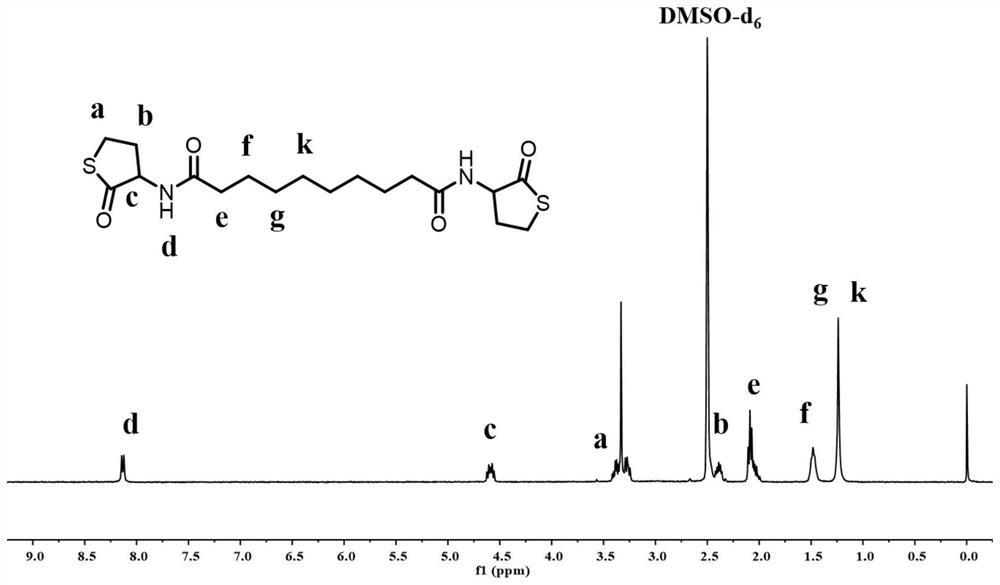

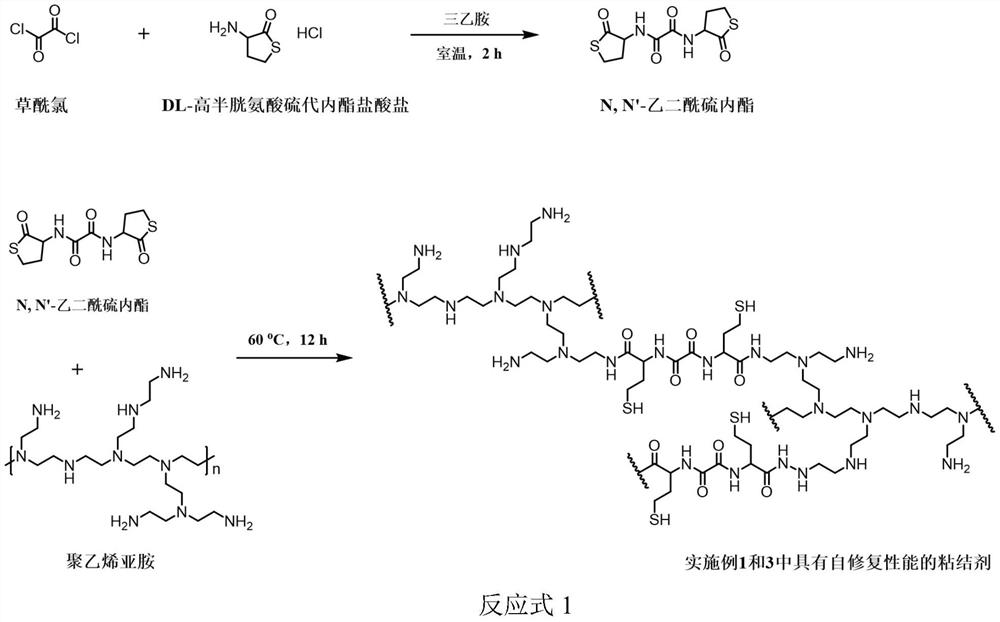

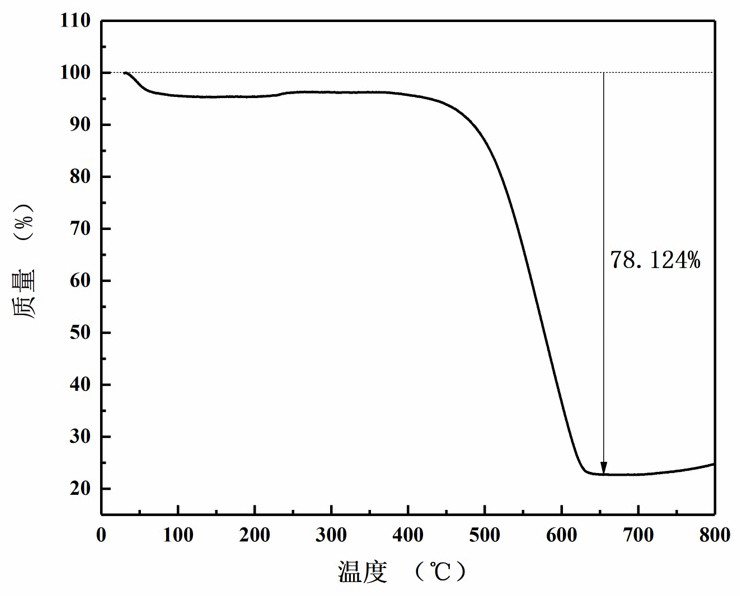

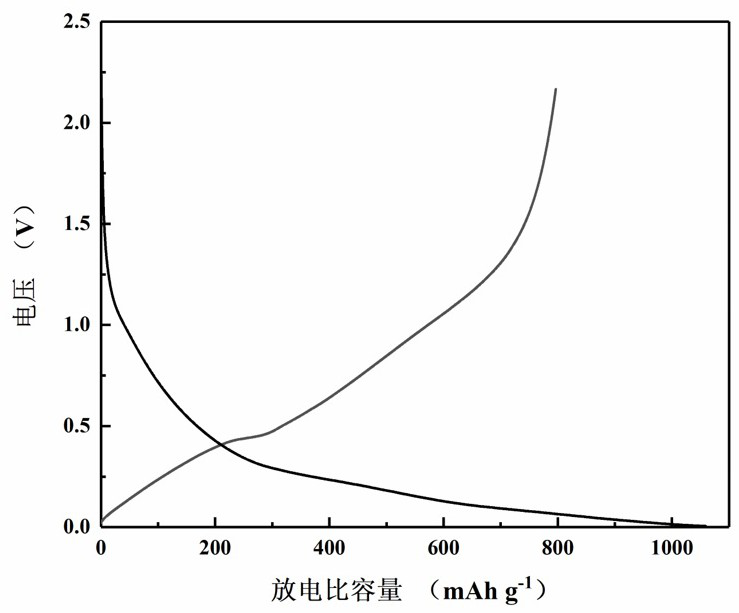

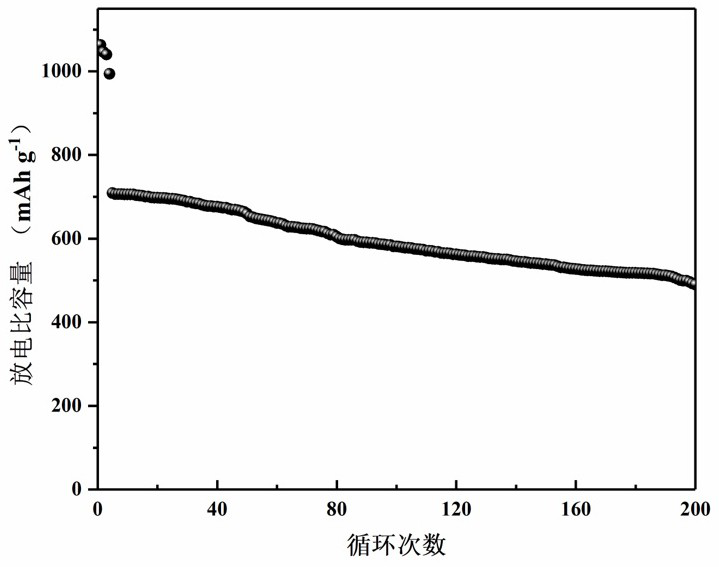

Preparation method and application of lithium battery binder with self-repairing performance

ActiveCN111909374AHigh discharge specific capacityImprove cycle stabilityCell electrodesLi-accumulatorsCellulosePolylysine

The invention relates to a preparation method and application of a lithium battery binder with self-repairing performance. The method comprises the following steps: adding a component A containing a disulfide lactone functional group and a component B containing an amino functional group into a solvent, and reacting at 50-100 DEG C for 12 hours to obtain the polymer binder with self-repairing performance for the lithium battery, wherein the component A containing the sulfur lactone functional group is N,N'-oxalyl sultone, N,N'-malonyl sultone, N,N'-butanedioyl sultone, N,N'-glutaryl sultone, N,N'-adipoyl sultone or N,N'-sebacoyl sultone; and the component B containing the amino functional group is polyethyleneimine, chitosan, amino cellulose or polylysine. The polymer binder disclosed by the invention can enable the positive electrode of the lithium battery to have a self-repairing characteristic, so that the problem of pulverization of an electrode material is greatly improved, and the specific discharge capacity and the cycling stability of the lithium battery are favorably improved.

Owner:HEBEI UNIV OF TECH

Silicon carbon anode material and preparation method thereof

ActiveCN110416500ASolve the technical problem of volume expansionLimit volume expansionCell electrodesSecondary cellsSlurryCarbon nanomaterials

The invention discloses a silicon carbon anode material and a preparation method thereof. The silicon carbon anode material in the invention comprises covalent organic frameworks, a silicon nanomaterial and a carbon nanomaterial; the covalent organic frameworks have hole channels; the silicon nanomaterial is dispersed in the hole channels; and the carbon nanomaterial is dispersed in the covalent organic frameworks and the silicon nanomaterial. The preparation method of the silicon carbon anode material in the invention comprises the steps of: S1, mixing the covalent organic frameworks with thesilicon nanomaterial, so that a mixture is obtained; and S2, adding the mixture into slurry of the carbon nanomaterial; filtering after stirring for 20-50 min, and drying filtrates at 60-100 DEG C for 1-3 h. The silicon nanomaterial is limited in the hole channel by the silicon carbon anode material; the expansion of silicon is inhibited; and the problems of serious pulverization, low cycle lifeand the like due to the fact that the silicon expansion rate is large can be solved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

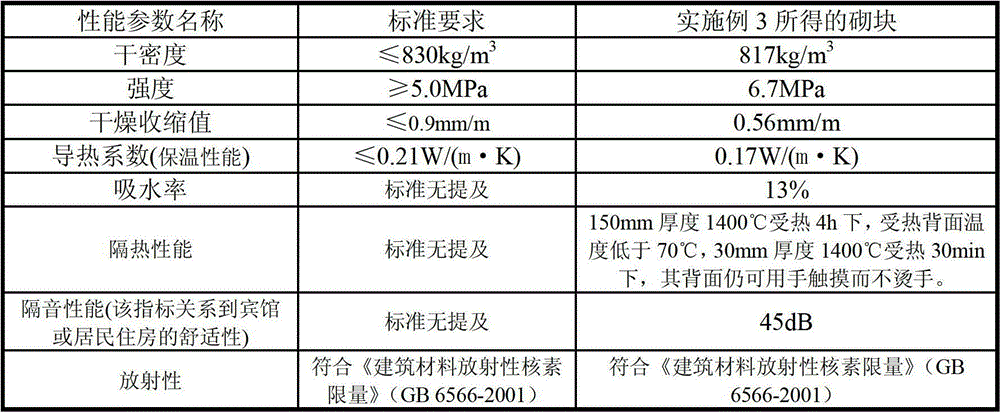

Steam-cured high-performance foam concrete block, production method and application thereof

The invention discloses a steam-cured high-performance foam concrete block which comprises 55-60% of cement, 7-9% of slag powder, 5-8% of sand, 0.5-1.0% of a water reducing agent, 0.88-3% of a curing agent, 0.06-0.3% of a foaming agent and 24-26% of water, wherein the mass of the slag powder is less than 20% of that of the cement which is P.O42.5R cement. According to the foam concrete block, the curing agent is used, so that structural pulverization, collapse of dies and the like are avoided, and the steam-curing effect is improved; water-proof, heat preservation and thermal insulation effects of products are good, and building energy saving is facilitated; the products have good durability and the same service life with a main construction; and the problems of low strength, pulverization, large shrinkage, collapse of dies and the like of low-density foam concrete are solved.

