A preparation method and application of a lithium battery binder with self-healing properties

A lithium battery and binder technology, applied in the field of lithium battery binder preparation, can solve the problems of electrode material structure damage, poor high temperature resistance, limited mechanical strength, etc., and achieve high discharge specific capacity and high cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]The preparation and application of the lithium battery binder with self-repairing properties is characterized in that it comprises the following steps:

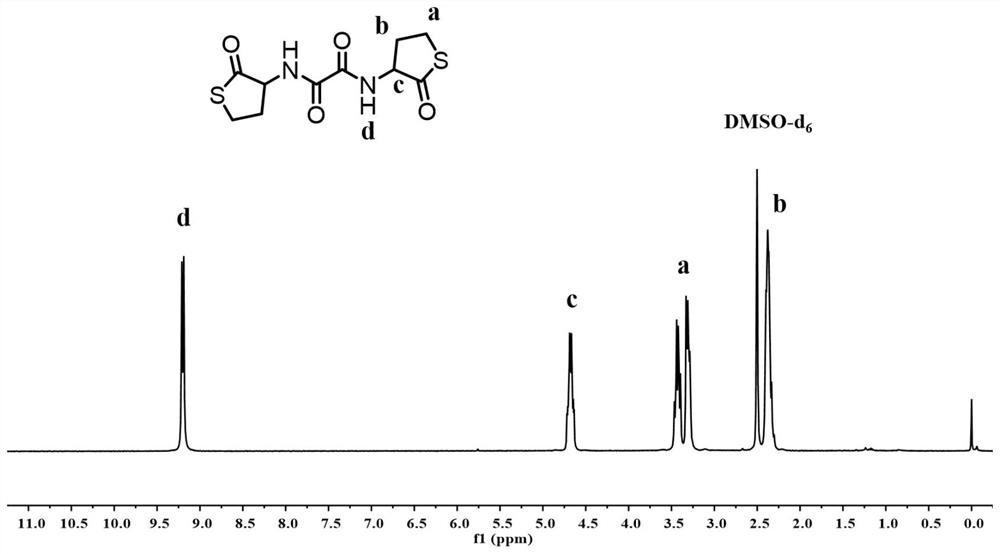

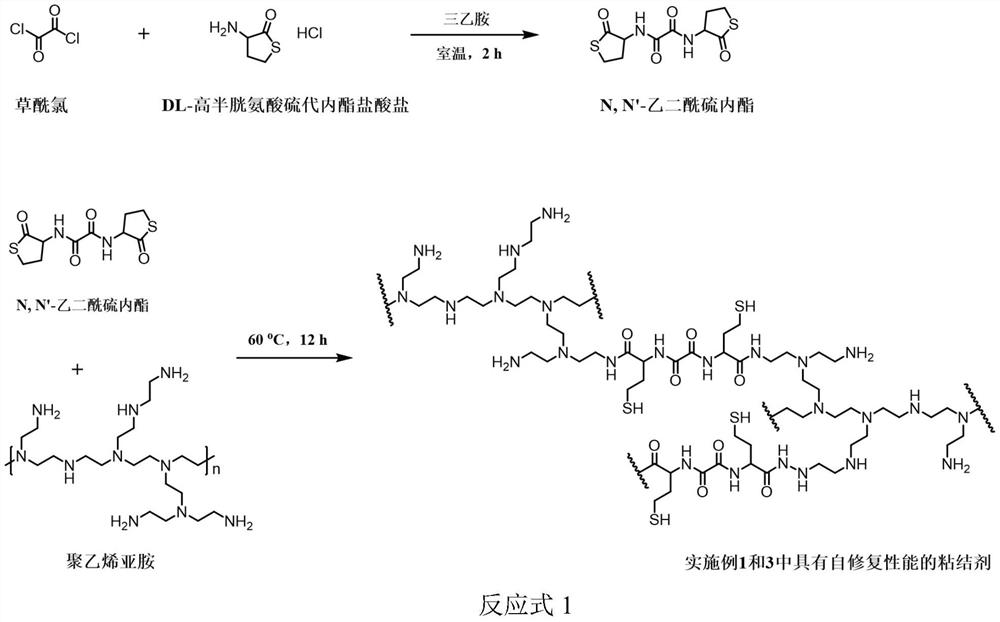

[0039] (1) Synthesis of dithiolactone-containing functional group component A: N,N'-oxalylthiolactone: Weigh 6.15g (40mmol) DL-homocysteine thiolactone hydrochloride and dissolve it in 50mL In anhydrous dichloromethane, 11.1 mL of triethylamine was slowly added thereto, cooled to 0°C, and 1.70 mL (20 mmol) of oxalyl chloride was added dropwise to the solution. After the reaction system was stirred at room temperature for 2 hours, excess solvent was removed by rotary evaporation. The remaining solids were successively washed with 100 mL of 0.1 mol / L dilute hydrochloric acid and 300 mL of deionized water, and dried in vacuum. Finally, N,N'-oxalylthiolactone is obtained.

