A self-growing aqueous phase phosphate adsorption material and its preparation method and application

An adsorption material, self-growth technology, applied in the field of environment and materials, can solve the problem of egg shell waste pollution and other problems, achieve good economic benefits, improve adsorption efficiency, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

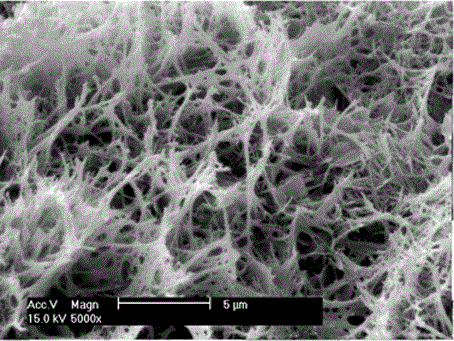

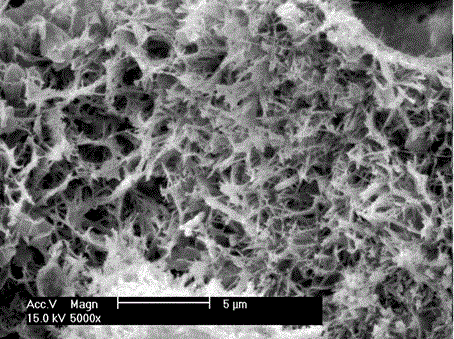

Image

Examples

preparation example Construction

[0025] The specific steps of the preparation method of the structure self-growing water phase phosphate adsorption material prepared by using clay and egg shell powder are as follows:

[0026] (1) Put the washed egg shell powder into a high-temperature box furnace for pre-sintering, the calcination temperature is 550°C, the holding time: 1 h, and the egg shell powder is obtained by ball milling and sieving.

[0027] (2) Put the pretreated egg shell powder and clay into the ball mill according to the ratio required by the formula to mix, dry ball mill, pass through a 60-mesh sieve after mixing, then add an appropriate amount of deionized water for granulation, and pass through a 50-mesh sieve After that, it is aged for 24 hours.

[0028] (3) Weigh 2g of stale powder, carry out compression molding under the pressure of 2MPa, and press into it. The pressed hollow cylindrical sample was calcined in a box furnace at 700 °C for 2 h.

[0029] (4) Place the sintered sample in a high...

Embodiment 1

[0031] The weight ratio of the raw material formula is: clay 50wt%, egg shell 50wt%.

[0032] The specific steps of the preparation method are:

[0033] (1) Put the washed egg shell powder into a high-temperature box furnace for pre-sintering, the calcination temperature is 550°C, the holding time: 1 h, and the egg shell powder is obtained by ball milling and sieving.

[0034] (2) Put the pretreated egg shell powder and clay into the ball mill according to the ratio required by the formula to mix, dry ball mill, pass through a 60-mesh sieve after mixing, then add an appropriate amount of deionized water for granulation, and pass through a 50-mesh sieve After that, it is aged for 24 hours.

[0035] (3) Weigh 2g of stale powder, carry out compression molding under the pressure of 2MPa, and press into it. The pressed hollow cylindrical sample was calcined in a box furnace at 700 °C for 2 h.

[0036] (4) Place the sintered sample in a high-pressure heat treatment device and coo...

Embodiment 2

[0039] The weight ratio of the raw material formula is: clay 40wt%, egg shell 60wt%.

[0040] The specific steps of the preparation method are:

[0041] (1) Put the washed egg shell powder into a high-temperature box furnace for pre-sintering, the calcination temperature is 550°C, the holding time: 1 h, and the egg shell powder is obtained by ball milling and sieving.

[0042](2) Put the pretreated egg shell powder and clay into a ball mill according to the ratio required by the formula to mix, dry ball mill, pass through a 60-mesh sieve after mixing, then add an appropriate amount of deionized water for granulation, and pass through a 50-mesh sieve After that, it is aged for 24 hours.

[0043] (3) Weigh 2g of stale powder, carry out compression molding under the pressure of 2MPa, and press into it. The pressed hollow cylindrical sample was calcined in a box furnace at 700 °C for 2 h.

[0044] (4) Place the sintered sample in a high-pressure heat treatment device and cook f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com