Owner:罗云峰 +2

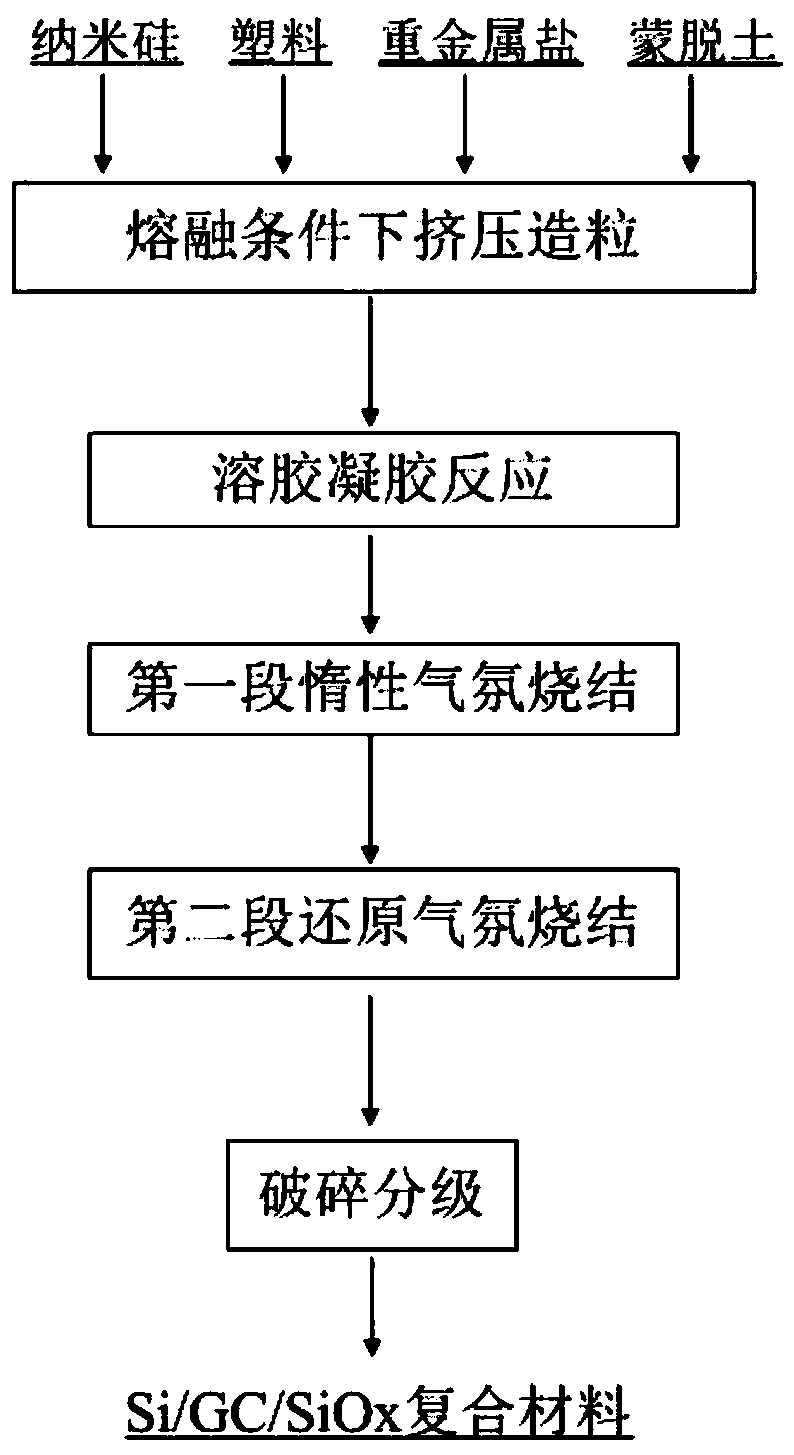

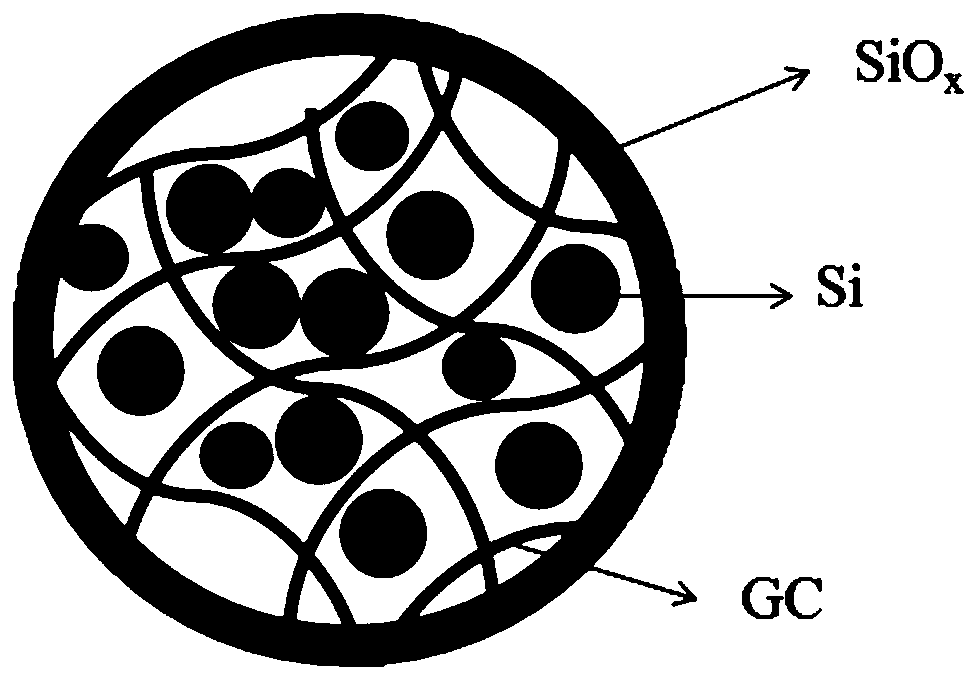

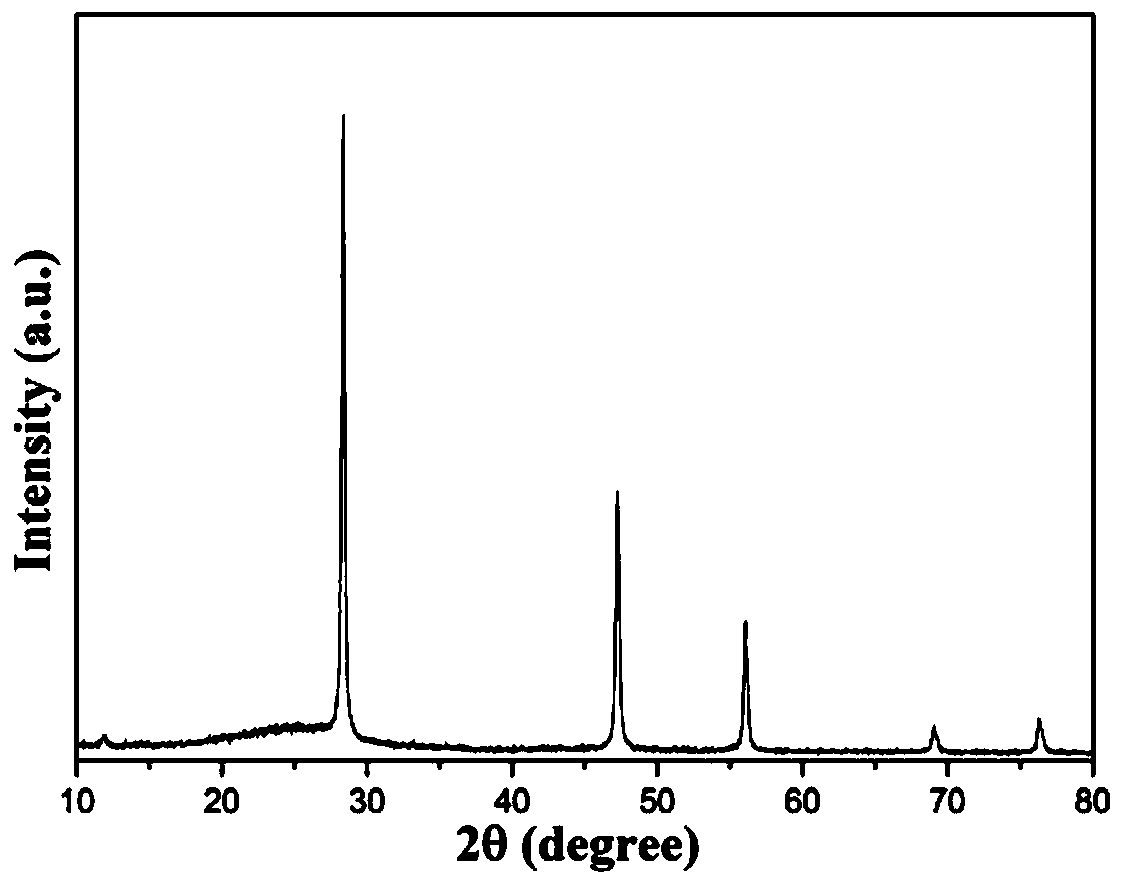

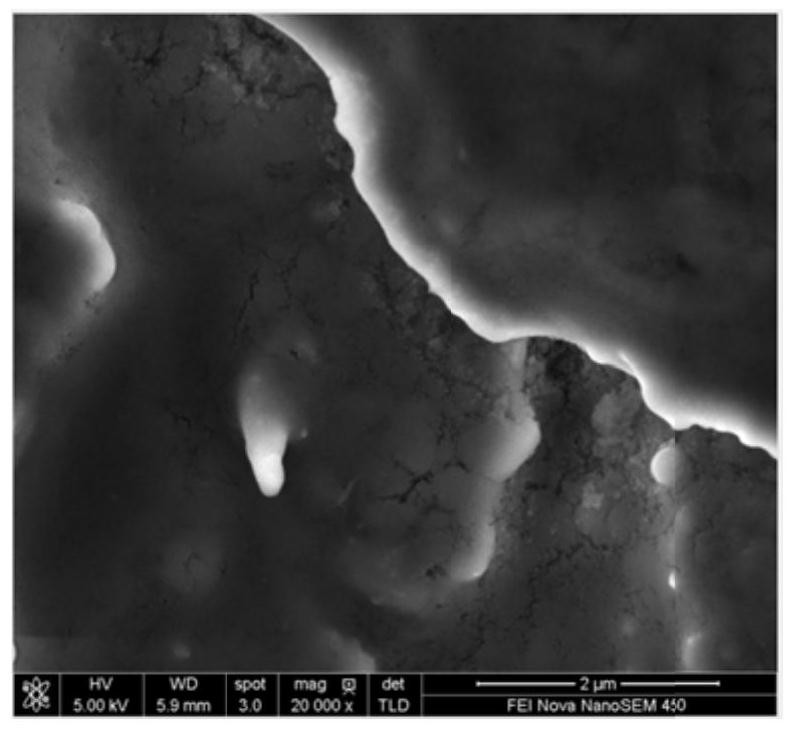

Preparation method of silicon-based composite material for lithium ion power battery

ActiveCN109755546AImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsElectrical batterySilicon dioxide

The invention discloses a preparation method of a silicon-based composite material for a lithium ion power battery, belonging to the field of negative electrode materials for lithium ion batteries. The method comprises the steps of mixing the raw materials for extrusion and granulation under molten conditions by using nano silicon, plastic and montmorillonite as raw materials and adding heavy metal salt as a catalyst to obtain a nano-silicon / plastic / montmorillonite composite material; adding a nonionic surfactant and a cationic surfactant to the hydrochloric acid solution to obtain a mixed solution, adding the nano-silicon / plastic / montmorillonite composite material to the mixed solution to carry out a sol-gel reaction to obtain a nano-silicon / plastic / silica composite material; and obtaining the silicon-based composite material by subjecting the nano-silicon / plastic / silica composite material to carbothermal reduction. The preparation method provided by the invention, by utilizing the characteristics of inducing catalytic plastics and catalytic graphitization in heavy metal salts, realizes low temperature graphitization and graphitized carbon uniformly coating nano silicon particlesby using plastic as a carbon source, thereby improving electrochemical performance of silicon anode materials.

