Coral powder ecological functional interior wall material

An ecological function, coral powder technology, applied in the field of coatings, can solve problems such as polluting the indoor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

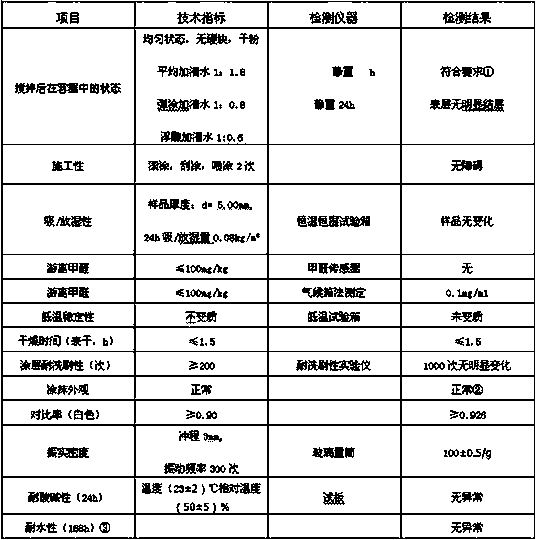

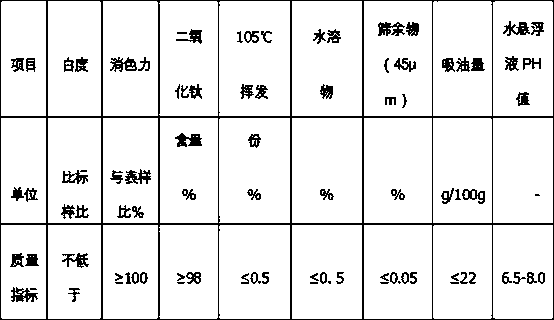

[0225] The coral ecological function interior wall material is characterized in that it is made of the following raw materials in parts by weight: 30 parts of coral powder (calcined), particle size 600-1200 mesh; 7 parts of talcum powder, 600-1000 mesh; 9 parts of gray calcium , 600~1000 mesh; 17 parts of bentonite (calcined), particle size 200 mesh; 9 parts of quartz powder, particle size 200 mesh; 6 parts of polyvinyl alcohol, particle size 200 mesh; 4 parts of propyl methylcellulose; 7 parts of vinyl acetate; 5 parts of titanium dioxide; 2 parts of dispersant; 1 part of water reducer; 1 part of strong defoaming powder.

Embodiment 2

[0238] Coral powder preparation method: rinse the coral sand with water for 15 minutes. Dehydrated through a dehydration sieve, sent to a calciner to be calcined at 800-850°C, cooled to 100-150°C by a water cooler, and ultra-finely ground to 600-1200 mesh to obtain coral powder.

[0239] The coral powder preparation method selects 4 kinds of particle sizes, and can produce products of various specifications, namely 600 mesh, 800 mesh, 1000 mesh, and 1200 mesh. Its characteristics are: porous structure, strong adsorption, good hygroscopicity, and the number of abrasions can reach 1000 times.

Embodiment 3

[0241] Preparation method of coral powder ecological functional interior wall material:

[0242] Batching process: put in the fine material first and then the coarse material. Coral powder→talc powder→ash calcium→bentonite→quartz powder→polyvinyl alcohol→tetraacicular zinc oxide whiskers→hydroxypropyl methylcellulose→vinyl acetate→titanium dioxide→water reducing agent→strong defoaming powder, Twelve kinds of raw (auxiliary) materials have been prepared, which can meet the requirements of physical performance indicators, ensure the realization of product function physical performance indicators, have the ability to purify air, adjust indoor humidity, prevent mold, fire and flame retardant, easy to repair, washable, Salt spray resistance, abrasion resistance, scratch resistance, no deformation, thixotropy, weather resistance, durability, smoothness, lubricity, plasticity, film forming, fullness, good gloss, elasticity, wash resistance, impact resistance , compression resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com