Method for preparing polyphenylene-sulfide-based strongly acidic ion exchange fiber

A technology of ion exchange fiber and polyphenylene sulfide fiber, which is applied in the field of preparation of strong acid ion exchange fiber, can solve complex irradiation grafting process and other problems, and achieve the effects of simplified preparation process, reduced production cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

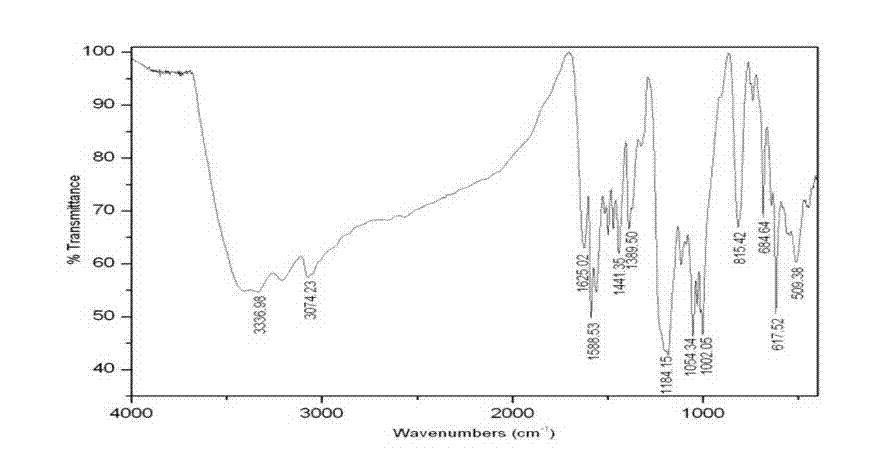

Image

Examples

Embodiment 1

[0035] The preparation method of polyphenylene sulfide-based strong acid ion exchange fiber of the present invention, its detailed steps are as follows:

[0036] a. Friedel-Crafts crosslinking reaction: put 1.0800g of polyphenylene sulfide fiber and 40mL of organic solvent 1,2-dichloroethane into a 100mL three-necked flask, swell at room temperature for 20h, and add crosslinking agent chlorine after swelling Diethyl ether 0.35mL, catalyst anhydrous tin tetrachloride 0.55mL, under the stirring of a magnetic stirrer, heat the reaction solution to 48°C in an oil bath, react at this temperature for 12h, cool to room temperature after the reaction, and the obtained product Washing with distilled water, after washing, boil the product in a reactor with HCl with a concentration of 1mol / L for 6h, wash with distilled water until neutral, then extract the product with acetone in a solvent extraction device for 6h, and then The acetone in the product was washed with distilled water to re...

Embodiment 2

[0039] The preparation method of polyphenylene sulfide-based strong acid ion exchange fiber of the present invention, its detailed steps are as follows:

[0040] a. Friedel-Crafts crosslinking reaction: put 1.0801g of polyphenylene sulfide fiber and 40mL of organic solvent 1,2-dichloroethane into a 100mL three-necked flask, swell at room temperature for 12h, and add crosslinking agent chlorine after swelling Diethyl ether 0.35mL, catalyst anhydrous tin tetrachloride 0.55mL, stir with a magnetic stirrer, heat the reaction solution to 40°C in an oil bath, react at 40°C for 12h, cool to room temperature after the reaction, and cool the cooled The product was washed with distilled water. After washing, it was boiled for 6 hours with HCl with a concentration of 1 mol / L in the reactor. After boiling, it was washed with distilled water until it was neutral, and the product obtained was extracted with acetone for 6 hours in a solvent extraction device, and then used The acetone in the...

Embodiment 3

[0043] The preparation method of polyphenylene sulfide-based strong acid ion exchange fiber of the present invention, its detailed steps are as follows:

[0044] a. Friedel-Crafts crosslinking reaction: put 10.8005g of polyphenylene sulfide fiber and 130mL of organic solvent 1,2-dichloroethane into a 250mL three-necked flask, and swell at room temperature for 12h. After swelling, add the crosslinking agent chlorine Methyl ether 3.7mL, catalyst anhydrous tin tetrachloride 5.8mL, stir with a magnetic stirrer, heat the reaction solution to 50°C in an oil bath, react at 50°C for 12h, cool to room temperature after the reaction, and cool the cooled The product was washed with distilled water. After washing, it was boiled for 9 hours with HCl with a concentration of 1 mol / L in the reactor. After boiling, it was washed with distilled water until neutral, and then the product obtained was extracted with absolute ethanol in a solvent extraction device for 12 hours. Then wash and remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com