Owner:湖南宸宇富基新能源科技有限公司

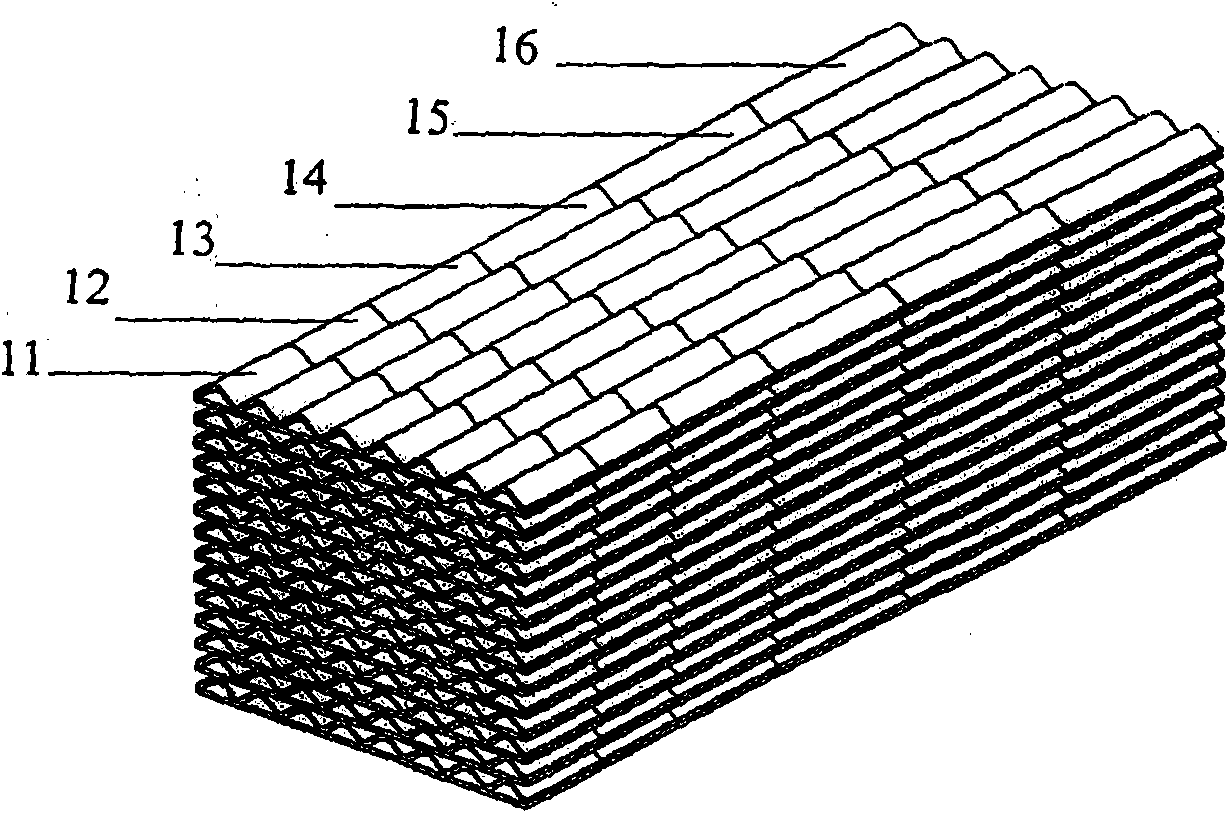

Furnace building method for rotary kiln tube body inner liner

The invention relates to a furnace building method for a rotary kiln tube body inner liner. The furnace building method comprises the steps that (1) a tube body is divided into a plurality of sections in the diameter direction, and then, the tube body is divided into a plurality of strips in an axial direction; (2) fireproof combined blocks are manufactured; (3) the fireproof combined blocks are welded on the tube body in the axial direction, and a line of fireproof combined blocks are arranged in the section of tube body; (4) the step (3) is repeated, and a plurality of lines of fireproof combined blocks are installed; (5) an anchoring element is welded in a tube body strip seam of the fireproof combined blocks; (6) a fireproof heat insulation plate is arranged in a tube body strip seam of the anchoring element; (7) fireproof casting materials are fully filled in the strip seam provided with the fireproof heat insulation plate; (8) the fireproof casting materials are dried and cured, and the furnace building construction of the region is completed; the steps are repeated until the furnace building construction of the whole rotary kiln tube body inner liner is completed. The furnace building method has the advantages that the structure is simple, the construction is convenient, the cost is low, the heat insulation performance of a rotary kiln can be improved, the energy consumption of the rotary kiln can be reduced, the heat loss of the rotary kiln can be reduced, and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

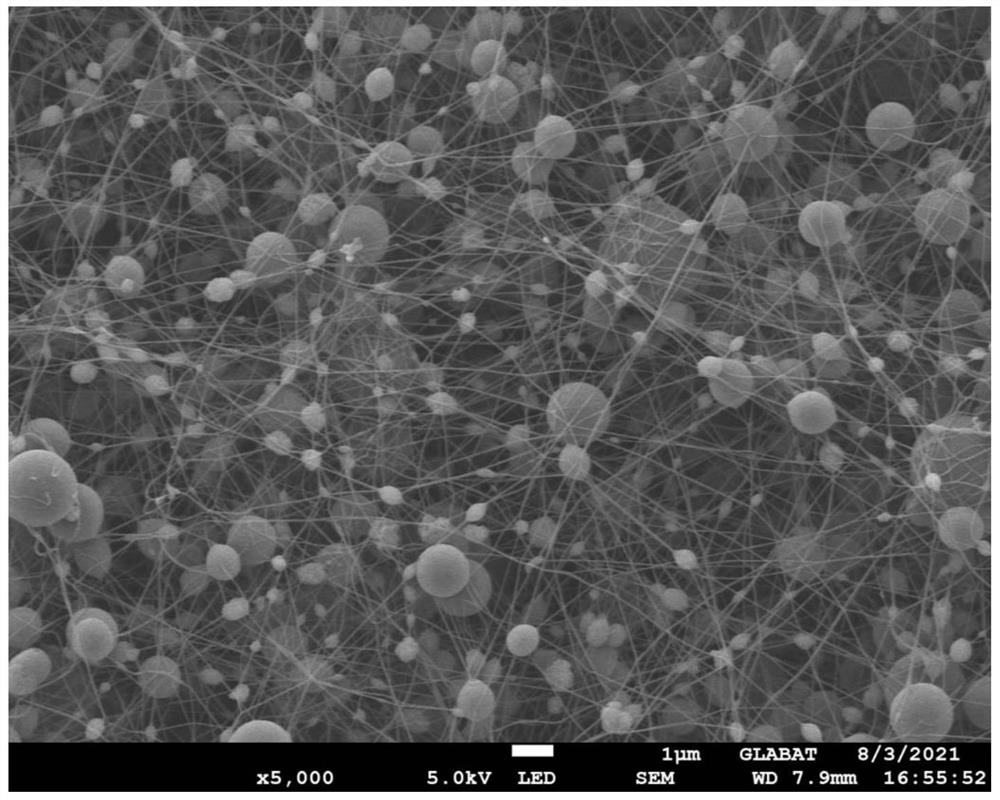

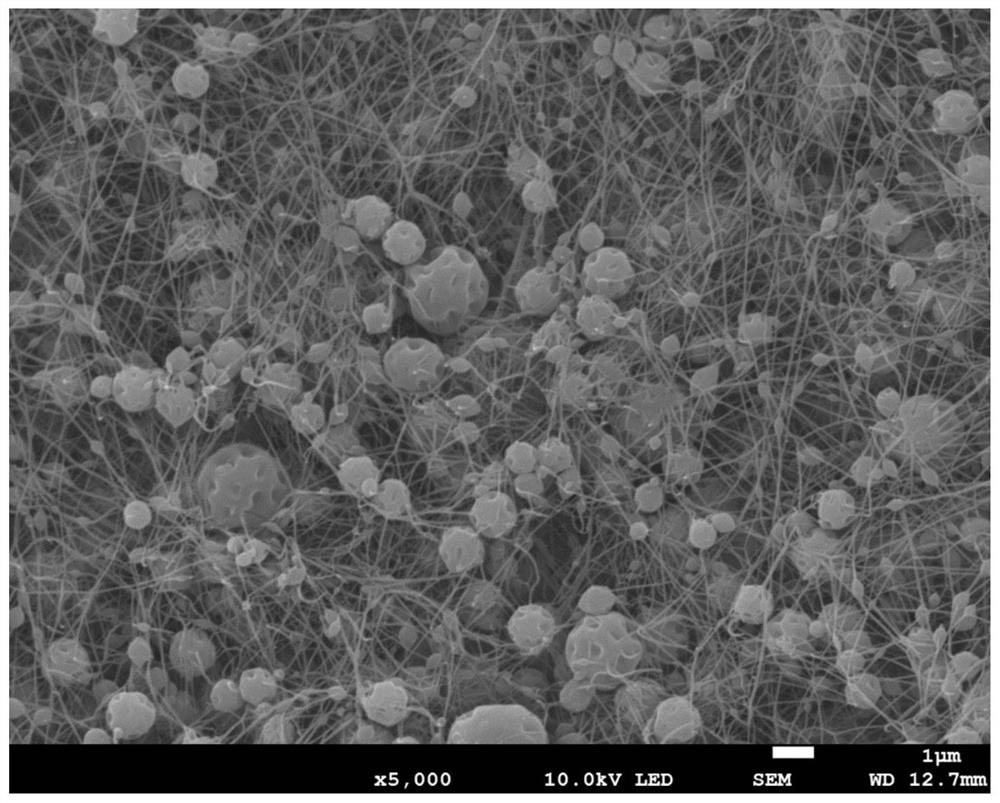

Polyimide coating modified polyolefin composite diaphragm and preparation method thereof

PendingCN113969006AEasy to prepareImprove integritySecondary cellsCell component detailsPolyimide membraneElectrospinning

The invention discloses a polyimide coating modified polyolefin composite diaphragm and a preparation method thereof. The preparation method comprises the following steps: synthesizing a PAA solution with certain intrinsic viscosity through a two-step method, preparing a polyimide film with fiber / microsphere composite morphology by using an electrostatic spinning technology, preparing a polyimide dispersion liquid, adding a polymer adhesive into the polyimide dispersion liquid, stirring at a high speed by using a homogenizer to obtain a polyimide coating slurry, uniformly coating the surface of a polyolefin diaphragm with the polyimide coating slurry, and drying to obtain the polyimide coating modified polyolefin diaphragm with the fiber / microsphere composite morphology. According to the invention, the process is simple and easy to implement, the bonding strength between the polyimide coating and the polyolefin diaphragm layer is high, the thermal dimensional stability and electrolytic solution wettability of the diaphragm can be obviously improved, and the polyolefin diaphragm can play a role in hole closing at a high temperature besides the diaphragm function at a normal temperature, so that short circuit in the battery is prevented, and the safety of the battery is further improved.

