Paper tray processing technology

A processing technology and paper support technology, applied in pulp raw material addition process, paper, papermaking, etc., can solve problems such as soft touch, high cost, and inability to achieve diversity of paper support colors, so as to promote raw and cooked conversion, coating layer color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

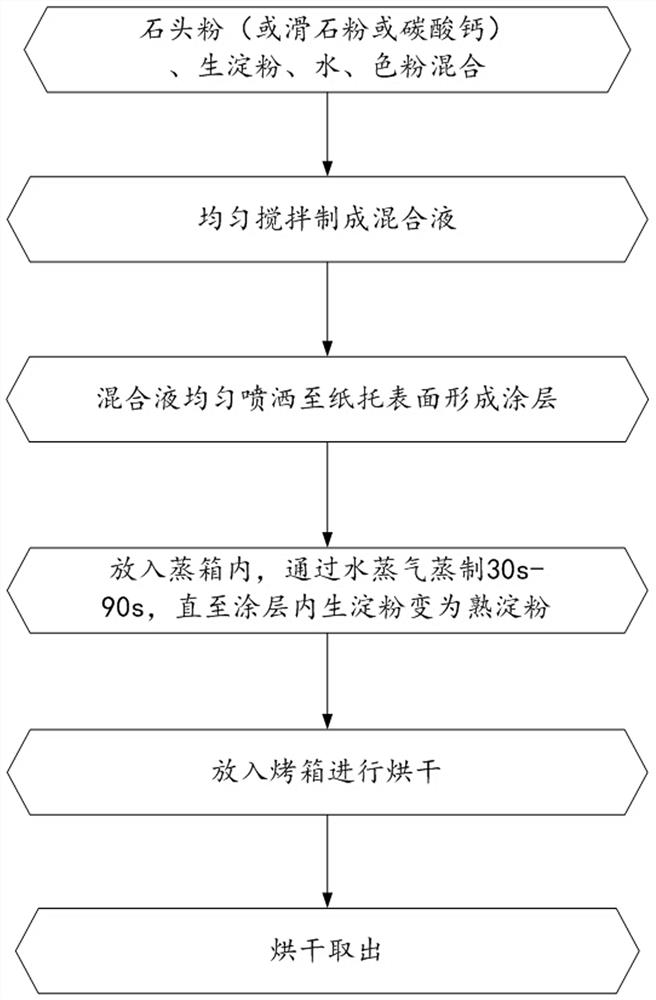

[0016] Such as figure 1 with figure 2 As shown, a kind of paper tray processing technology provided in this embodiment includes the following steps:

[0017] 1. Mix raw starch, water and stone powder or talcum powder or calcium carbonate at the same time and stir evenly to make a mixed liquid;

[0018] 2. Spray or coat the mixture evenly on the surface of the paper tray to form a coating;

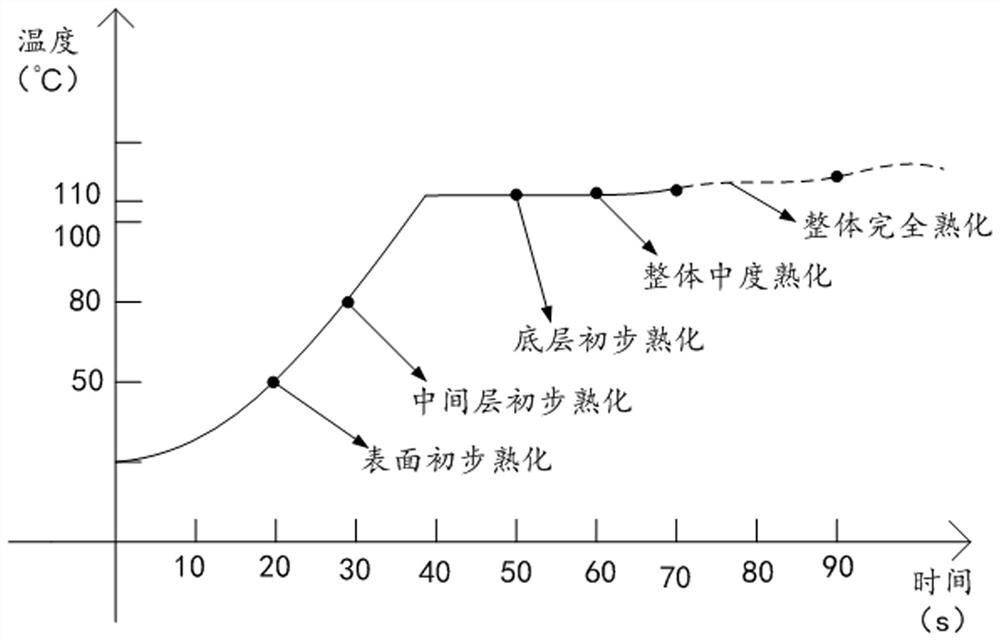

[0019] 3. Put the sprayed paper tray into the steam box and steam for 30s-90s by steam. The curve of temperature and time during the curing process of the coating is shown as follows: figure 2 As shown, the surface of the coating is preliminarily matured at 20s, the middle layer of the coating is preliminarily cured at 30s, the bottom layer of the coating is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com