[0040] (2) Synthesis of a binder for lithium ions with self-healing properties: 100 mg of N,N'-oxalylthiolactone containing dithiolactone functional...

Embodiment 2

[0044] The preparation and application of the lithium battery binder with self-repairing properties is characterized in that it comprises the following steps:

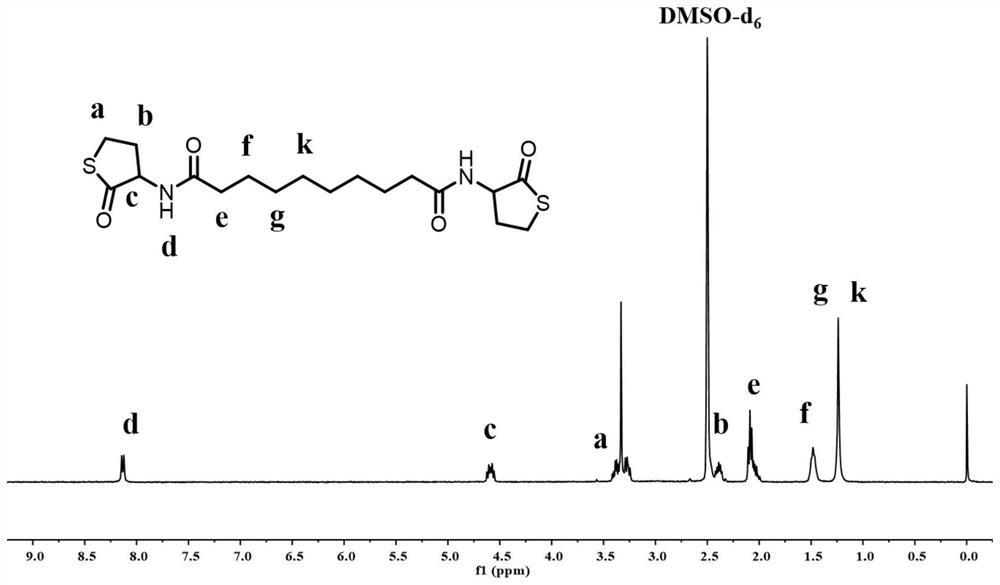

[0045] (1) Synthesis of dithiolactone-containing functional group component AN, N'-sebacoyl thiolactone: Weigh 6.15g (40mmol) DL-homocysteine thiolactone hydrochloride and add it to 13.44 g NaHCO 3 In a suspoemulsion of dioxane and water, the volume ratio of dioxane to water was 2:1 (120ml in total), and the mixture was stirred for 30 minutes. Then within 30 minutes, 4.27mL (20mmol) of sebacoyl chloride was added dropwise to the mixture, stirred overnight at room temperature, the resulting solid was suction filtered, washed with 200mL of deionized water, and filtered to obtain N,N'-sebacoyl sulfide Lactone.

[0046] (2) Synthesis of a binder for lithium ions with self-healing properties: 100 mg of N,N'-sebacoyl thiolactone containing dithiolactone functional groups and 200 mg of polyamino functional group-containin...

Embodiment 3

[0050] The preparation and application of the lithium battery binder with self-repairing properties is characterized in that it comprises the following steps:

[0051] (1) Synthesis of AN,N'-oxalylthiolactone containing dithiolactone functional group component: weigh 6.15g (40mmol) DL-homocysteine thiolactone hydrochloride and dissolve in 50mL Slowly add 11.1 mL of triethylamine into dichloromethane water, and cool to 0° C., then gradually add 1.70 mL (20 mmol) of oxalyl chloride dropwise into the solution. After the reaction system was stirred at room temperature for 2 hours, excess solvent was removed by rotary evaporation. The remaining solids were successively washed with 100 mL of 0.1 mol / L dilute hydrochloric acid and 300 mL of deionized water, and dried in vacuum. Finally, N,N'-oxalylthiolactone is obtained.

[0052] (2) Synthesis of a binder for lithium ions with self-healing properties: 100 mg of N,N'-oxalylthiolactone containing dithiolactone functional groups an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com