Owner:北京宇程科技有限公司

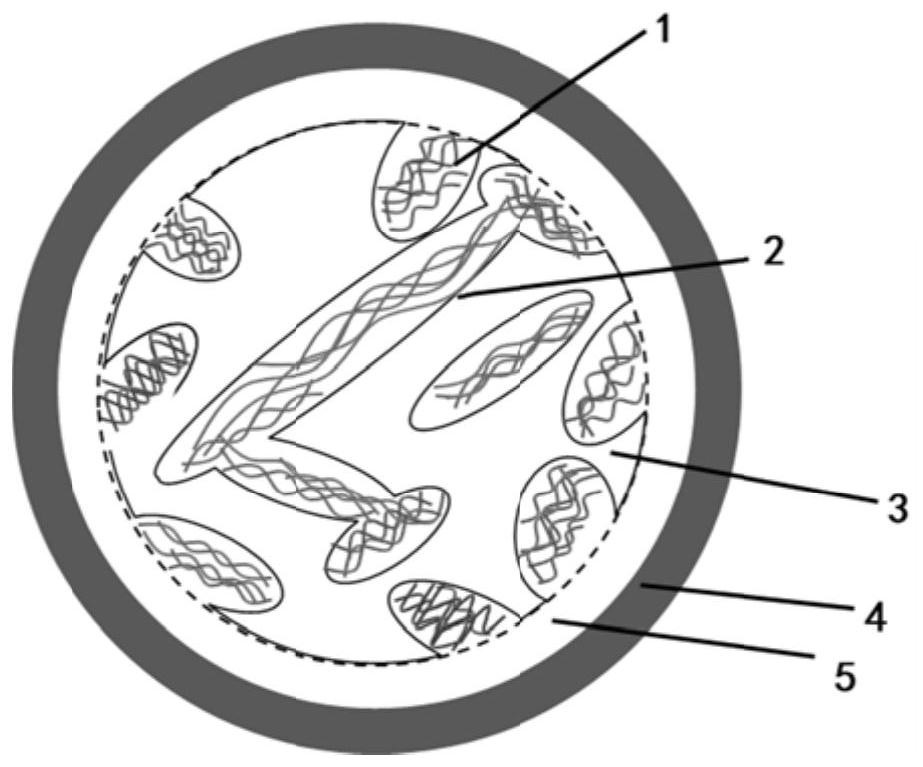

Silicon composite material, preparation method thereof, negative plate and lithium ion battery

ActiveCN112885998AImprove conductivityHigh mechanical strengthMaterial nanotechnologyCell electrodesCarbon coatingLithium-ion battery

The invention discloses a silicon composite material and a preparation method thereof, a negative plate and a lithium ion battery. The silicon composite material comprises through-hole silicon and a carbon coating layer, wherein a one-dimensional carbon material is arranged in a pore channel of the through-hole silicon. According to the invention, the through-hole silicon with the one-dimensional carbon material arranged in the hole channel, the conductivity of silicon particles can be improved from the interior of the silicon material. And meanwhile, the pore channels of the through-hole silicon provide a good buffer space for the material, so that the volume expansion of the material is avoided. A network structure formed by staggering the one-dimensional carbon material in a pore channel of the through-hole silicon can effectively constrain volume expansion of the silicon material, the internal structure of silicon particles is greatly stabilized, the problem of pulverization is solved, a conductive network among the silicon particles is effectively maintained, and the cycle performance of a battery prepared from the material is effectively improved. In addition, the arrangement of the carbon coating layer is beneficial to reducing the contact between the silicon composite material and electrolyte in the use process, so that the side reaction is reduced, and the electronic conductivity of the silicon composite material can be further improved.

Owner:HIGHPOWER TECH HUIZHOU

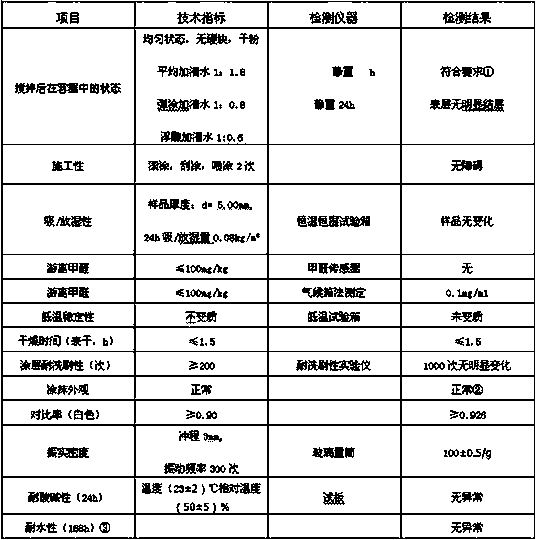

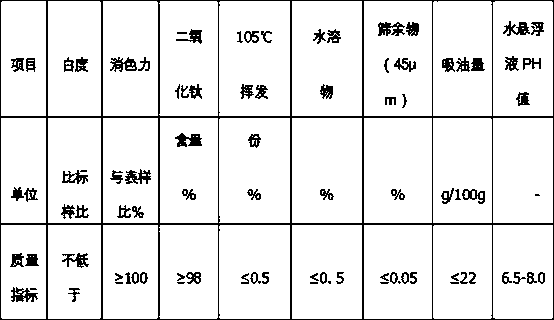

Coral powder ecological functional interior wall material

The invention relates to healthy, environmental-friendly and functional interior wall material, namely, a coral powder ecological functional interior wall material. The coral powder ecological functional interior wall material is prepared from coral powder, talc powder, ash calcium, bentonite, quartz powder, polyvinyl alcohol powder, tetrapod-shaped zinc oxide whiskers, hydroxypropyl methyl cellulose, vinyl acetate, titanium dioxide, polycarboxylate superplasticizer and antifoaming powder. The main raw (auxiliary) materials are inorganic materials with mineral components, and the master batchis calcined to form a porous structure. By adopting the tetrapod-shaped zinc oxide whiskers, free harmful gases such as formaldehyde, toluene, ammonia and TVOC in air can be adsorbed in a long term, and a decomposing and purifying effect is realized to avoid harm to human health and pollution to indoor environment; due to the special functions of the product, the product has the characteristics ofair purification, indoor humidity adjustment, bacteria resistance and bacteriostasis, release of negative oxygen ions, release of mineral trace elements, long service life and the like; the physicalperformance indexes can be ensured to meet the requirements, and the due special properties of the product are obtained.

Owner:佟朝富

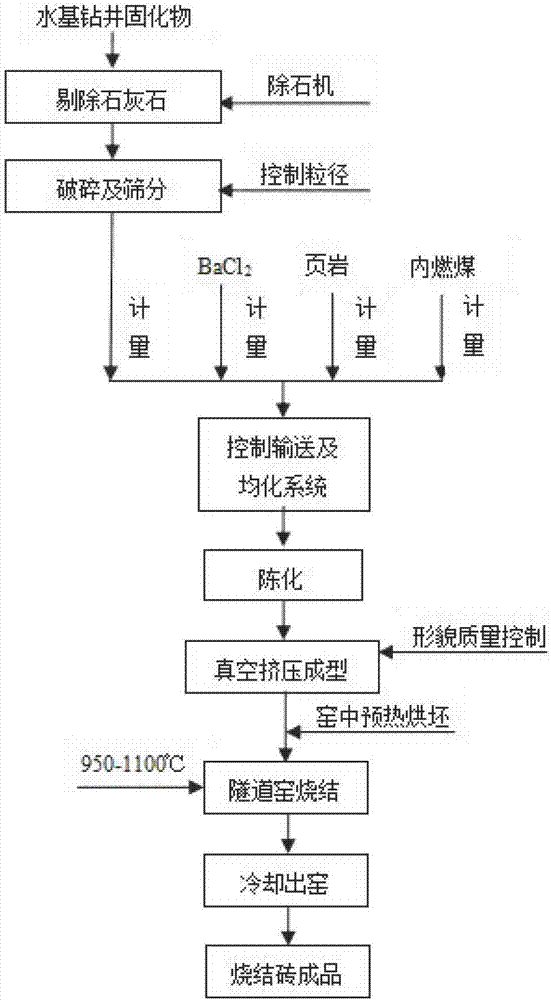

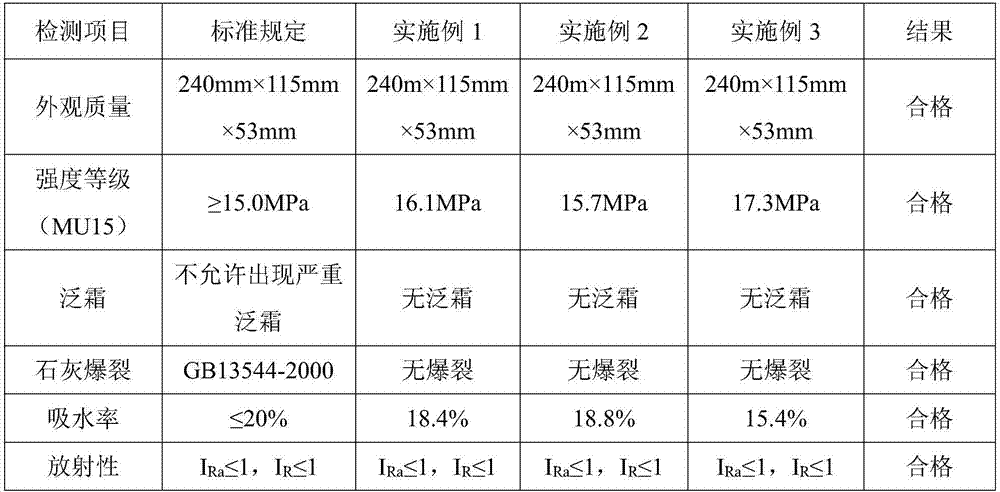

Method for preparing sintered brick by water-based well drilling condensate modification

InactiveCN107459337ASolve the problem of whiteningSolve the problem of bloomingCeramic materials productionClaywaresWater basedCombustion

The invention discloses a method for preparing a sintered brick by water-based well drilling condensate modification. The method comprises a step (1) of causing water-based well drilling condensate to undergo preliminary crushing, adopting a stone removal device to remove most of limestone therein, performing deep crushing on the water-based well drilling condensate from which the limestone has been removed, performing sieving, and obtaining powder with the fineness lower than 1 mm; a step (2) of causing the water-based well drilling condensate powder obtained through the step (1) to be evenly mixed with modifier barium salt, shale soil and internal combustion coal, and obtaining a mixed material; a step (3) of adding water into the mixed material obtained through the step (2), performing stirring, and performing ageing for 2-3 days; a step (4) of making the aged mixed material into a green brick, performing drying and high-temperature sintering, and obtaining the finished sintered brick. According to the method for preparing the sintered brick by water-based well drilling condensate modification, the problems that in the prior art, a brick body of a sintered brick prepared from the water-based well drilling condensate becomes white, bursts and powders are effectively solved.

