Silicon-based composite negative electrode plate, preparation method, and lithium ion secondary battery

A negative electrode, silicon-based technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of limited cycle stability improvement, low electrical conductivity, and complicated preparation process, so as to broaden the commercial application prospects and improve the overall The effect of capacity, high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

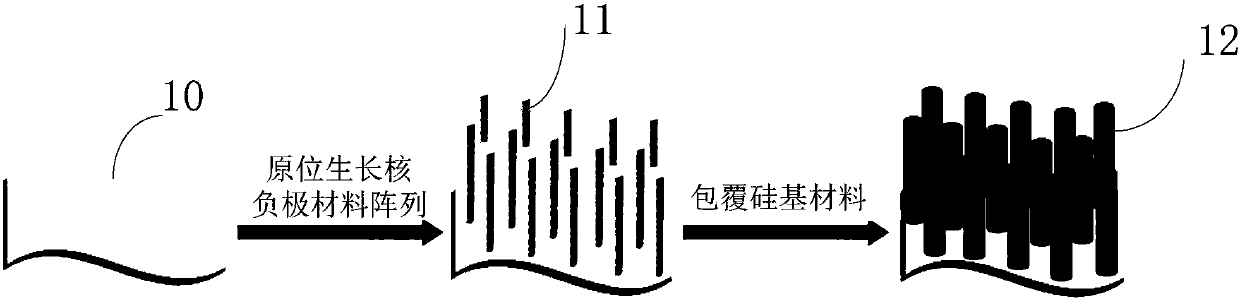

[0044] Correspondingly, an embodiment of the present invention also provides a method for preparing a silicon-based composite negative electrode sheet, comprising the following steps:

[0045] Taking the current collector as the base, depositing and growing the nuclear negative electrode material in situ on the surface of the current collector by chemical deposition, the nuclear negative electrode material is arranged on the current collector in a one-dimensional vertical array structure; the nuclear negative electrode material is carbon One or more of nanotubes, carbon nanofibers, porous carbon, graphene, lithium-intercalated metals and alloys, lithium titanate, transition metal oxides, double metal oxides, metal sulfides, metal nitrides and metal phosphides kind;

[0046] Then, the silicon-based material is coated on the outer surface of the core negative electrode material by physical or chemical coating methods to obtain a one-dimensional silicon-based core-shell composite...

Embodiment 1

[0063] A method for preparing a silicon-based composite negative plate with a vertical tin (Sn) nanotube as a core, a Si / C composite as a shell, and a copper foil as a current collector, comprising the following steps:

[0064] (1) Copper foil is used as the deposition substrate, and the ZnO seed layer is deposited on the substrate by magnetron sputtering: First, put the copper foil in ethanol and acetone for 10 minutes, and then take it out and rinse it with deionized water several times, and dry it. Then put it into the vacuum chamber; evacuate to a vacuum degree of 2.4×10 -4 Pa, feed argon and oxygen, and heat the sample delivery chamber to 800°C; use a ZnO ceramic target with a purity of 99.9%, and magnetron sputtering for 0.5 hours to obtain a copper foil substrate with a ZnO seed layer deposited; LZn(NO 3 ) 2 In a mixed solution of 0.025mol / L hexamethylenetetramine, the ZnO seed layer grows into an array of ZnO nanorods arranged vertically through a hydrothermal reacti...

Embodiment 2

[0068] A vertical Zn 2 GeO 4 A method for preparing a silicon-based composite negative plate in which the nanowire is the core, the nano-Si particles are the shell, and the flexible carbon fiber cloth is the current collector, comprising the following steps:

[0069] (1) Using flexible carbon fiber cloth as a deposition substrate, it was sonicated in ethanol solution for 5 minutes and washed with deionized water to purify; 0.6g GeO 2 , 1.65g Zn(CH 3 COO) 2 ·H 2 O was added to a mixture of 60mL DETA and 20mL deionized water, and stirred continuously for 1 hour to obtain a homogeneous solution; the homogeneous solution was transferred together with the purified carbon fiber cloth to a 100mL hydrothermal reaction kettle, and subjected to hydrothermal reaction at 180°C After 48 hours, cool to room temperature; wash with deionized water and ethanol 5 times respectively, and dry to obtain vertical Zn 2 GeO 4 Carbon fiber cloth of nanowire array; wherein, the obtained Zn 2 GeO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Transverse diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com