Owner:四川华恒正合石化科技有限公司

Method for preparing polycrystal mullite fibers

ActiveCN102465358BGood flexibilityLow brittleness indexInorganic material artificial filamentsFiberStrong acids

The invention relates to a method for preparing polycrystal mullite fibers, which is characterized by comprising the following steps of: dissolving aluminite powder into a mixture of formic acid and acetic acid, and heating and refluxing to prepare mixed sol solution of aluminium basic and aluminium acetate; adding acid silicone sol without sodium into the mixed sol of aluminium basic and aluminium acetate; adding spinning auxiliaries into the evenly mixed solution; adding a surface active agent in the mixture; adding one or more of tartaric acid, citric acid or lactic acid in spinning dope; fibering the mixture under the condition of injection or thrown silk; initially drying polycrystal alumina fiber strand; and heating the polycrystal alumina fiber strand at the temperature of 500-1,400 DEG C. The polycrystal mullite fiber prepared by the method is free from using inorganic strong acid, cannot cause environment pollution, has high fiber softness, good toughness and low friability index, and solves the problem of pulverization of the polycrystal mullite fiber, which always exists.

Owner:山东鲁阳浩特高技术纤维有限公司

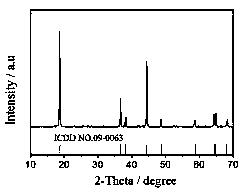

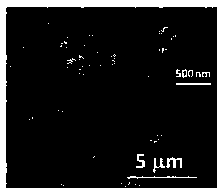

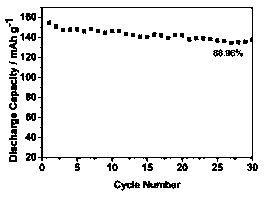

High-crystallinity submicron nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

InactiveCN110492096AReduce shufflingShorten the transmission pathCell electrodesManganeseCrystallinity

The invention discloses a high-crystallinity submicron nickel-cobalt-manganese ternary positive electrode material and a preparation method thereof. An ethanol solution is used as a base solution, a mixed salt solution and a mixed alkali solution are added into the base solution to prepare the material. The method includes (1) adding the mixed salt solution of nickel, cobalt and manganese, and themixed alkali solution of sodium carbonate and ammonia water into alkali base solution, heating and stirring the mixture to form a suspension, filtering the suspension to obtain a solid, and washing and drying the solid to obtain a ternary precursor; and (2) mixing a lithium salt and the ternary precursor according to a molar ratio that Li:(Ni + Co + Mn) = (1-1.2):1, grinding the mixture, carryingout low-temperature presintering, carrying out heat preservation sintering, and cooling to obtain the high-crystallinity submicron nickel-cobalt-manganese ternary positive electrode material. The preparation method disclosed by the invention has the beneficial effects that an additive or an auxiliary agent is not required to be used, the high-crystalline submicron nickel-cobalt-manganese ternarypositive electrode material with uniformly dispersed particles is obtained, and the cycling stability of the battery is favorably improved.

Owner:GUIZHOU UNIV

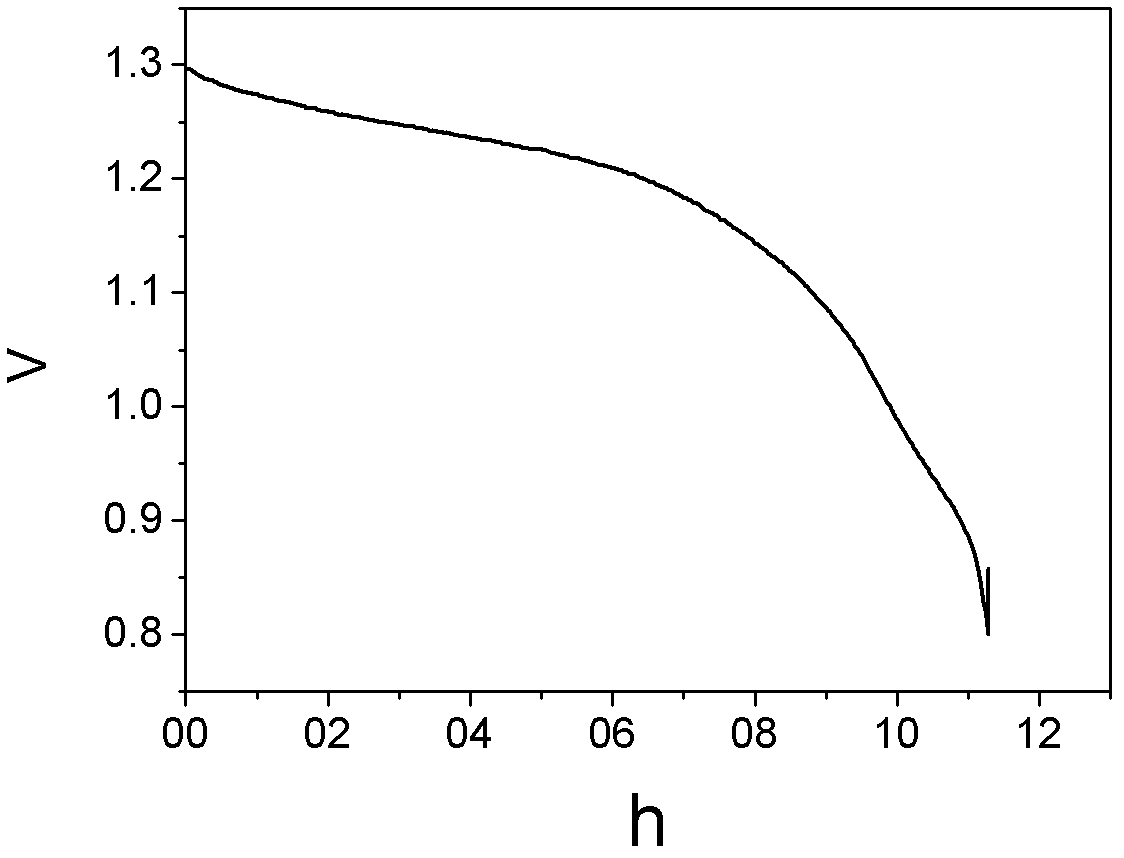

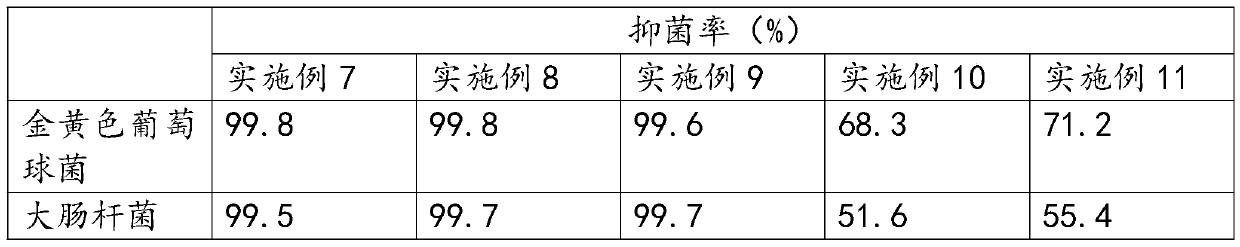

Disposable nickel hydrogen battery negative electrode material, negative electrode piece, battery and preparation methods thereof

InactiveCN102593437AHigh discharge specific capacitySolve the chalking problemFinal product manufactureAlkaline accumulator electrodesAlloyNickel–hydrogen battery

The invention relates to a negative electrode material of a nickel hydrogen battery, and specifically relates to a disposable high-capacity replaceable nickel hydrogen battery negative electrode material. The invention also relates to a negative electrode piece, a nickel hydrogen electrode and preparation methods of the negative electrode piece and the nickel hydrogen electrode. The disposable nickel hydrogen battery negative electrode material comprises the following components in percentage by mass based on the total mass of the components: 35.56%-68.51% of LaNi5, 3.36%-8.03% of MgH2, 24.21%-56.10% of a bonding agent and 1.25%-3.08% of foam nickel. The negative electrode piece is made of the disposable nickel hydrogen battery negative electrode material, and the nickel hydrogen battery comprises the negative electrode piece. The method for preparing the negative electrode piece or the nickel hydrogen battery comprises the steps of mixing, piece pressing, welding and the like. According to the invention, the technical problems of the existing nickel hydrogen battery that the discharge specific capacity is low and the alloy is atomized easily are solved.

Owner:SHANGHAI JIAO TONG UNIV

Preparation process of multi-layer composite automobile leather

ActiveCN111284108AGood flexibilityIncrease elasticityLiquid surface applicatorsOrganic chemistryNonwoven fabricCollagen fiber

The invention discloses a preparation process of multi-layer composite automobile leather. The automobile leather sequentially comprises a sunscreen coating layer, a leather layer, a non-woven fabriclayer, a non-glue cotton layer and a knitted fabric layer from outside to inside. The preparation process of the automobile leather comprises the following steps: step 1, depilating, degreasing, softening and pickling dry leather or salt leather to obtain leather collagen fibers, tanning and dyeing the leather collagen fibers, washing the leather collagen fibers with water, taking the leather collagen fibers out of a drum, and carrying out stacking and drying in vacuum to obtain leather; step 2, uniformly spraying a sun-screening emulsion on the surface of the leather prepared in the step 1 ina spraying manner, and then performing heating and shaping to obtain leather containing a sun-screening coating layer; and step 3, sequentially stacking the leather containing a sunscreen coating layer prepared in the step 2, non-woven fabric, non-glue cotton and knitted fabric, and performing pressing, sewing and trimming to obtain the multi-layer composite automobile leather. The sunscreen emulsion is uniformly sprayed on the surface of the leather in a spraying manner, so that the protective property and the sunscreen property of the leather are improved, and the ageing resistance of the automobile leather is improved.

Owner:YANGZHOU DERWINS PLASTICS TECH

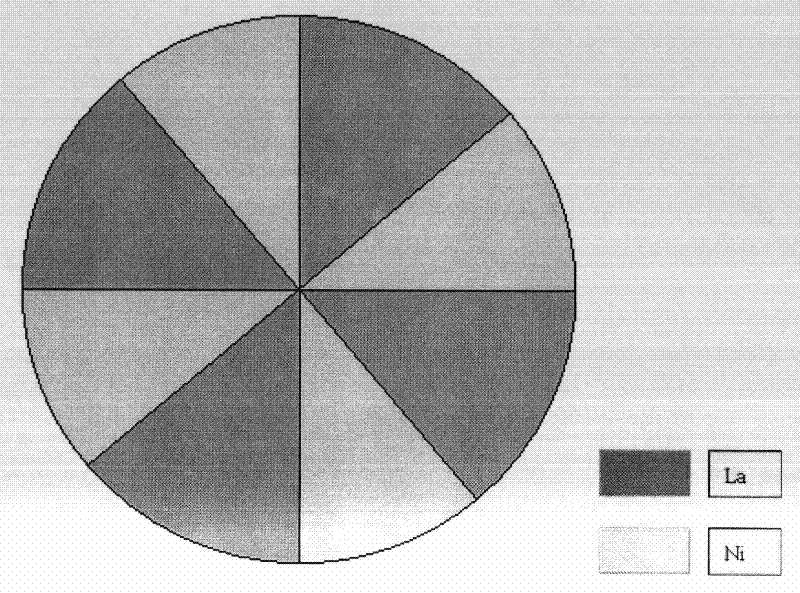

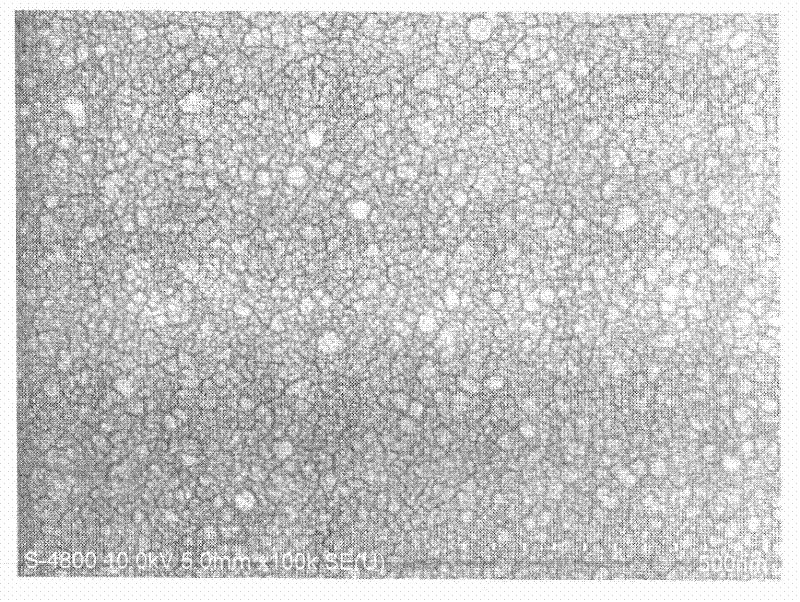

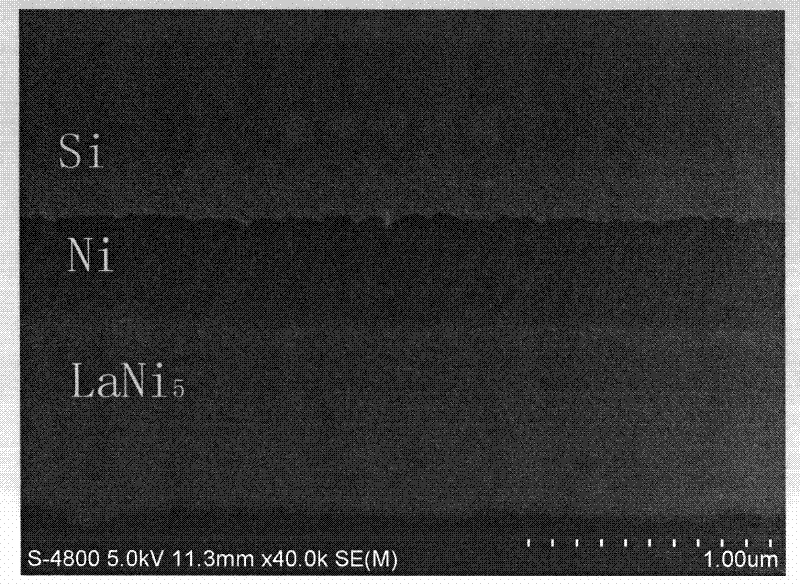

Preparation method of LaNi5 film and application thereof

InactiveCN102220560AEasy to makePrecise control of stoichiometric ratiosVacuum evaporation coatingSputtering coatingHydrogenRadio frequency magnetron sputtering

The invention discloses a preparation method of a LaNi5 film and application thereof in the aspect of a hydrogen sensitive sensor. The preparation method comprises the steps of: manufacturing a layer of Ni film as a buffer layer on a Si substrate; depositing a LaNi5 film on the Ni film by using a radio frequency magnetron sputtering method, wherein the target material for depositing the LaNi5 film is a fan-shaped target consisting of a La target and a fan-shaped Ni sheet, and the sputtering conditions comprise power of 120-200W, temperature between 350 DEG C and 500 DEG C, target-substrate distance of 3.5 cm, air pressure of 0.6 Pa and time of 20 minutes. The prepared LaNi5 film is a polycrystalline film with low surface density, large specific surface area and uniform crystalline grains; the polycrystalline film is suitable to be used as a gas sensor. In addition, the LaNi5 film has strong hydrogen absorption capacity and contributes to improving the response capability of the hydrogen sensitive sensor; and therefore, the LaNi5 film prepared by the method has better application prospect in the aspect of the hydrogen sensitive sensor.

Owner:HUBEI UNIV

Lithium ion battery non-aqueous electrolyte and lithium ion battery

PendingCN114094166ACyclic stabilityHigh capacity retentionSecondary cellsElectrolytic agentSulfonate

The invention provides a lithium ion battery non-aqueous electrolyte and a lithium ion battery. The lithium ion battery non-aqueous electrolyte comprises an electrolyte, a non-aqueous solvent and an additive, wherein the additive comprises a sulfonate additive and an ether compound. The invention provides the lithium ion battery non-aqueous electrolyte which is prepared by compounding the sulfonate additive and the ether compound additive so that side reaction, stress corrosion cracking, transition metal dissolution and impedance increase between a positive electrode material and the electrolyte can be inhibited; and the non-aqueous electrolyte of the lithium ion battery can also avoid the problem of lithium metal pulverization in the lithium supplement process of a silicon-carbon negative electrode, then the highly reversible circulation of lithium metal is realized, the stable circulation of the lithium ion battery is realized, and the reversible specific capacity of a ternary positive electrode material and the first coulombic efficiency of a silicon negative electrode material are remarkably improved.

Owner:北京胜能能源科技有限公司

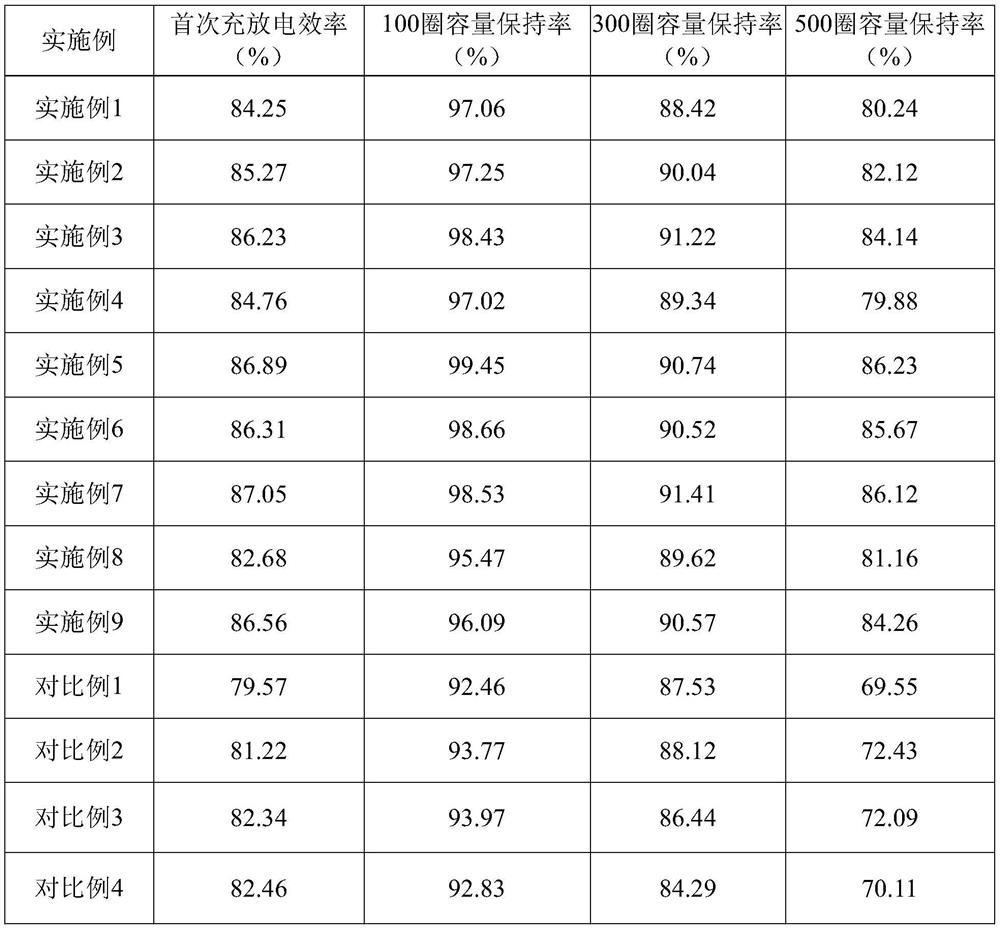

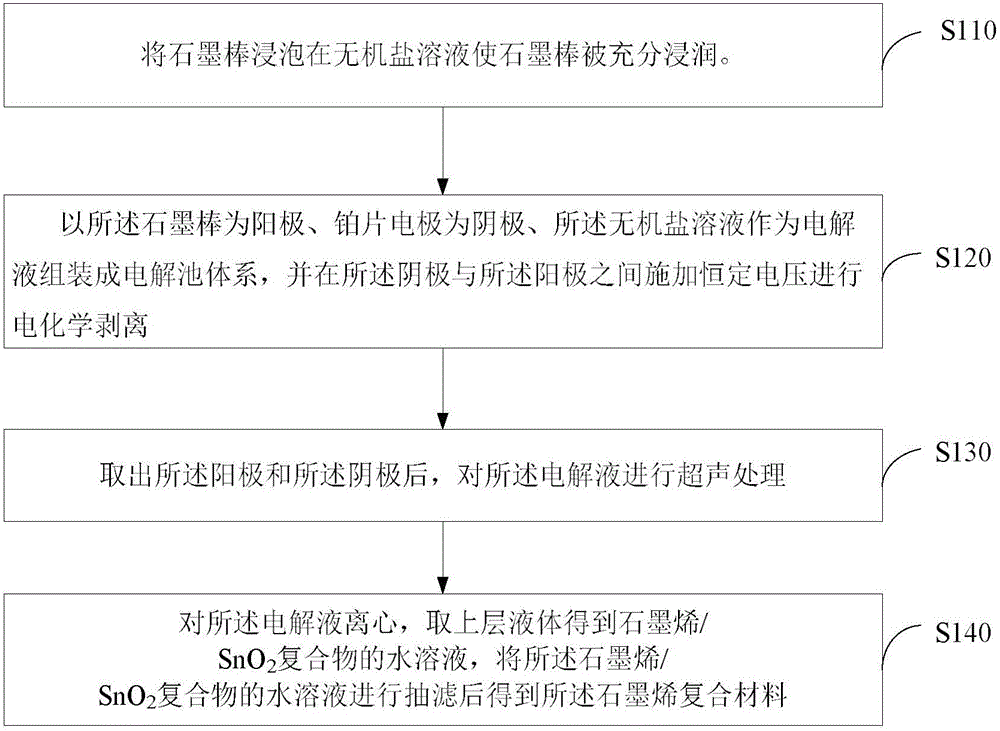

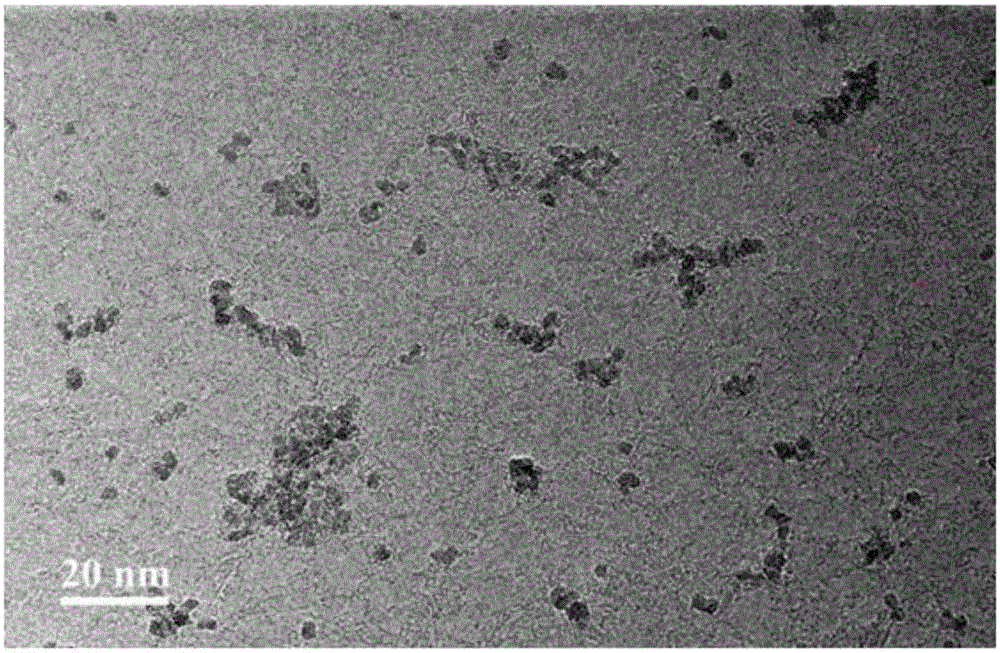

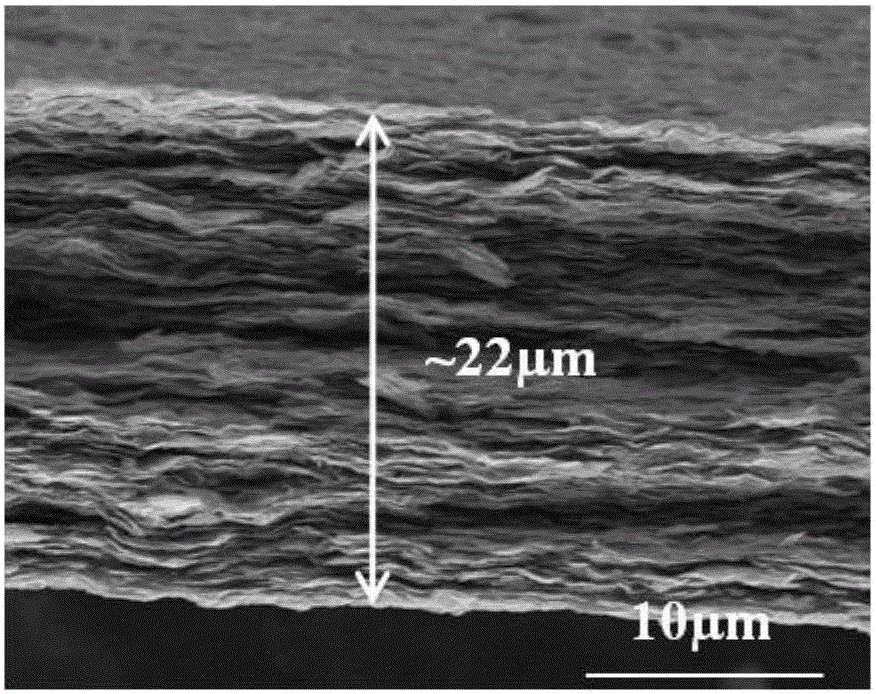

High-thermal-conductivity flexible graphene composite material and preparation method therefor, and lithium ion battery

InactiveCN105845903AImprove performanceImprove structural stabilityCell electrodesSecondary cellsFiltrationPotassium

The invention relates to a preparation method for a high-thermal-conductivity flexible lithium ion battery negative electrode graphene composite material. The preparation method comprises the following steps of enabling a graphite rod to be soaked in an inorganic salt solution to be fully wetted; taking the graphite rod as the positive electrode, taking a platinum sheet electrode as the negative electrode, and taking the inorganic salt solution as the electrolyte to be assembled into an electrolytic tank system, and applying a constant voltage between the negative electrode and the positive electrode to carry out electrochemical stripping; taking out the positive electrode and the negative electrode, and carrying out ultrasonic processing on the electrolyte; centrifuging the electrotype, taking the upper layer liquid to obtain a graphene / SnO<2> compound aqueous solution; and carrying out suction filtration on the graphene / SnO<2> compound aqueous solution to obtain the graphene composite material, wherein the inorganic salt solution is selected from one kind of a sodium stannate solution and a potassium stannate solution. The invention also provides the high-thermal-conductivity flexible lithium ion battery negative electrode graphene composite material and a lithium ion battery. The high-thermal-conductivity flexible lithium ion battery negative electrode graphene composite material and the lithium ion battery are relatively high in thermal dissipation and stability.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

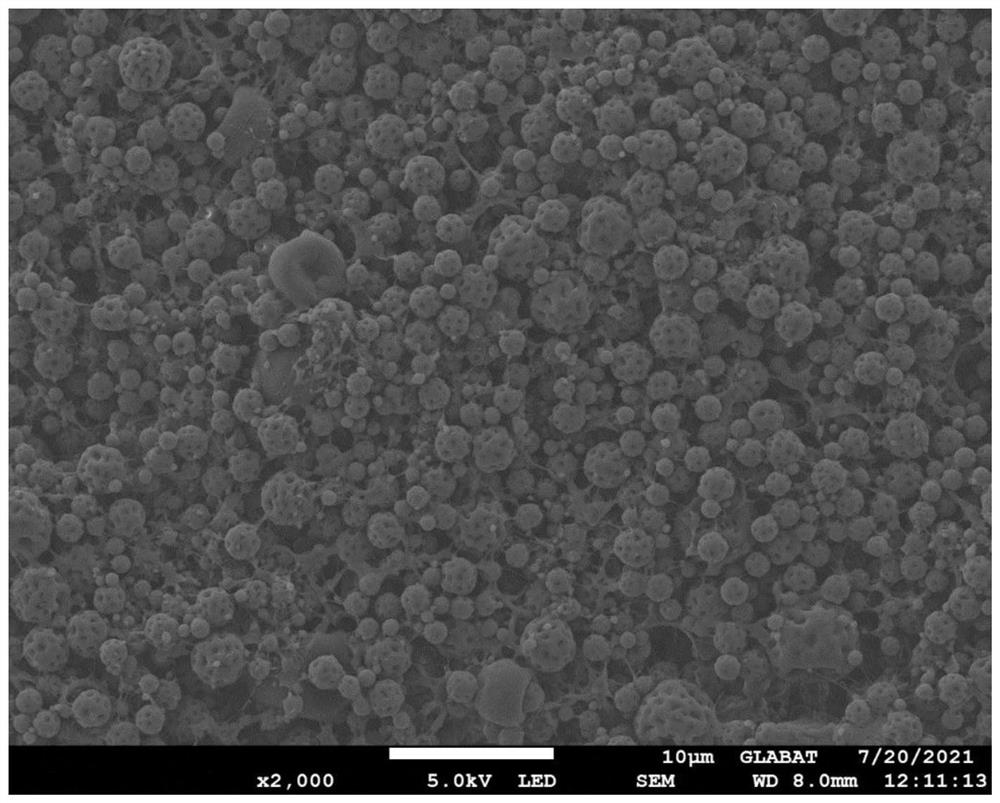

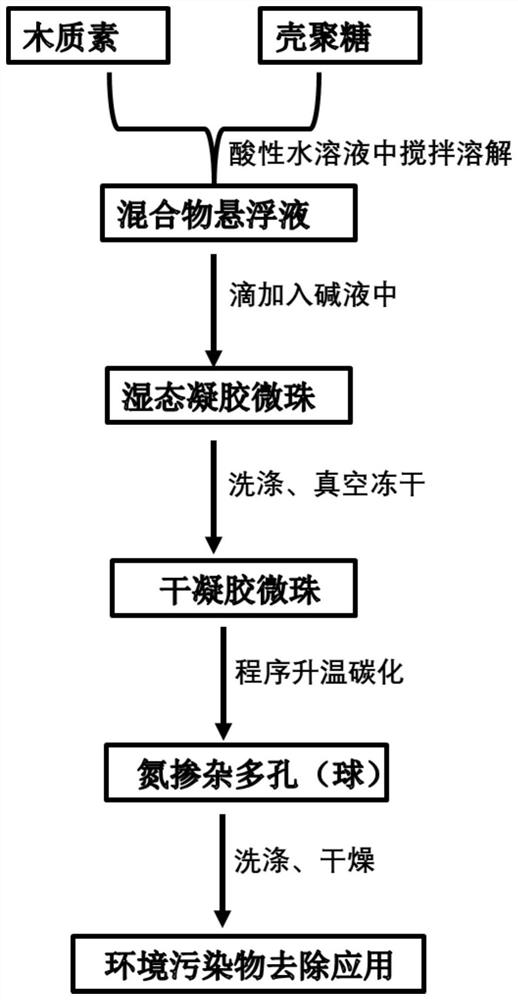

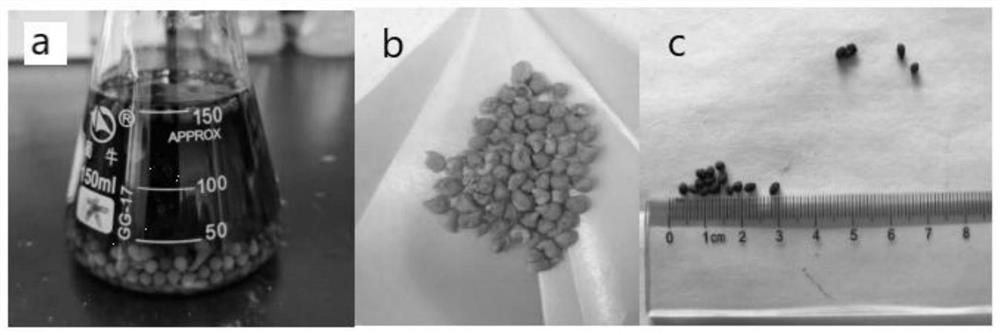

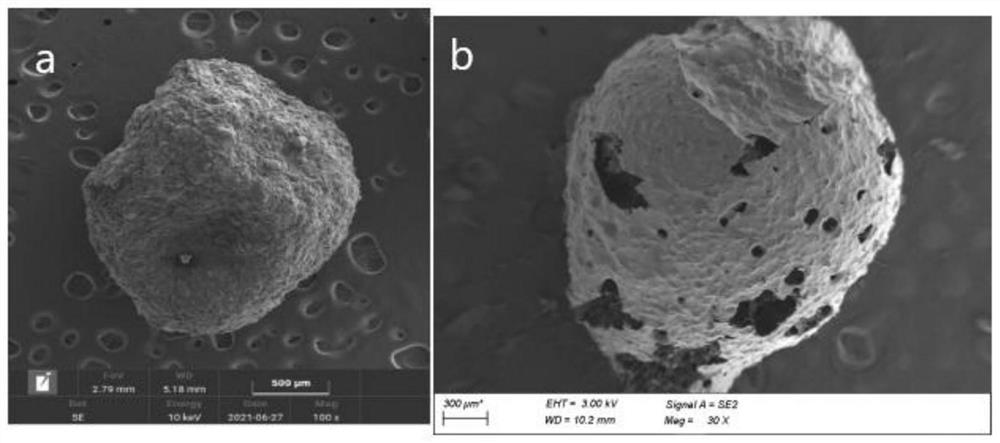

Millimeter-scale nitrogen-doped porous carbon sphere as well as preparation and application thereof

PendingCN114146679AImprove adsorption capacityHigh yieldGas treatmentOther chemical processesOrganic solventFreeze-drying

The invention belongs to the field of preparation of carbon adsorbents, and particularly provides a preparation method of millimeter-scale nitrogen-doped porous carbon spheres, a mixed solution A dissolved with lignin, chitosan and acid is obtained, then the mixed solution A is dropwise added into an alkali solution under the stirring condition for self-assembly, solid-liquid separation is performed after standing and curing, and lignin-chitosan gel microspheres are obtained; treating the gel microspheres by using a water-containing solvent, and then carrying out solid-liquid separation to obtain a solid and a solution with the pH value of 7-9; carrying out vacuum freeze drying treatment on the solid to obtain precursor spheres; the water-containing solvent is water or a mixed solvent of water and an organic solvent, and the organic solvent is a solvent capable of being mixed and dissolved with water; and performing pyrolysis carbonization on the precursor spheres at the temperature of 500-800 DEG C in a protective atmosphere, and then washing and drying a carbonized product to obtain the nitrogen-doped porous carbon spheres. The method can be used for preparing the millimeter-scale carbon spheres with excellent adsorption performance.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

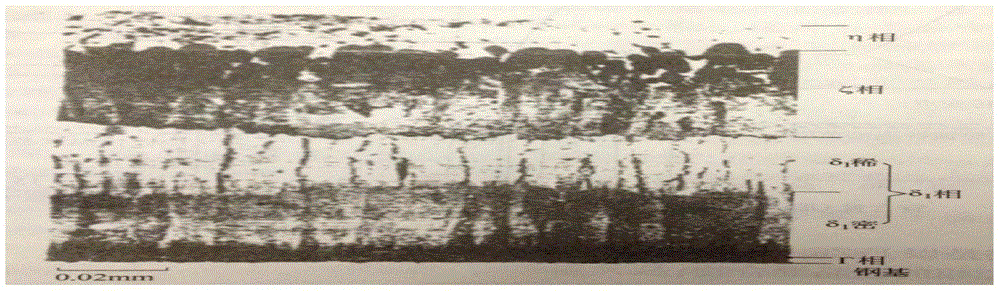

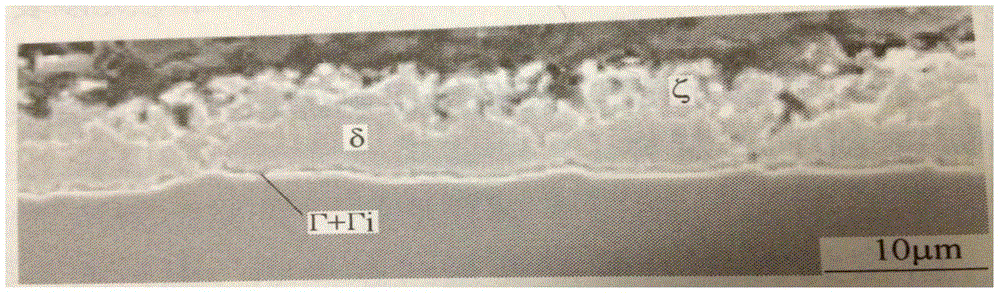

Production method of non-pulverized thick-specification zinc-iron alloyed plate

InactiveCN104947023ASolve the coating pulverization problemReduce manufacturing costHot-dipping/immersion processesTime rangeAluminium

The invention discloses a production method of a non-pulverized thick-specification zinc-iron alloyed plate. The method solves the problems that an existing thick-specification zinc-iron alloyed plate is serious in pulverization, large in shear mount and the like. According to the technical scheme, strip steel with the thickness ranging from 1.6mm to 2.0mm is annealed, galvanized, alloyed, flattened, cut and the like on a continuous production line to obtain the zinc-iron alloyed plate. According to the galvanization step, the temperature of galvanized zinc is controlled to 460+ / -5 DEG C, dipping time ranges from 5 seconds to 7 seconds, and the content of galvanized zinc aluminum ranges from 0.12wt% to 0.14 wt%. The method is simple in technology and can effectively solve the problems of the too high pulverization level and side brightening, and the production cost is reduced.

Owner:武汉钢铁有限公司

Silica sol composite graphite felt as well as preparation method and application thereof

PendingCN114541137AHigh strengthGood insulation effectCarbon fibresChemical industryPolymer chemistryViscose

The invention provides a silica sol composite graphite felt as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, carrying out gum dipping treatment on a viscose-based graphite felt in modified silica sol, and then carrying out passivating treatment, the characteristic that the modified silica sol and cellulose in the viscose-based graphite felt can be subjected to a cross-linking reaction to form a net structure is utilized, so that the internal structure of fibers in the viscose-based graphite felt is changed, and the strength of the finally obtained composite graphite felt is further improved; meanwhile, the modified silica sol can also form a good protective film on the outer surface of the graphite felt, so that the problem of felt body oxidation caused by water separated out of a felt body in the high-temperature passivation treatment process of the graphite felt is avoided, the heat preservation performance of the graphite felt is effectively improved, the service life of the graphite felt is prolonged, and the service life of the graphite felt is prolonged. Finally, the silica sol composite graphite felt with excellent comprehensive performance is obtained.

Owner:辽宁兴汇碳材料科技有限公司

Aluminum-containing ferroalloy for steelmaking deoxidizing

The invention discloses a deoxidizing agent for steelmaking, which contains 40% to 70% of aluminum, 0.5% to 20% of tungsten and / or molybdenum, the remaining are iron and unavoidable impurity. The alloy solves the problem of easy pulverization of current aluminum matrix complex deoxidizer.

Owner:谢应凯

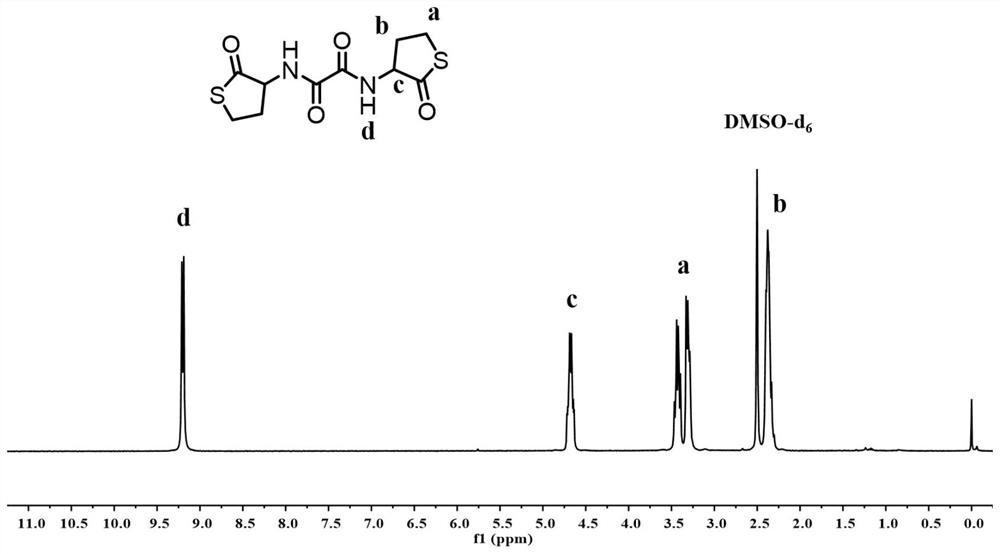

A preparation method and application of a lithium battery binder with self-healing properties

ActiveCN111909374BImprove cycle stabilitySolve the chalking problemCell electrodesLi-accumulatorsThiolactonePolylysine

The invention relates to a preparation method and application of a lithium battery binder with self-repairing performance. The method comprises the following steps: adding component A containing dithiolactone functional group and component B containing amino functional group into a solvent, and reacting at 50-100° C. for 12 hours to obtain a lithium battery polymer with self-repairing performance material binder; the component A of the sulfur-containing lactone functional group is N,N'-oxalylthiolactone, N,N'-malonylthiolactone, N,N'-succinylthiolactone lactone, N,N'-glutaryl thiolactone, N,N'-adipyl thiolactone or N,N'-sebacoyl thiolactone; the amino functional group-containing component B is Polyethyleneimine, chitosan, aminocellulose or polylysine. The polymer binder of the present invention can make the positive electrode of the lithium battery have the characteristic of self-repairing, thereby greatly improving the powdering problem of the electrode material, and is beneficial to improving the discharge specific capacity and cycle stability of the lithium battery.

Owner:HEBEI UNIV OF TECH

A preparation method of a silicon clad composite material based on porous carbon

InactiveCN109037620AImprove performanceSolve the chalking problemCell electrodesSecondary cellsAluminium chlorideDistillation

The invention discloses a preparation method of a silicon-coated composite material based on porous carbon, which comprises the following steps: step 1, adding phenolic resin into absolute ethanol, stirring to complete dissolution, adding polyvinylpyrrolidone, stirring to complete dissolution, and obtaining mixed dispersion liquid ; 2, adding an aluminum chloride solution into the mixed dispersionliquid for ultrasonic reaction for 10 to 20 min, and then introducing concentrated ammonia water into the suspension to obtain a mixed suspension; 3, ultrasonically reacting the mixed suspension for1 to 3 h, and then performing reduced pressure distillation reaction to realize complete evaporation to obtain mix solid; 4, adding the mixed solid into a reaction kettle for sealing non-oxygen carbonization for 3 to 8 h, taking out, and soaking in a hydrochloric acid solution for 30 to 60 min, removing and drying to obtain a porous carbon structure; 5, adding a nano silicon material and a silanecoupling agent into absolute ethanol, and performing ultrasonic treatment to uniformly disperse to obtain a silicon-based coating liquid; 6, soaking the porous carbon structure into the silicon-basedcoating liquid for 10 to 15 min later, taking out and drying, and then carrying out a reduction reaction for 2 To 4 h to obtain a composite material.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Aluminum-manganese-magnesium-iron alloy for steelmaking deoxidation, desulfurization and alloying and production method

InactiveCN110331254AOptimize the smelting processIncrease yieldProcess efficiency improvementMetalMagnesium alloy

The invention discloses an aluminum-manganese-magnesium-iron alloy for steelmaking deoxidation, desulfurization and alloying and a production method thereof. The aluminum-manganese-magnesium-iron alloy comprises the following components of, by weight, 20%-45% of Al, 5%-40% of Mn, 1%-15% of Mg and the balance Fe and inevitable impurity elements. The alloy is casted and formed through protected smelting in an intermediate frequency furnace by using metal iron, metal aluminum, electrolytic manganese or ferromanganese and aluminum-magnesium alloy, so that the problem of low metal yield is solved,and the problem of alloy pulverization is also solved.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

Furnace building method for rotary kiln tube body inner liner

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Carbon-coated silicon negative electrode material with hollow structure and preparation method thereof

The invention discloses a carbon-coated silicon negative electrode material with a hollow structure prepared by taking ZIF-67 as a template and a preparation method of the carbon-coated silicon negative electrode material, and the preparation method comprises the following steps: ultrasonically dispersing silicon powder into methanol, and respectively adding 2-methylimidazole and cobalt salt under a stirring condition; standing, carrying out centrifugal separation, and drying to obtain a precursor Si@ ZIF-67; ultrasonically dispersing the obtained Si @ ZIF-67 in ethanol, and adding the obtained Si @ ZIF67 into a tannic acid solution under a stirring condition; standing, centrifugally separating, washing with ethanol, drying and carbonizing to obtain a product, namely the carbon-coated silicon negative electrode material with the hollow structure. The silicon-carbon negative electrode material prepared by the method can inhibit overlarge volume expansion of silicon in the charging and discharging process to a certain extent, provides a proper space for volume expansion of silicon powder, and can solve the problem of silicon powder pulverization caused by internal stress.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com